TDA4600 (SIEMENS)

Power supply Description based on TDA4601d (SIEMENS)

DESCRIPTIONS Pin 1 This is a 4v reference produced within the I.C. Pin 2 This pin detects the exact point at which energy stored in the chopper transformer collapses to zero via R824 and R825, and allows Q1 to deliver drive volts to the chopper transistor. It also opens the switch at pin 4 allowing the external capacitor C813 to charge from its external feed resistor R810. Pin 3 H.T. control/feedback via photo coupler D830. The voltage at this pin controls the on time of the chopper transistor and hence the output voltage. Normally it runs at Approximately 2v and regulates H.T. by sensing a proportion of the +4v reference at pin 1, offset by conduction of the photo coupler D830 which acts like a variable resistor. An increase in the conduction of transistor D830 and therefor a reduction of its resistance will cause a corresponding reduction of the positive voltage at Pin 3. A decrease in this voltage will result in a shorter on time for the chopper transistor and therefor a lowering of the output voltage and vice versa, oscillation frequency also varies according to load, the higher the load the lower the frequency etc. should the voltage at pin 3 exceed 2.3v an internal flip flop is triggered causing the chopper drive mark space ratio to extend to 244 (off time) to 1 (on time), the chip is now in over volts trip condition. Pin 4 At this pin a sawtooth waveform is generated which simulates chopper current, it is produced by a time constant network R810 and C813. C813 charges when the chopper is on and is discharged when the chopper is off, by an internal switch strapping pin 4 to the internal +2v reference, see Fig 2. The amplitude of the ramp is proportional to chopper drive. In an overload condition it reaches 4v amplitude at which point chopper drive is reduced to a mark-space ratio of 13 to 1, the chip is then in over current trip. The I.C. can easily withstand a short circuit on the H.T. rail and in such a case the power supply simply squegs quietly. Pin 4 is protected by internal protection components which limit the maximum voltage at this pin to 6.5v. Should a fault occur in either of the time constant components, then the chopper transistor will probably be destroyed. Pin 5 This pin can be used for remote control on/off switching of the power supply, it is normally held at about +7v and will cause the chip to enter standby mode if it falls below 2v. Pin 6 Ground. Pin 7 Chopper switch off pin. This pin clamps the chopper drive voltage to 1.6v in order to switch off the chopper. Pin 8 Chopper base current output drive pin. Pin 9 L.T. pin, approximately 9v under start-up conditions and 16v during normal running, Current consumption of the I.C. is typically 135mA. The voltage at this pin must reach 6.7v in order for the chip to start-up.

DESCRIPTIONS Pin 1 This is a 4v reference produced within the I.C. Pin 2 This pin detects the exact point at which energy stored in the chopper transformer collapses to zero via R824 and R825, and allows Q1 to deliver drive volts to the chopper transistor. It also opens the switch at pin 4 allowing the external capacitor C813 to charge from its external feed resistor R810. Pin 3 H.T. control/feedback via photo coupler D830. The voltage at this pin controls the on time of the chopper transistor and hence the output voltage. Normally it runs at Approximately 2v and regulates H.T. by sensing a proportion of the +4v reference at pin 1, offset by conduction of the photo coupler D830 which acts like a variable resistor. An increase in the conduction of transistor D830 and therefor a reduction of its resistance will cause a corresponding reduction of the positive voltage at Pin 3. A decrease in this voltage will result in a shorter on time for the chopper transistor and therefor a lowering of the output voltage and vice versa, oscillation frequency also varies according to load, the higher the load the lower the frequency etc. should the voltage at pin 3 exceed 2.3v an internal flip flop is triggered causing the chopper drive mark space ratio to extend to 244 (off time) to 1 (on time), the chip is now in over volts trip condition. Pin 4 At this pin a sawtooth waveform is generated which simulates chopper current, it is produced by a time constant network R810 and C813. C813 charges when the chopper is on and is discharged when the chopper is off, by an internal switch strapping pin 4 to the internal +2v reference, see Fig 2. The amplitude of the ramp is proportional to chopper drive. In an overload condition it reaches 4v amplitude at which point chopper drive is reduced to a mark-space ratio of 13 to 1, the chip is then in over current trip. The I.C. can easily withstand a short circuit on the H.T. rail and in such a case the power supply simply squegs quietly. Pin 4 is protected by internal protection components which limit the maximum voltage at this pin to 6.5v. Should a fault occur in either of the time constant components, then the chopper transistor will probably be destroyed. Pin 5 This pin can be used for remote control on/off switching of the power supply, it is normally held at about +7v and will cause the chip to enter standby mode if it falls below 2v. Pin 6 Ground. Pin 7 Chopper switch off pin. This pin clamps the chopper drive voltage to 1.6v in order to switch off the chopper. Pin 8 Chopper base current output drive pin. Pin 9 L.T. pin, approximately 9v under start-up conditions and 16v during normal running, Current consumption of the I.C. is typically 135mA. The voltage at this pin must reach 6.7v in order for the chip to start-up.THE TDA4600 is an IC Semiconductor circuit for sup

plying power to electrical equipment

includes a control circuit with a first terminal for reference voltage

connected, via a voltage divider formed of series connected resistances,

to the anode of a diode; a second terminal for zero-crossing

identification connected via a resistance to the cathode of the diode; a

third terminal serving as an actual value input directly connected to a

divider point of the voltage divider; a fourth terminal delivering a

sawtooth voltage connected via a resistance to a terminal of a

transformer primary winding; a fifth terminal serving as a protective

input connected via a resistance to the cathode of another diode and,

via two other resistances, to the cathode of a third diode having an

anode connected to an input of a rectifier circuit; a sixth terminal for

a reference potential connected via a capacitor to the fourth terminal

and via another capacitor to the anode of the first-mentioned diode; a

seventh terminal and an eighth terminal for respectively determining a

control pulse potential of and pulse-controlling a transistor both

connected via a resistance to a capacitor leading to the base of the

transistor; and a ninth terminal serving as a power-supply input

connected both to the cathode of the other diode and, via a capacitor,

to a respective terminal of two secondary windings of the transformer.

plying power to electrical equipment

includes a control circuit with a first terminal for reference voltage

connected, via a voltage divider formed of series connected resistances,

to the anode of a diode; a second terminal for zero-crossing

identification connected via a resistance to the cathode of the diode; a

third terminal serving as an actual value input directly connected to a

divider point of the voltage divider; a fourth terminal delivering a

sawtooth voltage connected via a resistance to a terminal of a

transformer primary winding; a fifth terminal serving as a protective

input connected via a resistance to the cathode of another diode and,

via two other resistances, to the cathode of a third diode having an

anode connected to an input of a rectifier circuit; a sixth terminal for

a reference potential connected via a capacitor to the fourth terminal

and via another capacitor to the anode of the first-mentioned diode; a

seventh terminal and an eighth terminal for respectively determining a

control pulse potential of and pulse-controlling a transistor both

connected via a resistance to a capacitor leading to the base of the

transistor; and a ninth terminal serving as a power-supply input

connected both to the cathode of the other diode and, via a capacitor,

to a respective terminal of two secondary windings of the transformer. 1.

