The digital CHASSIS SCC-K43A-A (AE-4) was introduced by SONY in September 1996.

It's quite complex in all parts.

The power supply has the first place of complexity after the Digital Board Unit.

CHASSIS SCC-K43A-A (AE-4) Switching power supply circuit:A power supply circuit has a so-called composite resonance type switching converter equipped with a primary resonance circuit for forming a voltage resonance type converter at a primary side, and a secondary resonance circuit comprising a secondary winding and a secondary parallel resonance capacitor at a secondary side. The secondary side is equipped with active clamp means for stabilizing a DC output low voltage taken out from an intermediate tap of the secondary winding to control the conduction angle of an auxiliary main switching element in accordance with the level of the DC output low voltage, whereby the power loss due to the cross-regulation of the DC output low voltage can be reduced, and the power conversion efficiency can be enhanced.

1. A switching power supply circuit, characterized by comprising: switching means having a main switching element for conducting a switching operation on a DC input voltage and outputting a switching result; an insulating converter transformer that is designed so as to provide a coupling coefficient required for the loose coupling between a primary side and a secondary side, and transmits the output of said switching means achieved at the primary side to the secondary side; a primary parallel resonance circuit constructed by connecting a primary parallel resonance capacitor to a primary winding wound around said converter transformer in parallel equivalently; a first secondary parallel resonance circuit constructed by connecting a first secondary parallel resonance capacitor to a secondary winding wound around the insulating converter transformer in parallel; first DC output voltage generating means for receiving an alternating voltage achieved at said secondary winding wound around said insulating converter transformer and conducting a rectifying operation on the alternating voltage thus received to a DC output main voltage; first stabilized voltage control means for performing voltage-stabilizing control on the DC output main voltage by controlling the switching frequency and conduction angle of said main switching element in accordance with the level of the DC output main voltage; a second secondary parallel resonance circuit constructed by connecting, in parallel, a second secondary parallel resonance capacitor to the winding portion between an intermediate tap of said secondary winding wound around said insulating converter transformer and the earth at the secondary side; second DC output voltage generating means for receiving an alternating voltage achieved at the intermediate tap of said secondary winding wound around said insulating converter transformer and conducting a rectifying operation on the alternating voltage thus received to achieve a DC output low voltage; active clamp means constructed by connecting, in parallel, a series connection circuit comprising a clamp capacitor and an auxiliary switching element to the winding portion between the intermediate tap of said secondary winding wound around said insulating converter transformer and the earth at the secondary side; and second voltage-stabilizing control means for executing the conduction angle control of said auxiliary switching element in accordance with the level of the DC output low voltage to perform the voltage-stabilizing control on the DC output low voltage. 2. The switching power supply circuit as claimed in claim 1, wherein there are provided a plurality of constructing portions each of which comprises said second secondary parallel resonance circuit, said second DC output voltage generating means, said active clamp means and said second voltage-stabilizing control means.

Description:

BACKGROUND OF THE INVENTION

1. Field of the Invention

The present invention relates to a switching power supply circuit equipped to various types of equipment as a power supply source.

2. Description of the Related Art

The applicant of this application previously proposed a technique of constructing a composite resonance type converter as a switching power supply circuit by combining a voltage resonance type converter of one stone at a primary side and a half-wave rectifying type voltage resonance circuit at a secondary side, providing an active clamp circuit at the secondary side and stabilizing the DC output voltage thereof by controlling the conduction angle of the switching element of the active clamp circuit.

FIG. 10 is a circuit diagram of a conventional switching power supply circuit which can be constructed on the basis of the invention previously proposed by the applicant of this application.

In the power supply circuit shown in FIG. 10 , a full-wave rectifying circuit comprising a bridge rectifying circuit Di and a smoothing capacitor Ci is equipped as a rectifying and smoothing circuit to which commercial alternating power (alternating input voltage VAC) is input to achieve a DC input voltage, whereby the rectified and smoothed voltage Ei corresponding to the once level of the alternating input voltage VAC is achieved.

At the primary side of the power supply circuit, a self-excited type is constructed as a voltage resonance type converter circuit which carries out a single-end operation on the basis of a one-stone switching element Q 1 . In this case, a bipolar transistor having high resistance to voltage (BJT; junction type transistor) is used as the switching element Q 1 .

The base of the switching element Q 1 is connected to the anode of the smoothing capacitor Ci (rectified and smoothed voltage Ei) through a starting resistor Rs to achieve base current at the starting time from a rectifying and smoothing line.

A drive winding NB which is provided at the primary side of an insulating converter transformer PIT so as to have a turn number of 1T (turn), and a series resonance circuit for self-excited resonance driving which comprises a series an inductor LB, a resonance capacitor CB and a base current limiting resistor RB is connected between the base of the switching element Q 1 and the earth at the primary side. A switching frequency fs for turning on/off the switching element Q 1 is generated by the self-excited circuit. For example, the switching frequency fs is set to 66 KHz by the series resonance circuit.

A route for clamp current flowing when the switching element Q 1 is turned off is formed by a clamp diode DD 1 inserted between the base of the switching element Q 1 and the cathode (the earth at the primary side) of the smoothing capacitor Ci. The collector of the switching element Q 1 is connected to one end of the primary winding N 1 of the insulating converter transformer PIT, and the emitter thereof is grounded.

A route for clamp current flowing when the switching element Q 1 is turned off is formed by a clamp diode DD 1 inserted between the base of the switching element Q 1 and the cathode (the earth at the primary side) of the smoothing capacitor Ci. The collector of the switching element Q 1 is connected to one end of the primary winding N 1 of the insulating converter transformer PIT, and the emitter thereof is grounded. A parallel resonance capacitor Cr is connected between the collector and emitter of the switching element Q 1 in parallel. In this case, a primary series resonance circuit of the voltage resonance type converter is formed by the capacitance of the parallel resonance capacitor Cr itself and the leakage inductance L 1 of the primary winding N 1 side of the insulating converter transformer PIT.

The insulating converter transformer PIT transmits the switching output of the switching element Q 1 to the secondary side. The insulating converter transformer PIT is equipped with an EE-type core comprising two E-type cores of ferrite material or the like which are assembled such that both the magnetic legs thereof are confronted to each other, and the primary winding N 1 and the secondary winding N 2 are wound around the center magnetic leg of the EE-type core by using a divisional bobbin so as to be separated from each other. Further, the EE-type core is assembled so that a gap is formed in the center magnetic leg thereof, whereby loose coupling based on a required coupling coefficient is achieved.

One end of the primary winding N 1 of the insulating converter transformer PIT is connected to the switching element Q 1 , and the other end thereof is connected to the anode of the smoothing capacitor Ci (rectified and smoothed voltage Ei). Accordingly, an alternating voltage having the period corresponding to the switching frequency occurs at the primary winding N 1 when the switching output of the switching element Q 1 is supplied to the primary winding Ni.

Further, at the secondary side of the insulating converter transformer PIT, an alternating voltage induced by the primary winding N 1 is generated at the secondary winding N 2 . In this case, a secondary parallel resonance capacitor C 2 is connected to the secondary winding N 2 in parallel, so that a parallel resonance circuit is formed by the leakage inductance L 2 of the secondary winding N 2 and the capacitance of the secondary parallel resonance capacitor C 2 . The parallel resonance circuit sets the alternating voltage induced in the secondary winding N 2 to a resonance voltage, so that a voltage resonance operation can be achieved at the secondary side. That is, the power supply circuit described above has the construction of a “composite resonance type switching converter” in which a parallel resonance circuit for setting the switching operation to a voltage resonance type is provided at the primary side and a parallel resonance circuit for achieving the voltage resonance operation is provided at the secondary side.

