BACKGROUND

The

invention relates to a tuning unit with bandswitch for high frequency

receivers, especially radio and television receivers, having a

potentiometer system for the control of capacity diodes, the said

potentiometer system consisting of a plurality of parallel resistance

paths along which wiper contacts can be driven by means of screw

spindles disposed adjacent one another in a common insulating material

housing in which a bandswitch formed of metal rods is associated with

each tuning spindle.

In these tuning units, the working voltages

of the capacity diodes in the tuning circuits are recorded once a

precise tuning to the desired frequency has been performed. A

potentiometer tuning system has great advantages over the formerly used

channel selectors operating with mechanically adjustable capacitors

(tuning condensers) or mechanically adjustable inductances

(variometers), mainly because it is not required to have such great

precision in its tuning mechanism.

Tuning units with

bandswitches formed of variable resistances and combined with

interlocking pushbuttons controlling the supply of recorded working

voltages to capacity diodes are known. Channel selection is accomplished

by depressing the knobs, and the tuning or fine tuning are performed

by turning the knobs. The resistances serving as voltage dividers in

these tuning units are combined into a component unit such that they

are in the form of a ladderlike pattern on a common insulating plate

forming the cover of the housing in which the tuning spindles and wiper

contacts corresponding to the variable resistances are housed. The

number of resistances corresponds to the number of channels or

frequencies which are to be recorded. The wiper contact picks up a

voltage which, when applied to the capacity diodes determines their

capacitance and hence the frequency of the corresponding oscillating

circuit. The adjustment of the wipers is performed by turning the

tuning spindle coupled to the tuning knob. By the depression of a

button the electrical connection between a contact rod and a tuning

spindle is brought about and thus the selected voltage is applied to

the capacity diodes. Since the push buttons release one another, it is

possible simply by depressing another button to tune to a different

receiving frequency or a different channel, as the case may be.

To

permit the switching of a number of channels in a certain tuning

range, bandswitches for a plurality of tuning ranges, such as UHF and

VHF for example, are often provided in the tuning units described

above. In the pushbutton tuning unit of the above-named type, the

bandswitch consists of a printed circuit board which is fastened on the

housing of the tuning unit, and a switch lever which is preset by

means of the pushbutton by turning, and is operated by depressing the

pushbutton while at the same time selecting the channel.

Where

this combination of knobs and pushbuttons is not possible, the

selection of the range is accomplished by means of an additional lever

which can be set over to select the range.

However, since such

tuning units require too many riveting operations when they are

assembled, tuning units were later created in which the individual

parts in the voltage divider and pushbutton housing were loosely

inserted and/or held in place by projections, lugs, hooks or tabs of

resilient plastic. In spite of these initial improvements, the

bandswitch, especially the one associated with the tuning units, was

still technically intricate and very expensive.

THE INVENTION

It

is the object of the invention, therefore, to create an additionally

improved and simplified tuning unit containing a bandswitch of simple,

space-saving and reliably operating design.

In accordance with

the invention, this object is accomplished in a tuning unit with

bandswitch of the kind described in the beginning by joining the tuning

spindles for rotation with sleeves simultaneously forming the control

knobs, which are mounted in apertures in the front plate of the housing

and have each a flange engaging the back of the front plate around the

aperture, the said flange being slightly larger than the aperture and

tapering conically away from the back of the front plate.

In

further development, the sleeves can be joined telescopically for

rotation with the tuning spindles, and the flange is able to engage the

back side of the front plate when the sleeve is in the position in

which it is drawn out of the front plate. The sleeves constructed in

this manner, whose portions projecting from the apertures in the front

plate form the control knobs for the tuning spindles, permit easy

assembly of the tuning unit

and at the same time assure positive co-rotation of sleeves and

spindles. The sleeves can be pushed from the front side of the front

plate through the apertures onto the clutch surfaces of the spindles,

this inward pushing being easily accomplished on account of the taper,

and the dropping out of the sleeve being prevented by the flange

engaging the back of the front plate. If the control knobs project only

slightly out of the front plate, they can be operated from the outside

by inserting a tool into them. With the telescoping type of coupling,

however, it is possible to draw the sleeves or control knobs further

outwardly so that they can be rotated by hand without the use of tools.

To

provide constant assurance of the axial fixation of the tuning

spindles, the tuning spindle ends farthest from the front plate can each

be provided with an annular groove engaged by a spring bracket whose

one leg is supported against the housing and whose other leg is forked

to form two spring arms, each bent in the opposite direction and each

engaging one of the two opposite walls of the annular groove. The tuning

spindles are secured against axial displacement by this construction

of the invention alone, without the need for further measures. This

facilitates the joining of the sleeves or control knobs to the tuning

spindle, because in this case there is no need for precise axial

fixation and extreme dimensional accuracy.