Semiconductor circuit for supplying power to electrical equipment,

comprising a transformer having a primary winding connected, via a

parallel connection of a collector-emitter path of a transistor with a

first capacitor, to both outputs of a rectifier circuit supplied, in

turn, by a line a-c voltage; said transistor having a base controlled

via a second capacitor by an output of a control circuit acted upon, in

turn by the rectified a-c line voltage as actual value and by a

reference voltage; said transformer having a first secondary winding to

which the electrical equipment to be supplied is connected; said

transformer having a second secondary winding with one terminal thereof

connected to the emitter of said transistor and the other terminal

thereof connected to an anode of a first diode leading to said control

circuit; said transformer having a third secondary winding with one

terminal thereof connected, on the one hand, via a series connection of a

third capacitor with a first resistance, to the other terminal of said

third secondary winding and connected, on the other hand, to the emitter

of said transistor, the collector of which is connected to said primary

winding; a point between said third capacitor and said first resistance

being connected to the cathode of a second diode; said control circuit

having nine terminals including a first terminal delivering a reference

voltage and connected, via a voltage divider formed of a third and

fourth series-connected resistances, to the anode of said second diode; a

second terminal of said control circuit serving for zero-crossing

identification being connected via a fifth resistance to said cathode of

said second diode; a third terminal of said control-circuit serving as

actual value input being directly connected to a divider point of said

voltage divider forming said connection of said first terminal of said

control circuit to said anode of said second diode; a fourth terminal of

said control circuit delivering a sawtooth voltage being connected via a

sixth resistance to a terminal of said primary winding of said

transforme

1.

Semiconductor circuit for supplying power to electrical equipment,

comprising a transformer having a primary winding connected, via a

parallel connection of a collector-emitter path of a transistor with a

first capacitor, to both outputs of a rectifier circuit supplied, in

turn, by a line a-c voltage; said transistor having a base controlled

via a second capacitor by an output of a control circuit acted upon, in

turn by the rectified a-c line voltage as actual value and by a

reference voltage; said transformer having a first secondary winding to

which the electrical equipment to be supplied is connected; said

transformer having a second secondary winding with one terminal thereof

connected to the emitter of said transistor and the other terminal

thereof connected to an anode of a first diode leading to said control

circuit; said transformer having a third secondary winding with one

terminal thereof connected, on the one hand, via a series connection of a

third capacitor with a first resistance, to the other terminal of said

third secondary winding and connected, on the other hand, to the emitter

of said transistor, the collector of which is connected to said primary

winding; a point between said third capacitor and said first resistance

being connected to the cathode of a second diode; said control circuit

having nine terminals including a first terminal delivering a reference

voltage and connected, via a voltage divider formed of a third and

fourth series-connected resistances, to the anode of said second diode; a

second terminal of said control circuit serving for zero-crossing

identification being connected via a fifth resistance to said cathode of

said second diode; a third terminal of said control-circuit serving as

actual value input being directly connected to a divider point of said

voltage divider forming said connection of said first terminal of said

control circuit to said anode of said second diode; a fourth terminal of

said control circuit delivering a sawtooth voltage being connected via a

sixth resistance to a terminal of said primary winding of said

transforme r

facing away from said transistor; a fifth terminal of said control

circuit serving as a protective input being connected, via a seventh

resistance to the cathode of said first diode and, through the

intermediary of said seventh resistance and an eighth resistance, to the

cathode of a third diode having an anode connected to an input of said

rectifier circuit; a sixth terminal of said control circuit carrying

said reference potential and being connected via a fourth capacitor to

said fourth terminal of said control circuit and via a fifth capacitor

to the anode of said second diode; a seventh terminal of said control

circuit establishing a potential for pulses controlling said transistor

being connected directly and an eighth terminal of said control circuit

effecting pulse control of the base of said transistor being connected

through the intermediary of a ninth resistance to said first capacitor

leading to the base of said transistor; and a ninth terminal of said

control circuit serving as a power supply input of said control circuit

being connected both to the cathode of said first diode as well as via

the intermediary of a sixth capacitor to a terminal of said second

secondary winding as well as to a terminal of said third secondary

winding.

r

facing away from said transistor; a fifth terminal of said control

circuit serving as a protective input being connected, via a seventh

resistance to the cathode of said first diode and, through the

intermediary of said seventh resistance and an eighth resistance, to the

cathode of a third diode having an anode connected to an input of said

rectifier circuit; a sixth terminal of said control circuit carrying

said reference potential and being connected via a fourth capacitor to

said fourth terminal of said control circuit and via a fifth capacitor

to the anode of said second diode; a seventh terminal of said control

circuit establishing a potential for pulses controlling said transistor

being connected directly and an eighth terminal of said control circuit

effecting pulse control of the base of said transistor being connected

through the intermediary of a ninth resistance to said first capacitor

leading to the base of said transistor; and a ninth terminal of said

control circuit serving as a power supply input of said control circuit

being connected both to the cathode of said first diode as well as via

the intermediary of a sixth capacitor to a terminal of said second

secondary winding as well as to a terminal of said third secondary

winding.Description:

The invention relates to a blocking oscillator type switching power supply for supplying power to electrical equipment, wherein the primary winding of a transformer, in series

with

the emitter-collector path of a first bipolar transistor, is connected

to a d-c voltage obtained by rectification of a line a-c voltage fed-in

via two external supply terminals, and a secondary winding of the

transformer is provided for supplying power to the electrical equipment,

wherein, furthermore, the first bipolar transistor has a base

controlled by the output of a control circuit which is acted upon in

turn by the rectified a-c line voltage as actual value and by a

set-point transmitter, and wherein a starting circuit for further

control of the base of the first bipolar transistor is provided.

with

the emitter-collector path of a first bipolar transistor, is connected

to a d-c voltage obtained by rectification of a line a-c voltage fed-in

via two external supply terminals, and a secondary winding of the

transformer is provided for supplying power to the electrical equipment,

wherein, furthermore, the first bipolar transistor has a base

controlled by the output of a control circuit which is acted upon in

turn by the rectified a-c line voltage as actual value and by a

set-point transmitter, and wherein a starting circuit for further

control of the base of the first bipolar transistor is provided.Such a blocking oscillator switching power supply is described in the German periodical, "Funkschau" (1975) No. 5, pages 40 to 44. It is well known that the purpose of such a circuit is to supply electronic equip

ment,

for example, a television set, with stabilized and controlled supply

voltages. Essential for such switching power supply is a power switching

transistor i.e. a bipolar transistor with high switching speed and high

reverse voltage. This transistor therefore constitutes an important

component of the control element of the control circuit. Furthermore, a

high operating frequency and a transformer intended for a high operating

frequency are provided, because generally, a thorough separation of the

equipment to be supplied from the supply naturally is desired. Such

switching power supplies may be constructed either for synchronized or

externally controlled operation or for non-synchronized or free-running

operation. A blocking converter is understood to be a switching power

supply in which power is delivered to the equipment to be supplied only

if the switching transist

ment,

for example, a television set, with stabilized and controlled supply

voltages. Essential for such switching power supply is a power switching

transistor i.e. a bipolar transistor with high switching speed and high

reverse voltage. This transistor therefore constitutes an important

component of the control element of the control circuit. Furthermore, a

high operating frequency and a transformer intended for a high operating

frequency are provided, because generally, a thorough separation of the

equipment to be supplied from the supply naturally is desired. Such

switching power supplies may be constructed either for synchronized or

externally controlled operation or for non-synchronized or free-running

operation. A blocking converter is understood to be a switching power

supply in which power is delivered to the equipment to be supplied only

if the switching transist or

establishing the connection between the primary coil of the transformer

and the rectified a-c voltage is cut off. The power delivered by the

line rectifier to the primary coil of the transformer while the

switching transistor is open, is interim-stored in the transformer and

then delivered to the consumer on the secondary side of the transformer

with the switching transistor cut off.

or

establishing the connection between the primary coil of the transformer

and the rectified a-c voltage is cut off. The power delivered by the

line rectifier to the primary coil of the transformer while the

switching transistor is open, is interim-stored in the transformer and

then delivered to the consumer on the secondary side of the transformer

with the switching transistor cut off.In the blocking converter described in the aforementioned reference in the literature, "Funkschau" (1975), No. 5, Pages 40 to 44, the power switching transistor is connected in the manner defined in the introduction to this application. In addition, a so-called starting circuit is provided. Because several diodes are generally provided in the overall circuit of a blocking oscillator according to the definition provided in the introduction hereto, it is necessary, in order not to damage these diodes, that due to the collector peak current in the case of a short circuit, no excessive stress of these diodes and possibly existing further sensitive circuit parts can occur.

