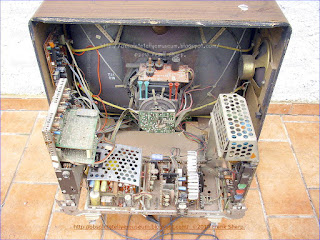

The TELEFUNKEN CHASSIS 712A was introducing first time a SMPS POWER

SUPPLY and chroma combined 3 chips design in video sections and further

using the 20AX SYSTEM CRT TUBE BUT HERE MADE BY TELEFUNKEN FACTORY.

It's mainly a modular chassis and highly sophisticated and complex.

This chassis THE TELEFUNKEN CHASSIS 712A was even featuring a DYNAMIC FOCUS in the Line deflection EHT circuitry.

Dynamic focus voltages for a CRT are obtained by utilizing the combined

parabolic conversion wave shapes for control of the focusing

electrode to provide sharp focus at all points in the raster. A

current source is coupled to the focus divider chain and the

conversion wave shape controls the current in the divider chain by

controlling the resistance in a transistor. No high voltage capacitors

are required since the dynamic voltages are coupled into the chain

near the low voltage end.

1. In a cathode ray tube device for displaying information by means of a

raster:

a cathode ray tube having an anode and a focus electrode;

an input source of AC voltage having variations of substantially parabolic waveform at both horizontal and vertical rates;

a source of high voltage DC coupled to the anode;

transistor means for amplifying said input AC voltage and coupled to ground and to the ac input source; and

resistive means including first and second elements, the first

element coupled between the source of high voltage and the focus

electrode, the second element coupled between the focus electrode and

the transistor means, the first element having a resistance

substantially greater than that of the second element.

2. A cathode ray tube device for displaying

information on a raster in accordance with claim 1 and wherein the

resistive means also includes a manually variable resistive means.

3. A cathode ray tube device for

displaying information on a raster in accordance with claim 2 wherein

the manually controllable resistive means is a focus control.

4. A cathode ray tube device for

displaying information on a raster in accordance with claim 1 and

further including an amplifier stage coupled between the source of AC

voltage and the transistor means.

5. A cathode ray tube device for displaying information on a raster

in accordance with claim 1 and wherein said lower DC voltage is

manually variable. 6. A cathode

ray tube device for displaying information on a raster in accordance

with claim 1 and further including a source of relatively low voltage

DC coupled to the junction of the second resistive means element and

the transistor means. 7. A

cathode ray tube device for displaying information on a raster in

accordance with claim 6 wherein the source of relatively low voltage

DC is coupled to the junction through a clamping diode means and a

biasing resistive means.

Description:

BACKGROUND OF THE INVENTION

This

invention relates to the field of cathode ray tubes and, more

particularly, to the provision for dynamic focusing voltages for use in

such tubes.

This

invention relates to the field of cathode ray tubes and, more

particularly, to the provision for dynamic focusing voltages for use in

such tubes.

In CRT devices, the major factor effecting spot

focus is the variation in the distance from the electron gun to the

fluorescent screen as the electron beam is swept from the center of the

screen to the outer areas. For accurate focusing of the beam at all

parts of the screen, the voltage applied to the focus electrode must be

varied as a function of the distance from the spot to the Z axis of

the CRT device, or, in other words, a function of the angle of

deflection. This requires a voltage which varies as the beam moves

horizontally and also as it moves vertically. As a reasonable

approximation, this requires a horizontal voltage variation at line

rate which is of essentially parabolic shape, and which is superimposed

on a similar function at the vertical frame rate. Earlier CRT designs

provided minimum spot de-focusing by optimizing focus at some point

intermediate the center of the CRT screen and the edges of the raster;

e.g., 30° from the Z axis was typical. Later it was recognized that a

better solution would be to add to the static focusing voltage a

voltage varying with the angle of deflection. All known circuits for

accomplishing dynamic focusing in this way have required high voltage

coupling capacitors and thus were expensive and not adaptable to solid

state implementation.

SUMMARY OF THE INVENTION

It

is therefore an object of the present invention to provide dynamic

focusing for a CRT utilizing waveforms which are already present in the

CRT device.

It

is a more particular object to devise such dynamic focusing with

solid state circuitry and without large and costly high voltage

capacitors.

These objects and others are provided by

circuitry constructed in accordance with the invention in which the

effective resistance of a transistor circuit is varied as a function of

the convergence waveform. The transistor circuit is coupled in series

with the focus divider chain, thus the current in the chain is varied

accordingly. No high voltage capacitors are required for coupling the

dynamic focus voltage to the CRT device since the transistor is near

the low voltage end of the divider chain. The convergence waveform is a

combination of two waveforms, one at line rate and one at frame rate,

each essentially of parabolic form.

BRIEF DESCRIPTION OF THE DRAWING

FIG. 1a is a diagram of a CRT device showing the dimensional basis for the problem which is solved by the invention.

FIG. 1b is a diagram of a dot pattern of a CRT device lacking the circuit of the invention.

FIGS. 2a-2c are illustrations of the voltage waveforms required for the invention.

FIG. 3 is a block diagram of a device utilizing a CRT and including the invention.

FIG. 4 is an embodiment of the circuitry of the invention.

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

The diagram of FIG. 1a is intended  to

make clear the problem to be solved by the circuit of the invention. A

3-gun cathode ray tube (CRT) 10 of the type used in color television

is shown in outline form. Such tubes typically have a rounded face

plate or screen 11 (bearing the phosphors) with a radius of curvature

R' longer than the entire tube length, however, the invention is

applicable even to flat face plate tubes. The electron beam thus

travels a path R2 from the point of deflection B to the edges of the

screen 11 which is longer than the path R1 to the central portion, ΔR

being the instantaneous difference. It will be seen then that the

focusing voltage must be adjusted to compensate for this difference as

the electron beam is swept from side to side and top to bottom of a

raster.

to

make clear the problem to be solved by the circuit of the invention. A

3-gun cathode ray tube (CRT) 10 of the type used in color television

is shown in outline form. Such tubes typically have a rounded face

plate or screen 11 (bearing the phosphors) with a radius of curvature

R' longer than the entire tube length, however, the invention is

applicable even to flat face plate tubes. The electron beam thus

travels a path R2 from the point of deflection B to the edges of the

screen 11 which is longer than the path R1 to the central portion, ΔR

being the instantaneous difference. It will be seen then that the

focusing voltage must be adjusted to compensate for this difference as

the electron beam is swept from side to side and top to bottom of a

raster.

FIG. 1b is a graphical representation of the spot

defocusing which occurs at the outer portions of a CRT screen if

dynamic focusing is not used. Instead of providing a sharp focus spot,

as at the center of the screen, a small circle is produced which

reduces the definition of the displayed information.

FIG. 2

shows the types of waveforms needed to provided dynamic focusing and

eliminate the de-focusing effect of FIG. 1b. As may be seen in FIG. 2a, a

roughly parabolic waveform repeating at frame rate, is needed for the

vertical dimension. A similar waveform, FIG. 2b, but repeating at

line rate, is needed for the horizontal dimension. FIG. 2c

illustrates the combined waveform with the horizontal rate greatly

reduced for clarity. As may be seen, no dynamic focusing voltage is

applied as the electron beam sweeps the central portion of the screen.

FIG. 3 is a block diagram of a typical video receiver

utilizing a raster to display information and is given here only for a

better understanding of the invention as the invention could, for

example, be utilized in a monitor which lacks much of this circuitry.