Furthermore, the

indicators associated with each potentiometer can be mounted in windows

in the front plate which are associated with each tuning spindle or

tuning knob for visual indication at the front, the other extremities

farthest from the front plate being mounted for pivoting on pins set in

the housing; the guiding pin on the spindle nut that is driven

longitudinally on each tuning spindle can be provided with a slit

disposed parallel to the long axis of the tuning spindles and can slide

within the indicator slide lever slot, with its surface resiliently

engaging the walls of said slot.

In an especially advantageous

embodiment, the tuning unit can have bandswitches each formed of a

displaceable metal rod which is in contacting engagement individually

with stationary metal rods which are common to all of the bandswitches

of a tuning unit. It contrast to the bandswitches known hitherto, which

as a rule consist of a printed circuit board with switchable contacts

thereon, this frequency bandswitch of the invention is of great

simplicity, can be manufactured simply and inexpensively, and at the

same time is very reliable in operation.

The displaceable and

stationary metal rods of the bandswitches can be formed of metal wires

or they can be of stamped sheet metal. Also, in further expansion of the

concept of the invention, the stationary metal rods thus formed can be

all entirely alike and merely offset from one another, thereby further

simplifying the manufacture and stocking thereof.

To permit

connection also to audiovisual apparatus, one or more of the stationary

metal rods can be divided electrically into at least two parts each.

In

a special development of this concept, lugs of insulating material can

be mounted on the front ends of the displaceable metal wires, these

lugs extending through windows in the front plate of the housing which

are associated with each tuning spindle and are provided with detents,

while the opposite ends can be held fixedly at the rear end of the

housing, and the displaceable metal wires can make contact with contact

humps on the stationary metal wires, the humps being offset from one

another to correspond to the detents in the windows, and the stationary

metal wires extending in back of the front plate, parallel to the

latter and parallel to one another.

To increase switching

reliability, bridges or sliding pieces made of insulating material can

be inserted between the contact humps of adjacent stationary wires

within the free space between two such parallel lying metal wires.

To

achieve easy displacement of the displaceable metal wires despite the

fixed end mounting on the housing, the displaceable metal wires, in

further embodiment of the invention, can have each an articulation

adjacent their end mountings, in the form of a vertically disposed

flattened portion. This flat permits the metal wires to be deflected

horizontally against a weak spring bias.

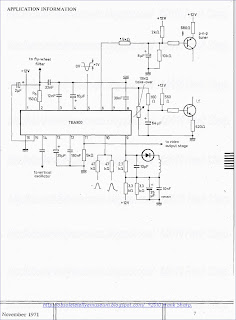

DESCRIPTION OF THE DRAWING

As

an example of the embodiment of the invention, there is represented in

the drawings a tuning unit with bandswitch for television receivers.

In these drawings,

FIG. 1 is a front elevational view of a tuning unit with bandswitch,

FIG. 2 is a plan view showing the bandswitch of the tuning unit of FIG. 1,

FIG. 3 is a side elevational, cross-sectional view of the tuning unit of FIG. 1,

FIG. 4 is a rear elevational view of the tuning unit of FIG. 1,

FIG. 5 is a plan view showing the indicator means of the tuning unit of FIG. 1,

FIG. 6 shows the sleeve with the operating knob and tuning spindle,

FIG. 7 shows the telescoping manner in which the sleeve is joined to the tuning spindle,

FIG. 8 is a fragmentary view of the bandswitch,

FIG. 9 is another fragmentary view of the bandswitch, and

FIG. 10 shows how the tuning spindle is fixed in position.

DESCRIPTION

The method of representation used in the drawings is greatly simplified, for the purpose of better del

ineating

the features of the invention. The tuning unit with bandswitch

consists of an insulating material housing 1 with a front plate 2,

which is closed by a cover plate 3 accommodating the resistance paths.

The housing 1 is divided by parallel sidewalls 4 into chambers in which

the tuning spindles 5 are disposed.

The embodiments is an 8-fold tuning unit having eight bandswitches assocated with each tuning spindle, and eight indicators.

Accordingly,

there are eight apertures 6 in a central row, through which the

operating knobs 7 of the sleeves 8 coupled with the tuning spindles 5

are passed. The operating knobs 7 have recessed surfaces 9 for turning

with a turning tool. In a row extending parallel above the row of the

apertures 6 there are eight windows 10, whose upper edge is provided

with notches 11. Lugs 12 of insulating material extend through the

windows 10 and engage the upper notches 11 and are joined behind the

front plate to displaceable metal wires 13 of the bandswitch. In a row

located beneath the row of apertures 6 another eight windows 14 are

provided, through which the ends of the pointers of the indicators 15

protrude.