The secondary side of the power supply circuit thus constructed is equipped with a half-wave rectifying circuit comprising a secondary rectifying diode D 01 and a smoothing capacitor C 01 2 , thereby achieving a main secondary DC output voltage E 01 corresponding to substantially the once level as the alternating voltage induced in the secondary winding N 2 . which are connected to the secondary winding N

Further, in this case, an intermediate tap is provided to the secondary winding N 2 , and a half-wave rectifying circuit comprising a rectifying diode D 02 and a smoothing capacitor C 02 is connected to the winding between the tap output line of the secondary winding N 2 and the earth at the secondary side as shown in FIG. 10 to generate and output a low secondary DC output voltage E 02 .

In the power supply circuit, an active clamp circuit is equipped to the secondary side. That is, an auxiliary switching element Q 2 of MOS-FET, a clamp capacitor C 3 and a clamp diode DD 2 are equipped as the secondary active clamp circuit. Further, a drive winding Ng 1 , a capacitor Cg 1 1 are equipped as a driving circuit system for driving the auxiliary switching element Q 2 . and a resistor Rg

A clamp diode DD 2 is connected between the drain and source of the auxiliary switching element Q 2 in parallel. As a connection manner, the anode of the clamp diode DD 2 is connected to the source, and the cathode is connected to the drain.

The drain of the auxiliary switching element Q 2 is connected to the connection point between the tap output line of the secondary winding N 2 and the anode of the rectifying diode D 02 3 . Further, the source of the auxiliary switching element Q 2 is connected to the earth at the secondary side. through a clamp capacitor C

Accordingly, the secondary active clamp circuit is constructed by connecting the clamp capacitor C 3 to the parallel connection circuit comprising the auxiliary switching element Q 2 and the clamp diode DD 2 in series. The circuit thus formed is further connected to the secondary winding N 2 in parallel.

As the driving circuit system of the auxiliary switching element Q 2 , a series connection circuit of a capacitor Cg 1 , a resistor Rg 1 and a drive winding Ng 1 is connected to the gate of the auxiliary switching element Q 2 as shown in FIG. 10 . The series connection circuit forms the self-excited driving circuit for the auxiliary switching element Q 2 . That is, a signal voltage VGS from the self-excited type driving circuit is applied to the gate of the switching element Q 2 to perform the switching operation. In this case, the drive winding Ng 1 is formed at the end portion side of the secondary winding N 2 , and the number of turns in this case is set to 1T (turn), for example.

As the driving circuit system of the auxiliary switching element Q 2 , a series connection circuit of a capacitor Cg 1 , a resistor Rg 1 and a drive winding Ng 1 is connected to the gate of the auxiliary switching element Q 2 as shown in FIG. 10 . The series connection circuit forms the self-excited driving circuit for the auxiliary switching element Q 2 . That is, a signal voltage VGS from the self-excited type driving circuit is applied to the gate of the switching element Q 2 to perform the switching operation. In this case, the drive winding Ng 1 is formed at the end portion side of the secondary winding N 2 , and the number of turns in this case is set to 1T (turn), for example. Accordingly, the voltage induced by the alternating voltage achieved at the primary winding N 1 1 . Further, in this case, voltages achieved at the secondary winding N 2 and the drive winding Ng 1 are opposite in polarity because of the relationship of the winding direction between the windings N 2 and Ng 1 . occurs at the drive winding Ng

In this embodiment, PWM control is carried out on the switching operation of the auxiliary switching element Q 2 by a control circuit 1 equipped to the secondary side. That is, the secondary DC output voltage E 01 , E 02 is supplied to the control circuit of an error amplifier, and the control circuit 1 applies the DC control voltage corresponding to E 01 , E 02 to the gate of the auxiliary switching element Q 2 to control the conduction angle of the auxiliary switching element Q 2 , whereby the DC output voltage is stabilized with respect to variations of the alternating input voltage VAC and the load power Po. For example, the main DC output voltage E 01 is stabilized to 135V.

In the circuit construction described above, the insulating converter transformer PIT may be EE-40 under the condition that the gap is set to 1 mm, the number of turns of the primary winding N 1 is set to 50T, the number of turns of the secondary winding N 2 is set to 55T and the number of turns of the drive winding NB=Ng 1 is set to 1T. Further, the resistance of the starting resistor Rs is set to 330 KΩ, the resistance of the resistor RB is set to 1Ω, the capacitance of the capacitor CB is set to 0.33 μF, the inductance of the inductor LB is set to 10 μH, the capacitance of the resonance capacitor Cr is set to 0.012 μF, the resistance of the resistor Rg 1 is set to 10Ω, the capacitance of the resonance capacitor C 2 is set to 0.012 μF, the capacitance of the clamp capacitor C 3 is set to 0.47 μF, and the switching frequency fs is equal to 66 KHz.

FIG. 11 shows the operation waveforms of the respective parts at the alternating input voltage VAC of 100V and the load power Po of 200 W. FIG. 12 shows the operation waveforms of the respective parts under no load and at the alternating input voltage VAC of 100V. It is apparent from FIGS. 11 and 12 that the conduction angle (TON period) of the auxiliary switching element Q 2 is controlled in accordance with the variation of the load power Po.

FIG. 13 shows the characteristic of the conduction angle (TON) and the AC/DC power conversion efficiency ηAC/DC with the variation of the load power Po, and FIG. 14 shows the characteristic of the conduction angle (TON) and the AC/DC power conversion efficiency ηAC/DC with the variation of the alternating input voltage VAC. As is apparent from FIGS. 13 and 14 , the conduction angle (TON) of the auxiliary switching element Q 2 with respect to the variation of the load power Po and the alternating input voltage VAC is controlled over the range from 4.6 μs to 13 μs.

As the conduction angle (TON) is increased due to reduction of the load power Po or increase of the alternating input voltage VAC, the conduction loss of the auxiliary switching element Q 2 is increased and thus the AC/DC power conversion efficiency (ηAC/DC) is lowered.

Further, the primary side voltage resonance pulse voltage V 1 occurring between both the ends of the main switching element Q 1 is equal to 530V to 850V when the alternating input voltage VAC ranges from 90V to 144V, and thus the main switching element Q 1 is required to have a voltage resistance to 900V. Further, the clamp voltage V 2 at the secondary side is equal to 160V to 350V, and thus the auxiliary switching element Q 2 is required to have a voltage resistance to 400V.

Current having a saw-tooth waveform flows in the switching elements Q 1 , Q 2 under the no-load state as indicated by current IQ 1 , IC 3 in FIG. 7 . Therefore, these large amounts of current flow in the primary winding N 1 , the secondary winding N 2 of the insulating converter transformer PIT and each switching element Q 1 , Q 2 , so that invalid current is increased and the input power at this time is equal to 13.5 W.

When stabilization is carried out on the main voltage (DC output main voltage) E 01 =135V with respect to the variations of the alternating input voltage VAC and the load current on the basis of the conduction angle control of the auxiliary switching element Q 2 of the secondary active clamp circuit, the auxiliary DC output voltage (DC output low voltage) E 02 , which is equal to 15V for example, exhibits cross regulation of 15V±1.5V.

When the load current of the DC output low voltage E 02 is varied by 0.5 A to 1.5 A, the cross regulation is further magnified to 15V±2.5V.

Therefore, in order to achieve a voltage-stabilized output voltage of 12 V with a three-terminal regulator having a low saturation voltage, the power loss of (17.5−12.0)×1.5=8.25 w at maximum occurs and thus the power conversion efficiency is further lowered.

As is understood from the foregoing description, the following problems (1) to (4) occur in the construction of the power supply circuit of FIG. 10 as described above, that is, in the construction in which the switching frequency of the auxiliary switching element Q 2 of the active clamp circuit is fixed and the DC output voltage is stabilized by controlling the conduction angle.

(1) the conduction time of the secondary auxiliary switching element Q 2 is increased due to reduction of the load power Po and increase of the alternating input voltage VAC, and thus the power loss is also increased, resulting in reduction in efficiency.