The RF amplifier 12, local oscillator 13, mixer 14, IF amplifier 15,

detector 16, sound portion 17, video amplifier 18 and color

demodulator 19 all function as is well known in the art. The detector

16 output is also coupled to sync circuits 20, which provide

synchronization for vertical and horizontal sweep circuits 21 and 22

respectively. The sync signals are coupled to the CRT 10 for providing

a raster on the screen 11 of the tube. The sweep circuits 21 and 22

are also coupled to a convergence circuit 24 which is coupled to the

CRT 10.

The vertical and horizontal sweep circuits 21 and 22

are coupled to the convergence circuit 24 which is connected to the

convergence coil of the CRT 10. In this embodiment of the invention

the convergence circuit 24 is also coupled through a dynamic focus

circuit 26 to the focus circuit 27 which is coupled to the CRT 10.

FIG.

4 is a schematic diagram of one embodiment of the dynamic focus

circuit of the invention. The terminal 30 is coupled to an amplifier

including a transistor Q1. The terminal 30 could be coupled through

the  convergence

circuit 24 as shown in FIG. 3 or from the pin cushion circuitry (not

shown) which also has the vertical rate parabolic waveform. A terminal

31 may couple an input signal, as from the convergence circuit, which

has the desired parabolic waveform at the horizontal or line rate. A

terminal 33 is coupled to a high voltage source; i.e., the CRT anode

voltage supply. Forming a voltage divider across the high voltage is a

tapped resistor R1, a potentiometer or variable resistor R2 (the

"focus" control) and a transistor Q2. The tap on resistor R1 is coupled

to the focus electrode of the CRT by way of a terminal 34. It will be

seen that the voltage on the terminal 34 can be varied or modulated

by varying the effective resistance of the transistor Q2. A low

voltage is coupled from a terminal 36 to the collector of the

transistor Q2 by way of a biasing transistor R3 and a clamping diode

D1. The voltage on terminal 36 is preferably a variable voltage to

provide for the slight variations which occur from one CRT to another.

A resistor R4 provides a feedback path, and a resistor R5 and a

capacitor C1 provide the necessary time constant. Once the focus

control R2 is set to provide minimum beam spot size at the center of

the screen, the added voltage, having parabolic waveforms at both

horizontal and vertical rate, will optimize the focusing at the edges

of the raster.

convergence

circuit 24 as shown in FIG. 3 or from the pin cushion circuitry (not

shown) which also has the vertical rate parabolic waveform. A terminal

31 may couple an input signal, as from the convergence circuit, which

has the desired parabolic waveform at the horizontal or line rate. A

terminal 33 is coupled to a high voltage source; i.e., the CRT anode

voltage supply. Forming a voltage divider across the high voltage is a

tapped resistor R1, a potentiometer or variable resistor R2 (the

"focus" control) and a transistor Q2. The tap on resistor R1 is coupled

to the focus electrode of the CRT by way of a terminal 34. It will be

seen that the voltage on the terminal 34 can be varied or modulated

by varying the effective resistance of the transistor Q2. A low

voltage is coupled from a terminal 36 to the collector of the

transistor Q2 by way of a biasing transistor R3 and a clamping diode

D1. The voltage on terminal 36 is preferably a variable voltage to

provide for the slight variations which occur from one CRT to another.

A resistor R4 provides a feedback path, and a resistor R5 and a

capacitor C1 provide the necessary time constant. Once the focus

control R2 is set to provide minimum beam spot size at the center of

the screen, the added voltage, having parabolic waveforms at both

horizontal and vertical rate, will optimize the focusing at the edges

of the raster.

Thus, there has been shown and described a

means of providing dynamic focusing for a CRT by using a voltage such

as the pin cushion correction voltage or the dynamic convergence

voltage to control the effective resistance of a solid state circuit

which in turn controls the current in the focus circuit of a CRT.

It

will be apparent that there are a number of variations and

modifications of the above-described embodiment and it is intended to

include all such as fall within the spirit and scope of the appended

claims.

CGE CT 8826 TV 26" TELECOLOR (TELEFUNKEN) CHASSIS 712A POWER

SUPPLY UTILIZING A DIODE AND CAPACITOR VOLTAGE MULTIPLIER FOR TRACKING

FOCUSING AND ULTOR VOLTAGES

A television receiver high voltage power supply

includes an ultor voltage output and an output voltage at some

potential lower than the ultor voltage. The supply is responsive to

kinescope beam current to vary the proportionate magnitudes of the

high and lower voltages at some predetermined ratio.

1.

In a television receiver electron beam deflection system, a power

supply comprising: 2. A circuit as

defined in claim 1 wherein said voltage multiplying means comprise at

least: 3. A circuit as defined in

claim 1 wherein: 4. A circuit as

defined in claim 3 wherein said lower voltage output means further

comprises: 5. A circuit as defined

in claim 1 wherein said lower output voltage means comprises a focus

voltage supply in a television receiver.

6. In a television receiver electron beam deflection circuit, a

power supply comprising: 7. A

circuit as defined in claim 6 and further comprising:

8. A circuit as defined in claim 6 wherein said

lower output voltage means comprises a focus voltage in a television

receiver.

Description:

POWER SUPPLY

This invention relates to high direct voltage power supplies and more

particularly to television receiver high voltage and focus voltage

supplies employing voltage multiplier arrangements.

In a television receiver, electron beam focusing in the kinescope is

commonly achieved by utilizing an electr

ostatic

focusing lens. For optimum focusing, it is necessary to vary the

strength of the focusing lens with varying beam current and electron

velocity (i.e., electron beam accelerating voltage). The focusing lens

may comprise, for example, a pair of cylindrically shaped members

mounted along the kinescope gun axis and having a separating space

between them. Focusing is accomplished by the electric field produced by

the geometry of the focusing members and the potential difference

between them --that is, by the shape and magnitude of the focusing

field. In order to maintain a beam or beams of electrons in optimum

focus under varying beam current conditions and differing electron beam

velocities, it is necessary to vary the focusing field. Since the

geometry of the focusing members is fixed, it is necessary to adjust the

voltage difference between these members to effect proper focusing.

As beam current increases, if the high voltage (the accelerating

potential of the electron beam) remains substantially constant, as is

the case with a regulated high voltage supply, a stronger focusing lens

is needed to maintain focusing of the electron beam. The strength of

the focusing lens can be increased, where, as in a color television

receiver, the focusing members are coupled to a focus voltage supply

and the high beam-accelerating voltage supply, respectively, by

decreasing the output of the focus voltage supply to increase the

potential gradient across the focusing lens. Thus, if the high voltage

is constant and the beam current increases, the focus voltage as a

percentage of the high voltage should be decreased to maintain focus at

high beam current levels. Further, if the high voltage

(electron-accelerating potential) is not maintained constant but

decreases somewhat, and therefore the electron velocity decreases as

beam current increases, the strength of the focusing lens should be

increased which again requires a reduction in focus voltage. The

percentage reduction in focus voltage customarily is equal to or

greater than the corresponding percentage reduction in high voltage.

This effect is commonly referred to as "focus tracking."

In

television receivers, it is common to develop the high voltage from a

secondary winding on the horizontal deflection output transformer.

The flyback pulses developed during horizontal retrace are stepped up

by the flyback transformer and rectified to produce the necessary high

voltage. Further, it is common to provide separate rectifying means

coupled to a lower voltage tap on the flyback transformer, to develop a

focus voltage in a color television receiver.

U.S. Pat. No. 2,879,447 (issued to J. O. Preisig) assigned to the

present assignee discloses such an arrangement including means for

obtaining the necessary "focus tracking" described above.

The present invention obviates the need for separate transformer

windings for the high voltage and focus voltage supplies but provides

the desired focus tracking while deriving both high voltage

(beam-accelerating voltage) and focus voltage from a common point on

the horizontal output transformer by means of a voltage multiplier

arrangement.