Considering the operation of a blocking oscillator, this means that, in the event of a short circuit, the number of collector current pulses per unit time must be reduced. For this purpose, a control and regulating circuit is provided. Simultaneously, a starting circuit must bring the blocking converter back to normal operation when the equipment is switched on, and after disturbances, for example, in the event of a short circuit. The starting circuit shown in the literature reference "Funkschau" on Page 42 thereof, differs to some extent already from the conventional d-c starting circuits. It is commonly known for all heretofore known blocking oscillator circuits, however, that a thyristor or an equivalent circuit replacing the thyristor is essential for the operation of the control circuit.

It is accordingly an object of the invention to provide another starting circuit. It is a further object of th

e

invention to provide a possible circuit for the control circuit which

is particularly well suited for this purpose. It is yet another object

of the invention to provide such a power supply which is assured of

operation over the entire range of line voltages from 90 to 270 V a-c,

while the secondary voltages and secondary load variations between

no-load and short circuit are largely constant.

e

invention to provide a possible circuit for the control circuit which

is particularly well suited for this purpose. It is yet another object

of the invention to provide such a power supply which is assured of

operation over the entire range of line voltages from 90 to 270 V a-c,

while the secondary voltages and secondary load variations between

no-load and short circuit are largely constant.With the foregoing and other objects in view, there is provided, in accordance with the invention, a blocking oscillator-type switching power supply for supplying power to electrical equipment wherein a primary winding of a transformer, in series with an emitter-collector path of a first bipolar transistor, is connected to a d-c voltage obtained by rectification of a line a-c voltage fed-in via two external supply terminals, a secondary winding of the transformer being connectible to the electrical equipment for supplying power thereto, the first bipolar transistor having a base controlled by the output of a control circuit acted upon, in turn, by the rectified a-c line voltage as actual value and by a set-point transmitter, and including a starting circuit for further control of the base of the first bipolar transistor, including a first diode in the starting circuit having an anode directly connected to one of the supply terminals supplied by the a-c line voltage and a cathode connected via a resistor to an input serving to supply power to the control circuit, the input being directly connected to a cathode of a second diode, the second diode having an anode connected to one terminal of another secondary winding of the transformer, the other secondary winding having another terminal connected to the emitter of the first bipolar transmitter.

In accordance with another feature of the inventio

n,

there is provided a second bipolar transistor having the same

conduction type as that of the first bipolar transistor and connected in

the starting circuit with the base thereof connected to a cathode of a

semiconductor diode, the semiconductor diode having an anode connected

to the emitter of the first bipolar transistor, the second bipolar

transistor having a collector connected via a resistor to a cathode of

the first diode in the starting circuit, and having an emitter connected

to the input serving to supply power to the control circuit and also

connected to the cathode of the second diode which is connected to the

other secondary winding of the transformer.

n,

there is provided a second bipolar transistor having the same

conduction type as that of the first bipolar transistor and connected in

the starting circuit with the base thereof connected to a cathode of a

semiconductor diode, the semiconductor diode having an anode connected

to the emitter of the first bipolar transistor, the second bipolar

transistor having a collector connected via a resistor to a cathode of

the first diode in the starting circuit, and having an emitter connected

to the input serving to supply power to the control circuit and also

connected to the cathode of the second diode which is connected to the

other secondary winding of the transformer.In accordance with a further feature of the invention, the base of the second bipolar transistor is connected to a resistor and via the latter to one pole of a first capacitor, the anode of the first diode being connected to the other pole of the first capacitor.

In accordance with an added feature of the invention, the input serving to supply power to the control circuit is connected via a second capacitor to an output of a line rectifier, the output of the line rectifier being directly connected to the emitter of the first bipolar transistor.

In accordance with an additional feature of the invention, the other secondary winding is connected at one end to the emitter of the first bipolar transistor and to a pole of a third capacitor, the third capacitor having a

nother

pole connected, on the one hand, via a resistor, to the other end of

the other secondary winding and, on the other hand, to a cathode of a

third diode, the third diode having an anode connected via a

potentiometer to an actual value input of the control circuit and, via a

fourth capacitor, to the emitter of the first bipolar transistor.

nother

pole connected, on the one hand, via a resistor, to the other end of

the other secondary winding and, on the other hand, to a cathode of a

third diode, the third diode having an anode connected via a

potentiometer to an actual value input of the control circuit and, via a

fourth capacitor, to the emitter of the first bipolar transistor.In accordance with yet another feature of the invention, the control circuit has a control output connected via a fifth capacitor to the base of the first bipolar transistor for conducting to the latter control pulses generated in the control circuit.

In accordance with a concomitant feature of the invention, there is provided a sixth capacitor shunting the emitter-collector path of the first transistor.

Other features which are considered as characteristic for the invention are set forth in the appended claim.

Although the invention is illustrated and described herein as embodied in a blocking oscillator type switching power supply, it is nevertheless not intended to be limited to the details shown, since various modifications and structural changes may be made therein without departing from the spirit of the invention and within the scope and range of equivalents of the claims.

The construction and method of operation of the invention, however, together with additional objects and advantages thereof will be best understood from the following description of specific embodiments when read in connection with the accompanying drawings, in which:

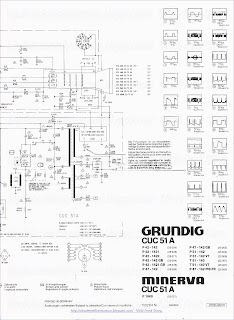

FIGS. 1 and 2 are circuit diagrams of the blocking oscillator type switching power supply according to the invention; and

FIG. 3 is a circuit diagram of the control unit RS of FIGS. 1 and 2.

Referring now to the drawing and, first, particularly to FIG. 1 thereof, there is shown a rectifier circuit G in the form of a bridge current, which is acted upon by a line input represented by two supply terminals 1' and 2'. Rectifier outputs 3' and 4' are shunted by an emitter-collector path of an NPN power transistor T1 i.e. t

he

series connection of the so-called first bipolar transistor referred to

hereinbefore with a primary winding I of a transformer Tr. Together

with the inductance of the transformer Tr, the capacitance C1 determines

the frequency and limits the opening voltages of the switch embodied by

the first transistor T1. A capacitance C2, provided between the base of

the first transistor T1 and the control output 7,8 of a control circuit

RS, separates the d-c potentials of the control or regulating circuit

RS and the switching transistor T1 and serves for addressing this

switching transistor T1 with pulses. A resistor R1 provided at the

control output 7,8 of the control circuit RS is the negative-feedback

resistor of both output stages of the control circuit RS. It determines

the maximally possible output pulse current of the control circuit RS. A

secondary winding II of the transformer Tr takes over the power supply

of the control circuit, in steady state operation, via the diode D1. To

this end, the cathode of this diode D1 is directly connected to a power

supply input 9 of the control circuit RS, while the anode thereof is

connected to one terminal of the secondary winding II. The other

terminal of the secondary winding II is connected to the emitter of the

power switching transistor T1.