Now, the bandswitch consists in each case of a

displaceable metal wire 13 which can be brought into working engagement

with stationary metal wires 16, which are all of the same construction

and are only disposed offset from one another. While the displaceable

metal wire 13 extends substantially parallel to the longitudinal axis

and thus at right angles to the front plate 2, the stationary,

parallelly disposed metal wires 16 are parallel to the front plate 2 and

are thus inserted at a right angle to the displaceable metal wire. A

departure from parallelism or from the right angle, as the case may be,

takes place substantially only when the displaceable metal wire 13 is

deflected to the two outer notches. The rearward end 18 of the

displaceable metal wire, which forms a vertical loop, is tightly

inserted into a receiver 17. Just ahead of the loop 18, the metal wire

13 is provided with a vertically disposed portion 19 by a flattening on

the metal wire 13. The movement, when the metal wire 13 is deflected

into the desired notches or detents, takes place horizontally by the

flex

ing

of these portions 19. The stationary metal wires 16 are held tightly

in their positions in projections 20 on the housing, or by lugs or the

like. Since three switch actions are provided, that is, three ranges,

for each tuning spindle, a bandswitch consists of one displaceable metal

wire and three stationary metal wires 16, which are used for all

switches.

To permit each bandswitch to have exactly three

switching actions, each of the three stationary metal wires 16 has one

contact hump 21 corresponding to one of the detents 11 in the windows 10

of the front plate 2. The contact humps 21 are thus located one next

to the other as seen from the front plate 2. So that the displaceable

metal wire 13 will always come into mechanical and electrical contact

only with the desired contact hump, and prevent short circuits,

insulating bridges 22 are installed between the adjacent metal wires 16,

said insulating bridges being stationary.

If more or less than

three switching actions are desired, all that need be done in the case

of the bandswitch of the invention is to change the number of

stationary metal rods or wires accordingly.

The sleeves 8 with

the operating knob 7 have a flange 23 engaging the back of the front

plate 2 and tapering back to the point where it joins the tuning

spindle. This enables the sleeves to be pushed in, in the case of a

housing that has already been manufactured with the tuning spindle

installed, without creating the possibility that the sleeves 8 might

escape after they have been inserted. The sleeves 8 are connected to

the tuning spindles 5 usually by means of driving surfa

ces.

If manual operation without tools is to be possible, rather than

requiring a tool for the operation of the sleeves, the coupling of the

sleeve 8 to the tuning spindle will be a telescoping coupling (see FIG.

7).

The actual firm axial fixation of the tuning spindle 5 is

located on the rear end of the housing. Here the tuning spindle 5 has an

annular groove 24 which is engaged by a spring by means of two

diametrically disposed spring arms 25 and 26. The spring arms 25 and 26

have oppositely curved lugs and are supported on the housing at their

terminal and marginal surfaces and their lugs engage opposite axial

walls 27 and 28 of the annular groove 24.

Additional support is provided by the common, bent foot 29 of the spring arms 25 and 26 against the cover plate of the housing.

The indic

ator

means of the tuning unit with bandswitch consists of a pointer 15

which is movable within the window 14, and a cam 30 which is a

prolongation of the pointer 15. At its rearward end, the pointer is

mounted rotatably in the housing on pin 31. Within the cam 30 slides a

guiding pin 32 which is attached to the spindle nut or carriage 40.

Upon the rotation of the tuning spindle, the spindle nut is

longitudinally displaceable therewith. In order to achieve good

guidance and hence precise indication, the guiding pin has a slit 33

extending parallel to the longitudinal axis of the tuning spindle 5, so

that it will resiliently engage the cam 30 within the slot thereof.

The necessary soldering lugs are indicated at 34.

On

the basis of the design of the tuning unit with bandswitch in

accordance with the invention, a desired frequency range--UHF, for

example--can be selected by deflecting a displaceable metal wire 13 into

one of the detents 11 by means of the lug 12 mounted thereon. Within

this range, a transmitter or channel can then be selected by turning the

tuning spindle 5. The transmitter preselected in th

is

manner can then be tuned in by means of a keyboard or by electronic

recall from a keyboard which is not shown. The fine tuning of this

tuned-in transmitter, as well as the selection of a different

transmitter within the same frequency range, is accomplished by turning

the tuning spindle 5.

All of the details explained in the above description and represented in the drawings are important to the invention.