Circuits embodying the present invention include a horizontal output

transformer having a high voltage winding, voltage-multiplying means

coupled to the high voltage winding for producing the ultor voltage for

a television receiver, and lower voltage output means associated with

the voltage multiplying means and responsive to beam current for

producing a voltage which tracks with the ultor voltage.

A better understanding of the present invention and its features and

advantages can be obtained by reference to the single FIGURE and the

description below.

In the drawing, a voltage supply constructed in accordance with the

present invention is illustrated partially in block and partially in

schematic form.

Referr

ing

to the FIGURE, horizontal deflection circuits 10 include a horizontal

output stage (not shown) which produces a generally sawtooth current

waveform characterized by a relatively slow rise time during a trace

portion of each deflection cycle and a relatively rapid fall time

during a retrace portion of each deflection cycle. For clarity, the

deflection windings and associated horizontal output circuitry are not

shown. Such a circuit is shown in detail in RCA Television Service

Data 1968 No. 20, published by RCA Sales Corporation, Indianapolis,

Indiana. It is sufficient for the purposes of the present invention to

note that during the retrace portion of each deflection cycle, energy

in the form of a voltage pulse commonly referred to as a flyback pulse

is coupled by means of a primary winding 11 of a horizontal output

transformer 12 to a secondary winding 13 thereof. The turns ratio of

transformer 12 is selected to step up the voltage of this flyback pulse

appearing at a high voltage terminal 14 on secondary winding 13. The

voltage magnitude of this flyback pulse is partially dependent upon

the turns ratio of transformer 12 and in the circuit illustrated is of

the order of 6.25 kilovolts. This will produce an ultor voltage (V

1 )

of approximately 25 kilovolts at ultor output terminal 40 when applied

to the voltage quadrupler described below.

The voltage multiplier may be designed to multiply by any number n by

adding or subtracting successive stages of multiplication. Thus, the

necessary stepped up flyback voltage magnitude will be approximately V

1 /n where V

1

is the desired ultor voltage at terminal 40 and n is the number of

stages of multiplication.

When the system is initially put into operation, positive flyback

pulses will cause a first undirectional conductive device such as a

diode 18 to be forward biased and conduct to charge a focus output

charge storage device such as a capacitor 21 in the polarity shown and

at a potential nearly equal to the peak flyback voltage appearing at

high voltage terminal 14. As the flyback pulse decreases from its peak

value, a second unidirectional conductive device 20 will then be

forward biased, since its anode connected to terminal 50 will be more

positive than its cathode, the latter being at the same voltage as

terminal 14 at this time. When device 20 conducts, at least a portion

of the charge on the output or focus charge storage device 21 is

transferred to a first charge storage device 15 in the polarity shown.

The transfer of charge continues during successive deflection cycles

by the conduction of a third unidirectional conductive device 22 to

charge a second charge storage device 23, the conduction of a fourth

unidirectional conductive device 24 to charge a third charge storage

device 17, the conduction of a fifth unidirectional conductive device

26 to charge a fourth charge storage device 25, the conduction of a

sixth unidirectional conductive device 28 to charge a fifth charge

storage device 19, and the conduction of a seventh unidirectional

conductive device 30 to charge a final charge storage device 27.

Assuming there are no losses within the system and no current is being

drawn from the system as successive flyback pulses occur, the charge

storage devices mentioned, with the exception of devices 15 and 21 as

will be explained below, will each become charged to approximately the

peak to peak value of the transformed flyback pulse waveform

illustrated on the drawing. The charge storage device 21 charges only

during the positive flyback pulse portion of the waveform and, as a

consequence of a resistor 16 coupled in series with conductive device

18, charges to a voltage less than the peak amplitude of the flyback

pulse. Therefore, when conductive device 20 conducts, storage device

15 charges to a voltage equal to the voltage across storage device 21

plus the negative voltage at terminal 14 occurring between flyback

pulses (i.e., less than the peak-to-peak value of the waveform at

terminal 14 by, for example, 200 volts). Adding the series voltages

across charge storage devices 21, 23, 25 and 27, the output voltage at

terminal 40 will be approximately three times the peak to peak

flyback voltage plus the voltage across storage device 21 or almost

four times the peak-to-peak flyback voltage. Kinescope charge storage

device 29, illustrated in dotted lines, is the capacitance of the

aquadag coating on the associated kinescope to ground. A resistance 31

is serially coupled from the final charge storage device 27 to an

output terminal 40 and serves as a current-limiting resistance to

protect the horizontal output circuit in the event of kinescope

arcing.

As

current is drawn from the system due to a flow of beam current within

the kinescope, charge storage devices 21, 23, 25, 27 and 29 begin to

discharge to supply the output current. As this occurs, the voltage

across these devices will decrease. The unidirectional conductive

devices 22, 26 and 30 conduct to equalize the voltage across storage

devices in the upper series connection (in the drawing) with those

across devices in the lower series connection. The flyback pulse will be

coupled via charge storage devices 15, 17 and 19 and unidirectional

conductive devices 18, 20, 26 and 30 will conduct when forward biased

to restore the charge on the charge storage devices. Unidirectional

devices 20, 24 and 28 then conduct to again equalize voltages. A mean

direct current will flow through the charge transfer unidirectional

conductive devices and resistance 16 serially coupled to the first

unidirectional conductive device 18. As beam current increases, this

mean current increases, thus developing a larger voltage drop across

resistance 16. Since the voltage at terminal 50 is approximately

one-quarter that of the ultor voltage V

1 at terminal 40,

and since resistance 16 is relatively large as compared with the forward

resistance of the unidirectional conductive devices, the percentage

decrease of the voltage V

2 present at terminal 50 will be

greater than the percentage decrease of the ultor voltage present at

terminal 40 for high beam current. The utilization of resistance 16 in

series relation to unidirectional conductive device 18 provides the

proper relationship between the focus voltage and ultor voltage. It is

noted that although resistance 16 is illustrated as a separate element,

it may be incorporated within a unidirectional conductive device as

for example, one having a higher forward resistance than the remaining

devices 20, 22, 24, 26, 28 and 30.

A voltage dividing network comprising resistors 32, 34 and 36 serially

coupled from terminal 50 to ground provide a network from which an

adjustable voltage V

3 can be extracted by means of a

variable resistor 34.

Although the present invention is particularly suitable for focus

tracking applications, it may be useful wherever a voltage which is

responsive to beam current is desired.

The parameters listed below have been utilized in the preferred

embodiment.

Capacitors 15, 17, 19 21, 23, 25, 27 2,000 picofarads Capacitor 29

2,500 picofarads Resistors 16 22 kiloohms 31 10 kiloohms Resistors 32 5

megohms 34 15 megohms 36 30 megohms Diodes 18, 20, 22 9 kilovolt peak

inverse voltage,5 milliamp 24,26,28,30 5 ampere surge.

Other References:

IBM Technical Disclosure Bulletin, vol. 17, No. 4, Sep. 1974, K. H. Knickmeyer, pp. 1091-1092.

Arentsen et al, Electronic Applications, vol. 34, No. 2, Philips Semiconductor Application Lab., pp. 52-60.

Loewe Opta, Circuit Schematic, Aug. 1st, 1980.

Thomson-Brandt, Circuit Schematic, Apr. 15th, 1981.

Blaupunkt, Circuit Schematic, (undated).

Grundig, Circuit Schematic, (undated).

ITT, Circuit Schematic, (undated).

Telefunken, Circuit Schematic, (undated).

Schneider, Circuit Schematic, (undated).