he

series connection of the so-called first bipolar transistor referred to

hereinbefore with a primary winding I of a transformer Tr. Together

with the inductance of the transformer Tr, the capacitance C1 determines

the frequency and limits the opening voltages of the switch embodied by

the first transistor T1. A capacitance C2, provided between the base of

the first transistor T1 and the control output 7,8 of a control circuit

RS, separates the d-c potentials of the control or regulating circuit

RS and the switching transistor T1 and serves for addressing this

switching transistor T1 with pulses. A resistor R1 provided at the

control output 7,8 of the control circuit RS is the negative-feedback

resistor of both output stages of the control circuit RS. It determines

the maximally possible output pulse current of the control circuit RS. A

secondary winding II of the transformer Tr takes over the power supply

of the control circuit, in steady state operation, via the diode D1. To

this end, the cathode of this diode D1 is directly connected to a power

supply input 9 of the control circuit RS, while the anode thereof is

connected to one terminal of the secondary winding II. The other

terminal of the secondary winding II is connected to the emitter of the

power switching transistor T1.The cathode of the diode D1 and, therewith, the power supply terminal 9 of the control circuits RS are furthermore connected to one pole of a capacitor C3, the other pole of which is connected to the output 3' of the rectifier G. The capacitance of this capacitor C3 thereby smoothes the positive half-wave pulses and serves simultaneously as an energy storage device during the starting period. Another secondary windi

ng

III of the transformer Tr is connected by one of the leads thereof

likewise to the emitter of the first transistor T1, and by the other

lead thereof via a resistor R2, to one of the poles of a further

capacitor C4, the other pole of which is connected to the

first-mentioned lead of the other secondary winding III. This second

pole of the capacitor C4 is simultaneously connected to the output 3' of

the rectifier circuit G and, thereby, via the capacitor C3, to the

cathode of the diode D1 driven by the secondary winding II of the

transformer Tr as well as to the power supply input 9 of the control

circuit RS and, via a resistor R9, to the cathode of a second diode D4.

The second pole of the capacitor C4 is simultaneously connected directly

to the terminal 6 of the control circuit RS and, via a further

capacitor C 6, to the terminal 4 of the control circuit RS as well as,

additionally, via the resistor R6, to the other output 4' of the

rectifier circuit G. The other of the poles of the capacitor C4 acted

upon by the secondary winding II is connected via a further capacitor C5

to a node, which is connected on one side thereof, via a variable

resistor R4, to the terminals 1 and 3 of the control circuit RS, with

the intermediary of a fixed resistor R5 in the case of the terminal 1.

On the other side of the node, the latter and, therefore, the capacitor

C5 are connected to the anode of a third diode D2, the cathode of which

is connected on the one hand, to the resistor R2 mentioned hereinbefore

and leads to the secondary winding III of the transformer Tr and, on the

other hand, via a resistor R3 to the terminal 2 of the control circuit

RS.

ng

III of the transformer Tr is connected by one of the leads thereof

likewise to the emitter of the first transistor T1, and by the other

lead thereof via a resistor R2, to one of the poles of a further

capacitor C4, the other pole of which is connected to the

first-mentioned lead of the other secondary winding III. This second

pole of the capacitor C4 is simultaneously connected to the output 3' of

the rectifier circuit G and, thereby, via the capacitor C3, to the

cathode of the diode D1 driven by the secondary winding II of the

transformer Tr as well as to the power supply input 9 of the control

circuit RS and, via a resistor R9, to the cathode of a second diode D4.

The second pole of the capacitor C4 is simultaneously connected directly

to the terminal 6 of the control circuit RS and, via a further

capacitor C 6, to the terminal 4 of the control circuit RS as well as,

additionally, via the resistor R6, to the other output 4' of the

rectifier circuit G. The other of the poles of the capacitor C4 acted

upon by the secondary winding II is connected via a further capacitor C5

to a node, which is connected on one side thereof, via a variable

resistor R4, to the terminals 1 and 3 of the control circuit RS, with

the intermediary of a fixed resistor R5 in the case of the terminal 1.

On the other side of the node, the latter and, therefore, the capacitor

C5 are connected to the anode of a third diode D2, the cathode of which

is connected on the one hand, to the resistor R2 mentioned hereinbefore

and leads to the secondary winding III of the transformer Tr and, on the

other hand, via a resistor R3 to the terminal 2 of the control circuit

RS.The nine terminals of the control circuit RS have the following purposes or functions:

Terminal 1 supplies the internally generated reference voltage to ground i.e. the nominal or reference value required for the control or regulating process;

Terminal 2 serves as input for the oscillations provided by the secondary winding III, at the zero point of which, the pulse start of the driving pulse takes place;

Terminal 3 is the control input, at which the existing actual value is communicated to the control circuit RS, that actual value being generated by the rectified oscillations at the secondary winding III;

Terminal 4 is responsive to the occurrence of a maximum excursion i.e. when the largest current flows through the first transistor T1 ;

Terminal 5 is a protective input which responds if the rectified line voltage drops too sharply; Terminal 6 serves for the power supply of the control process and, indeed, as ground terminal;

Terminal 7 supplies the d-c component required for charging the coupling capacitor C2 leading to the base of the first transistor T1 ;

Terminal 8 supplies the control pulse required for the base of the first transistor T1 ; and

Terminal 9 serves as the first terminal of the power supply of the control circuit RS.

Further details of the control circuit RS are described hereinbelow.

The capacity C3 smoothes the positive half-wave pulses which are provided by the secondary winding II, and simultaneously serves as an energy storage device during the starting time. The secondary winding III generates the control voltage and is simultaneously used

as

feedback. The time delay stage R2 /C4 keeps harmonics and fast

interference spikes away from the control circuit RS. The resistor R3 is

provided as a voltage divider for the second terminal of the control

circuit RS. The diode D2 rectifies the control pulses delivered by the

secondary winding III. The capacity C5 smoothes the control voltage. A

reference voltage Uref, which is referred to ground i.e. the potential

of terminal 6 is present at the terminal 1 of the control circuit RS.

The resistors R4 and R5 form a voltage divider of the input-difference

control amplifier at the terminal 3. The desired secondary voltage can

be set manually via the variable resistor R4. A time-delay stage R6 /C6

forms a sawtooth rise which corresponds to the collector current rise of

the first bipolar transistor T1 via the primary winding I of the

transformer Tr. The sawtooth present at the terminal 4 of the control

circuit RS is limited there between the reference voltage 2 V and 4 V.

The voltage divider R7 /R8 (FIG. 2), brings to the terminal 5 of the

control circuit RS the enabling voltage for the drive pulse at the

output 8 of the control circuit RS.

as

feedback. The time delay stage R2 /C4 keeps harmonics and fast

interference spikes away from the control circuit RS. The resistor R3 is

provided as a voltage divider for the second terminal of the control

circuit RS. The diode D2 rectifies the control pulses delivered by the

secondary winding III. The capacity C5 smoothes the control voltage. A

reference voltage Uref, which is referred to ground i.e. the potential

of terminal 6 is present at the terminal 1 of the control circuit RS.

The resistors R4 and R5 form a voltage divider of the input-difference

control amplifier at the terminal 3. The desired secondary voltage can

be set manually via the variable resistor R4. A time-delay stage R6 /C6

forms a sawtooth rise which corresponds to the collector current rise of

the first bipolar transistor T1 via the primary winding I of the

transformer Tr. The sawtooth present at the terminal 4 of the control

circuit RS is limited there between the reference voltage 2 V and 4 V.

