The THOMSON CHASSIS ICC4 is was introducing some sophisticated features which are: Full PLL Synthesizer with Ucontroller independent from all. Matrix RGB control with Automatic Black - CutOff - Gain and White / Drive calibration circuit HA11494 (HITACHI) Analog setup value via Micro I2 Bus directly to Matrix RGB control HA11494 (HITACHI) No regulations of Deflections time base...........

The chassis ICC4 is complex and an example of how to complicate a portable TV chassis with features in circuit and technical solutions, uncommon found.

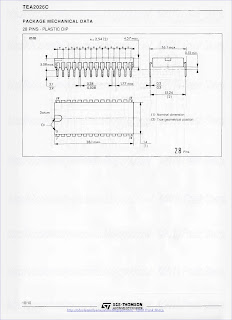

(TEA2026) COLOR TV SCANNING AND POWER SUPPLY PROCESSOR TEA2026C

DEFLECTION .C ERAMIC

500kHz RESONATOR F

ERAMIC

500kHz RESONATOR F

REQUENCY REFERENCE

.NO LINE AND FRAME OSCILLATOR ADJUSTMENT .

DUAL PLL FOR LINE DEFLECTION

.HIGH PERFORMANCE SYNCHRONIZATION

.SUPER SANDCASTLE OUTPUT .VIDEO IDENTIFICATION CIRCUIT

.AUTOMATIC 50/60Hz STANDARD IDENTIFICATION

.EXCELLENT INTERLACING CONTROL

.SPECIAL PATENTED FRAME SYNCHRO DEVICE FOR VCR OPERATION

.FRAME SAW-TOOTH GENERATOR

.FRAME PHASE MODULATOR FOR THYRISTOR

SMPS CONTROL

.ERROR AMPLIFIER AND PHASE MODULATOR

.SYNCHRONIZATION WITH HORIZONTAL DEFLECTION

.SECURITY CIRCUIT AND START UP PROCESSOR

GENERAL DESCRIPTION

INTRODUCTION

This integrated circuit uses l2L bipolar technology and combines analog signal processing with digital processing. Timing signals are obtained from a voltage-control- ied oscillator (VCO) operating at 500 kHz by means of a cheap ceramic resonator. This avoids the frequency adjustment normally required with line and frame oscillators. A chain of dividers and appropriate logic circuitry produce very accurately defined sampling pulses and the necessary timing signals. The principal functions implemented are :

■ Horizontal scanning processor.

■ Frame scanning processor: Two applications

are possible :

. D Class Power stage using an external thyristor.

. B Class Power stage using an external power

amplifier with fly-back generator such as the

TDA2172.

■ Line and frame synchronization separation.

■ Dual phase-locked loop horizontal scanning.

■ High performance frame and line synchronization with interlacing control.

■ Video identification circuit.

■ Super sandcastle.

■ Automatic 50-60 Hz standard identification.

■ VCR input for PLL time constant and frame

synchro switching.

■ AGC key pulse output.

■ Frame saw-tooth generator and phase modulator.

■ Switching mode regulated power supply comprising error amplifier and phase modulator.

■ Security circuit and start-up processor.

■ 500 KHz VCO

The circuit is supplied in a 28 pin DIP case.

V cc= 12 V.

SYNCHRONIZATION SEPARATOR

Line synchronization separator is clamped to black level of input video signal with synchronization pulse bottom level measurement. The synchronization pulses are divided centrally be tween the black level and the synchronization pulse bottom level, to improve performance on video signals in noise conditions.

FRAME SYNCHRONIZATION

Frame synchronization is fully integrated (no external capacitor required).

The frame timing identification logic permits automatic adaptation to 50 - 60 Hz standards or non-interlaced video.

An automatic synchronization window width system

provides :

■ fast frame capture (6.7 ms wide window),

■ good noise immunity (0.4 ms narrow window).

The internal generator starts the discharge of the saw-tooth generator so that it is not disturbed by line fly-back effects. Thanks to the logic control, the beginning of the charge phase does not depend on any disturbing effect of the line fly-back. A 32 ps timing is automatically applied on standardized transmissions, for perfect interlacing. In VCR mode, the discharge time is controlled by an internal monostable independent of the line frequency and gives a direct frame synchronization. HORIZONTAL SCANNING

HORIZONTAL SCANNING

The horizontal scanning frequency is obtained from the 500 KHz VCO. The circuit uses two phase-locked loops (PLL) : the first one controls the frequency, the second one controls the relative phase of the synchronization and line fly-back signals.

The frequency PLL has two switched time constants

to provide :

■ capture with a short time constant,

■ good noise immunity after capture with a long time constant.

The output pulse has a constant duration of 26 ps, independent of Vcc and any delay in switching off the scanning transistor.

VIDEO IDENTIFICATION

The horizontal synchronization signal is sampled by a 2 ps pulse within the synchronization pulse. The signal is integrated by an external capacitor. The identification function provides three different levels :

■ 0 V : no video identification

• 6 V : 60 Hz video identification

■ 12 V : 50 Hz video identification

This information may be used for timing research in the case of frequency or voltage synthesizer type receivers, and for audio muting. SUPER SANDCASTLE with 3 levels : burst, line fly back, frame blanking. In the event of vertical scanning failure, the frame blanking level goes high to protect the tube.

VCR INPUT

This provides for continuous use of the short time constant of the first phase-locked loop (frequency). In VCR mode, the frame synchronization window widens out to a search window and there is no delay of frame fly-back (direct synchronization).

FRAME SCANNING

Frame saw-tooth generator: The current to charge the capacitor is automatically switched to 60 Hz operation to maintain constant amplitude. Frame phase modulator (with two differential inputs) : The output signal is a pulse at the line frequency, pulse width modulated by the voltage at the differential pre - amplifier input. This signal is used to control a thyristor which provides the scanning current to the yoke. The sawtooth output is a low impedance and can therefore be used in class B operation with a power amplifier circuit.

SWITCH MODE POWER SUPPLY (SMPS) SECONDARY REGULATION

This power supply uses a differential error amplifier with an internal reference voltage of 1.26 V and a phase modulator operating at the line frequency. The power transistor is turned off by the line fly-back. The "soft start" device imposes a very small conduction angle on starting up, this angle progressively in creases to its nominal regulation value. The maximum conduction angle may be monitored by forcing a voltage on pin 15. This pin may also be used for current limitation.

SECURITY CIRCUIT AND START UP PROCESSOR

When the security input (pin 28) is at a voltage exceeding 1.26 V the three outputs are simultaneously cut off until this voltage drops below the 1.26 V threshold again. In this case the switch mode power supply is restarted by the "soft start" system. If this cycle is repeated three times, the three outputs are cut off definitively. To reset the safety logic circuits Vcc must be lower than 3.5 V. This circuit eliminates the risk to switch off the TV receiver in the event of a flash affecting the tube. On starting up, the horizontal and vertical scanning functions come into operation at Vcc = 6 V. The power supply then comes into operation progressively, only when c p 2 is normally locked. On shutting down, (with Vcc < 5.25 V) the three functions are inhibited simultaneously after the first line fly-back.

APPLICATION INFORMATION ON FRAME

SCANNING IN SWITCHED MODE:

Fundamentals (s ee Figure 80)

The secondary winding of EHT transformer provides

the energy required by frame yoke.

The frame current modulation is achieved by

modulating the horizontal saw-tooth current and

subsequent integration by a ”L.C” network to reject

the horizontal frequency component.

ee Figure 80)

The secondary winding of EHT transformer provides

the energy required by frame yoke.

The frame current modulation is achieved by

modulating the horizontal saw-tooth current and

subsequent integration by a ”L.C” network to reject

the horizontal frequency component.

General Description

The basic circuit is the phase comparator ”C1”

which compares the horizontal saw-tooth and the

output voltage of Error Amplifier ”A”.