CRT TV EHT VOLTAGE MULTIPLIER - KASKADE COCKCROFT-WALTON CASCADE CIRCUIT FOR VOLTAGE MULTIPLICATION:

A

Cockcroft-Walton cascade circuit comprises an input voltage source and a

pumping and storage circuit with a series array of capacitors with

pumping and storage portions of the circuit being interconnected by

silicon rectifiers, constructed and arranged so that at least the

capacitor nearest the voltage source, and preferably one or more of the

next adjacent capacitors in the series array, have lower tendency to

internally discharge than the capacitors in the array more remote from

the voltage source.

1. An improved voltage multiplying circuit comprising,

2.

An improved voltage multiplying circuit in accordance with claim 1

wherein said first pumping capacitor is a self-healing impregnated

capacitor which is impregnated with a high voltage impregnant.

3.

An improved voltage multiplying circuit in accordance with claim 1

wherein said first pumping capacitor comprises a foil capacitor.

Description:

BACKGROUND OF THE INVENTION

The

invention relates in general to Cockcroft-Walton cascade circuits for

voltage multiplication and more particularly to such circuits with a

pumping circuit and a storage circuit composed of capacitors connected

in series, said pumping circuits and storage circuit being linked with

one another by a rectifier circuit whose rectifiers are preferably

silicon rectifiers, especially for a switching arrangement sensitive to

internal discharges of capacitors, and more especially a switching

arrangement containing transistors, and especially an image tube

switching arrangement.

Voltage multiplication cascades composed

of capacitors and rectifiers are used to produce high D.C. voltages from

sinusoidal or pulsed alternating voltages. All known voltage

multiplication cascades and voltage multipliers are designed to be

capacitance-symmetrical, i.e., all capacitors used have the same

capacitance. If U for example is the maximum value of an applied

alternating voltage, the input capacitor connected directly to the

alternating voltage source is charged to a D.C. voltage with a value U,

while all other capacitors are charged to the value of 2U. Therefore, a

total voltage can be obtained from the series-connected capacitors of a

capacitor array.

In voltage multipliers, internal resistance is

highly significant. In order to obtain high load currents on the D.C.

side, the emphasis in the prior art has been on constructing voltage

multipliers with internal resistances that are as low as possible.

Internal

resistance of voltage multipliers can be reduced by increasing the

capacitances of the individual capacitors by equal amounts. However, the

critical significance of size of the assembly in the practical

application of a voltage multiplier, limits the extent to which

capacitance of the individual capacitors can be increased as a practical

matter.

In television sets, especially color television sets,

voltage multiplication cascades are required whose internal resistance

is generally 400 to 500 kOhms. Thus far, it has been possible to achieve

this low internal resistance with small dimensions only by using

silicon diodes as rectifiers and metallized film capacitors as the

capacitors.

When silicon rectifiers are used to achieve low

internal resistance, their low forward resistance produces high peak

currents and therefore leads to problems involving the pulse resistance

of the capacitors. Metallized film capacitors are used because of space

requirements, i.e., in order to ensure that the assembly will have the

smallest possible dimensions, and also for cost reasons. These film

capacitors have a self-healing effect, in which the damage caused to the

capacitor by partial evaporation of the metal coating around the point

of puncture (pinhole), which develops as a result of internal

spark-overs, is cured again. This selfhealing effect is highly desirable

as far as the capacitors themselves are concerned, but is not without

its disadvantages as far as the other cirucit components are concerned,

especially the silicon rectifiers, the image tubes, and the components

which conduct the image tube voltage.

It is therefore an important object of the invention to improve voltage multiplication cascades of the type described above.

It is a further object of the invention to keep the size of the entire assembly small and the internal resistance low.

It is a further object of the invention to increase pulse resistance of the entire circuit.

It is a further object of the invention to avoid the above-described disadvantageous effects on adjacent elements.

It

is a further object of the invention to achieve multiples of the

foregoing objects and preferably all of them consistent with each other.

SUMMARY OF THE INVENTION

In

accordance with the invention, the foregoing objects are met by making

at least one of the capacitors in the pumping circuit, preferably

including the one which is adjacent to the input voltage source, one

which is less prone to internal discharges than any of the individual

capacitors in the storage circuit.

The Cockcroft-Walton cascade

circuit is not provided with identical capacitors. Instead, the

individual capacitors are arranged according to their loads and designed

in such a way that a higher pulse resistance is attained only in

certain capacitors. It can be shown that the load produced by the

voltage in all the capacitors in the multiplication circuit is

approximately the same. But the pulse currents of the capacitors as well

as their forward flow angles are different. In particular, the

capacitors of the pumping circuit are subjected to very high loads in a

pulsed mode. In the voltage multiplication cascade according to the

invention, these capacitors are arranged so that they exhibit fewer

internal discharges than the capacitors in the storage circuit.

The

external dimensions of the entire assembly would be unacceptably large

if one constructed the entire switching arrangement using such

capacitors.

The voltage multiplication cascade according to the invention also makes it possible to construct a reliably operating

arrangement

which has no tendency toward spark-overs, consistent with satisfactory

internal resistance of the voltage multiplication cascade and small

dimensions of the entire assembly. This avoids the above cited

disadvantages with respect to the particularly sensitive components in

the rest of the circuit and makes it possible to design voltage

multiplication cascades with silicon rectifiers, which are characterized

by long lifetimes. Hence, a voltage multiplication cascade has been

developed particularly for image tube circuits in television sets,

especially color television sets, and this cascade satisfies the highest

requirements in addition to having an average lifetime which in every

case is greater than that of the television set.

A further aspect

of the invention is that at least one of the capacitors that are less

prone to internal discharges is a capacitor which is impregnated with a

high-voltage impregnating substance, especially a high-voltage oil such

as polybutene or silicone oil, or mixtures thereof. In contrast to

capacitors made of metallized film which have not been impregnated, this

allows the discharge frequency due to internal discharges or

spark-overs to be reduced by a factor of 10 to 100.

According to a

further important aspect of the invention, at least one of the

capacitors that are less prone to internal discharges is either a foil

capacitor or a self-healing capacitor. In addition, the capacitor in the

pumping circuit which is adjacent to the voltage source input can be a

foil capacitor which has been impregnated in the manner described above,

while the next capacitor in the pumping circuit is a self-healing

capacitor impregnated in the same fashion.

Other objects,

features and advantages of the invention will be apparent from the

following detailed description of preferred embodiments, taken in

connection with the accompanying drawing, the single FIGURE of which:

BRIEF DESCRIPTION OF THE DRAWING

is a schematic diagram of a circuit made according to a preferred embodiment of the invention.

DETAILED DESCRIPTION OF PREFERRED EMBODIMENTS

The

voltage multiplier comprises capacitors C1 to C5 and rectifiers D1 to

D5 connected in a cascade. An alternating voltage source UE is connected

to terminals 1 and 2, said voltage source supplying for example a

pulsed alternating voltage. Capacitors C1 and C2 form the pumping

circuit while capacitors C3, C4 and C5 form the storage circuit.

In

the steady state, capacitor C1 is charged to the maximum value of the

alternating voltage UE as are the other capacitors C2 to C5. The desired

high D.C. voltage UA is picked off at terminals 3 and 4, said D.C.

voltage being composed of the D.C. voltages from capacitors C3 to C5.

Terminal 3 and terminal 2 are connected to one pole of the alternating

voltage source UE feeding the circuit, which can be at ground potential.

In the circuit described here, a D.C. voltage UA can be picked off

whose voltage value is approximately 3 times the maximum value of the

pulsed alternating voltage UE. By using more than five capacitors, a

correspondingly higher D.C. voltage can be obtained.

The

individual capacitors are discharged by disconnecting D.C. voltage UA.

However, they are constantly being recharged by the electrical energy

supplied by the alternating voltage source UE, so that the voltage

multiplier can be continuously charged on the output side.

According

to the invention, in this preferred embodiment, capacitor C1 and/or C2

in the pumping circuit are designed so that they have a lower tendency

toward internal discharges than any of the individual capacitors C3, C4

and C5 in the storage circuit.