(2) The peak value of the voltage resonance pulse voltage VI occurring in the primary switching element Q 1 increases in proportion to the alternating input voltage VAC, so that the switching element Q 1 has a voltage resistance to 900V in the AC 100V system and a voltage resistance to 1800V in the AC 200V system. Therefore, an expensive switching element Q 1 must be prepared.

(3) Under the no-load state, the invalid power is large, and the voltage resonance pulse voltage V 1 is larger than under a load-applied state, so that a heat radiating plate is needed to the auxiliary switching element Q 2 .

(4) Since the cross regulation of the DC output lower voltage E 02 taken out from the secondary side is large, a three-terminal series regulator is required to stabilize the DC output low voltage E 02 , and thus the power loss is further increased. Therefore, the power conversion efficiency is lowered.

SUMMARY OF THE INVENTION

Therefore, in consideration of the foregoing problems, according to the present invention, there is provided a switching power supply circuit comprising: switching means having a main switching element for conducting a switching operation on a DC input voltage and outputting a switching result; an insulating converter transformer that is designed so as to provide a coupling coefficient required for the loose coupling between a primary side and a secondary side, and transmits the output of the switching means achieved at the primary side to the secondary side; a primary parallel resonance circuit constructed by connecting a primary parallel resonance capacitor to a primary winding wound around the converter transformer equivalently and in parallel; a first secondary parallel resonance circuit constructed by connecting a first secondary parallel resonance capacitor to a secondary winding wound around the insulating converter transformer in parallel; first DC output voltage generating means for receiving an alternating voltage achieved at the secondary winding wound around the insulating converter transformer and conducting a rectifying operation on the alternating voltage thus received to a DC output main voltage; first stabilized voltage control means for performing voltage-stabilizing control on the DC output main voltage by controlling the switching frequency and conduction angle of the main switching element in accordance with the level of the DC output main voltage; a second secondary parallel resonance circuit constructed by connecting, in parallel, a second secondary parallel resonance capacitor to the winding portion between an intermediate tap of the secondary winding wound around the insulating converter transformer and the earth at the secondary side; second DC output voltage generating means for receiving an alternating voltage achieved at the intermediate tap of the secondary winding wound around the insulating converter transformer and conducting a rectifying operation on the alternating voltage thus received to achieve a DC output low voltage; active clamp means constructed b y connecting, in parallel, a series connection circuit comprising a clamp capacitor and an auxiliary switching element to the winding portion between the intermediate tap of the secondary winding wound around the insulating converter transformer and the earth at the secondary side; and second voltage-stabilizing control means for executing the conduction angle control of the auxiliary switching element in accordance with the level of the DC output low voltage to perform the voltage-stabilizing control on the DC output low voltage.

y connecting, in parallel, a series connection circuit comprising a clamp capacitor and an auxiliary switching element to the winding portion between the intermediate tap of the secondary winding wound around the insulating converter transformer and the earth at the secondary side; and second voltage-stabilizing control means for executing the conduction angle control of the auxiliary switching element in accordance with the level of the DC output low voltage to perform the voltage-stabilizing control on the DC output low voltage. In the switching power supply circuit thus constructed, there is achieved a so-called composite resonance type switching converter in which the primary resonance circuit to form the voltage resonance type converter is provided at the primary side, and the secondary resonance circuit comprising the secondary winding and the secondary parallel resonance capacitor is provided at the secondary side. On the basis of this construction, the active clamp means for stabilizing the DC output low voltage taken from the intermediate tap of the secondary winding is provided at the secondary side, and the conduction angle of the auxiliary main switching element is controlled in accordance with the level of the DC output low voltage, whereby the power loss due to the cross regulation of the DC output low voltage can be reduced and the power conversion efficiency can be enhanced.

BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 is a circuit diagram showing the construction of a switching power supply circuit according to an embodiment of the present invention;FIG. 2 is a cross-sectional view showing the construction of an insulating converter transformer;

FIGS. 3A and 3B is an equivalent circuit diagram showing each operation when mutual inductance is equal to +M/−M;

FIG. 4 is a waveform diagram showing the operation of the main part in the power supply circuit of the embodiment of the present invention;

FIG. 5 is a waveform diagram showing the operation of the main part in the power supply circuit of the embodiment of the present invention;

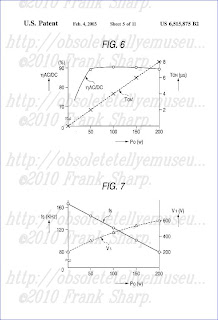

FIG. 6 is a diagram showing characteristics of the power supply circuit of the embodiment with respect to variation of load power;

FIG. 7 is a diagram showing characteristics of the power supply circuit of the embodiment with respect to variation of load power;

FIG. 8 is a circuit diagram showing the construction of a switching power supply circuit according to another embodiment of the present invention;

FIG. 9 is a circuit diagram showing the construction of a switching power supply circuit according to another embodiment of the present invention;

FIG. 10 is a circuit diagram showing the construction of a conventional switching power supply circuit;

FIG. 10 is a circuit diagram showing the construction of a conventional switching power supply circuit; FIG. 11 is a waveform diagram showing the operation of the main part of the conventional switching power supply circuit;

FIG. 12 is a waveform diagram showing the operation of the main part of the conventional switching power supply circuit;

FIG. 12 is a waveform diagram showing the operation of the main part of the conventional switching power supply circuit;  FIG. 13 is a diagram showing the characteristics of power conversion efficiency and conduction angle control with respect to variation of load power in the conventional power supply circuit; and

FIG. 13 is a diagram showing the characteristics of power conversion efficiency and conduction angle control with respect to variation of load power in the conventional power supply circuit; and FIG. 14 is a diagram showing the characteristics of the power conversion efficiency and the conduction angle control with respect to variation of an alternating input voltage in the conventional power supply circuit.

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

Preferred embodiments according to the present invention will be described hereunder with reference to the accompanying drawings.FIG. 1 shows the construction of a switching power supply circuit according to an embodiment of the present invention.

In the power supply circuit shown in FIG. 1 , a full-wave rectifying circuit comprising a bridge rectifying circuit Di and a smoothing capacitor Ci is equipped as a rectifying and smoothing circuit to which commercial alternating power (alternating input voltage VAC) is input to achieve a DC input voltage, and a rectified and smoothed voltage Ei having the level which is once as large as the alternating input voltage VAC.

In the power supply circuit shown in FIG. 1 , a full-wave rectifying circuit comprising a bridge rectifying circuit Di and a smoothing capacitor Ci is equipped as a rectifying and smoothing circuit to which commercial alternating power (alternating input voltage VAC) is input to achieve a DC input voltage, and a rectified and smoothed voltage Ei having the level which is once as large as the alternating input voltage VAC. A one-stone switching element Q 1 is equipped as a switching converter for receiving and intermitting the rectified and smoothed voltage Ei (DC input voltage), thereby providing a voltage resonance type converter for performing a switching operation based on a single end system.

In this case, a self-excited type is adopted as the voltage resonance type converter which performs the single end operation with a one-stone switching element Q 1 . A bipolar transistor having a high voltage resistance (BJT: junction type transistor) is used for the switching element Q 1 .

A series resonance circuit for self-excited driving which comprises a series connection circuit of a driving winding NB, a resonance capacitor CB and a base current limiting resistor RB is connected between the base of the switching element Q 1 and the earth at the primary side.

Further, a route for clamp current which flows when the switching element Q 1 is turned off is formed by a clamp diode DD inserted between the base of the switching element Q 1 and the cathode of the smoothing capacitor Ci (the earth at the primary side). A starting resistor RS is inserted to achieve the base current at the starting time from a rectifying and smoothing line.

A parallel resonance capacitor Cr is connected in parallel between the collector and emitter of the switching element Q 1 . A primary parallel resonance circuit of the voltage resonance type converter is formed by the capacitance of the parallel resonance capacitor Cr itself and the leakage inductance L 1 of the primary winding N 1 side of the insulating converter transformer PIT.