The voltage divider R7 /R8 (FIG. 2), brings to the terminal 5 of the

control circuit RS the enabling voltage for the drive pulse at the

output 8 of the control circuit RS.The diode D4, together with the resistor R9 in cooperation with the diode D1 and the secondary winding II, forms the starting circuit provided, in accordance with the invention. The operation thereof is as follows:

After the switching power supply is switched on, d-c voltages build up at the collector of the switching transistor T1 and at the input 4 of the control circuit RS, as a function in time of the predetermined time constants. The positive sinusoidal half-waves charge the capacitor C3 via the starting diode D4 and the starting resistor R9 in dependence upon the time constant R9.C3. Via the protective input terminal 5 and the resisto

r

R11 not previously mentioned and forming the connection between the

resistor R9 and the diode D1, on the one hand, and the terminal 5 of the

control circuit RS, on the other hand, the control circuit RS is biased

ready for switching-on, and the capacitor C2 is charged via the output

7. When a predetermined voltage value at the capacitor C3 or the power

supply input 9 of the control circuit RS, respectively, is reached, the

reference voltage i.e. the nominal value for the operation of the

control voltage RS, is abruptly formed, which supplies all stages of the

control circuit and appears at the output 1 thereof. Simultaneously,

the switching transistor T1 is switched into conduction via the output

8. The switching of the transistor T1 at the primary winding T of the

transformer Tr is transformed to the second secondary winding II, the

capacity C3 being thereby charged up again via the diode D1. If

sufficient energy is stored in the capacitor C3 and if the re-charge via

the diode D1 is sufficient so that the voltage at a supply input 9 does

not fall below the given minimum operating voltage, the switching power

supply then remains connected, so that the starting process is

completed. Otherwise, the starting process described is repeated several

times.

r

R11 not previously mentioned and forming the connection between the

resistor R9 and the diode D1, on the one hand, and the terminal 5 of the

control circuit RS, on the other hand, the control circuit RS is biased

ready for switching-on, and the capacitor C2 is charged via the output

7. When a predetermined voltage value at the capacitor C3 or the power

supply input 9 of the control circuit RS, respectively, is reached, the

reference voltage i.e. the nominal value for the operation of the

control voltage RS, is abruptly formed, which supplies all stages of the

control circuit and appears at the output 1 thereof. Simultaneously,

the switching transistor T1 is switched into conduction via the output

8. The switching of the transistor T1 at the primary winding T of the

transformer Tr is transformed to the second secondary winding II, the

capacity C3 being thereby charged up again via the diode D1. If

sufficient energy is stored in the capacitor C3 and if the re-charge via

the diode D1 is sufficient so that the voltage at a supply input 9 does

not fall below the given minimum operating voltage, the switching power

supply then remains connected, so that the starting process is

completed. Otherwise, the starting process described is repeated several

times.In FIG. 2, there is shown a further embodiment of the circuit for a blocking oscillator type switching power supply, according to the invention, as shown in FIG. 1. Essential for this circuit of FIG. 2 is the presence of a second bipolar transistor T2 of the type of the first bipolar transistor T1 (i.e. in the embodiments of the invention, an npn-transistor), which forms a further component of the starting circuit and is connected with the collector-emitter path thereof between the resistor R9 of the starting circuit and the current supply input 9 of the control circuit RS. The base of this second transistor T2 is connected to a node which leads, on the one hand, via a resistor R10 to one electrode of a capacitor C7, the other electrode of which is connected to the anode of the diode D4 of the starting circuit and, accordingl

y,

to the terminal 1' of the supply input of the switching power supply G.

On the other hand, the last-mentioned node and, therefore, the base of

the second transistor T2 are connected to the cathode of a Zener diode

D3, the anode of which is connected to the output 3' of the rectifier G

and, whereby, to one pole of the capacitor C3, the second pole of which

is connected to the power supply input 9 of the control circuit RS as

well as to the cathode of the diode D1 and to the emitter of the second

transistor T2. In other respects, the circuit according to FIG. 2

corresponds to the circuit according to FIG. 1 except for the resistor

R11 which is not necessary in the embodiment of FIG. 2, and the missing

connection between the resistor R9 and the cathode of the diode D1,

respectively, and the protective input 5 of the control circuit RS.

y,

to the terminal 1' of the supply input of the switching power supply G.

On the other hand, the last-mentioned node and, therefore, the base of

the second transistor T2 are connected to the cathode of a Zener diode

D3, the anode of which is connected to the output 3' of the rectifier G

and, whereby, to one pole of the capacitor C3, the second pole of which

is connected to the power supply input 9 of the control circuit RS as

well as to the cathode of the diode D1 and to the emitter of the second

transistor T2. In other respects, the circuit according to FIG. 2

corresponds to the circuit according to FIG. 1 except for the resistor

R11 which is not necessary in the embodiment of FIG. 2, and the missing

connection between the resistor R9 and the cathode of the diode D1,

respectively, and the protective input 5 of the control circuit RS.Regarding the operation of the starting circuit according to FIG. 2,

it can be stated that the positive sinusoidal half-wave of the line

voltage, delayed by the time delay stage C7, R10 drives the base of the

transistor T2 in the starting circuit. The amplitude is limited by the

diode D3 which is provided for overvoltage protection of the control

circuit RS and which is preferably incorporated as a Zener diode. The

second transistor T2 is switched into conduction. The capacity C3 is

charged, via the serially connected diode D4 and the resistor R9 and the

collector-emitter path of the transistor T2, as soon as the voltage

between the terminal 9 and the terminal 6 of the control circuit RS i.e.

the voltage U9, meets the condition U9 <[UDs -UBE (T2)].

it can be stated that the positive sinusoidal half-wave of the line

voltage, delayed by the time delay stage C7, R10 drives the base of the

transistor T2 in the starting circuit. The amplitude is limited by the

diode D3 which is provided for overvoltage protection of the control

circuit RS and which is preferably incorporated as a Zener diode. The

second transistor T2 is switched into conduction. The capacity C3 is

charged, via the serially connected diode D4 and the resistor R9 and the

collector-emitter path of the transistor T2, as soon as the voltage

between the terminal 9 and the terminal 6 of the control circuit RS i.e.

the voltage U9, meets the condition U9 <[UDs -UBE (T2)].Because of the time constant R9.C3, several positive half-waves are necessary in order to increase the voltage U9 at the supply terminal 9 of the control circuit RS to such an extent that the control circuit RS is energized. During the negative sine half-wave, a partial energy chargeback takes place from the capacitor C3 via the emitter-base path of the transistor T2 of the starting circuit and via the resistor R10 and the capacitor C7, respectively, into the supply network. At approximately 2/3 of the voltage U9, which is limited by the diode D3, the control circuit RS is switched on. At the terminal 1 thereof, the reference voltage Uref then appears. In addition, the voltage divider R5 /R4 becomes effective. At the terminal 3, the control amplifier receives the voltage forming the actual value, while the first bipolar transistor T1 of the blocking-oscillator type switching power supply is addressed pulsewise via the terminal 8.

Because the capacitor C6 is charged via the resistor R6, a higher voltage than Uref is present at the terminal 4 if the control circuit RS is activated. The control voltage then discharges the capacitor C6 via the terminal 4 to half the value of the reference voltage Uref, and immediately cuts off the addressing input 8 of the control circuit RS. The first driving pulse of the switching transistor T1 is thereby limited to a minimum of time. The power for switching-on the control circuit RS and for driving the transistor T1 is supplied by the capacitor C3. The voltage U9 at the capacitor C3 then drops. If the voltage U9 drops below the switching-off voltage value of the control circuit RS, the latter is then inactivated. The next positive sine half-wave would initiate the starting process again.

By switching the transistor T1, a voltage is transformed in the secondary winding II of the transformer Tr. The positive component is rectified by the diode D1, recharing of the capacitor C3 being thereby provided. The voltage U9 at the output 9 does not, therefore, drop below the minimum value required for the operation of the control circuit RS, so that the control circuit RS remains activated. The power supply continues to operate in the rhythm of the existing conditions. In operation, the voltage U9 at the supply terminal 9 of the control circuit RS has a value which meets the condition U9 >[UDs -UBE (T2)], so that the transistor T2 of the starting circuit remains cut off.

For the internal layout of the control circuit RS, the construction shown, in particular, from FIG. 3 is advisable. This construction is realized, for example, in the commercially available type TDA 4600 (Siemens AG).