It is evident that those skilled

in the art, once given the benefit of the foregoing disclosure, may now

make numerous other uses and modifications of, and departures from the

specific embodiments described herein without departing from the

inventive concepts. Consequently, the invention is to be construed as

embracing each and every novel feature and novel combination of features

present in, or possessed by, the apparatus and techniques herein

disclosed and limited solely by the scope and spirit of the appended

claims.

Inventors:Petrick, Paul (Landshut, DT)

Schwedler, Hans-peter (Landshut, DT)

Holzer, Alfred (Schonbrunn, DT)

ERNST ROEDERSTEIN SPEZIALFABRIK

US Patent References:

3714528 ELECTRICAL CAPACITOR WITH FILM-PAPER DIELECTRIC 1973-01-30 Vail

3699410 SELF-HEALING ELECTRICAL CONDENSER 1972-10-17 Maylandt

3463992 ELECTRICAL CAPACITOR SYSTEMS HAVING LONG-TERM STORAGE CHARACTERISTICS 1969-08-26 Solberg

3457478 WOUND FILM CAPACITORS 1969-07-22 Lehrer

3363156 Capacitor with a polyolefin dielectric 1968-01-09 Cox

2213199 Voltage multiplier 1940-09-03 Bouwers et al.

CGE CT 8826 TV 26" TELECOLOR (TELEFUNKEN) CHASSIS 712A

TELEFUNKEN CHASSIS 712A Switching Power supply voltage stabilizer:

A power supply voltage stabiliz

er

comprising a transformer, of which the primary winding is connected

to a switching means for controlling power supply to the primary

winding. An oscillator circuit is associated with the switching means

in order to control on/off operation of the switching means. An

abnormal overvoltage and/or overcurrent detection circuit is provided

for terminating the oscillation operation of the oscillator circuit

when impending overvoltage and/or overcurrent is detected.

1. A power supply voltage stabilizer comprising:

a transformer including a primary winding connected to a power source and a secondary winding for output purposes;

switching means connected to said primary winding for controlling power supply to said primary winding;

an oscillator circuit for controlling on/off operation of said switching means; and

abnormal condition detection means for developing a control signal

for terminating oscillation operation of said oscillator circuit when

an abnormal condition is detected;

said oscillator circuit

including an astable multivibrator, and variable impedance means for

varying an oscillation frequency of said astable multivibrator.

2. A power supply voltage stabilizer comprising:

a transformer including a primary winding connected to a power source and a secondary winding for output purposes;

switching means connected to said primary winding for controlling power supply to said primary winding;

an oscillator circuit for controlling on/off operation of said switching means; and

abnormal condition detection means for developing a control signal

for terminating oscillation operation of said oscillator circuit when

an abnormal condition is detected;

said transformer further

including an auxiliary winding for developing a voltage proportional

to that developed through said secondary winding, said voltage

developed through said auxiliary winding being applied to said

oscillator circuit for driving said oscillator circuit;

said

abnormal condition detection means including an overvoltage

detection circuit connected to said auxiliary winding for developing

said control signal when an overvoltage is developed through said

auxilliary winding;

said oscillator circuit comprising an

astable multivibrator, and variable impedance means for varying an

oscillation frequency of said astable multivibrator.

3. A power supply voltage stabilizer comprising:

a transformer including a primary winding connected to a power source and a secondary winding for output purposes;

switchi ng means connected to said primary winding for controlling power supply to said primary winding;

ng means connected to said primary winding for controlling power supply to said primary winding;

an oscillator circuit for controlling on/off operation of said switching means; and

abnormal condition detection means for developing a control signal

for terminating oscillation operation of said oscillator circuit when

an abnormal condition is detected;

said transformer further

including an auxiliary winding for developing a voltage proportional

to that developed through said secondary winding, said voltage

developed through said auxiliary winding being applied to said

oscillator circuit for driving said oscillator circuit;

said abnormal condition detec tion

means including an overvoltage detection circuit connected to said

auxiliary winding for developing said control signal when an

overvoltage is developed through said auxiliary winding;

tion

means including an overvoltage detection circuit connected to said

auxiliary winding for developing said control signal when an

overvoltage is developed through said auxiliary winding;

said overvoltage detection circuit including a latching means for continuously developing said control signal.

4. A power supply voltage stabilizer comprising:

a transformer including a primary winding connected to a power source and a secondary winding for output purposes;

switching means connected to said primary winding for controlling power supply to said primary winding;

an oscillator circuit for controlling on/off operation of said switching means;

abnormal condition detection means for developing a control signal

for terminating oscillation operation of said oscillator circuit when

an abnormal condition is detected;

said transformer further

including an auxiliary winding for developing a voltage proportional

to that developed through said secondary winding, said voltage

developed through said auxiliary winding being applied to said

oscillator circuit for driving said oscillator circuit;

said

abnormal condition detection means including an overvoltage

detection circuit connected to said auxiliary winding for developing

said control signal when an overvoltage is developed through said

auxiliary winding;

said overvoltage detection circui t further includes,

t further includes,

a reference voltage generation means for developing a reference

voltage proportional to a voltage applied from said power source; and

comparing means for comparing said voltage developed through said

auxiliary winding with said reference voltage in order to develop said

control signal when said voltage developed through said auxiliary

winding exceeds said reference voltage.

5. A power supply voltage stabilizer comprising:

a transformer including a primary winding connected to a power source and a secondary winding for output purposes;

switching means connected to said primary winding for controlling power supply to said primary winding;

an oscillator circuit for controlling on/off operation of said switching means; and

abnormal condition detection means for developing a control signal

for terminating oscillation operation of said oscillator circuit when

an abnormal condition is detected;

said abnormal condition

detection means including an overcurrent detection circuit connected

to said primary winding for developing said control signal when an

overcurrent flows through said primary winding;

wherein said

oscillator circuit includes an astable multivibrator, and variable

impedance means for varying an oscillation frequency of said astable

multivibrator.

6. A power supply voltage stabilizer comprising:

a transformer including a primary winding connected to a power source and a secondary winding for output purposes;

switching means connected to said primary winding for controlling power supply to said primary winding;

an oscillator circuit for controlling on/off operation of said switching means; and

abnormal condition detection means for developing a control signal

for terminating oscillation operation of said oscillator circuit when

an abnormal condition is detected;

said abnormal condition

detection means including an overcurrent detection circuit connected

to said primary winding for developing said control signal when an

overcurrent flows through said primary winding;

said overcurrent detection circuit including a latching means for continuously developing said control signal;

said oscillator circuit including an astable multivibrator, and

variable impedance means for varying an oscillation frequency of said

astable multivibrator.

7. The

power supply voltage stabilizer of claim 1, 2, 5, or 6, wherein said

variable impedance means comprise a photo transistor, and wherein a

light emitting diode is connected to said secondary wind

ing

for emitting a light of which amount is proportional to a voltage

developed through said secondary winding, said light emitted from said

light emitting diode being applied to said photo transistor.

8. The power supply voltage stabilizer

of claim 7, wherein said light emitting diode and said photo

transistor are incorporated in a single photo coupler.

9. A power supply voltage stabilizer

comprising:

a transformer including a primary winding connected to a power source and a secondary winding for output purposes;

switching means connected to said primary winding for controlling power supply to said primary winding;

an oscillator circuit for controlling on/off operation of said switching means; and

abnormal condition detection means for developing a control signal

for terminating oscillation operation of said oscillator circuit when

an abnormal condition is detected;

said transformer further

including an auxiliary winding for developing a voltage proportional

to that developed through said secondary winding, said voltage

developed through said auxiliary winding being applied to said

oscillator circuit for driving said oscillator circuit;

said

abnormal condition detection means including an overvoltage

detection circuit connected to said auxiliary winding for developing

said control signal when an overvoltage is developed through said

auxilliary winding;

said overvoltage detection circuit including a latching means for continuously developing said control signal;

said oscillator circuit including an astable multivibrator, and

variable impedance means for varying an oscillation frequency of said

astable multivibrator.