An orthogonal control transformer PRT shown in FIG. 1 is a saturable reactor around which a resonance current detecting winding ND, a driving winding NB and a control winding NC are wound. The orthogonal control transformer PRT is used to drive the switching element Q 1 and perform voltage-stabilizing control. As shown in FIG. 1 , the resonance current detecting winding ND and the driving winding NB are wound around the orthogonal control transformer PRT, and also the control winding NC is wound around the orthogonal control transformer PRT in the direction orthogonal to the winding direction of the resonance current detecting winding ND and the driving winding NB.

In the orthogonal control transformer PRT, the switching output achieved at the resonance current detecting winding ND is induced in the driving winding NB through trans-coupling, whereby drive current is output from the series resonance circuit (NB, CB) forming a self-excited oscillation circuit through the base current limiting resistor RB to the base of the switching element Q 1 , whereby the switching element Q 1 carries out the switching operation at the switching frequency determined on the basis of the resonance frequency of the series resonance circuit. The switching output achieved at the collector of the switching element Q 1 is transferred to the primary winding N 1 of the insulating converter transformer PIT.

The insulating converter transformer PIT is provided to transfer the switching output of the switching converter achieved at the primary side to the secondary side.

As shown in FIG. 2 , the insulating converter transformer PIT is equipped with an EE-type core comprising two E-type cores CR 1 , CR 2 of ferrite material which are assembled so that the magnetic legs thereof are confronted to each other, and the primary winding N 1 and the secondary winding N 2 are wound around the center magnetic leg of the EE-type core while they are separated from each other by using a dividing bobbin B. Further, the center magnetic leg is designed to have a gap G therein, thereby achieving loose coupling based on a required coupling coefficient.

As shown in FIG. 2 , the insulating converter transformer PIT is equipped with an EE-type core comprising two E-type cores CR 1 , CR 2 of ferrite material which are assembled so that the magnetic legs thereof are confronted to each other, and the primary winding N 1 and the secondary winding N 2 are wound around the center magnetic leg of the EE-type core while they are separated from each other by using a dividing bobbin B. Further, the center magnetic leg is designed to have a gap G therein, thereby achieving loose coupling based on a required coupling coefficient. The gap G can be formed by making the center magnetic leg of each of the E-type cores CR 1 , CR 2 shorter than the two outer magnetic legs thereof. Further, the coupling coefficient k is set to about 0.7 to 0.8 so that loose coupling can be attained, and thus it is harder to achieve the saturation state.

As shown in FIG. 1 , the winding-starting end portion of the primary winding N 1 of the insulating converter transformer PIT is connected to the collector of the switching element Q 1 , and the winding-ending end portion is connected to the anode of the smoothing capacitor Ci (rectified and smoothed voltage Ei) through the detecting winding ND. Accordingly, the switching output of the switching element Q 1 is supplied to the primary winding N 1 , thereby generating an alternating voltage having the period corresponding to the switching frequency.

The alternating voltage induced by the primary winding N 1 occurs in the secondary winding N 2 2 is connected to the secondary winding N 2 in parallel, so that a first parallel resonance circuit is formed by the leakage inductance L 2 of the secondary winding N 2 and the capacitance of the secondary parallel resonance capacitor C 2 . The parallel resonance circuit sets the alternating voltage induced in the secondary winding N 2 to a resonance voltage, and thus the voltage resonance operation is performed at the secondary side. That is, the power supply circuit of this embodiment has the construction of a “composite resonance type switching converter” in which a parallel resonance circuit for setting the switching operation to a voltage resonance type is provided at the primary side, and also a parallel resonance circuit for achieving the voltage resonance operation is provided at the secondary side. at the secondary side of the insulating converter transformer PT. In this case, the secondary parallel resonance capacitor C

At the secondary side of the power supply circuit thus formed, a rectifying diode D 01 and a smoothing capacitor C 01 is connected to the secondary parallel resonance circuit comprising the secondary winding N 2 and the secondary parallel resonance capacitor C 2 in a connection style shown in FIG. 1 to thereby form a half-wave rectifying circuit, and a secondary DC output main voltage E 01 is mainly generated by the half-wave rectifying circuit (D 01 , C 01 ). The secondary DC output main voltage E 01 is equal to about 135V, for example.

The secondary DC output main voltage E 01 is branched and input to a control circuit 1 A, and the control circuit 1 A generates a control signal to stabilize the DC output main voltage E 01 .

That is, in the control circuit 1 A, the level of the control current (DC current) flowing in the control winding NC is varied in accordance with variation of the level of the DC output main voltage E 01 . Accordingly, the inductance LB of the driving winding NB is variable, and the resonance frequency of the series resonance circuit in the self-excited oscillation driving circuit, that is, the switching frequency of the switching element Q 1 is variably controlled, thereby stabilizing the DC output main voltage E 01 .

Here, when the switching frequency is variably controlled, the period TOFF during which the switching element Q 1 is off is set to a fixed value, and under this condition, the period TON during which the switching element Q 1 is on is variably controlled. In this specification, such composite control as described above will be referred to as “composite control system”.

With respect to the operation at the secondary side of the insulating converter transformer PIT, two cases where the mutual inductance M between the inductance L 1 of the primary winding N 1 and the inductance L 2 of the secondary winding N 2 is equal to +M (additive polarity) and where the mutual inductance M is equal to −M (subtractive polarity) exist in accordance with the polarities (winding direction) of the primary winding N 1 and the secondary winding N 2 , the connection relationship between the rectifying diodes D 01 , D 02 and the polarity variation of the alternating voltage excited in the secondary winding N 2 .

For example, when it is equivalent to the circuit shown in FIG. 3A , the mutual inductance M is equal to +M, and when it is equivalent to the circuit shown in FIG. 3B , the mutual inductance M is equal to −M.

Comparing this operation with the operation at the secondary side shown in FIG. 1 , when the alternating voltage achieved at the secondary winding N 2 has positive polarity, the rectified current flows in the secondary rectifying diode (D 01 ) in the half-wave rectifying circuit of the secondary side, and thus this operation can be regarded as an operation mode of +M (forward operation).

The polarities of the primary winding N 1 and the secondary winding N 2 of the insulating converter transformer PIT may be the additive polarity coupling or the subtractive polarity coupling. Further, the winding directions of the primary winding N 1 and the secondary winding N 2 are set to be the same or opposite to each other. In any case, the coupling coefficient is set to 0.7 to 0.8 to achieve the loose coupling.

In the power supply circuit of this embodiment, a tap output is provided to the secondary winding N 2 at the secondary side of the insulating converter transformer PIT as shown in FIG. 1 2 and the earth at the secondary side is set to N 3 . Further, a secondary parallel resonance capacitor C 4 is connected to the winding N 3 between the tap output line and the earth at the secondary side in parallel, so that a second parallel resonance circuit is formed by the leakage inductance L 3 of the winding portion having the winding number N 3 and the capacitance of the secondary parallel resonance capacitor C 4 . . The number of turns of the winding portion between the tap of the secondary winding N

Further, a rectifying diode D 02 and a smoothing capacitor C 02 are connected to the secondary parallel resonance circuit in the connection manner as shown in FIG. 1 to thereby form the half-wave rectifying circuit. An auxiliary DC output voltage, that is, a secondary DC output low voltage E 02 is generated by the half-wave rectifying circuit (D 02 , C 02 ). The secondary DC output low voltage E 02 is set to about 12V, for example.

In the power supply circuit described above, an active clamp circuit is provided at the secondary side. That is, an auxiliary switching element Q 2 of MOS-FET, a clamp capacitor C 3 and a clamp diode DD 2 of a body diode are equipped as the secondary active clamp circuit. Further, a drive winding Ng 1 , a capacitor Cg 1 and a resistor Rg 1 are equipped as a driving circuit system for driving the auxiliary switching element Q 2 .

The clamp diode DD 2 is connected between the drain and source of the auxiliary switching element Q 2 in parallel. The connection style is set so that the anode of the clamp diode DD 2 is connected to the source and the cathode thereof is connected to the drain.