The comparator output will go ”high” when the

horizontal saw-tooth voltage is higher than the ”A”

output voltage. Thus, the Pin 4 output signal is

switched in synchronization with the horizontal frequency

and the duty cycle is modulated at frame

frequency.

A driver stage delivers the current required by the

external power switch.

The external thyristor provides for energy transfer

between transformer and frame yoke.

The thyristor will conduct during the last portion of

horizontal trace phase and for half of the horizontal

retrace.

The inverse parallel-connected diode ”D” conducts

during the second portion of horizontal retrace and

at the beginning of horizontal trace phase.

Main advantages of this system are :

- Power thyristor soft ”turn-on”

Once the thyristor has been triggered, the current

gradually rises from 0 to IP, where IP will reach

the maximumvalue at the end of horizontal trace.

The slope current is determined by, the current

available through the secondary winding, the

yoke impedance and the ”L.C.” filter characteristics.

- Power thyristor soft ”turn-off”

The secondary output current begins decreasing

and falls to 0 at the middle of retrace. The thyristor

is thus automatically ”turned-off”.

- Excellent efficiency of power stage dueto very

low ”turn-on” and ”turn-off” switching losses.

Frame Flyback

During flyback, due to the loop time constant, the

frame yoke current cannot be locked onto the

reference saw-tooth. Thus the output of amplifier

”A” will remain high and the thyristor is blocked.

The scanning current will begin flowing through

diode ”D”. As a consequence, the capacitor ”C”

starts charging upto the flyback voltage.The thyristor

is triggeredas soon as the yoke current reaches

the maximum positive value.

- Full line synchronized derived supplyies.

High engineered PCB Circuit (see)

Teletext add on capability.

General Description

The basic circuit is the phase comparator ”C1”

which compares the horizontal saw-tooth and the

output voltage of Error Amplifier ”A”.

The comparator output will go ”high” when the

horizontal saw-tooth voltage is higher than the ”A”

output voltage. Thus, the Pin 4 output signal is

switched in synchronization with the horizontal frequency

and the duty cycle is modulated at frame

frequency.

A driver stage delivers the current required by the

external power switch.

The external thyristor provides for energy transfer

between transformer and frame yoke.

The thyristor will conduct during the last portion of

horizontal trace phase and for half of the horizontal

retrace.

The inverse parallel-connected diode ”D” conducts

during the second portion of horizontal retrace and

at the beginning of horizontal trace phase.

Main advantages of this system are :

- Power thyristor soft ”turn-on”

Once the thyristor has been triggered, the current

gradually rises from 0 to IP, where IP will reach

the maximumvalue at the end of horizontal trace.

The slope current is determined by, the current

available through the secondary winding, the

yoke impedance and the ”L.C.” filter characteristics.

- Power thyristor soft ”turn-off”

The secondary output current begins decreasing

and falls to 0 at the middle of retrace. The thyristor

is thus automatically ”turned-off”.

- Excellent efficiency of power stage dueto very

low ”turn-on” and ”turn-off” switching losses.

Frame Flyback

During flyback, due to the loop time constant, the

frame yoke current cannot be locked onto the

reference saw-tooth. Thus the output of amplifier

”A” will remain high and the thyristor is blocked.

The scanning current will begin flowing through

diode ”D”. As a consequence, the capacitor ”C”

starts charging upto the flyback voltage.The thyristor

is triggeredas soon as the yoke current reaches

the maximum positive value.

- Full line synchronized derived supplyies.

High engineered PCB Circuit (see)

Teletext add on capability.

This chassis is implementing a Frame deflection technology with SSVD (Switched Synchronous Vertikal Deflection) tech, using thyristor Line deflection flyback energy switching; You can see HERE the origin of this Deflection technology were exactly was born and used.

Switching regulator power supply device combined with the horizontal

deflection circuit of a television receiver which it supplies:  Step-up

switching regulator power supply device comprising, connected between

the poles of a rectifier circuit supplied by an isolating voltage

step-down transformer and loaded by a first filter capacitor, and

inductance and the collector-emitter path of a first switching

transistor of NPN type, a first diode whose anode is connected to the

junction of the inductance and to the collector of said transistor and

whose cathode is connected to a second filter and storage capacitor

supplying a voltage at its output which supplies a horizontal deflection

circuit of a television receiver.

Step-up

switching regulator power supply device comprising, connected between

the poles of a rectifier circuit supplied by an isolating voltage

step-down transformer and loaded by a first filter capacitor, and

inductance and the collector-emitter path of a first switching

transistor of NPN type, a first diode whose anode is connected to the

junction of the inductance and to the collector of said transistor and

whose cathode is connected to a second filter and storage capacitor

supplying a voltage at its output which supplies a horizontal deflection

circuit of a television receiver.

This horizontal deflection circuit which comprises in cascade a horizontal oscillator, a driver stage and an output stage, forms an integral part of the circuit controlling said first transistor and determines the repetition period of the switching, because it is started under an initial voltage slightly less than the unregulated input voltage of the device.

The switching transistor is being turned off in synchronism with the turning off of the trace switch transistor by using flyback pulses of negative polarity to bias the base thereof.

1. A power supply device with switching regulation and boosting of its

DC output voltage, combined with a horizontal deflection circuit of a

television receiver, supplied thereby and which comprises in cascade a

horizontal oscillator, a driver stage and an output stage including a

trace switch transistor and a line transformer, this device comprising

an inductance and the collector-emitter path of a switching transistor

connected in series between the poles of a DC input voltage source, a

rectifying diode connected by its anode to the junction between the

inductance and the collector of said switching transistor and by its

cathode to one of the terminals of a filtering and storage capacitor

whose other terminal is connected to the emitter of said transistor, so

as to apply across its terminals an initial DC voltage slightly lower

than said input voltage, when said switching transistor is turned off,

and a regulated DC output voltage with a level higher than said input

voltage, when said transistor is recurrently, alternately turned on and

off, the level of said output voltage depending on the duty cycle of

said switching transistor states, and a control circuit feeding the base

of said switching transistor and including a regulator stage comparing

an adjustable fraction of said output voltage to a fixed reference

voltage and supplying a regulating current or voltage proportional to

the difference between said compared voltages, a pulse-width modulator

triggered by means of a recurrent signal and supplying a rectangular

signal whose duty cycle varies as a function of said regulating current

or voltage, another driver stage receiving the rectangular signal and

controlling said switching transistor, the regulation and boosting of

said output voltage being controlled by the initially independent

starting up of the entire horizontal deflection circuit when supplied by

said initial voltage from said power supply device as soon as a DC

input voltage is applied thereto and which then delivers recurrent

trigger pulses to said pulse-width modulator, one of the supply inputs

of said other driver stage receiving directly a first voltage waveform

whose positive alternations comprise constant-voltage plateau and whose

negative alternations comprise negative-going horizontal flyback pulses

provided by a first secondary winding of said line transformer, so as to

control the turning off of said switching transistor substantially

simultaneously with that of the trace switch transistor.

2. A power supply device as claimed in claim 1, wherein said other

driver circuit comprises a third transistor whose emitter is connected

to the base of said switching transistor and which is of the same type

as the latter, whose collector is connected, through said supply input,

to said first secondary winding of said line transformer to receive

therefrom said first waveform and whose base is coupled to the output of

said pulse-width modulator.

3. A power supply device as claimed in claim 2, wherein the collector of

said third transistor is connected, through a resistor to the supply

input and its emitter is connected, furthermore, to that of the

switching transistor through another resistor so that the negative-going

flyback pulses, applied to the collector of said third transistor,

control the symmetric (reverse) saturation thereof so as to reversely

bias the base-emitter junction of said switching transistor.