10. A power supply voltage stabilizer comprising:

a transformer including a primary winding connected to a power source and a secondary winding for output purposes;

switching means connected to said primary winding for controlling power supply to said primary winding;

an oscillator circuit for controlling on/off operation of said switching means;

abnormal condition detection means for developing a control signal

for terminating oscillation operation of said oscillator circuit when

an abnormal condition is detected;

said transformer further including an auxiliary winding for developing a voltage proportional to that developed th rough

said secondary winding, said voltage developed through said

auxiliary winding being applied to said oscillator circuit for

driving said oscillator circuit;

rough

said secondary winding, said voltage developed through said

auxiliary winding being applied to said oscillator circuit for

driving said oscillator circuit;

said abnormal condition

detection means including an overvoltage detection circuit connected

to said auxiliary winding for developing said control signal when an

overvoltage is developed through said auxiliary winding;

said overvoltage detection circuit including,

a reference voltage generation means for developing a reference

voltage proportional to a voltage applied from said power source; and

comparing means for comparing said voltage developed through said

auxiliary winding with said reference voltage in order to develop said

control signal when said voltage developed through said auxiliary

winding exceeds said reference voltage;

said oscillator

circuit including an astable multivibrator, and a variable impedance

means for varying an oscillation frequency of said astable

multivibrator.

11. A power supply voltage stabilizer comprising:

transformer means including a primary winding connected to a power

source, a secondary winding for producing an output voltage, and an

auxiliary winding for developing a voltage proportional to said output

voltage produced by said secondary winding;

switching means

connected to said primary winding for controlling the power supply

from said power source to said primary winding;

oscillator circuit means for controlling the on/off operation of said switching means;

overvoltage detection circuit means connected to said auxiliary

winding for developing a control signal to terminate the oscillation

operation of said oscillator circuit means when an overvoltage condition

is detected, said overvoltage detection circuit means including,

means for developing a reference potential, and

comparing

means responsive to said voltage developed at said auxiliary winding

and to said reference potential for comparing said reference

potential with said voltage developed at said auxiliary winding and

for generating said control signal to terminate the oscillation

operation of said oscillator circuit means when said voltage

developed at said auxiliary winding exceeds said reference potential.

12. A power supply voltage stabilizer comprising:

transformer means including a primary winding connected to a power

source and having a voltage supplied thereto, a secondary winding for

producing an output voltage, and an auxiliary winding for developing

a voltage proportional to said output voltage produced by said

secondary winding;

switching means connected to said primary

winding for controlling the power supply from said power source to

said primary winding;

oscillator circuit means for controlling the on/off operation of said switching means;

overcurrent detection circuit means connected to said primary

winding for developing a control signal to terminate the oscillation

operation of said oscillator circuit means when an overcurrent

condition is detected, said overcurrent detection circuit means

including,

means for monitoring said voltage supplied to said primary winding of said transformer means,

means for measuring the amount of current passing through said

primary winding of said transformer means by translating said amount of

current into a corresponding amount of voltage potential,

switching means responsive to said corresponding amount of voltage

potential for switching to a first switched condition when the

corresponding voltage potential exceeds a predetermined voltage

potential and for switching to a second switched condition when said

voltage potential does not exceed said predetermined voltage potential,

and

comparing means responsive to said voltage supplied to

said primary winding and connected to an output of said switching

means for generating said control signal to terminate oscillation

operation of said oscillator circuit means when said switching means

switches to said first switched condition in response to the

exceeding of said predetermined voltage potential by said

corresponding voltage potential.

13. A power supply voltage stabilizer in accordance with claim 11

or 12 wherein said comparing means comprises a double base diode.

Description:

BACKGROUND AND SUMMARY OF THE INVENTION

The

present invention relates to a power supply voltage stabilizer and,

more particularly, to a power supply voltage stabilizer employing a

switching system for controlling power supply to a transformer

included in the power supply voltage stabilizer.

In the

conventional power supply voltage stabilizer employing a switching

system for controlling power supply to a transformer included in the

power supply voltage stabilizer, there is a possibility that an

abnormal overvoltage will be developed from an output terminal

thereof and/or an abnormal overcurrent may flow through the primary

winding of the transformer.

Accordingly, an object of the

present invention is to provide a protection means for protecting the

power supply voltage stabilizer from an abnormal overvoltage and/or

overcurrent.

Another object of the present invention is to

provide a detection means for detecting an impending overvoltage

and/or overcurrent occurring within the power supply voltage

stabilizer.

Other objects and further scope of applicability

of the present invention will become apparent from the detailed

description given hereinafter. It should be understood, however, that

the detailed description and specific examples, while indicating

preferred embodiments of the invention, are given by way of illustration

only, since various changes and modifications within the spirit and

scope of the invention will become apparent to those skilled in the

art from this detailed description.

The power supply voltage stabilizer of the present invention mainly

comprises a transformer including a primary winding connected to a

commercial power source through a rectifying circuit, a secondary

winding for output purposes, and an auxiliary winding. A driver circuit

including a switching means is connected to the primary winding for

controlling the power supply to the primary winding. An oscillator

circuit is associated with the switching means to control ON/OFF

operation of the switching means, thereby controlling the power supply

to the primary winding.

power supply voltage stabilizer of the present invention mainly

comprises a transformer including a primary winding connected to a

commercial power source through a rectifying circuit, a secondary

winding for output purposes, and an auxiliary winding. A driver circuit

including a switching means is connected to the primary winding for

controlling the power supply to the primary winding. An oscillator

circuit is associated with the switching means to control ON/OFF

operation of the switching means, thereby controlling the power supply

to the primary winding.

To achieve the above objects,

pursuant to an embodiment of the present invention, an overvoltage

detection circuit is connected to the auxiliary winding. The

overvoltage detection circuit functions to compare a voltage created

in the auxiliary winding with the rectified power supply voltage, and

develop a control signal, when an impending overvoltage is detected,

for terminating operation of the oscillator circuit, thereby

precluding power supply to the primary winding.

In another

embodiment of the present invention, an overcurrent detection circuit

is provided for detecting an impending overcurrent flowing through

the primary winding to develop a control signal for terminating

operation of the oscillator circuit.

BRIEF DESCRIPTION OF THE DRAWINGS

The

present invention will become more fully understood from the

detailed description given hereinbelow and the accompanying drawings,

which are given by way of illustration only, and thus are not

limitative of the present invention and wherein:

FIG. 1 is a circuit diagram of a basic construction of a power supply voltage stabilizer of the present invention;

FIG.

2 is a block diagram of an embodiment of a power supply voltage

stabilizer of the present invention, which includes an oscillator

circuit and an over voltage detection circuit;

FIG. 3 is a

circuit diagram of an embodiment of the overvoltage detection circuit

included in the power supply voltage stabilizer of FIG. 2;

FIG.

4 is a circuit diagram of an embodiment of the oscillator circuit

included in the power supply voltage stabilizer of FIG. 2;

FIG. 5 is a waveform chart for explaining operation of the oscillator circuit of FIG. 4;

FIG.

6 is a block diagram of another embodiment of a power supply voltage

stabilizer of the present invention, which includes an oscillator

circuit and an overcurrent detection circuit; and

FIG. 7 is a

circuit diagram of an embodiment of the overcurrent detection circuit

included in the power supply voltage stabilizer of FIG. 6.