The drain of the auxiliary switching element Q 2 is connected to the connection point between the tap output line of the secondary winding N 2 and the anode of the rectifying diode D 02 3 . The source of the auxiliary switching element Q 2 is connected to the earth at the secondary side. through the clamp capacitor C

Accordingly, the active clamp circuit is constructed by connecting the clamp capacitor C 3 to the parallel connection circuit of the auxiliary switching element Q 2 and the clamp diode DD 2 in series. The circuit thus formed is further connected to the winding portion (winding N 3 ) extending from the intermediate tap of the secondary winding N 2 to the earth at the secondary side in parallel.

Further, as shown in FIG. 1 , the series connection circuit of the resistor Rg 1 , the capacitor Cg 1 and the drive winding Ng 1 is connected to the gate of the auxiliary switching element Q 2 as the driving circuit system for the auxiliary switching element Q 2 . The series connection circuit forms a self-excited driving circuit for the auxiliary switching element Q 2 . That is, the signal voltage from the self-excited driving circuit is applied to the gate of the switching element Q 2 to perform the switching operation.

Further, as shown in FIG. 1 , the series connection circuit of the resistor Rg 1 , the capacitor Cg 1 and the drive winding Ng 1 is connected to the gate of the auxiliary switching element Q 2 as the driving circuit system for the auxiliary switching element Q 2 . The series connection circuit forms a self-excited driving circuit for the auxiliary switching element Q 2 . That is, the signal voltage from the self-excited driving circuit is applied to the gate of the switching element Q 2 to perform the switching operation. In this case, the drive winding Ng 1 is formed at the winding-start end portion side of the secondary winding N 2 , and the number of turns thereof is set to 1T (turn). Accordingly, a voltage induced by the alternating voltage achieved in the primary winding N 2 occurs in the drive winding Ng 1 . In this case, the voltages having the opposite polarities are achieved at the secondary winding N 2 and the drive winding Ng 1 in view of the winding-direction relationship therebetween. The operation of the drive winding Ng 1 is guaranteed if the number of turns thereof is equal to 1T, however, it is not limited to this value.

In this embodiment, the switching operation of the auxiliary switching element Q 2 is subjected to the PWM control by a control circuit 1 B equipped at the secondary side. That is, the secondary DC output low voltage E 02 is supplied to the control circuit 1 B of the error amplifier, and the control circuit 1 B applies the DC control voltage corresponding to the voltage E 02 to the gate of the auxiliary switching element Q 2 to control the conduction angle of the auxiliary switching element Q 2 , whereby the DC output low voltage E 02 is stabilized with respect to the variations of the alternating input voltage VAC and the load power Po.

The power supply circuit thus constructed was tested under the condition that the resonance capacitor Cr=8200 pF, the resonance capacitor C 2 =8200 pF, the resonance capacitor C 4 =0.1 μF, the clamp capacitor C 3 =3.3 μF, and an auxiliary low on-resistance MOS-FET having a voltage resistance to 5 A/50V was used as the auxiliary switching element Q 2 .

FIG. 4 shows the operating waveforms of the respective parts under the condition that the alternating input voltage VAC=100V, the load power of the DC output main voltage E 01 02 line (12V line) is equal to 18 W (=12V×1.5 A) and the load power Po is equal to 200 W. line (135V line) is equal to 182 W, the load power of the DC output low voltage E

FIG. 4 shows the operating waveforms of the respective parts under the condition that the alternating input voltage VAC=100V, the load power of the DC output main voltage E 01 02 line (12V line) is equal to 18 W (=12V×1.5 A) and the load power Po is equal to 200 W. line (135V line) is equal to 182 W, the load power of the DC output low voltage E  FIG. 5 shows the operating waveforms of the respective parts under the condition that the load power of the DC output main voltage E 01 line (135V line) is equal to 32 W, the load power of the DC output low voltage E 02 line (12V line) is equal to 18 W (=12V×1.5 A) and the load power Po=50 W.

FIG. 5 shows the operating waveforms of the respective parts under the condition that the load power of the DC output main voltage E 01 line (135V line) is equal to 32 W, the load power of the DC output low voltage E 02 line (12V line) is equal to 18 W (=12V×1.5 A) and the load power Po=50 W. FIG. 6 shows the characteristics of AC/DC power conversion efficiency ηAC/DC and the conduction angle (TON′) of the auxiliary switching element Q 2 with respect to variation of the load power Po, and FIG. 7 shows the characteristics of the switching frequency fs and resonance voltage V 1 of the switching element Q 1 with respect to variation of the load power Po.

FIG. 6 shows the characteristics of AC/DC power conversion efficiency ηAC/DC and the conduction angle (TON′) of the auxiliary switching element Q 2 with respect to variation of the load power Po, and FIG. 7 shows the characteristics of the switching frequency fs and resonance voltage V 1 of the switching element Q 1 with respect to variation of the load power Po. As is apparent from FIGS. 4 and 5 , with respect to the main switching element Q 1 , the switching frequency fs and the conduction angle TON are subjected to composite control, and with respect to the auxiliary switching element Q 2 , the conduction angle (TON′) is controlled.

As is apparent from the comparison between FIGS. 6 , 7 and FIG. 13 for the prior art, this embodiment enhances the AC/DC power conversion efficiency ηAC/DC to 90% or more when the power load Po ranges from 50 W to 200 W.

The resonance voltage V 1 is equal to 750V at the alternating input voltage VAC of 144V, and a product having a voltage resistance to 800V may be used as the switching element Q 1 . In the AC 200V system, a product having a voltage resistance to 1500V may be used.

With respect to the conduction angle (TON′) control of the auxiliary switching element Q 2 , in order to stabilize the cross-regulation voltage 12.5V to 17.5V of the DC output low voltage E 02 2 is equal to about 2 W when the load current of the DC output low voltage E 02 is equal to 1.5 A, and thus the power loss can be reduced by 6.25 W as compared with the power loss (8.25 W) of the prior art. =15V±2.5V to 12V, the control range may be set to 4 μs to 1 μs, and thus the control range is slight. The power loss of the auxiliary switching element Q

FIG. 8 shows a switching power supply circuit according to a second embodiment of the present invention.

FIG. 8 shows a case where the switching element Q 1 at the primary side is formed of MOS-FET and a separate excitation type oscillating circuit based on IC is provided in connection with the switching element Q 1 . The same elements as shown in FIG. 1 are represented by the same reference numerals, and the description thereof is omitted.

In this case, a one-stone switching element Q 1 is equipped as a switching converter for receiving and intermitting the rectified and smoothed voltage Ei (DC input voltage), and a voltage resonance type converter for performing a so-called single end type switching operation is provided.

The voltage resonance type converter of this embodiment adopts the separate excitation type construction. The drain of the switching element Q 1 of MOS-FET is connected to the anode of the smoothing capacitor Ci through the primary winding N 1 of the insulating converter transformer PIT, and the source of the switching element Q 1 of MOS-FET is connected to the earth at the primary side.

A parallel resonance capacitor Cr is connected between the drain and source of the switching element Q 1 in parallel. A primary parallel resonance circuit is formed by the capacitance of the parallel resonance capacitor Cr and the leakage inductance achieved at the primary winding N 1 1 , whereby the switching operation of the switching element Q 1 is made to be based on the voltage resonance style. of the insulating converter transformer PIT. The resonance operation of the parallel resonance circuit is achieved in accordance with the switching operation of the switching element Q

Further, a clamp diode DD 1 based on a so-called body diode equipped to MOS-FET is connected in parallel between the drain and source of the switching element Q 1 , thereby forming a route for clamp current flowing during the period when the switching element is turned off.

The switching element Q 1 is driven to carry out the switching operation, for example, by a switching driving portion 10 comprising an integrated circuit (IC) integrally equipped with an oscillation circuit 2 and a drive circuit 3 .