4. A power supply device as claimed in claim 2, wherein the collector of

said third transistor is connected to said power supply input through a

fourth diode conducting in the normal direction of its

collector-emitter path, and wherein its emitter is further connected, on

the one hand, through a resistor, to the emitter of the switching

transistor and, on the other hand, through another resistor and a fifth

diode conducting in the reverse direction to that of the base-emitter

junction of the switching transistor, so as to transmit to the base

thereof negative-going flyback pulses through a voltage divider formed

by said two resistors in series.

5. A power supply device as claimed in claim 1, wherein said other

driver circuit comprises a third transistor whose emitter is connected

to the base of said switching transistor, whose collector is connected

to that of this latter so as to form a so-called Darlington circuit and

whose base coupled, moreover, to said pulse-width modulator is further

connected, through a resistor and a diode in series, to said first

secondary winding of said line transformer so as to control the

simultaneous turn off of both transistors of said Darlington circuit by

simultaneously reversely biasing their respective base-emitter

junctions, connected in series, by means of negative-going flyback

pulses.

6. A power supply device as claimed in any one of the preceding claims,

wherein said pulse-width modulator, supplied at its input with a voltage

waveform whose positive alternations comprise positive-going flyback

pulses and whose negative alternations comprise constant

negative-voltage plateaux, comprises a passive circuit which forms a

simple integrator during positive alternations because one of its

resistors is shunted by a diode and which is a cascaded double

integrator during negative alternations of this waveform so as to

deliver during the trace periods of the scan a linearly decreasing

negative current which, added to the positive regulating current,

supplies the base of a fourth comparator transistor, so that the turning

off of this latter through equality of the negative and positive

currents supplied to this base controls the beginnings of the saturation

of said switching transistor in such a manner that the duration of this

saturation varies inversely with variation of said output voltage.

7. A power supply device as claimed in claim 6, wherein said comparator

transistor is biased, furthermore, at its base by means of a resistor

which connects it to the positive pole of said input voltage source, so

that

1. A power supply device with switching regulation and boosting of its

DC output voltage, combined with a horizontal deflection circuit of a

television receiver, supplied thereby and which comprises in cascade a

horizontal oscillator, a driver stage and an output stage including a

trace switch transistor and a line transformer, this device comprising

an inductance and the collector-emitter path of a switching transistor

connected in series between the poles of a DC input voltage source, a

rectifying diode connected by its anode to the junction between the

inductance and the collector of said switching transistor and by its

cathode to one of the terminals of a filtering and storage capacitor

whose other terminal is connected to the emitter of said transistor, so

as to apply across its terminals an initial DC voltage slightly lower

than said input voltage, when said switching transistor is turned off,

and a regulated DC output voltage with a level higher than said input

voltage, when said transistor is recurrently, alternately turned on and

off, the level of said output voltage depending on the duty cycle of

said switching transistor states, and a control circuit feeding the base

of said switching transistor and including a regulator stage comparing

an adjustable fraction of said output voltage to a fixed reference

voltage and supplying a regulating current or voltage proportional to

the difference between said compared voltages, a pulse-width modulator

triggered by means of a recurrent signal and supplying a rectangular

signal whose duty cycle varies as a function of said regulating current

or voltage, another driver stage receiving the rectangular signal and

controlling said switching transistor, the regulation and boosting of

said output voltage being controlled by the initially independent

starting up of the entire horizontal deflection circuit when supplied by

said initial voltage from said power supply device as soon as a DC

input voltage is applied thereto and which then delivers recurrent

trigger pulses to said pulse-width modulator, one of the supply inputs

of said other driver stage receiving directly a first voltage waveform

whose positive alternations comprise constant-voltage plateau and whose

negative alternations comprise negative-going horizontal flyback pulses

provided by a first secondary winding of said line transformer, so as to

control the turning off of said switching transistor substantially

simultaneously with that of the trace switch transistor.

2. A power supply device as claimed in claim 1, wherein said other

driver circuit comprises a third transistor whose emitter is connected

to the base of said switching transistor and which is of the same type

as the latter, whose collector is connected, through said supply input,

to said first secondary winding of said line transformer to receive

therefrom said first waveform and whose base is coupled to the output of

said pulse-width modulator.

3. A power supply device as claimed in claim 2, wherein the collector of

said third transistor is connected, through a resistor to the supply

input and its emitter is connected, furthermore, to that of the

switching transistor through another resistor so that the negative-going

flyback pulses, applied to the collector of said third transistor,

control the symmetric (reverse) saturation thereof so as to reversely

bias the base-emitter junction of said switching transistor.

4. A power supply device as claimed in claim 2, wherein the collector of

said third transistor is connected to said power supply input through a

fourth diode conducting in the normal direction of its

collector-emitter path, and wherein its emitter is further connected, on

the one hand, through a resistor, to the emitter of the switching

transistor and, on the other hand, through another resistor and a fifth

diode conducting in the reverse direction to that of the base-emitter

junction of the switching transistor, so as to transmit to the base

thereof negative-going flyback pulses through a voltage divider formed

by said two resistors in series.

5. A power supply device as claimed in claim 1, wherein said other

driver circuit comprises a third transistor whose emitter is connected

to the base of said switching transistor, whose collector is connected

to that of this latter so as to form a so-called Darlington circuit and

whose base coupled, moreover, to said pulse-width modulator is further

connected, through a resistor and a diode in series, to said first

secondary winding of said line transformer so as to control the

simultaneous turn off of both transistors of said Darlington circuit by

simultaneously reversely biasing their respective base-emitter

junctions, connected in series, by means of negative-going flyback

pulses.

6. A power supply device as claimed in any one of the preceding claims,

wherein said pulse-width modulator, supplied at its input with a voltage

waveform whose positive alternations comprise positive-going flyback

pulses and whose negative alternations comprise constant

negative-voltage plateaux, comprises a passive circuit which forms a

simple integrator during positive alternations because one of its

resistors is shunted by a diode and which is a cascaded double

integrator during negative alternations of this waveform so as to

deliver during the trace periods of the scan a linearly decreasing

negative current which, added to the positive regulating current,

supplies the base of a fourth comparator transistor, so that the turning

off of this latter through equality of the negative and positive

currents supplied to this base controls the beginnings of the saturation

of said switching transistor in such a manner that the duration of this

saturation varies inversely with variation of said output voltage.

7. A power supply device as claimed in claim 6, wherein said comparator

transistor is biased, furthermore, at its base by means of a resistor

which connects it to the positive pole of said input voltage source, so

that  it

remains saturated in the absence of flyback pulses supplied by said

horizontal deflection circuit so as to maintain the switching transistor

in a cut off state.

8. A power supply device as claimed in any one of the preceding claims,

wherein said control circuit, except for the regulator stage which is

supplied by said output voltage, is supplied by said input voltage.

9. A power supply device as claimed in any one of the preceding claims 1

to 6, wherein said DC supply voltage of said control circuit, with the

exception of one of the inputs of said regulator stage receiving said

output voltage, is supplied by a secondary winding of said line

transformer, through a rectifier circuit including a diode and a

filtering capacitor.

it

remains saturated in the absence of flyback pulses supplied by said

horizontal deflection circuit so as to maintain the switching transistor

in a cut off state.

8. A power supply device as claimed in any one of the preceding claims,

wherein said control circuit, except for the regulator stage which is

supplied by said output voltage, is supplied by said input voltage.

9. A power supply device as claimed in any one of the preceding claims 1

to 6, wherein said DC supply voltage of said control circuit, with the

exception of one of the inputs of said regulator stage receiving said

output voltage, is supplied by a secondary winding of said line

transformer, through a rectifier circuit including a diode and a

filtering capacitor.

The present invention relates to a switching voltage regulator power supply device combined with the horizontal deflection circuit of a television receiver which it supplies with DC voltage. It relates, more particularly, to DC voltage supply devices of the type which boost or increase the voltage supplied at the output of the device in relation to the level of a DC voltage applied to its input and which regulate this level by recurrent switching of this input voltage, this switching being synchronous with the (horizontal) line frequency of the television receiver supplied by this device.