The block diagram of the control circuit according to FIG. 3

shows

the power supply thereof via the terminal 9, the output stage being

supplied directly whereas all other stages are supplied via Uref. In the

starting circuit, the individual subassemblies are supplied with power

sequentially. The d-c output voltage potential of the base current gain

i.e. the voltage for the terminal 8 of the control circuit RS, and the

charging of the capacitor C2 via the terminal 7 are formed even before

the reference voltage Uref appears. Variations of the supply voltage U9

at terminal 9 and the power fluctuations at the terminal 8/terminal 7

and at the terminal 1 of the control circuit RS are leveled or smoothed

out by the voltage control. The temperature sensitivity of the control

circuit RS and, in particular, the uneven heating of the output and

input stages and input stages on the semiconductor chip containing the

control circuit in monolithically integrated form are intercepted by the

temperature compensation provided. The output values are constant in a

specific temperature range. The message for blocking the output stage,

if the supply voltage at the terminal 9 is too low, is given also by

this subassembly to a provided control logic.

shows

the power supply thereof via the terminal 9, the output stage being

supplied directly whereas all other stages are supplied via Uref. In the

starting circuit, the individual subassemblies are supplied with power

sequentially. The d-c output voltage potential of the base current gain

i.e. the voltage for the terminal 8 of the control circuit RS, and the

charging of the capacitor C2 via the terminal 7 are formed even before

the reference voltage Uref appears. Variations of the supply voltage U9

at terminal 9 and the power fluctuations at the terminal 8/terminal 7

and at the terminal 1 of the control circuit RS are leveled or smoothed

out by the voltage control. The temperature sensitivity of the control

circuit RS and, in particular, the uneven heating of the output and

input stages and input stages on the semiconductor chip containing the

control circuit in monolithically integrated form are intercepted by the

temperature compensation provided. The output values are constant in a

specific temperature range. The message for blocking the output stage,

if the supply voltage at the terminal 9 is too low, is given also by

this subassembly to a provided control logic.The outer voltage divider of the terminal 1 via the r

esistors

R5 and R4 to the control tap U forms, via terminal 3, the variable side

of the bridge for the control amplifier formed as a differential

amplifier. The fixed bridge side is formed by the reference voltage Uref

via an internal voltage divider. Similarly formed are circuit portions

serving for the detection of an overload short circuit and circuit

portions serving for the "standby" no-load detection, which can be

operated likewise via terminal 3.

esistors

R5 and R4 to the control tap U forms, via terminal 3, the variable side

of the bridge for the control amplifier formed as a differential

amplifier. The fixed bridge side is formed by the reference voltage Uref

via an internal voltage divider. Similarly formed are circuit portions

serving for the detection of an overload short circuit and circuit

portions serving for the "standby" no-load detection, which can be

operated likewise via terminal 3.Within a provided trigger circuit, the driving pulse length is determined as a function of the sawtooth rise at the terminal 4, and is transmitted to the control logic. In the control logic, the commands of the trigger circuit are processed. Through the zero-crossing identification at input 2 in the control circuit RS, the control logic is enabled to start the control input only at the zero point of the frequency oscillation. If the voltages at the terminal 5 and at the terminal 9 are too low, the control logic blocks the output amplifier at the terminal 8. The output amplifier at the terminal 7 which is responsible for the base charge in the capacitor C2, is not touched thereby.

The base current gain for the transistor T1 i.e. for the first transistor in accordance with the definition of the invention, is formed by two amplifiers which mutually operate on the capacitor C2. The roof inclination of the base driving current for the transistor T1 is impressed by the collector current simulation at the terminal 4 to the amplifier at the terminal 8. The control pulse for the transistor T1 at the terminal 8 is always built up to the potential present at the terminal 7. The amplifier working into the terminal 7 ensures that each new switching pulse at the terminal 8 finds the required base level at terminal 7.

Supplementing the comments regarding FIG. 1, it should also be mentioned that the cathode of the diode D1 connected by the anode thereof to the one end of the secondary winding II of the transformer Tr is connected via a resistor R11 to the protective input 5 of the control circuit RS whereas, in the circuit according to FIG. 2, the protective input 5 of the control circuit RS is supplied via a voltage divider R8, R7 directly from the output 3', 4' of the rectifier G delivering the rectified line a-c voltage, and which obtains the voltage required for executing its function. It is evident that the first possible manner of driving the protective input 5 can be used also in the circuit according to FIG. 2, and the second possibility also in a circuit in accordance with FIG. 1.

The control circuit RS which is shown in FIG. 3 and is realized in detail by the building block TDA 4600 and which is particularly well suited in conjunction with the blocking oscillator type switching power supply according to the invention has 9 terminals 1-9, which have the following characteristics, as has been explained in essence hereinabove:

Terminal 1 delivers a reference voltage Uref which serves as the constant-current source of a voltage divider R5.R4 which supplies the required d-c voltages for the differential amplifiers provided for the functions control, overload detection, short-circuit detection and "standby"-no load detection. The dividing point of the voltage divider R5 -R4 is connected to the terminal 3 of the control circuit RS. The terminal 3 provided as the control input of RS is controlled in the manner described hereinabove as input for the actual value of the voltage to be controlled or regulated by the secondary winding III of the transformer Tr. With this input, the lengths of the control pulses for the switching transistor T1 are determined.

Via the input provided by the terminal 2 of the control circuit RS, the zero-point identification in the control circuit is addressed for detecting the zero-point o

f

the oscillations respectively applied to the terminal 2. If this

oscillation changes over to the positive part, then the addressing pulse

controlling the switching transistor T1 via the terminal 8 is released

in the control logic provided in the control circuit.

f

the oscillations respectively applied to the terminal 2. If this

oscillation changes over to the positive part, then the addressing pulse

controlling the switching transistor T1 via the terminal 8 is released

in the control logic provided in the control circuit.A sawtooth-shaped voltage, the rise of which corresponds to the collector current of the switching transistor T1, is present at the terminal 4 and is minimally and maximally limited by two reference voltages. The sawtooth voltage serves, on the one hand as a comparator for the pulse length while, on the other hand, the slope or rise thereof is used to obtain in the base current amplification for the switching transistor T1, via the terminal 8, a base drive of this switching transistor T1 which is proportional to the collector current.

The terminal 7 of the control circuit RS as explained hereinbefore, determines the voltage potential for the addressing pulses of the transistor T2. The base of the switching transistor T1 is pulse-controlled via the terminal 8, as described hereinbefore. Terminal 9 is connected as the power supply input of the control circuit RS. If a voltage level falls below a given value, the terminal 8 is blocked. If a given positive value of the voltage level is exceeded, the control circuit is activated. The terminal 5 releases the terminal 8 only if a given voltage potential is present.

Forei

gn References:

gn References:DE2417628A1 1975-10-23 363/37

DE2638225A1 1978-03-02 363/49

Other References:

Grundig Tech. Info. (Germany), vol. 28, No. 4, (1981).

IBM Technical Disclosure Bulletin, vol. 19, No. 3, pp. 978, 979, Aug. 1976.

German Periodical, "Funkschau", (1975), No. 5, pp. 40 to 44.

Peruth, Gunther (Munich, DE) Siemens Aktiengesellschaft (Berlin and Munich, DE)

CHASSIS CUC 51KT TUNER UNIT (TUNER BAUSTEIN 29504-001.36)

TUA2000 VHF + OSC + MIX TDA5430 VIF TBA120T SIF TBA120T (Siemens) SIF (Sound IF)

TBA120T (Siemens) SIF (Sound IF)

The TUA 2000-4 is a monolithically integrated circuit and suitable as a tuner for the VHF

range up to 400 Mkz, e.g. for TV tuners.