The switching driving portion 10 is connected to the line for the rectified and smoothed voltage Ei through a starting resistor Rs. For example when a power source voltage is applied to the switching driving portion 10 through the starting resistor Rs at the power source turn-on time, the switching driving portion 10 is actuated.

The oscillation circuit 2 of the switching driving portion 10 carries out the oscillation operation having the frequency based on a control signal from the control circuit 1 A to output an oscillation signal. The oscillation signal is converted to a drive voltage in the drive circuit 3 , and output to the gate of the switching element Q 1 , whereby the switching element Q 1 is allowed to carry out the switching operation based on the oscillation signal generated in the oscillation circuit 2 . Accordingly, the switching frequency of the switching element Q 1 and the duty of the on/off period in one switching period is dependently determined on the basis of the oscillation signal generated in the oscillation circuit 2 .

The oscillation frequency of the oscillation circuit 2 is set so that the control circuit 1 A is varied in accordance with variation of the level of the DC output main voltage E 01 . That is, the switching frequency and conduction angle of the switching element Q 1 is variably controlled in accordance with the level of the DC output main voltage E 01 , thereby stabilizing the DC output main voltage E 01 .

At the secondary side of the insulating converter transformer PIT, DC output low voltages E 02 , E 03 of two systems are achieved in addition to the DC output main voltage E 01 .

That is, two tap outputs are provided to the secondary winding N 2 as shown in FIG. 8 (the winding portion between the first tap of the secondary winding N 2 and the earth at the secondary side is represented by N 3 and the winding portion between the second tap of the secondary winding N 2 and the earth at the secondary side is represented by N 4 ).

Like the case of FIG. 1 , a parallel resonance capacitor C 4 is connected to the winding N 3 in parallel, and a parallel resonance circuit is formed by the leakage inductance of the winding N 3 4 , and further a rectifying diode D 02 and a smoothing capacitor C 02 are connected to each other in the connection manner

shown in FIG. 8 to form a half-wave rectifying circuit. The DC output low voltage E 02 is generated by the half-wave rectifying circuit (D 02 , C 02 ). The secondary DC output low voltage E 02 is set to about 12V. and the capacitance of the secondary parallel resonance capacitor C

shown in FIG. 8 to form a half-wave rectifying circuit. The DC output low voltage E 02 is generated by the half-wave rectifying circuit (D 02 , C 02 ). The secondary DC output low voltage E 02 is set to about 12V. and the capacitance of the secondary parallel resonance capacitor C PIT, Like the circuit construction for the winding N 3 , a parallel resonance capacitor C 5 is connected to the winding N 4 in parallel, and a parallel resonance circuit is formed by the leakage inductance of the winding N 4 and the capacitance of the secondary parallel resonance capacitor C 5 . Further, a rectifying diode D 03 and a smoothing capacitor C 03 are connected to each other in the connection manner shown in FIG. 8 to form a half-wave rectifying circuit. The DC output low voltage E 03 is generated by the half-wave rectifying circuit (D 03 , C 03 ). The secondary DC output low voltage E 03 is set to about 5V, for example.

In the power supply circuit, an active clamp circuit is equipped to each of the DC output low voltage E 02 and E 03 lines.

An auxiliary switching element Q 2 of MOS-FET, a clamp capacitor C 3 and a clamp diode DD 2 02 line. Further, a driving circuit system for driving the auxiliary switching element Q 2 comprises a drive winding Ng 1 , a capacitor Cg 1 and a resistor Rg 1 The active clamp circuit is constructed by connecting the series connection circuit of the auxiliary switching element Q 2 and the clamp capacitor C 3 to the winding N 3 in parallel. of a body diode are provided as the active clamp circuit for the DC output low voltage E

The switching operation of the auxiliary switching element Q 2 is subjected to the PWM control by the control circuit 1 B. That is, the secondary DC output low voltage E 02 is supplied to the control circuit 1 B of the error amplifier, and the controller 1 B applies the corresponding DC control voltage to the gate of the auxiliary switching element Q 2 to control the conduction angle of the auxiliary switching element Q 2 , whereby the DC output low voltage E 02 is stabilized with respect to the variations of the alternating input voltage VAC and the load power Po.

The active clamp circuit for the DC output low voltage E 03 line is equipped with an auxiliary switching element Q 3 of MOS-FET, a clamp capacitor C 6 and a clamp diode DD 3 of a body diode. A driving system for the auxiliary switching element Q 3 comprises the drive winding Ng 1 2 ), a capacitor Cg 2 and a resistor Rg 2 . The active clamp circuit is constructed by connecting the series connection circuit of the auxiliary switching element Q 3 and the clamp capacitor C 6 to the winding N 4 in parallel. (commonly used with the driving system of the auxiliary switching element Q

Further, the switching operation of the auxiliary switching element Q 3 is subjected to the PWM control by a control circuit iC. That is, the secondary DC output low voltage E 03 is supplied to the control circuit iC of the error amplifier, and the control circuit iC applies the corresponding DC control voltage to the gate of the auxiliary switching element Q 3 to control the conduction angle of the auxiliary switching element Q 3 , whereby the DC output low voltage E 03 is stabilized with respect to the variations of the alternating input voltage VAC and the load power Po.

FIG. 9 shows a switching power supply circuit according to a third embodiment of the present invention. In this embodiment, the construction of the primary side of the insulating converter transformer PIT is the same as shown in

FIG. 1 . With respect to the construction of the secondary side, the connection manner of each element is the same as the embodiment of FIG. 8 , however, the windings N 3 and N 4 are provided separately from the secondary winding N 2 . The drive winding Ng 1 is formed at the winding-start end portion of the winding N 3 by 1T, for example. This embodiment is suitably applied to a case where the output current of the DC output low voltage E 02 , E 03 is equal to a large current value such as 2 A or more.

The embodiments shown in FIGS. 8 and 9 are directed to a case where two or more pairs of DC output low voltages (E 02 , E 03 , . . . ) in addition to the DC output main voltage E 01 are taken out at the secondary side, and an active clamp circuit is added to each DC output low voltage line as shown in FIGS. 8 and 9 .

The embodiments shown in FIGS. 8 and 9 are directed to a case where two or more pairs of DC output low voltages (E 02 , E 03 , . . . ) in addition to the DC output main voltage E 01 are taken out at the secondary side, and an active clamp circuit is added to each DC output low voltage line as shown in FIGS. 8 and 9 . In the second and third embodiments, the insulating converter transformer PIT can be implemented in any combination case where the polarities of the primary winding N 1 and the secondary winding N 2 are in additive polarity relationship or subtractive polarity relationship and the winding directions thereof are the same (coaxial) or opposite to each other.

The foregoing description is made on the power supply circuit according to the embodiments of the present invention. However, the present invention is not limited to the above-described embodiments. For example, the main switching element Q 1 is not limited to the bipolar transistor, and it may be formed of MOS-FET, BJT, IGBT or the like. The auxiliary switching element Q 2 may be formed of BJT, IGBT or the like. Further, another element such as SIT (Static Induction Thyristor) or the like may be used.

The secondary rectifying circuit formed so as to contain the secondary resonance circuit is also not limited to the construction of the above-described embodiments, and another circuit construction may be adopted.

As is understood from the foregoing description, in the composite resonance type switching converter having the active clamp means at the secondary side, the AC/DC power conversion efficiency can be enhanced. Particularly, the invalid power when the load power is below ½ (i.e., under a light load) can be reduced. For example, the invalid power can be reduced by about 4 W at the load power of 200 W, and it can be reduced by 11 W under no-load state.

Further, the power loss to stabilize the voltage due to the cross-regulation (voltage variation) of the DC output low voltage can be greatly reduced.

Still further, the voltage resistance of the main switching element can be reduced from 900V to 800V in the case of AC 100V system, and from 1800V to 1500V in the case of AC 200V system. Further, the voltage resistance of the auxiliary switching element can be reduced from 400V to 50V. From this effect, enhancement of the switching characteristics and reduction of the cost of the power supply circuit can be promoted.