Switched step-up or boost voltage regulator devices of this type are known, particularly from the publications U.S. Pat. Nos. 3,571,697 (or 3,736,496) and they are related to switched mode power supply devices or DC-DC converters of the so-called unisolated flyback type, in which the collector-emitter path of a bipolar switching transistor is connected in series with a commutating inductance between the terminals of a DC source supplying an input voltage and a rectifying diode is connected between the junction of the inductance with the transistor and one of the plates of a filtering or storage capacitor (in parallel with the load), so that the current stored in the inductance during the conducting period of the transistor is used for charging the capacitor (and supplying the load) through the diode during its consecutive cut-off period. The use of a switched-mode power supply device of this type in television receivers for supplying, particularly, the horizontal deflection circuit thereof has been described, for example, in two articles by VAN SCHAIK entitled respectively "AN INTRODUCTION TO SWITCHED-MODE POWER SUPPLIES IN TV RECEIVERS" and "CONTROL CIRCUITS FOR SMPS IN TV RECEIVERS," appearing respectively on pages 93 to 108 of No. 3, Vol. 34, of September 1976 and on pages 162 to 180 of No. 4 of this same volume, of December 1976, in the English language Dutch review "ELECTRONIC APPLICATIONS BULLETIN" of PHILIPS', or on pages 181 to 195 of No. 135 of July 1977 and on pages 210 to 226 of No. 136 of October 1977 of the British review "MULLARD TECHNICAL COMMUNICATIONS." Since none of the switched-mode power supply devices described in these articles, isolated or not from the mains, whether they use a forward or a flyback converter, supplies at its output a DC voltage for supplying the horizontal deflection circuit before the switching transistor has been turned on (saturated or conducting) one or more times, the control circuit of this transistor must comprise an independent relaxation oscillator and must be supplied by the same DC input voltage (rectified and smoothed voltage of the AC mains) as the switching circuit comprising the inductance and the transistor in series. Synchronization of the switching with the horizontal deflection can only occur subsequently, when the horizontal oscillator and/or the horizontal deflection circuit as a whole have begun to operate, as soon as the supply voltage supplied thereto by the device which operates independently on starting up, has become sufficient. This synchronization of the switching with the horizontal deflection, advantageous for reducing or eliminating the interferences visible on the screen which are caused by high-frequency energy radiation due to abrupt transitions of power switching, particularly when the switching transistor is being cutt off, is generally carried out by means of a signal comprising flyback or retrace pulses, taken at the terminals of an auxiliary secondary winding of the line tranformer whose primary winding is generally connected between the output of the switched-mode power supply device and one of the terminals of the trace switch which is provided in the output stage. It is also possible to use for this purpose the signal provided by the horizontal oscillator (see, for example, the publication FR-A-2 040 217).

In a switched-mode supply for a television receiver described in the publication FR-A-2 261 670, the circuit for controlling the switching transistor of a forward-type converter, supplied with the rectified and smoothed voltage of the mains, comprises a bistable trigger circuit of flip-flop one of whose outputs is coupled back to one of its trigger inputs through a regulating circuit comprising a sawtooth voltage generator and a voltage comparator providing transitions which control the setting of the flip-flop, when the sawtooth voltage reaches the level of a voltage proportional to the amplitude of the flyback pulse. The other one of the two complementary outputs of this flip-flop is coupled back to its other trigger input through a so-called starting loop comprising an ascending voltage wave-form which approaches asymptotically a predetermined voltage level smaller than a predetermined fraction of the nominal level which the amplitude of the flyback pulse must reach in normal operation, and a voltage comparator providing transitions which control the recurrent resetting of the flip-flop to its initial state until the flyback pulse has reached or exceeded a threshold amplitude slightly below its nominal amplitude. When this threshold amplitude has been exceeded, resetting of the flip-flop is controlled by the flyback pulses themselves, negative-going in the present case, which supplant the starting pulses. Such an arrangement is equivalent to an astable multivibrator during the starting period, which later becomes a monostable one and triggered by the flyback pulses and whose quasi-stable state has a variable duration, depending on the amplitude of these pulses so as to obtain regulation thereof by the duty cycle. The pulse which controls the closing of the switch (saturation of the switching transistor) begins here with the leading edge of the flyback pulse and its duration or length is modulated as a function of the current drawn by the load and of the variation of the rectified and smoothed voltage, so that its end controlling the opening of the supply switch (cutting off the transistor) occurs during the trace portion of the horizontal deflection. Thus it can be seen that this switched-mode supply, like most of the known ones, effects regulation of its output voltage by varying the duty cycle as a reverse function of the level thereof.

Since

the high-frequency radiation is precisely at its most intense during

abrupt transitions of current in the switching inductance and of the

voltage accross its terminals, the appearance of one or more vertical

lines (light or dark according to the sense of the modulation of the

carrier wave by the video signal) may be observed, contrasting with the

nor mal

contents of the picture, whose location on the screen depends on the

duration of the pulse controlling the switching transistor. The effect

of this radiation becomes particularly troublesome when the input signal

of the radio-frequency stages or tuner is small, particularly when the

selected channel is situated in the lower part of the VHF band, for the

automatic gain-control device of the receiver acts on the gain of the

high-frequency and/or intermediate-frequency input stages, so that the

sensitivity (amplification) of the receiver is then maximum and this

also as concerns the spurious radiated signals.

mal

contents of the picture, whose location on the screen depends on the

duration of the pulse controlling the switching transistor. The effect

of this radiation becomes particularly troublesome when the input signal

of the radio-frequency stages or tuner is small, particularly when the

selected channel is situated in the lower part of the VHF band, for the

automatic gain-control device of the receiver acts on the gain of the

high-frequency and/or intermediate-frequency input stages, so that the

sensitivity (amplification) of the receiver is then maximum and this

also as concerns the spurious radiated signals.

The present invention, on the one hand, avoids or at least appreciably reduces the interferences visible on the screen by controlling the cutting off of the switching transistor in synchronism with the leading edge or the flyback pulse and, on the other hand, the starting of the horizontal deflection circuit by means of a simple circuit without any special oscillator, and provides efficient protection of the switching transistor which remains cut off when the horizontal deflection circuit is not operating. This is made possible by using a step-up switching regulator supply device of the type described in the publication U.S. Pat. No. 3,571,697 and whose control circuit includes, in accordance with the invention, the horizontal deflection circuit, which it supplies.

The object of the present invention is a power supply device with boosting and regulation of its output voltage by switching, combined with a horizontal sweep circuit of a television receiver, which it supplies and which comprises a horizontal oscillator, a driver stage and an output stage including a line transformer, this device comprising an inductance and the collector-emitter path of a switching transistor connected in series between the poles of a DC input voltage source, a rectifiying diode connected by its anode to the junction between the inductance and the collector of the transistor and by its cathode to one of the terminals of a filtering capacitor whose other terminal is connected to the emitter of the transistor so as to supply between its terminals an initial output voltage, slightly lower than the input voltage, when the transistor is cut off permanently, and a regulated DC output voltage with a level higher than the input voltage, when the transistor is recurrently alternately turned on and off, the level of this output voltage depending on the duty cycle of the respective states of this transistor, and a control circuit for driving the base of the transistor and including a regulator stage comparing an adjustable fraction of the output voltage to a fixed reference voltage and supplying a regulating current or voltage proportional to the difference between these compared voltages, to a pulse-width modulator triggered by means a recurrent signal and supplying a rectangular signal whose duty cycle varies as a function of this regulating current or voltage, and another driver stage receiving the rectangular signal and controlling the switching transistor.