RF section

Few externa! components

Stable oscillator frequency and amplitude with very low interference radiation

Optimal rejection of oscillator and input frequencies at the IF output due to a decoupled

active ring mixer circuit

High interference voltage resistance

High-impedance mixer input, for symmetrical and asymmetrical connections

IF post-amplifier for the UHF IF signal

IF section

@

Optimal cross-talk rejection

@

Large signal-modulation range

@

Low noise figure with wide minimum over large load-impedance range

Circuit description

The TUA 2000-4 contains a symmetrical mixer input, as well as a multiplicative mixer. The

oscillator amplitude is regulated. All oscillator operating currents and voltages are stabilized,

so that the oscillator’s amplitude and frequency are largely independent of temperature

and operating voltage changes.

The IF amplifier has been provided with a high impedance input.

The output has two open collector connections.

During UHF operation, oscillator and mixer are switched off and the UHF IF input coupling

stage is activated.

RF section

Few external components

Stable oscillator frequency and amplitude with very low interference radiation

Optimal rejection of oscillator and input frequencies at the iF output due to a decoupled

active ring mixer circuit

High interference voltage resistance

High-impedance mixer input, for symmetrical and asymmetrical connections

IF post-amplifier for the UHF IF signa!

IF section

@

Optima! cross-talk rejection

@

Large signal-modulation range

@

Low noise figure with wide minimum over large load-impedance range

Pin description

- “Open collector” output of the IF SAW driver

- “Open collector” output of the IF SAW driver

- Input for external reference voltage

- Low-ohmic collector output to the high reference point of a parallel resonant circuit

- High-ohmic base input to the high reference point of a parallel resonant circuit

- Oscillator signal output for counter connection

- GND

- “Open collector” output of the mixer

- “Open collector” output of the mixer

- Supply voltage

- Asymmetrical IF signal input for the UHF IF signal

- Mixer high-impedance differential input

- Mixer high-impedance differential input

- Switching voltage input for the VHF-UHF switch selection

- Asymmetrical signal input of the IF SAW amplifier

- GND

CHASSIS CUC 51KT TUNING UNIT (ABSTIMMUNG BAUSTEIN 29304-003.21).

TMS1100NLP (Texas Instruments) Ucontroller

TMS3705NI (Texas Instruments) Tuning drive / control.

MCM2802P (Motorola) Tuning Memory

TMS1100NLP (Texas Instruments) Ucontroller

TMS3705NI (Texas Instruments) Tuning drive / control.

MCM2802P (Motorola) Tuning Memory

General

| General Information | The TMS1100 is an expanded memory version of the TMS1000. The TMS1100 doubles the RAM and ROM available in the TMS1000. |

Production | Early 1975 |

Architecture

| Type | Data Word | Address Space | Instructions | Assists | Reg's GP | Reg's Math | Reg's Index | IO Ports | Stack | Interrupts | Memory |

| PMOS, MCU | 4-bit | 1KB | 43 Standard Instructions & 1024 Micro- instructions | NA | 1 | 1 | 0 | "K" Inputs 4 bits parallel, "R" Outputs 11 lines / bits, "O" Outputs 8 bits parallel | 1x10bits | None | ROM 2KB RAM 64B |

Texas Instruments TMS1000

General

| General Information | Texas

Instruments was locked in a race with Intel to create the first

microprocessor. By most accounts Intel won with the 4004, but

there are a few die hard TI fans who say the TMS1000 was first, because

it was the first “computer on a chip” and that the 4004 was just a

calculator chip. Texas Instruments followed the Intel 8080 with the 4-bit TMS1000. So, while Intel was leading the industry in microprocessors, TI led with this industry unique design "a computer on a chip", specifically designed for control and automation purposes. The 1000 was the first MCU (MicroComputer Unit) , which is an MPU (MicroProcessor Unit) with other support chips (such as RAM, ROM, counters, timers, I/O interfaces) integrated on to the same silicon chip. The original 1000 family consists of 6 chips the TMS1000 and TMS1200 are basic chips, the TMS1070 and TMS1270 are high voltage versions to interface to displays, the TMS1100 and TMS1300 provide twice the on-board ROM and RAM. The TMS1000, TMS1070, and TMS1100 are 28-lead packages, the TMS1200, TMS1270, and TMS1300 are 40-lead versions of the same chips (just 200 to the 28-lead chip numbers). In the 80's TI added to the 1000 family. The 28-lead TMS1170 started with a TMS1100 base and added fluorescent display drive capability and expanded memory (2KB ROM). The TMS1370 was the same as the TMS1170 and added 27 I/O lines. An expanded memory group based on the original TMS1000 chips was also created. They were the TMS1400, TMS1470, and TMS1700 (64 Bytes RAM, 4KB ROM). There were 40-lead versions of the TMS1400 and TMS1470, which because the TMS1600 and TMS1670. CMOS versions were also added, denoted with a "C" suffix, such as TMS1200C. The TMS1000 also had system evaluator chips. The original evaluator chips were the TMS1098 and TMS1099. These 64-lead evaluator chips were ROM-less versions of their corresponding standard chips. The TMS1099 supported the TMS1000/TMS1200 and the TMS1070/1270. The TMS1098 supported the TMS1100/1300. Later evaluators were introduced to support the entire TMS1000 family, they were the SE1000P (supports TMS1000,1070,1200,1700), SE2200P (supports TMS1100,1170,1300,1370), and the SE1400P (supports 1400, 1470, 1600, 1670). The success of the the TMS1000 is demonstrated by its long lifecycle (over 20 years) and its expanded product line. The TMS1000 is found in many appliances, control systems, and games. Most of these chips were sourced by companies for direct use in their products and will have custom or house numbers on the chips (not the standard numbers listed above). Even TI used custom numbers in its products. |

GRUNDIG SUPER COLOR C2405 SERIE F3015 CHASSIS CUC51KT Microcomputer processing approach for a non-volatile TV station memory tuning system:

A television tuning system having a non-volatile memory for storing

digital tune words is electrically updated by a microcomputer type

architecture control circuitry. A ROM memory matrix is provided for the

storage of VHF minimum and maximum binary tune words corresponding to

each of twelve VHF channels in addition to a UHF minimum and maximum

binary tune word encompassing all possible 72 UHF channels. Tuning of

individual VHF and UHF chanels is accomplished by incrementing or

decrementing a given tune word within the minimum and maximum limits

established in the ROM memory matrix by means of a microcomputer

processing approach.

A television tuning system having a non-volatile memory for storing

digital tune words is electrically updated by a microcomputer type

architecture control circuitry. A ROM memory matrix is provided for the

storage of VHF minimum and maximum binary tune words corresponding to

each of twelve VHF channels in addition to a UHF minimum and maximum

binary tune word encompassing all possible 72 UHF channels. Tuning of

individual VHF and UHF chanels is accomplished by incrementing or

decrementing a given tune word within the minimum and maximum limits

established in the ROM memory matrix by means of a microcomputer

processing approach.

TMS1000 General

General Information:

Texas

Instruments was locked in a race with Intel to create the first

microprocessor. By most accounts Intel won with the 4004, but there are a

few die hard TI fans who say the TMS1000 was first, because it was

the first “computer on a chip” and that the 4004 was just a calculator

chip.

Texas Instruments followed the Intel 8080 with

the 4-bit TMS1000. So, while Intel was leading the industry in

microprocessors, TI led with this industry unique design "a computer on

a chip", specifically designed for control and automation purposes.

The 1000 was the first MCU (MicroComputer Unit) , which is an MPU

(MicroProcessor Unit) with other support chips (such as RAM, ROM,

counters, timers, I/O interfaces) integrated on to the same silicon

chip.