SONY TRINITRON CONVERGENCE DEFLECTING DEVICE FOR SINGLE-GUN, PLURAL-BEAM COLOR PICTURE TUBE In a color picture tube of the single-gun, plural-beam type in which a central beam and two side beams originate in a common horizontal plane and are all made to pass through the center of an electron lens for focussing the beams on the color screen with the central beam emerging from the lens along the optical axis of the latter and the side beams emerging from the lens along paths that are oppositely divergent from the axis, the divergent side beams are acted upon by an electrostatic convergence deflecting device constituted by pairs of horizontally spaced plates arranged along the divergent paths and having voltages applied thereacross to produce electric fields by which the divergent side beams passing therethrough are deflected to converge at a common spot with the central beam on the apertured grill or mask associated with the screen, and a main deflection yoke produces magnetic fields by which the beams are deflected horizontally and vertically, respectively, for causing the beams to scan the screen; the horizontal distances between the plates of each pair are varied in the vertical direction from a maximum at the common horizontal plane to minimums at the opposed edges of the plates remote from such common plane so as to correspondingly vary the strengths of the electric fields and thus correct distortions in the rasters of the side beams.

1. A single-gun, plural-beam color picture tube comprising a color screen, beam generating means directing a central beam and two side beams in a common horizontal plane toward said screen, electron lens means defining a focusing field having a center through which the beams pass and by which the bundle of electrons in each of the beams are focused on said color screen with the central beam emerging from said lens along the optical axis of the latter and said two side beams emerging from said lens along paths that are oppositely divergent from said central beam, electrostatic convergence deflecting means including a pair of horizontally spaced plates arranged along each of said divergent paths, said spaced plates of each pair being disposed at the inside and outside, respectively, of the side beam in the related divergent path and having voltages applied thereacross to produce an electric field by which the respective side beam passing therethrough is deflected horizontally to converge at a common spot with said central beam and the other of said side beams, and a main deflection yoke producing magnetic fields by which said beams are deflected horizontally and vertically respectively, for causing the beams to scan said screen and produce respective rasters on the latter; said convergence deflecting means being located within the field produced by said yoke to deflect said beams vertically so that said beams are similarly deflected vertically within said convergence deflecting means, and the horizontal distance between said plates of each of said pairs varying progressively in the vertical direction normal to said common horizontal plane from a maximum at said common horizontal plane to minimums at the opposed edges of the plates remote from said common plane so as to correspondingly vary the strength of the respective electric field for changing the rasters of said side beams with respect to the raster of said central beam and thereby compensating for deviations between said rasters as produced by said magnetic fields of the main deflection yoke. 2. A single gun, plural-beam color picture tube according to claim 1, in which the inner plate of each of said pairs which is closest to said central beam is flat, and the other plate of the respective pair is convex at the side thereof facing away from said inner plate. 3. A single-gun, plural-beam color picture tube according to claim 1, in which the plates of each of said pairs are convex at the sides thereof facing away from each other.

1. A single-gun, plural-beam color picture tube comprising a color screen, beam generating means directing a central beam and two side beams in a common horizontal plane toward said screen, electron lens means defining a focusing field having a center through which the beams pass and by which the bundle of electrons in each of the beams are focused on said color screen with the central beam emerging from said lens along the optical axis of the latter and said two side beams emerging from said lens along paths that are oppositely divergent from said central beam, electrostatic convergence deflecting means including a pair of horizontally spaced plates arranged along each of said divergent paths, said spaced plates of each pair being disposed at the inside and outside, respectively, of the side beam in the related divergent path and having voltages applied thereacross to produce an electric field by which the respective side beam passing therethrough is deflected horizontally to converge at a common spot with said central beam and the other of said side beams, and a main deflection yoke producing magnetic fields by which said beams are deflected horizontally and vertically respectively, for causing the beams to scan said screen and produce respective rasters on the latter; said convergence deflecting means being located within the field produced by said yoke to deflect said beams vertically so that said beams are similarly deflected vertically within said convergence deflecting means, and the horizontal distance between said plates of each of said pairs varying progressively in the vertical direction normal to said common horizontal plane from a maximum at said common horizontal plane to minimums at the opposed edges of the plates remote from said common plane so as to correspondingly vary the strength of the respective electric field for changing the rasters of said side beams with respect to the raster of said central beam and thereby compensating for deviations between said rasters as produced by said magnetic fields of the main deflection yoke. 2. A single gun, plural-beam color picture tube according to claim 1, in which the inner plate of each of said pairs which is closest to said central beam is flat, and the other plate of the respective pair is convex at the side thereof facing away from said inner plate. 3. A single-gun, plural-beam color picture tube according to claim 1, in which the plates of each of said pairs are convex at the sides thereof facing away from each other.

Description:

This invention relates generally to color picture tubes of the single-gun, plural-beam type, and particularly to tubes of that type in which the plural beams are passed through the optical center of a common electron lens by which the beams are focussed on the color phosphor screen.

In single-gun, plural-beam color picture tubes of the described type, for example, as specifically disclosed in U.S. Pat. No. 3,448,316, issued June 3, 1969, and having a common assignee herewith, three laterally spaced electron beams are emitted by a beam generating or cathode assmebly and directed in a common substantially horizontal plane with the central beam coinciding with the optical axis of the single electron focussing lens and the two outer or side beams being converged to cross the central beam at the optical center of the lens and thus emerge from the latter along paths that are divergent from the optical axis. Arranged along such divergent paths are respective pairs of convergence deflecting plates constituting a convergence deflecting device and having voltages applied thereacross to produce electric fields which laterally deflect the divergent beams in a substantially horizontal plane for causing all beams to converge at a common spot on the apertured beam selecting grill or shadow mask associated with the color screen. Further, arranged between the convergence de flecting device and the screen is a main deflection yoke which, in response to its reception of horizontal and vertical sweep signals, produces horizontal and vertical magnetic deflection fields acting on all of the beams to cause the latter to scan the color screen in predetermined rasters. Since the beams are horizontally spaced and non-parallel during their passage through the horizontal deflection field, the distances that the side beams travel through such field will be respectively greater and less than the distance that the central beam travels through the field when the beams are deflected toward one side or the other side of the screen. If the horizontal deflection field has a uniform flux density thereacross, the side beam traveling therethrough for the greater distance will be deflected to a greater extent than the side beam traveling the shorter distance through the field and misconvergence of the beams will result. Even if the horizontal deflection field is given a non-uniform flux density thereacross, misconvergence of the beams can be thereby avoided only when the beams are deflected toward one side or the other of the screen midway between the top and bottom of the screen, that is, when the common plane of the beams passing through the horizontal deflection field is directed horizontally, that is, substantially perpendicular to the vertical lines of magnetic flux of the horizontal deflection field. However, when the common plane of the beams passing through the horizontal deflection field is substantially inclined from the horizontal, that is, when the vertical deflection field deflects the beams to cooperate with the horizontal deflection field in directing the beams toward an upper or lower corner of the screen, the difference between the distances traveled by the side beams through the horizontal deflection field is further increased and hence may not be compensated by the non-uniform flux density established across the horizontal deflection field. Thus, the rasters of the side beams may have shapes that are oppositely distorted with respect to the shape of the raster of the central beam.

flecting device and the screen is a main deflection yoke which, in response to its reception of horizontal and vertical sweep signals, produces horizontal and vertical magnetic deflection fields acting on all of the beams to cause the latter to scan the color screen in predetermined rasters. Since the beams are horizontally spaced and non-parallel during their passage through the horizontal deflection field, the distances that the side beams travel through such field will be respectively greater and less than the distance that the central beam travels through the field when the beams are deflected toward one side or the other side of the screen. If the horizontal deflection field has a uniform flux density thereacross, the side beam traveling therethrough for the greater distance will be deflected to a greater extent than the side beam traveling the shorter distance through the field and misconvergence of the beams will result. Even if the horizontal deflection field is given a non-uniform flux density thereacross, misconvergence of the beams can be thereby avoided only when the beams are deflected toward one side or the other of the screen midway between the top and bottom of the screen, that is, when the common plane of the beams passing through the horizontal deflection field is directed horizontally, that is, substantially perpendicular to the vertical lines of magnetic flux of the horizontal deflection field. However, when the common plane of the beams passing through the horizontal deflection field is substantially inclined from the horizontal, that is, when the vertical deflection field deflects the beams to cooperate with the horizontal deflection field in directing the beams toward an upper or lower corner of the screen, the difference between the distances traveled by the side beams through the horizontal deflection field is further increased and hence may not be compensated by the non-uniform flux density established across the horizontal deflection field. Thus, the rasters of the side beams may have shapes that are oppositely distorted with respect to the shape of the raster of the central beam.