In

accordance with the invention, the horizontal deflection forming an

integral part of the circuit controlling the switching transistor,

determines therefor, from the start, the repetition period of the

rectangular signal controlling it, and one of the supply inputs of the

other driver stage receives directly a first voltage waveform whose

positive alternations, comprise DC voltage plateaux and whose negative

alternations comprise negative-going flyback pulses supplied by a first

secondary winding of the line transformer, so as to control the cut-off

the switching transistor substantially simultaneously with that of the

trace switch transistor.

In

accordance with the invention, the horizontal deflection forming an

integral part of the circuit controlling the switching transistor,

determines therefor, from the start, the repetition period of the

rectangular signal controlling it, and one of the supply inputs of the

other driver stage receives directly a first voltage waveform whose

positive alternations, comprise DC voltage plateaux and whose negative

alternations comprise negative-going flyback pulses supplied by a first

secondary winding of the line transformer, so as to control the cut-off

the switching transistor substantially simultaneously with that of the

trace switch transistor.

The invention will be better understood and other of its objects, characteristics, features and advantages will become clear from the following description and the accompanying drawings which refer thereto, given solely by way of example, in which:

FIG. 1 is partly a block diagram and partly a schematic diagram of a power supply device combined with the horizontal deflection circuit in accordance with the invention;

FIG. 2 shows waveforms of two voltages and of a current at different points of the circuit of FIG. 1;

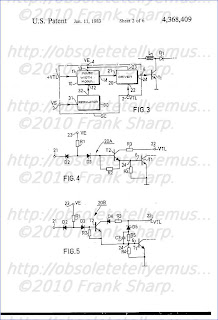

FIG. 3 is a block diagram of the circuit for controlling the switching transistor;

FIGS. 4 and 5 are schematic diagrams of two different embodiments of the driver circuit 20 forming the output stage of the control circuit of FIG. 3;

FIG. 6 is the block diagram of one embodiment of the pulse-width modulator 10 of the circuit of FIG. 3;

FIG. 7 shows three voltage waveforms at different points of the circuit of FIG. 6;

FIG. 8 is a schematic diagram of one embodiment of the pulse-width modulator 10 of the circuit of FIG. 3, using discrete components;

FIG. 9 shows a current waveform and two voltage waveforms at different points of the circuit of FIG. 8;

FIG. 10 is a schematic diagram of a conventional embodiment of a regulator stage 30 adapted to supply the modulation input of the modulator of FIG. 8; and

FIGS. 11 and 12 are partial respective schematic diagrams of two embodiments of a power supply device in accordance with the invention.

FIG.

1 shows the schematic diagram of the power stages of the power supply

device and of the horizontal deflection circuit of the television

receiver, which it supplies and in block diagram form the respective

circuits which control them.

FIG.

1 shows the schematic diagram of the power stages of the power supply

device and of the horizontal deflection circuit of the television

receiver, which it supplies and in block diagram form the respective

circuits which control them.

The DC input voltage VE which is not regulated is supplied by a rectifier bridge R with four diodes, supplied at its input by the secondary winding of an insulating step-down transformer TS, whose primary winding is supplied by the AC mains. The output terminals of rectifier bridge R are connected respectively to the terminals of a first filtering capacitor C1 across which this input voltage VE is taken.

The positive pole P of this source of the input voltage VE is connected to one of the terminals of an energy-storage inductance L, whereas its negative pole N is connected to ground G of the receiver, which is isolated from the mains. The other terminal of inductance L is connected, on the one hand, to the collector of a first NPN bipolar switching transistor T1, whose emitter is connected to ground G and, on the other hand, to the anode of a first diode D1 whose cathode is connected to the positive terminal of a second filtering and storage capacitor C2. With the negative terminal of this second capacitor C2 connected to ground G, the output voltage VS which supplies the load is taken between its terminals.

Such a supply device BS provides both step-up or boost and regulation of its output voltage level, because the first switching transistor T1 and the first diode D1 thereof are connected so as to conduct respectively currents flowing through inductance L in the same direction, it supplies at its output formed by the terminals of the second capacitor C2, an initial DC voltage VSI as soon as the primary winding of the insulating transformer TS is connected to the mains. This initial voltage VSI which is equal to the input voltage VE less the forward voltage drop VD1 across the first diode D1, is then supplied to the load until the control circuit SC is started up, whose output 6 is connected to the base of the first transistor T1 so as to cause it to be alternately turned on and off.

When the first transistor T1 is turned on by

positively biasing its base-emitter junction, its collector-emitter path

connects the junction of the inductance L with the anode of the first

diode D1 to ground G. Diode D1 being then reversely biased, it ceases to

conduct and the inductance L connected by the first transistor T1

between the positive P and negative N poles of the source supplying the

unregulated DC input voltage VE, then conducts a linearly increasing

current IL so as to store the energy which increases with the square of

the conduction duration of the first transistor T1, until this latter is

cut off. At the instant when the first transistor T1 is cut off after

the control circuit SC has brought its base-emitter voltage to zero or

below, the voltage at the terminals of inductance L is reversed so that,

at its junction with the collector of transistor T1 and the anode of

diode D1, there appears a voltage VM greater than the input voltage VE,

which results in the forward biasing of diode D1. Consequently, from the

instant when transistor T1 is cut off, dio de

D1 conducts a linearly decreasing current until the energy stored in

the form of a current IL in the inductance L, which charges the second

capacitor C2 to an output voltage VS greater than the input voltage VE,

disappears. The regulation of the level of the output voltage VS is here

effected in a conventional way, by varying the duty cycle, i.e. the

radio (quotient) between the duration of the conducting period of

transistor T1 and the sum of the respective durations of two of its

successive conducting and cut off periods, as a function of the desired

output voltage VS (determined by comparison to a stable reference

voltage).

de

D1 conducts a linearly decreasing current until the energy stored in

the form of a current IL in the inductance L, which charges the second

capacitor C2 to an output voltage VS greater than the input voltage VE,

disappears. The regulation of the level of the output voltage VS is here

effected in a conventional way, by varying the duty cycle, i.e. the

radio (quotient) between the duration of the conducting period of

transistor T1 and the sum of the respective durations of two of its

successive conducting and cut off periods, as a function of the desired

output voltage VS (determined by comparison to a stable reference

voltage).

According to the invention, a supply device BS of the above-described type is combined with the horizontal deflection circuit SH of a television receiver, which it supplies, so that this latter forms an integral part of its control circuit SC and for determining the repetition period of its operation and so that the above-mentioned regulation by varying the duty cycle maintains a stable peak-to-peak amplitude of the sawtooth scanning current and/or the very high voltage for biasing the electrodes (anode, focusing electrode and accelerating grid) of the cathode-ray tube, which are obtained by rectifying the horizontal flyback pulses supplied by a step-up secondary winding (not shown) of the line transformer TL.

The horizontal deflection circuit SH which comprises in cascade the horizontal oscillator OH whose known phase control circuit with respect to the horizontal sync signal separated from the composite video signal has not been shown here, the driver stage HD controlled by the horizontal oscillator OH and controlling the output stage OS of the horizontal deflection, is as a whole supplied by the above-described regulated power supply device BS. In fact, the positive supply input AL of the horizontal deflection circuit SH is connected by means of a fuse FS to the junction of the cathode of the first diode D1 with the positive terminal of the second capacitor C2, which forms the positive output terminal SP of the regulated power supply device BS. This supply input AL is connected directly to that of the driver circuit HD and, preferably, through a conventional Zener diode or series ballast transistor voltage regulator VR, to that of the horizontal oscillator OH, which are moreover connected to the isolated ground G.

