CRT TUBE RTC (PHILIPS) A42/591X

• 90° deflection

• In-line gun, thermally stable; electrostatic hi-bi-potential focus

• 29, 1 mm neck diameter

• Hi-Bri screen with pigmented phosphor featuring high brightness and increased contrast performance

• Soft-Flash technology offering improved set reliability

• Slotted shadow mask optimized for minimum moire

• Fine pitch over entire screen

• Phosphor lines follow glass contour

• Quick-heating cathodes

• Internal magnetic shield

• Reinforced envelope for push-through mounting

• When combined with an appropriate hybrid saddle toroidal deflection unit (e.g. AT1216 or AT1470),

it forms a self-converging and raster correction free assembly.

FLASHOVER PROTECTION

With the high voltage used with this tube (max. 27,5 kV) internal flashovers may occur. As a result of

the Soft-Flash technology these flashover currents are limited to approx. 60 A offering higher set

reliability, optimum circuit protection and component savings.

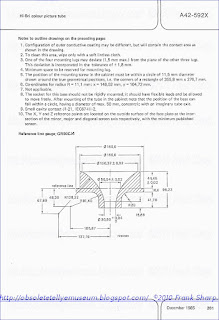

Primary protective circuitry using properly grounded spark gaps and series isolation resistors (preferably

carbon composition) is still necessary to prevent tube damage. The spark gaps should be connected to

all picture tube electrodes at the socket according to the figure below; they are not required on the

heater pins. No other connections between the outer conductive coating and the chassis are permissible.

The spark gaps should be designed for a breakdown voltage at the focusing electrode (g3) of 11 kV

(1,5 x Vg3 max. at Va,g4 = 25 kV), and at the other electrodes of 1,5 to 2 kV.

The values of the series isolation resistors should be as high as possible (min. 1,5 kQ) without causing

deterioration of the circuit performance. The resistors should be able to withstand an instantaneous

surge of 20 kV for the focusing circuit and 12 kV for the remaining circuits without arcing.

DEGAUSSING

The picture tube is provided with an internal magnetic shield. This shield and the shadow mask with

its suspension system may be provided with an automatic degaussing system, consisting of one

magnetic coil winding mounted on the cone of the picture tube.

AT ancient times VALVO was an components office of PHILIPS then the converted to the above company was started and the previous closed.Valvo Bauelemente GmbH is a Germany based company, specializing in the delevopment, manufacture and marketing of ferrite components for microwave and rf applications. Initially part of the Philips Components group this business has 30 years experience in the design and production of standard and special ferrite devices.When Philips closed its activity located in Hamburg, Valvo Bauelemente GmbH continues this circulator and isolator business and started 1999 as an independent company, only 100 meters off the former Philips location.

The company's history began in 1924 - a year after the introduction of broadcasting in Germany - with the establishment of a radio ray tube factory by the Hamburg company CHF Müller. Benedictines built many companies that produced radio tubes and the brand "Valvo" one of the few that are pervasive in the long run. 1927 joined CHF Müller and radio tube factory with Philips companies, and the tube manufacturing was relocated to a suitable site in Hamburg-Lokstedt. Already in the 30s advanced to the manufacturing program to electrolytic capacitors, speakers, and special tubes Hochohmwiderstände.

The Development of the present comp

rehensive Valvo organization began

after the war. In Hamburg-Lokstedt bigger and modern factory buildings

for the manufacture of electron tubes were built in Hamburg-Stellingen

began with the manufacture of ceramic capacitors, which was then

developed into a long horn on, and in Herborn founded Philips is later

taken over by Valvo work for Electrolyte and plastic film capacitors.

rehensive Valvo organization began

after the war. In Hamburg-Lokstedt bigger and modern factory buildings

for the manufacture of electron tubes were built in Hamburg-Stellingen

began with the manufacture of ceramic capacitors, which was then

developed into a long horn on, and in Herborn founded Philips is later

taken over by Valvo work for Electrolyte and plastic film capacitors.Valvo 1951, the production of ceramic magnetic components. The set up for this new manufacturing plant in Hamburg was already the largest of its kind in Germany. With the broadcast of the first experimental television broadcasts Began in 1951, the manufacture of television picture tubes. From these first attempts gave rise to the Bildröhrenfabrik Aachen, which is now the largest color picture tube plant in Europe. 1953 with the introduction of semiconductor technology in Hamburg-Lokstedt a key step in a new era has been done. From the radio tube factory, the tubes and semiconductor plants.

The sales departments have since 1955, a private office building in Hamburg, Valvo-house. They are supported by six branch offices in the care of professional clients. In addition, sales contracts are entered into with 13 distributors.

To Valvo organization in which more than 8000 employees, which are now the four works: the tubes and semiconductor plants in Hamburg, the Hamburg factory for electronic co

mponents, the Bildröhrenfabrik Aachen

and the capacitors work Herborn. These large manufacturing plants pose a

significant production potential; its importance is enhanced by

cooperation with 120 components factories in 30 countries as part of the

Philips company, including the Valvo GmbH is a subsidiary of the

General Association of German Industry Philips (Alldephi).

mponents, the Bildröhrenfabrik Aachen

and the capacitors work Herborn. These large manufacturing plants pose a

significant production potential; its importance is enhanced by

cooperation with 120 components factories in 30 countries as part of the

Philips company, including the Valvo GmbH is a subsidiary of the

General Association of German Industry Philips (Alldephi).Valvo has done in its 50-year history many contributions to the development of electronic engineering in Germany. In the radio tube factory in Hamburg, including the first Acid-tubes, the first German multigrid tubes as well as the first tube types for ac heater was manufactured in series. In the picture tube technique with the rectangular tube in standardized aspect ratio, of the 110 ° deflection and the picture tube, which can be operated without additional protective glazing, remarkable improvements have been introduced. Today, the partnership offered by Valvo "European television technology", under which one understands the euro color picture tubes and Ablenktechnik with strand wound saddle coils enforced. The latest development is the picture tube with Schnellheizkatoden. From the large number of special tube developments here only Hochleistungsklystron should be mentioned that works in many of the UHF television channels at home and abroad.