The original 1000 family consists of 6 chips the

TMS1000 and TMS1200 are basic chips, the TMS1070 and TMS1270 are high

voltage versions to interface to displays, the TMS1100 and TMS1300

provide twice the on-board ROM and RAM. The TMS1000, TMS1070, and

TMS1100 are 28-lead packages, the TMS1200, TMS1270, and TMS1300 are

40-lead versions of the same chips (just 200 to the 28-lead chip

numbers).

In the 80's TI added to the 1000 family. The

28-lead TMS1170 started with a TMS1100 base and added fluorescent

display drive capability and expanded memory (2KB ROM). The TMS1370 was

the same as the TMS1170 and added 27 I/O lines. An expanded memory

group based on the original TMS1000 chips was also created. They were

the TMS1400, TMS1470, and TMS1700 (64 Bytes RAM, 4KB ROM). There were

40-lead versions of the TMS1400 and TMS1470, which because the TMS1600

and TMS1670. CMOS versions were also added, denoted with a "C" suffix,

such as TMS1200C.

The TMS1000 also had system

evaluator chips. The original evaluator chips were the TMS1098 and

TMS1099. These 64-lead evaluator chips were ROM-less versions of their

corresponding standard chips. The TMS1099 supported the

TMS1000/TMS1200 and the TMS1070/1270. The TMS1098 supported the

TMS1100/1300. Later evaluators were introduced to support the entire

TMS1000 family, they were the SE1000P (supports

TMS1000,1070,1200,1700), SE2200P (supports TMS1100,1170,1300,1370), and

the SE1400P (supports 1400, 1470, 1600, 1670).

The

success of the the TMS1000 is demonstrated by its long lifecycle (over

20 years) and its expanded product line. The TMS1000 is found in many

appliances, control systems, and games. Most of these chips were

sourced by companies for direct use in their products and will have

custom or house numbers on the chips (not the standard numbers listed

above). Even TI used custom numbers in its products. The TMS1000 was

used as a customized chip in the Texas Instruments "Speak and Spell"

educational toy line (See Pictures at bottom).

1. A broadcast receiver tuning system for tuning said broadcast receiver to a selected frequency comprising:

first means for storing digital tune words responsive to a binary address for outputting a selected said digital tune word,

second means for storing said selected digital tune word and said

binary address operably associated with said first means for storing,

a microcomputer operable for selectively changing said digital tune words in said first and second means for storing, and

means for converting said digital tune word stored in said second

means for storing into an analog voltage operative to tune said

broadcast receiver to said selected frequency.

2. A tuning system of claim 1 wher ein said microcomputer comprises:

means for incrementing and decrementing said digital tune word stored

in said second means in updating said digital tune word,

ein said microcomputer comprises:

means for incrementing and decrementing said digital tune word stored

in said second means in updating said digital tune word,

means for providing a plurality of operating instructions and logic functions operative of said microcomputer,

means for storing binary data responsive to said binary address and

said instructions operative for incrementing and decrementing said

digital tune word stored in said second means for storing, and

means for inputting control functions operably associated with said means for providing a plurality of operating instructions.

3. A tuning system of claim 1 wherein said means for converting

comprises: a pulse width modulator generator for outputting a digital

signal proportional to said digital tune word, and

a digital to analog converter for converting said digital signal into

said analog voltage for tuning said broadcast receiver to said selected

frequency.

4. A tuning system of claim 1 wherein said broadcast receiver comprises a television set.

5. A tuning system of claim 1 wherein said first means

for storing digital tune words comprises a nonvolatile random access

memory.

6. A tuning system of claim 1 wherein said second means

for storing said digital tune word and said binary address comprises a

shift register.

7. A tuning system of claim 2 wherein said means for

incrementing and decrementing comprises an arithmetic logic unit.

8. A tuning system of claim 7 wherein said arit

TMS1100NLP

a one bit full adder operably associated with said plurality of shift

registers for adding and subtracting said digital tune words and said

binary data stored in said plurality of shift registers, and

TMS1100NLP

a one bit full adder operably associated with said plurality of shift

registers for adding and subtracting said digital tune words and said

binary data stored in said plurality of shift registers, and

means for storing said digital tune words and said binary data operably

associated with said plurality of shift registers and said one bit full

adder.

9. A tuning system of claim 2 wherein said means for

providing a plurality of operating instructions and logic functions

comprises: a program counter,

an instruction memory responsive to said program counter for outputting binary instructions, and

a program logic array responsive to said binary instructions for outputting a plurality of said logic functions.

10. A tuning system of claim 9 further including a

microprogram counter operably associated with said program counter.

11. A broadcast receiver tuning system for tuning said broadcast

receiver to a selected frequency comprising: a first memory matrix  for storing digital tune words corresponding to said selected frequency,

for storing digital tune words corresponding to said selected frequency,

means for generating a binary address for addressing said digital tune word from said first memory,

means for storing said binary address and said addressed digital tune

words operably associated with said first memory and said means for

generating said binary address,

means connected to said address

and tune word storing means for incrementing and decrementing said

addressed digital tune word for updating said digital tune word,

means responsive to said binary address for outputting selected binary

data from a second memory matrix, said binary data used for

incrementing and decrementing said addressed digital tune word,

means connected to said incrementing and decrementing means for

providing a plurality of operating instructions and logic functions

operative for updating said digital tune word,

means for

inputting control functions operably associated with said means for

providing a plurality of operating instructions, and

means for

converting said addressed digital tune word into an analog voltage

operative to tune said broadcast receiver to said selected frequency.

12. A tuning system of claim 11 wherein said digital

tune words further correspond to a plurality of VHF and UHF television

channels.

13. A tuning system of claim 11 wherein said means for

storing said binary address and said addressed digital tune word

comprises a shift register.

14. A tuning system of claim 11 wherein said means for incrementing and

decrementing comprises: a plurality of shift registers,

a one bit full adder operably associated with said plurality of shift

registers for adding and subtracting said digital tune words and said

binary data stored in said plurality of shift registers, and

means for storing said digital tune words and said binary data operably

associated with said plurality of shift registers and said one bit full

adder.

15. A tuning system of claim 11 wherein said means for

providing a plurality of operating instructions and logic functions

comprises: a program counter,

an instruction memory responsive to said program counter for outputting binary instructions, and

a program logic array responsive to said binary instructions for outputting a plurality of said logic functions.

16. A tuning system of claim 11 wherein said means for

inputting logic control functions comprises an input logic  status

switch.

status

switch.

17. A tuning system of claim 11 wherein said means for converting

comprises: a pulse width modulator generator for outputting a digital

signal proportional to said digital tune word, and

a digital to analog converter for converting said digital signal into

said analog voltage for tuning said broadcast receiver to said selected

frequency.

18. A tuning system of claim 15 further including a

microprogram counter operably associated with said program counter.

19. A tuning system of claim 14 further including an

automatic channel shift encode for normalization of a binary VHF

increment value comprising one of said binary data stored in said second

memory matrix.

20. A television tuning system for tuning said television to a selected

VHF and UHF channel comprising: a first memory matrix for storing

digital tune words corresponding to said VHF and UHF channels,

means for generating a binary address on a multibus line for outputting said digital tune words from said first memory,

a shift register operably associated with said first memory and said

means for generating a binary address for storing said digital tune word

and said binary address,

a shift register operably associated with said first memory and said

means for generating a binary address for storing said digital tune word

and said binary address,

an arithmetic logic unit for

incrementing and decrementing said digital tune word stored in said

serial shift register in updating said digital tune word,

means for providing a plurality of operating instructions and logic functions operative in updating said digital tune word,

a second memory matrix for storing binary data used in incrementing

and decrementing said digital tune word, said second memory matrix

responsive to said binary address and said operating instructions, said

second memory matrix also operably associated with said arithmetic logic

unit,

an input logic status switch for inputting control

functions operably associated with said means for providing a plurality