The supply input AL of the horizontal deflection circuit SH is furthermore connected to one of the primary winding terminals B1 of the line transformer TL, whose other terminal AB is connected in parallel to the collector of another switching transistor TH, of NPN type, called trace switch transistor, to the cathode of a second so-called shunt recovery diode DR, to one of the terminals of another capacitor CR, called line-retrace capacitor, and to one of the plates of an additional capacitor CS, called trace capacitor, which supplies the horizontal deflection coils LH one terminal of which is connected to its other terminal during the trace periods of the scanning. The emitter of the scanning transistor TH, the anode of the "shunt" recovery diode DR, the other terminal of the retrace capacitor CR and the other terminal of the horizontal deflection coils LH are all connected to ground G. This assembly of components thus connected forms the output stage OS whose operation is well-known and does not form part of the invention.

As was mentioned above, as soon as the primary winding of the step-down isolating transformer TS is connected to the mains, rectifier R supplies the first filtering capacitor C1 so as to provide between its terminals P and N a unregulated low DC voltage VE. With the first transistor T1 then turned off, this input voltage is applied through the inductance L and the first diode D1 to the second capacitor C2 so as to obtain between the terminal SP and ground G an initial output voltage VSI substantially equal to VE-VD1, which is approximately equal to 60 percent of the regulated output voltage VS. This initial output voltage VSI (equal to about 0.6 VS) is sufficient to cause the generation of autonomous oscillations by the horizontal oscillator OH. This latter supplies at its output, connected to the input of driver circuit HD, pulses at an independent frequency close to the line frequency. In response to these pulses, driver circuit HD, also supplied by device BS, provides at the base of the trace switch transistor TH pulses controlling its periodical cut off at this independent frequency and its consecutive turning on after a period greater than the duration of the flyback period, so that the recovery diode DR may take the current from the deflector LH during substantially the first half of the trace portion of the scan. During flyback or retrace, with both transistor TH and diode DR cut off, the energy stored in the form of currents respectively in the inductances of deflector LH and of the primary winding B1 of the line transformer TL which are then, from the AC current point of view, connected in parallel, flow in an oscillating manner through the retrace capacitor CR which forms therewith a parallel resonant circuit whose resonance period determines the duration of the flyback period.

There then

appears periodically between point AB and ground G a voltage pulse VTH

having substantially a sinusoidal half-wave form, which is shown in

Diagram A of FIG. 2. The average value of this voltage VTH being then

equal to VSI, at start- up,

and to VS, during established operation. The line transformer TL

comprises, in addition to a very-high-voltage winding and other windings

for supplying rectifying circuits, not shown, two secondary windings

B2, B3 respectively supplying across their terminals, voltage waveforms

comprising flyback pulses with zero average values and with respectively

negative and positive polarities.

up,

and to VS, during established operation. The line transformer TL

comprises, in addition to a very-high-voltage winding and other windings

for supplying rectifying circuits, not shown, two secondary windings

B2, B3 respectively supplying across their terminals, voltage waveforms

comprising flyback pulses with zero average values and with respectively

negative and positive polarities.

This means that the first secondary winding B2 supplies a voltage waveform -VTL which, between two successive flyback pulses, comprises a positive plateau whose level is equal to the average value of these pulses and which is used, in accordance with the invention, to control the turn off of the first transistor T1 so that the interferences which would otherwise be visible only occur during the line-blanking periods comprising the line-retrace periods. The second secondary winding B3 then supplies a voltage waveform +VTL which is the reverse of or complementary to the preceding one -VTL.

One of the terminals of each of these secondary windings B2, B3 is connected to ground G, whereas their other terminals are respectively connected to two inputs 2 and 1 of the control circuit SC. A third input 3 of this latter is connected to the SP output of the supply device BS and a fourth input 4 is connected to the positive pole P of the input voltage source VE. A fifth terminal 5 of the control circuit SC is connected to ground G (or negative pole N) and its output 6 is connected to the base of the first transistor T1. This control circuit SC causes, following the start up of the horizontal deflection circuit SH, a first saturation of the first transistor T1 at a time determined by a pulse-width modulator operating by conventional comparison of a sawtooth voltage waveform the elaboration of which is controlled by a first flyback pulse, with a regulating voltage, depending on the output voltage VS. During this saturation period of transistor T1 which extends as far as the leading edge of the next flyback pulse, energy is stored in inductance L.

From the instant when transistor T1 is turned off, diode D1 transfers this stored energy to the second capacitor C2, at the terminals of which it causes an increase of the voltage VS with respect to its initial value VSI, until the current in diode D1 is canceled out, when it becomes reverse biased.

The collector-emitter voltage waveforms VTH of the trace switch transistor TH and VCE of the switching transistor T1 in established operation have been shown respectively by the diagrams A and B of FIG. 2. Diagram C of FIG. 2 shows the corresponding waveform of the current IL flowing through the inductance L.

When the base of the first transistor T1 receives from the output 6 of the control circuit SC a rectangular signal which turns it on at time instant t1, its collector-emitter voltage VCE (Diagram B) becomes close to zero (V CEsat ) and a linearly increasing current IL (Diagram C) flows through inductance L from time t1 until time t2 when transistor T1 is again turned off, which is controlled by the leading edge of the flyback pulse VTH (Diagram A). With the collector current of transistor T1 canceled at the end of the storage time of the excess minority carriers in the base, the voltage across the terminals of the inductance L inverses its polarity so as to be added to the input voltage VE, so that the collector-emitter voltage VCE (Diagram B) then reaches a level VM greater than VS (as well as VE), so as to apply forward bias to the first diode D1, which then conducts the current IL through the inductance L. This current IL, from time instant t2 when it reaches its maximum value IM, becomes linearly decreasing and it flows through the first diode D1 in the passing direction in order to recharge the second capacitor C2 and supply, in particular, the horizontal deflection circuit SH.

When the current IL passing through the first diode D1 is canceled out at time t3, the collector-emitter voltage VCE of the first transistor T1 becomes equal to the unregulated input voltage VE until the next turn on of the transistor T1, and the first diode D1 remains reversely biased until the time when this latter is cut off again.

From the above it can be easily seen that the principal advantage of this combined device resides in the fact that a single oscillator OH belonging to the horizontal deflection circuit SH is sufficient for controlling the two power switching transistors TH and T1.

Furthermore,

a possible overload in the circuitry of the television receiver, such

for example as a short-circuit of the trace switch transistor TH,

results in overloading the diode D and the inductance L. The first

transistor T1 which is consequently cut off is not subjected to this

overload and is therefore protected. In order to protect the rest of the

television receiver as well as inductance L and the first diode D1, a

fuse FS may be connected in series in the supply line from the second

capacitor C2. This fuse FS may also be inserted between pole P and

inductance L.

Furthermore,

a possible overload in the circuitry of the television receiver, such

for example as a short-circuit of the trace switch transistor TH,

results in overloading the diode D and the inductance L. The first

transistor T1 which is consequently cut off is not subjected to this

overload and is therefore protected. In order to protect the rest of the

television receiver as well as inductance L and the first diode D1, a

fuse FS may be connected in series in the supply line from the second

capacitor C2. This fuse FS may also be inserted between pole P and

inductance L.

It is moreover known that it is difficult to construct switched supplies for obtaining correct operation when it is not fully charged (for supplying, for example, a ready-state remote-control receiver). In the present case, the problem does not come up since, when the supply is in operation, there is always a minimum load formed by the horizontal deflection circuit. When this circuit is not operating, the supply circuit BS does not operate either, but it supplies an output voltage VSI of a value less than the nominal voltage VS which cannot cause damage and which may, for example, supply a ready-state receiver for television receivers having a remote control.

Finally, the control circuit SC allows transistor T1 to be cut off at the beginning of each flyback period, when the blanking circuit has extinguished the spot (s) on the cathode-ray tube. Thus, the spurious signals radiated into the receiver input circuits will cause no visible effect on the screen of the cathode-ray tube.

FIG. 3 shows in block diagram form the control circuit SC of FIG. 1.

FIG. 3 shows in block diagram form the control circuit SC of FIG. 1.