Also for semiconductors Valvo could play a key role early on. For example, in 1954, brought out types OC 70, OC 71 were first available in large quantities alloyed junction transistors on the German market, and the diffusionslegierten POB transistors (pushed out base) extended from 1959 the scope of the transistor in the FM area. A striking example of the successes of modern semiconductor technology, the close tolerance varicap BB 105, with which the automatic tuning for FM and TV reception could be solved economically justifiable.

1967 originated in Hamburg analog integrated circuits. They were among the first of such products manufactured in Europe. Today Valvo has a leading position in the field of integrated circuits for color televisions. The second generation of these circuits is already matured. It contributes significantly to the reduction of

the number of

individual components and the necessary adjustment processes. Also

numerous radio receiver as part of a progressive circuit design,

advanced integrated circuits are available.

the number of

individual components and the necessary adjustment processes. Also

numerous radio receiver as part of a progressive circuit design,

advanced integrated circuits are available.On the development of soft and hard magnetic oxide ceramic materials has been working steadily in recent decades, for example, would be the 110 °-Ablenktechnik without the high magnetic quality and dimensional accuracy of modern yoke rings from "Ferroxcube 3C2" not have been possible. For line transformers and modern power transformer, the new material "Ferroxcube 3C8" was introduced, and in the area of hard magnetic materials are "ferroxdure 380", "ferroxdure 260" and "ferroxdure 270" available.

On this basis, the broad technical Valvo GmbH presents its 50th anniversary as one of the leading suppliers of electronic equipment industry with a large production capacity and with the most modern technical equipment - a solid foundation for the further development of the position it has reached today.

-----------------------------------------------------------

vo GmbH begeht

am 1. April 1974 ihr 50jähriges Firmenjubiläum. Sie ist einer der

größten Bauelementehersteller in Deutschland und liefert heute - von

wenigen Ausnahmen abgesehen - sämtliche elektronischen Bauelemente für

die Konsumelektronik und die professionelle Elektronik.

vo GmbH begeht

am 1. April 1974 ihr 50jähriges Firmenjubiläum. Sie ist einer der

größten Bauelementehersteller in Deutschland und liefert heute - von

wenigen Ausnahmen abgesehen - sämtliche elektronischen Bauelemente für

die Konsumelektronik und die professionelle Elektronik. 1951

nahm Valvo die Produktion keramischer magnetischer Bauteile auf. Das

für diese Fertigung in Hamburg eingerichtete neue Werk war damals schon

das größte seiner Art in der Bundesrepublik. Mit der Ausstrahlung der ersten Fernsehversuchssendungen

1951

nahm Valvo die Produktion keramischer magnetischer Bauteile auf. Das

für diese Fertigung in Hamburg eingerichtete neue Werk war damals schon

das größte seiner Art in der Bundesrepublik. Mit der Ausstrahlung der ersten Fernsehversuchssendungen (Alldephi) gehört.

(Alldephi) gehört. 1967

entstanden in Hamburg integrierte Analogschaltungen. Sie gehörten zu

den ersten derartigen in Europa gefertigten Produkten. Heute hat Valvo

eine führende Stellung auf dem Gebiet der integrierten Schaltungen für

Farbfernsehgeräte. Die zweite Generation dieser Schaltungen ist bereits

herangereift. Sie trägt wesentlich zur Verringerung der Anzahl der

Einzel-Bauelemente und der erforderlichen Abgleichvorgänge bei. Auch für

Rundfunkempfänger werden zahlreiche im Rahmen eines fortschrittlichen

Schaltungskonzeptes entwickelte integrierte Schaltungen angeboten.

1967

entstanden in Hamburg integrierte Analogschaltungen. Sie gehörten zu

den ersten derartigen in Europa gefertigten Produkten. Heute hat Valvo

eine führende Stellung auf dem Gebiet der integrierten Schaltungen für

Farbfernsehgeräte. Die zweite Generation dieser Schaltungen ist bereits

herangereift. Sie trägt wesentlich zur Verringerung der Anzahl der

Einzel-Bauelemente und der erforderlichen Abgleichvorgänge bei. Auch für

Rundfunkempfänger werden zahlreiche im Rahmen eines fortschrittlichen

Schaltungskonzeptes entwickelte integrierte Schaltungen angeboten.

No comments:

Post a Comment

The most important thing to remember about the Comment Rules is this:

The determination of whether any comment is in compliance is at the sole discretion of this blog’s owner.

Comments on this blog may be blocked or deleted at any time.

Fair people are getting fair reply. Spam and useless crap and filthy comments / scrapers / observations goes all directly to My Private HELL without even appearing in public !!!

The fact that a comment is permitted in no way constitutes an endorsement of any view expressed, fact alleged, or link provided in that comment by the administrator of this site.

This means that there may be a delay between the submission and the eventual appearance of your comment.

Requiring blog comments to obey well-defined rules does not infringe on the free speech of commenters.

Resisting the tide of post-modernity may be difficult, but I will attempt it anyway.

Your choice.........Live or DIE.

That indeed is where your liberty lies.

Note: Only a member of this blog may post a comment.