DESCRIPTION OF THE PREFERRED EMBODIMENTS

R eferring

now in detail to the drawings, and to facilitate a more complete

understanding of the present invention, a basic construction of a power

supply voltage stabilizer of the present invention will be first

described with reference to FIG. 1.

eferring

now in detail to the drawings, and to facilitate a more complete

understanding of the present invention, a basic construction of a power

supply voltage stabilizer of the present invention will be first

described with reference to FIG. 1.

The power supply voltage stabillizer mainly comprises a transformer T including a primary winding N 1 connected to a commercial power source V, a secondary winding N 2 connected to an output terminal V 0 , and an auxiliary winding N 3 . An oscillator circuit OSC is associated with the primary winding N 1 and the auxiliary winding N 3 to control the power supply from the commercial power source V to the primary winding N 1 .

A rectifying circuit E is connected to the commercial power source V for applying a rectified voltage to a capacitor C 1 . A negative terminal of the capacitor C 1 is grounded, and a positive terminal of the capacitor C 1 is connected to the collector electrode of a switching transistor Q 5 through the primary winding N 1

of the transformer T. The oscillator circuit OSC performs the

oscillating operation when receiving a predetermined voltage, and

develops a control signal toward the base electrode of the switching

transistor Q 5 to control the switching operation of the switching transistor Q 5 . The switching transistor Q 5 functions to control the power supply to the primary winding N 1 , thereby controlling the power transfer to the secondary winding N 2 and the auxiliary winding N 3 .

The auxiliary winding N 3 is connected to a capacitor C 3 in a parallel fashion via a diode D 1 . A positive terminal of the capacitor C 3 is connected to the oscillator circuit OSC to supply a drive voltage Vc 3 . A negative terminal of the capacitor C 3 is connected to the emitter electrode of the switching transistor Q 5 and grounded. The positive terminal of the capacitor C 3 is connected to the primary winding N 1 via a diode D 2 and a capacitor C 2 in order to stabilize the initial condition of the oscillator circuit OSC.

The secondary winding N 2 functions to develop a predetermined voltage through the output terminal V 0 . A smoothing capacitor C 0 is connected to the secondary winding N 2 via a diode D 0 , and a series circuit of a resistor R 0 and a light emitting diode D i is connected to the smoothing capacitor C 0 in a parallel fashion. The light emitted from the light emitting diode D i is applied to a photo transistor Q 8 employed in the oscillator circuit OSC. The light emitting diode D i and the photo transistor Q 8 are preferably incorporated in a single package as a photo coupler.

The light amount emitted from the light emitting diode D i is proportional to the output voltage developed from the output terminal V 0 . The photo transistor Q 8

exhibits the impedance corresponding to the applied light amount.

The oscillator circuit OSC is so constructed that the oscillation

frequency is varied in response to variation of the impedance of the

photo transistor Q 8 . Accordingly, the ON/OFF operation of the switching transistor Q 5 is controlled in response to the output voltage level, thereby stabilizing the output voltage level.

In

the above constructed power supply voltage stabilizer, there is a

possibility that an abnormal overvoltage is developed through the

secondary winding N 2 and the auxiliary winding N 3 when the oscillator circuit OSC or the light emitting diode D i is placed in the fault condition.

FIG. 2 show s

an embodiment of the power supply voltage stabilizer of the present

invention, which includes means for precluding occurrence of the

above-mentioned overvoltage. Like elements corresponding to those of

FIG. 1 are indicated by like numerals.

s

an embodiment of the power supply voltage stabilizer of the present

invention, which includes means for precluding occurrence of the

above-mentioned overvoltage. Like elements corresponding to those of

FIG. 1 are indicated by like numerals.

The power supply voltage

stabilizer of FIG. 2 mainly comprises the transformer T, the

oscillator circuit OSC, a driver circuit 1 including the switching

transistor Q 5 , and an overvoltage detection circuit 3.

The positive terminal of the capacitor C 3

is connected to the driver circuit 1 and the oscillator circuit OSC

to apply the driving voltage thereto. The positive terminal of the

capacitor C 3 is also connected to the primary winding N 1 through the diode D 2 and a parallel circuit of the capacitor C 2 and a resistor R 2 in order to stabilize the initial start operation of the oscillator circuit OSC. The secondary winding N 2 is connected to an output level detector 2, which comprises the light emitting diode D i as shown in FIG. 1. The ON/OFF control of the switching transistor Q 5 is similar to that is achieved in the power supply voltage stabilizer of FIG. 1.

The secondary winding N 2 and the auxiliary winding N 3 are wound in the same polarity fashion and, therefore, the voltage generated through the auxiliary winding N 3 is proportional to that voltage generated through the secondary winding N 2 .

The overvoltage detection circuit 3 is connected to receive the

voltage at a point a as a power source voltage, and the voltage at a

point b which is connected to the positive terminal of the capacitor C 3 .

When the voltage level at the point b exceeds a reference level, the

overvoltage detection circuit 3 develops a control signal for

terminating the operation of the oscillator circuit OSC.

FIG. 3 shows a typical construction of the overvoltage detection circuit 3.

The voltage at the point a is applied to a series circuit of resistors R 3 and R 4 , and grounded. The voltage at the point b is applied to the connection point of the resistors R 3 and R 4 via a diode D 3 . The connection point of the resistors R 3 and R 4 is grounded through resistors R 5 and R 6 and a Zener diode Z 1 . A double-base diode (Trade Name Programmable Unijunction Transistor) P 1

is provided for developing the control signal to be applied to the

oscillator circuit OSC. The anode electrode of the programmable

unijunction transistor P 1 is connected to the connection point of the resistors R 3 and R 4 , the gate electrode of the programmable unijunction transistor P 1 is connected to the connection point of the resistors R 5 and R 6 , and the cathode electrode is connected to the oscillator circuit OSC.

When the voltage level of the point b exceeds a reference level VZ 1 , the programmable unijunction transistor P 1

is turned on to develop the control signal for terminating the

oscillation operation of the oscillator OSC. In this way, the impending

abnormal overvoltage is detected to protect the circuit elements. The

ON condition of the programmable unijunction transistor P 1

is maintained as long as the main power switch is closed, because

the overvoltage detection circuit 3 is connected to receive the

voltage from the point a.

The voltage detection circuit 3

does not necessarily employ the programmable unijunction transistor.

Another element showing the latching characteristics such as a

negative resistance element can be employed instead of the

programmable unijunction transistor.

FIG. 4 shows a typical construction of the oscillator circuit OSC.

The oscillation circuit OSC mainly comprises an astable multivibrator including transistors Q 1 , Q 2 and Q 3 , and an o utput stage including a transistor Q 4 . The astable multivibrator is connected to receive the voltage appearing across the capacitor C 3 ,

and develops an output signal of which frequency is determined by

the circuit condition as long as the multivibrator receives a voltage

greater than a predetermined level.

utput stage including a transistor Q 4 . The astable multivibrator is connected to receive the voltage appearing across the capacitor C 3 ,

and develops an output signal of which frequency is determined by

the circuit condition as long as the multivibrator receives a voltage

greater than a predetermined level.

The output signal of the output stage is applied to the base electrode of the switching transistor Q 5 included in the driver circuit 1 in order to switch the switching transistor Q 5 with a predetermined frequency. A transistor Q 9 is interposed between the base electrode of the transistor Q 3 and the grounded terminal. The transistor Q 9 is controlled by the control signal derived from the overvoltage detection circuit 3. Accordingly, the transistor Q 3

is turned off to terminate the oscillation operation when the

abnormal overvoltage is detected by the overvoltage detection circuit

3.