This control circuit SC comprises a pulse-width modulator stage 10 a first input 11 of which, connected to input 1, receives flyback pulses of positive polarity +VTL from the second secondary winding B3 of the line transformer TL (see FIG. 1 and a second input 12 of which receives a so-called regulating voltage or current whose level is proportional to the difference between the actual output voltage VS and a constant reference value, delivered by the output 32 of a regulating circuit or stage 30 whose input 31 is connected through input 3 to the positive output pole SP of the supply device BS supplying the regulated voltage VS. The variation of the regulating current or voltage causes the variation of the time instant when the instantaneous amplitude of a sawtooth voltage waveform, either with substantially constant slope and amplitude, reaches the level of this regulating voltage, or with a slope variable depending of the regulating current (which is added to the current for linearly charging a capacitor), reaches the predetermined level of a fixed reference (threshold) voltage, with respect to the beginning or the end of the sawtooth waveform. Thus a two-level rectangular signal with constant periodicity is generated, whose duty cycle varies as a function of the regulating current or voltage. If it is arranged, which is possible, for a reduction of the output voltage VS with respect to its nominal value defined by the reference voltage, to cause an increase in the duty cycle and for an increase in VS to have the opposite effect, regulation of this output voltage VS is provided, which tends to be stabilized to this nominal value.

The output 14 of modulator 10 supplies a first input 21 of the driver stage 20 of the first switching transistor T1, a second input 22 of which receives the flyback pulses of negative polarity -VTL, coming from the first secondary winding B2 of the line transformer TL.

FIGS. 4 and 5 illustrate two different embodiments of the driver stage 20 of FIG. 3, providing efficient turn off of the first transistor T1.

In FIG. 4, the driver stage 20A comprises a third supply input 23 which connected to the positive pole (P) of the source of the (unregulated) input voltage VE and to one of the terminals of a first resistor R1 (1.8 kiloohms) whose other terminal is connected in parallel to the anodes of two diodes D2 and D3 (of type 1N4148). The second of these diodes D3 has its cathode connected to the base of a third NPN transistor T2 and to one of the terminals of a second resistor R2 (220 ohms). The emitter of the third transistor T2 is connected to the other terminal of the second resistor R2 and to the output 24 of stage 20A, which is connected through the output 6 of the control circuit SC to the base of the first transistor T1. The collector of the second transistor T2 is connected through a third resistor R3 (10 ohms) to the second input 22 of stage 20A receiving the signal -VTL which comprises the negative-going flyback pulses and, between them, plateaux of a constant positive level (zero average value). The base of the first transistor T1 is coupled to its emitter and to ground G, through a fourth resistor R4 (100 ohms). The third transistor T2 is thus mounted as a common collector (emitter-follower) stage.

When the output 14 of modulator 10

(FIG. 3) which is connected to the input 21 of stage 20A supplies a low

state (level), i.e. a voltage close to zero, the thus positively biased

diode D2 becomes conducting so that its anode will be at a voltage of a

few tenths of a volt (0.7+V CEsat ) which is less than the

voltage required for making the three series PN junctions orientated in

the same direction conductive, the first of which is formed by the third

diode D3, the second is the base-emitter junction of a third transistor

T2 and the third that of the first transistor T1, which will thus

remain turned off. When, on the other hand, output 14 supplies a high

state or forms an open circuit (the output stage of modulator 10 being

formed by an open-collector transistor), diode D2 is cut off by its

reverse bias and the voltage VE applied to the input 23 causes a current

to flow through the first resistor R1, the diode D3 and the respective

base-emitter junctions of transistors T2 and T1 co nnected

in series. Under these circumstances and if, at the same time, the

voltage waveform -VTL applied to the collector of transistor T3 presents

its constant positive level portion, coinciding with the trace periods

of the horizontal scan, transistors T2 and T1 become simultaneously

saturated with the effect previously described insofar as the supply

device BS of FIG. 1 is concerned. On the other hand, when the voltage

waveform -VTL applied to the collector of the third transistor T2

becomes negative, during flyback periods, the current then flows between

terminals 23 and 22 of driver stage 20 A, through resistor R1, diode

D3, the base-collector junction of the third transistor T2 and resistor

R3. The third transistor T2 then operates along its symmetrical

saturation characteristics, i.e. it is inverted so that its collector

becomes emitter and vice versa. It then conducts a current in the

reverse direction between ground and the input 22 (negative) through the

resistor R4 across the terminals of which it causes, after removal of

the excess minority carriers from the base of the first transistor T1

through the third transistor T2, a voltage drop biasing said base

negatively with respect to the emitter. This negative voltage applied to

the base of reversely saturated transistor T3 allows a considerable

reduction in the storage time and a rapid turnoff of the first

transistor T1. Since the sawtooth generator of the pulse-width modulator

10 described above is controlled by positive-going flyback pulses, the

rectangular signal applied by its output 14 (FIG. 14) to input 21 of

stage 20A undergoes, during the flyback period following the turn off of

the first transistor T1, a transition from its high state to its low

state which causes diode D2 to conduct and, consequently, the third

transistor T2 (reversed) to be cut off before the waveform -VTL becomes

positive again and rebiases this transistor T2 the right way round.

nnected

in series. Under these circumstances and if, at the same time, the

voltage waveform -VTL applied to the collector of transistor T3 presents

its constant positive level portion, coinciding with the trace periods

of the horizontal scan, transistors T2 and T1 become simultaneously

saturated with the effect previously described insofar as the supply

device BS of FIG. 1 is concerned. On the other hand, when the voltage

waveform -VTL applied to the collector of the third transistor T2

becomes negative, during flyback periods, the current then flows between

terminals 23 and 22 of driver stage 20 A, through resistor R1, diode

D3, the base-collector junction of the third transistor T2 and resistor

R3. The third transistor T2 then operates along its symmetrical

saturation characteristics, i.e. it is inverted so that its collector

becomes emitter and vice versa. It then conducts a current in the

reverse direction between ground and the input 22 (negative) through the

resistor R4 across the terminals of which it causes, after removal of

the excess minority carriers from the base of the first transistor T1

through the third transistor T2, a voltage drop biasing said base

negatively with respect to the emitter. This negative voltage applied to

the base of reversely saturated transistor T3 allows a considerable

reduction in the storage time and a rapid turnoff of the first

transistor T1. Since the sawtooth generator of the pulse-width modulator

10 described above is controlled by positive-going flyback pulses, the

rectangular signal applied by its output 14 (FIG. 14) to input 21 of

stage 20A undergoes, during the flyback period following the turn off of

the first transistor T1, a transition from its high state to its low

state which causes diode D2 to conduct and, consequently, the third

transistor T2 (reversed) to be cut off before the waveform -VTL becomes

positive again and rebiases this transistor T2 the right way round.

FIG. 5 shows the schematic diagram of another embodiment of the driver circuit 20 of FIG. 3, designated by 20B, which has only been modified with respect to circuit 20A of FIG. 4 insofar as the collector circuit of the third transistor T2 and the base circuit of the first transistor T1 are concerned.

This modification is more particularly intented for the case where the negative peak amplitude of the voltage waveform -VTL applied to the base of the first transistor T1 through resistor R3 and the emitter-collector path of the reversely saturated third transistor T2, exceeds the reverse (Zener) avalanche-effect breakdown voltage of one of the base-emitter or base-collector junctions of the first transistor T1. This may occur when the first secondary winding B2 of the line transformer TL is also used for other functions in the television receiver.

To prevent the third transistor T2 from being reversely saturated (symmetrically), the circuit 20B comprises a fourth diode D4 inserted between the input 22 receiving the voltage waveform -VTL and the collector thereof, in series with the resistor R3 and connected to conduct in the same direction as its collector-emitter path. The input 22 is more over connected to the cathode of a fifth diode D5 (1N4148) whose anode is connected through a circuit formed by a fifth resistor R5 (330 ohms) and a third capacitor C3 (1nF) connected in parallel, to the base of the first transistor T1.