Accordingly, it is an object of this invention to provide a single-gun, plural-beam color picture tube in which the rasters of the several beams are free of distortion with respect to each other.

Another object is to provide a single-gun, plural-beam color picture tube in which distortions of the rasters of the several beams are avoided by a particular construction of the convergence deflecting device.

In accordance with an aspect of the invention, the described distortions of the rasters of the side beams with respect to the raster of the central beam are avoided by suitably varying, in the direction perpendicular to the common plane in which the beams originate, the distances between the paired plates of the convergence deflecting device, whereby to correspondingly vary the strengths of the electric fields between such plates by which the side beams are convergently deflected.

The above, and other objects, features and advantages of this invention, will be apparent in the following detailed description of illustrative embodiments which is to be read in connection with the accompanying drawing, wherein:

FIG. 1 is a schematic sectional view in a horizontal plane passing through the axis of a single-gun, plural-beam color picture tube of the type to which this invention is preferably applied;

FIG. 2 is a diagrammatic view to which reference is hereinafter made in explaining the invention;

FIG. 3 is a diagrammatic view showing the possible relative distortions of the rasters of the several beams, as seen from the viewer's side of the tube screen, and which are to be avoided by this invention;

FIG. 4 is a diagrammatic, transverse sectional view through the convergence deflecting device of a color picture tube according to a first embodiment of this invention; and

FIGS. 5-8 are views similar to FIG. 4, but showing other embodiments of the invention.

Referring to the drawings in detail, and initially to FIG. 1 thereof, it will be seen that a single-gun, plural-beam color picture tube of the type to which this invention may be applied comprises a glass envelope (indicated in broken lines) having a neck N and cone C extending from the neck to a color screen S provided with the usual arrays of color phosphors S R , S G and S B and with an apertured beam selecting grill or shadow mask G P . Disposed within neck N is an electron gun A having cathodes K R , K G and K B , each of which is constituted by a beam-generating source with the respective beam-generating surfaces thereof disposed as shown in a plane which is substantially perpendicular to the axis of the electron gun A. In the embodiment shown, the beam-generating surfaces are arranged in a straight line so that the respective beams B R , B G and B B emitted therefrom are directed in a substantially horizontal plane containing the axis of the gun, with the central beam B G being coincident with such axis. A first grid G 1 is spaced from the beam-generating surfaces of cathodes K R , K G and K B and has apertures g 1R , g 1G and g 1B formed therein in alignment with the respective cathode beam-generating surfaces. A common grid G 2 is spaced from the first and grid G 1 and has apertures g 2R , g 2G and g 2B 1 . Successively arranged in the axial direction away from the common grid G 2 are open-ended, tubular grids or electrodes G 3 , G 4 and G 5 , respectively with cathodes K R , K G and K B , grids G 1 and G 2 , and electrodes G 3 , G 4 and G 5 being suitably maintained in the depicted, assembled positions thereof. formed therein in alignment with the respective apertures of the first grid G

Referring to the drawings in detail, and initially to FIG. 1 thereof, it will be seen that a single-gun, plural-beam color picture tube of the type to which this invention may be applied comprises a glass envelope (indicated in broken lines) having a neck N and cone C extending from the neck to a color screen S provided with the usual arrays of color phosphors S R , S G and S B and with an apertured beam selecting grill or shadow mask G P . Disposed within neck N is an electron gun A having cathodes K R , K G and K B , each of which is constituted by a beam-generating source with the respective beam-generating surfaces thereof disposed as shown in a plane which is substantially perpendicular to the axis of the electron gun A. In the embodiment shown, the beam-generating surfaces are arranged in a straight line so that the respective beams B R , B G and B B emitted therefrom are directed in a substantially horizontal plane containing the axis of the gun, with the central beam B G being coincident with such axis. A first grid G 1 is spaced from the beam-generating surfaces of cathodes K R , K G and K B and has apertures g 1R , g 1G and g 1B formed therein in alignment with the respective cathode beam-generating surfaces. A common grid G 2 is spaced from the first and grid G 1 and has apertures g 2R , g 2G and g 2B 1 . Successively arranged in the axial direction away from the common grid G 2 are open-ended, tubular grids or electrodes G 3 , G 4 and G 5 , respectively with cathodes K R , K G and K B , grids G 1 and G 2 , and electrodes G 3 , G 4 and G 5 being suitably maintained in the depicted, assembled positions thereof. formed therein in alignment with the respective apertures of the first grid G

For operation of the electron gun A of FIG. 1, appropriate voltages are applied to the grids G 1 2 and to the electrodes G 3 , G 4 and G 5 . Thus, for example, a voltage of 0 to minus 400V is applied to the grid G 1 , a voltage of 0 to 500V is applied to the grid G 2 , a voltage of 13 to 20KV is applied to the electrodes G 3 and G 5 , and a voltage of 0 to 400V is applied to the electrode G 4 , with all of these voltages being based upon the cathode voltage as a reference. As a result, the voltage distributions between the respective electrodes and cathodes, and the respective lengths and diameters thereof, may be substantially identical with those of a unipotential-single beam type electron gun which is constituted by a single cathode and first and second, single-apertured grids. and G

With the applied voltage distribution as described hereinabove, an electron lens field will be established between grid G 2 and the electrode G 3 to form an auxiliary lens L' as indicated in dashed lines, and an electron lens field will be established around the axis of electrode G 4 , by the electrodes G 3 , G 4 and G 5 , to form a main lens L, again as indicated in dashed lines. In a typical use of electron gun A, bias voltages of 100V, 0V, 300V, 20KV, 200V and 20V may be applied respectively to the cathodes K R , K G and K B , the first and second grids G 1 and G 2 and the electrodes G 3 , G 4 and G 5 .

Further included in the electron gun A of FIG. 1 and electron beam convergence deflecting means F which comprise inner shielding plates P and P' disposed in the depicted spaced, relationship at opposite sides of the gun axis, and axially extending, deflector plates Q and Q' which are disposed, as shown, in outwardly spaced, opposed relationship to shielding plates P and P', respectively. Although depicted as substantially straight, it is to be understood that the deflector plates Q and Q' may, alternatively, be somewhat curved or outwardly bowed, as is well known in the art.

The shielding plates P and P' are equally charged and disposed so that the central electron beam B G will pass substantially undeflected therebetween, while the deflector plates Q and Q' have negative charges with respect to the plates P and P' so that electron beams B B and B R will be convergently deflected as shown by the respective passages thereof between the plates P and Q and the plates P' and Q'. More specifically, a voltage V P which is equal to the voltage applied to the electrode G 5 , may be applied to both shielding plates P and P', and a voltage V Q , which is some 200 to 300V lower than the voltage V P , is applied to the plates Q and Q' to result in the plates P and P' being at the same potential, and in the application of a deflecting voltage difference or convergence deflecting voltages V C between the plates P' and Q' and the plates P and Q and it is, of course, this convergence deflecting voltage V C which will impart the requisite convergent deflection to the electron beams B B and B R .