Now assume that a voltage Vc 3 is developed across the capacitor C 3 . When main power supply switch is closed, the voltage Vc 3 varies in a manner shown by a curve X in FIG. 5. When the voltage Vc 3 reaches a predetermined level, the astable multivibrator begins the oscillation operation. More specifically, the transistor Q 1 is first turned on because the base electrode of the transistor Q 1 is connected to a capacitor C 4 of which the capacitance value is relatively small. At this moment, the transistor Q 2 is held off.

Because of turning on of the transistor Q 1 , the capacitor C 4 is gradually charged through a resistor R 4 and the transistor Q 1 . Accordingly, the base electrode voltage of the transistor Q 1 is gradually increased and, hence, the emitter electrode voltage of the transistor Q 1 is also increased to turn on the transistor Q 2 . When the transistor Q 2 is turned on, the transistor Q 3 is also turned on. The base electrode voltage of the transistor Q 2 which is bypassed by a resistor R 1 is reduced and, therefore, the transistor Q 2 is stably on. At this moment, the transistor Q 1 is turned off.

When the transistor Q 3 is turned on, the transistor Q 4 is turned on to develop a signal to turn on the switching transistor Q 5 . Upon turning on of the transistor Q 3 , the charge stored in the capacitor C 4 is gradually discharged through paths shown by arrows in FIG. 4. Therefore, the base electrode voltage of the transistor Q 1 is gradually reduced. When the base electrode voltage of the transistor Q 1 becomes less than a predetermined level, the transistor Q 1 is turned on, and the transistor Q 2 , Q 3 and Q 4 are turned off. Accordingly, the transistor Q 5 is turned off. After passing the initial start condition, the driving voltage Vc 3 is held at a predetermined level as shown by a curve Y in FIG. 5 to maintain the above-mentioned oscillation operation.

The photo transistor Q 8 is disposed in the discharge path of the capacitor C 4 in order to control the discharge period in response to the impedance of the photo transistor Q 8 .

That is, the oscillation frequency is controlled in response to the

light amount emitted from the light emitting diode included in the

output level detector 2.

FIG. 6 shows another em bodiment

of the power supply voltage stabilizer of the present invention,

which includes means for precluding occurrence of an abnormal

overcurrent. Like elements corresponding to those of FIG. 2 are

indicated by like numerals.

bodiment

of the power supply voltage stabilizer of the present invention,

which includes means for precluding occurrence of an abnormal

overcurrent. Like elements corresponding to those of FIG. 2 are

indicated by like numerals.

In the power supply voltage

stabilizer of FIG. 1, there is a possibility that an abnormally large

current flows through the primary winding N 1 when the

magnetic flux is saturated due to requirement of large current at the

secondary winding side. The power supply voltage stabilizer of FIG. 6

includes an overcurrent detection circuit 4 for detecting an

impending abnormally large current.

A resistor R 9 is interposed between the emitter electrode of the switching transistor Q 5

included in the driver circuit 1 and the grounded terminal. The

overcurrent detection circuit 4 is connected to receive a signal from

the connection point of the resistor R 9 and the emitter electrode of the switching transistor Q 5 , thereby developing a control signal for terminating the oscillation operation of the oscillation circuit OSC.

FIG. 7 shows a typical construction of the overcurrent detection circuit 4.

The voltage at the point a is applied to a series circuit of resistors R 10 and R 11 , and grounded. The collector electrode of a transistor Q 10 is connected to the connection point of the resistors R 10 and R 11 through resistors R 12 and R 13 . The emitter electrode of the transistor Q 10 is grounded. The base electrode of the transistor Q 10 is connected to the connection point of the resistor R 9 and the emitter electrode of the switching transistor Q 5 via a resistor R 14 .

When the switching transistor Q 5 is turned on, a current flows through the resistor R 9 . When the voltage drop across the resistor R 9 exceeds a predetermined value due to a large current, the transistor Q 10 is turned on to turn on the programmable unijunction transistor P 1 . That is, when a large current flows through the primary winding N 1 , the programmable unijunction transistor P 1 develops the control signal to terminate the oscillation operation of the oscillator circuit OSC.

The

invention being thus described, it will be obvious that the same may

be varied in many ways. Such variations are not to be regarded as a

departure from the spirit and scope of the invention, and all such

modifications are intended to be included within the scope of the

following claims.

CHASSIS 712A SUPPLY UNIT (NETZTEIL SM)

AT 349354065

This is a SMPS Supply unit which seems simple but is not !

- 3 SUB Units are composing the FINAL device unit

1

- MAINS RECTIFIER + DEGAUSS PTC + BOBBIN FILTERS + CAPS (burned !! !!!) BS422

ET 309378996 (NETZEINGANG)

2

- Pulse Command unit with S417T (Telefunken) BS423 AT349354067 (ANSTEUERUNG)

3

- Secondary Voltages Generation and separation (With a LM317) BS426 AT349354068

(SEC.SPANNUNGSERZEUGUNG).

- CHROMA IA (1) with TDA2150 (Telefunken) BS202 AT349354052

- CHROMA II (2) with TDA2160 + TDA2140 (Telefunken) BS302

- Synchronization BS531 AT349354014 with ITT TBA950X2

- Frame Oscillator BS451 AT349354015

- Frame deflection output amplifier BS491 AT349354016 with BD312T + 2N5877T

(Motorola + Fairchild)

- E/W Correction unit BS501 AT349354017

- RGB ENDSTUFEN RGB OUT BS333 AT349354063

- TON ENDSTUFE SOUND UNIT BS151 AT349354008

- if video unit BS104 AT349 354 105.

Search and Tuning drive circuitry

.

- BS33 (UAA170 Siemens + UA741 Texas Instruments + CD4011 RCA) Display search

- SPP core unit with AY-3-8203 (General Instruments) + MSM4956 (General Instruments)

+ ER1400 EAROM (General Instruments)

- RECEIVER 5000 With U318M (Telefunken) BS48 AT349370969.

CGE CT 8826 TV 26" TELECOLOR (TELEFUNKEN) CHASSIS 712A TELEFUNKEN

CHASSIS 712 Drive circuit for an infrared remote control transmitter:

An infrared remote control transmitter includes at least one infrared

light-emitting diode poled with respect to a point of reference

potential so as to be conductive in response to voltages having the

opposite polarity of a DC supply voltage and to be nonconductive in

response to voltages having the same polarity as the DC supply voltage.

A push-pull amplifier is responsive to a pulse signal encoded to

represent a remote control message to selectively couple the DC supply

voltage or the reference potential to a capacitor coupled in series

between the push-pull amplifier and the light-emitting diode. The

capacitor is charged and discharged and an alternating drive voltage

for the light-emitting diode having portions with polarities both

the same as and opposite to the polarity of the DC supply voltage is

generated. The push-pull amplifier is arranged so that when a

component failure occurs, the portions of the alternating drive

voltage having the polarity opposite to the polarity of the DC supply

voltage are at least inhibited to prevent the continuous (i.e., DC)

emission of infrared radiation.

1. In an infrared remote control transmitter for controlling a television system, apparatus comprising:

a reference circuit point for receiving a reference potential;

a supply circuit point for receiving a DC supply voltage;

a battery connected with a predetermined polarity connected between said supply and reference circuit points;

at least one light-emitting diode for emitting infrared radiation

when rendered conductive, said light emitting diode having a cathode

and an anode, one of said cathode and anode being connected to said

reference circuit point, said light-emitting diode being poled with

respect to said reference circuit point so as to be conductive in

response to the application of a voltage to the other one of said

cathode and anode having the opposite polarity to said battery with

respect to said reference circuit point and non-conductive in response

to the application of a voltage to said other one of said cathode

and anode having the same polarity as said battery with respect to

said reference circuit point;

a source cir

cuit

point for receiving an input signal having pulses encoded to