Diode D5 isolates the base of transistor T1 from the input 22, when the waveform -VTL is positive, and connects them together through a resistive voltage divider formed by resistors R5 and R4 in series, when it becomes negative. Capacitor C3 accelerates the turn-off by favoring the transmission to the base of T1 of abrupt transitions of the negative flybacd pulses.

FIG.

6 is a diagram, partly in block form, of a possible embodiment of the

pulse-width modulator 10 of the control circuit SC of FIG. 3. Diagrams

D, E and F of FIG. 7 show the voltage waveforms applied respectively to

the input 11 (+VTL) and supplied by the output SI (VI) of the sawtooth

generator GD and by the output 14 (VP) of circuit 10A.

FIG.

6 is a diagram, partly in block form, of a possible embodiment of the

pulse-width modulator 10 of the control circuit SC of FIG. 3. Diagrams

D, E and F of FIG. 7 show the voltage waveforms applied respectively to

the input 11 (+VTL) and supplied by the output SI (VI) of the sawtooth

generator GD and by the output 14 (VP) of circuit 10A.

Modulator 10A of FIG. 5 comprises a sawtooth generator GD formed by a conventional integrator circuit comprising a first amplifier A1 (integrated operational amplifier, for example), an integrating resistor R1 inserted in series between the input 11 receiving the voltage waveform +VTL illustrated by Diagram D of FIG. 7 and supplied by the second secondary winding B3 of the line transformer TL, and the input (inverting) of amplifier A1, as well as an interating capacitor CI connected between this input and the output SI of amplifier A1 (capacitive feedback). In response to this waveform +VTL, the output of amplifier A1 forming the output SI of sawtooth generator GD, supplies a voltage waveform VI illustrated by the diagram E of FIG. 7 which comprises, during the period between time instants t0 and t2 corresponding to the trace period TA of the scan, a voltage decreasing linearly between a maximum value (positive) and a minimum value (negative), and during the flyback intervals preceding time instant t0 and succeding to time instant t2, an increasing voltage of substantially semi-cosinusoidal shape.

Voltage VI is applied to one of the inputs (-) of an analog voltage comparator which may be formed by means of a second differential-type amplifier A2 (integrated operational amplifier), whose other input (+) connected to the input 12 of modulator 10A, receives the regulating voltage VR supplied by the regulator stage (30 of FIG. 3). This regulating voltage VR, which is obtained by comparing the output voltage VS of the supply device BS of the circuit of FIG. 1 with a reference voltage (VZ supplied by a Zener diode, for example), is a DC voltage undergoing slow variations, shown in Diagram E of FIG. 7 by a dash-dot line.

When the waveform VI applied to the inverting input (-) of comparator A2 is greater than the regulating voltage VR, which is the case during the period between time instants t0 and t1, its output connected to the output 14 of modulator 10A provides a low state. When, on the other hand, it (VI) reaches or becomes less than VR, which occurs from the time instant t1, the output 14 of modulator 10A provides a high state (which causes saturation of the first transistor T1). This high state continues until time instant t4 subsequent to the time instant t2 of the beginning of the following flyback pulse whose leading edge controls the turn-off of the first transistor T1, when the waveform VI becomes greater than the regulating voltage VR. Thus there is obtained at the output 14 of modulator 10A a rectangular signal VP shown in Diagram F of FIG. 7, formed successively of a low-level (zero or negative) beginning during the first half of the flyback period TR and ending at time instant t1, and a high level going from time instant t1 to time instant t4. Time instant t1 of the positive transition of signal VP, which determines the beginning of conduction of the first transistor T1 is then situated during the trace period of the scan TA and its position with respect to the beginning t0 or to the end t2 thereof varies as a function of the regulating voltage VR. When the regulating voltage VR is negative (as on the Diagram E of FIG. 7), a predetermined fraction of the output voltage VS is greater than the reference voltage, the duration of the high level state (t2-t1) is less than half of the trace period of the scan T1. In the opposite case, this duration (t2-t1) is greater than TA/2. The modification of this duration (t2-t1) and thus of the duty cycle is carried out in the reverse direction of the variation of the output voltage VS so as to stabilize it at a previously adjusted level, with respect to this reference voltage. The waveform -VTL may also be applied to the input 11 of modulator 10A. In this case, the input of comparator A2 must also be inverted.

To obtain suitable operating limits, while taking into consideration particularly the value of inductance L, the duty cycle or the durations (t2-t1) must vary between 0, the case where the input voltage VE is equal to the nominal output voltage VS, and about two-thirds, the case where the maximum power is supplied for a minimum voltage at the input.

The ratio between the residual alternating voltage (hum) at the output and the alternating voltage at the input must also allow an image to be obtained which is not perturbed for the eye. A value less than or equal to a hundredth for this ratio gives satisfactory results.

FIG.

8 shows the simplified diagram of a practical embodiment (by means of

discrete components) of the pulse-width modulator 10 of FIG. 3.

Different waveforms of a current I1 and input +VTL and output VP

voltages are respectively illustrated by the Diagrams H, J and K of FIG.

9.

FIG.

8 shows the simplified diagram of a practical embodiment (by means of

discrete components) of the pulse-width modulator 10 of FIG. 3.

Different waveforms of a current I1 and input +VTL and output VP

voltages are respectively illustrated by the Diagrams H, J and K of FIG.

9.

The input 11 of modulator 10B of FIG. 3 receives the voltage

waveform +VTL which may be suppled either directly by the second

secondary winding B3 of line transformer TL, or through a coupling

capacitor whose one terminal is connected to the collector of the trace

switch transistor TH (see FIG. 1). This input 11 supplies a passive

shaping circuit, supplying negative-going (decreasing) sawtooth

waveforms during the trace periods of scan T1. This passive circuit

comprises a fourth coupling capacitor C4 (0.1μ) one terminal of which is

connected to the input 11 and the other of which is connected to one of

the terminals of a sixth resistor R6 (10 Kohms). The other terminal of

this resistor R6 is connected to one of the terminals of a seventh

resistor R7 (5.6 Kohms), to one of the terminals of a fifth capacitor C5

(5.6 nF) and to the anode of a sixth diode D6. The other terminal of

capacitor C5 is connected to ground G. The cathode of the sixth diode D6

and the other terminal of resistor R7 are both connected to one of the

terminals of an eighth resistor R8 (33 kohms), to that of a ninth

resistor R9 (470 ohms), to that of a sixth capacitor C6 (4.7 nF) and to

the regulation input 12 of modulator 10B, which is connected to the

output 32 of the regulator stage 30 (see FIG. 3). The other terminal of

capacitor C6 is connected to ground. The other terminal of resistor R8

is connected to the supply input 13 of modulator 10B receiving the input

voltage VE. The other terminal of the ninth resistor R9 is connected to

the base of a fourth NPN transistor T3, which forms the voltage

comparator stage, whose emitter is connected to ground and whose

collector (open), which forms the output 14 of modulator 10 B, is

connected to the input 21 of the driver stage 20A (of FIG. 4) or 20B (of

FIG. 5), formed by the cathode of the second diode D2. The value of

capacitor C6 has been chosen so as to limit the maximum negative voltage

applied to the base-emitter junction of transistor T3 to a value less

than its reverse avalanche breakdown voltage. When the input voltage

waveform +VTL is positive, as during the major portion of the flyback

periods TR, diode D6 short-circuits resistor R7 and we have then a

simple passive RC integrator formed by resistor R6 in series and two

capacitors C5 and C6 in parallel, whose output is connected to the base

of transistor T3 through resistor R9. Transistor T3 becomes conducting

when its base current IB formed by the sum of currents I1 and I2 becomes

positive. The current I1 shown by an arrow in FIG. 8 and on the Diagram