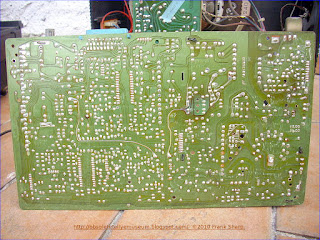

This Formenti F8 Chassis was very reliable and durable, few

problems were leaked capacitors in supply sections but

simple to repair.

It's generally PHILIPS Semiconductors based for

the signal processing, in supply parts is Siemens based, control system

is Motorola based. Line Output + EHT Transformer is an eldor (Elettronica d'orsenigo)) CRT

Tube is from Toshiba.

Pictured mains input & degauss PTC: 700134903

- Line deflection output (S2000)

- Frame deflection output TDA3653 (PHILIPS)

- Chroma + Luminance with TDA3562A (PHILIPS)

- IF + Synchronization with TDA4502A (PHILIPS)

- Tuner

- Audio Unit

PHILIPS TDA4502A SMALL SIGNAL COMBINATION FOR COLOUR TV

GENERAL DESCRIPTION

The integration into a single package of all small signal functions required for colour TV reception is

of all small signal functions required for colour TV reception is

achieved in the TDA4502A. The only additional circuits required for colour TV reception are the

deflection output stages, a sound detector and amplifier, and a colour decoder.

The IC includes a vision IF amplifier and video switching circuit, AFC circuit, AGC detector with

tuner output, an integral three—level sandcastle pulse generator, fully synchronized vertical and

horizontal drive outputs and a mute circuit with external availability. A triggered vertical divider

automatically adapts to 50 or 60 Hz operating mode thereby eliminating the need for external vertical

frequency control. The sound signal must be demodulated and amplified externally.

Features

Vision IF amplifier with synchronous demodulator

AGC detector, suitable for negative modulation

AGC output to tuner

AFC circuit with ON/OFF switch

Video preamplifier

Video switch to select the internal, or an external, video signal

Horizontal synchronization circuit with two control loops

Vertical synchronization [divider system) and sawtooth generation with automatic amplitude

adjustment for 50 and 60 Hz

Transmitter identification (mute)

O Sandcastle pulse generator

QUICK REFERENCE  DATA

DATA

K7 parameter symbol min. typ. max. unit

Supply voltage (pin 7) V7 9.5 12 13.2 V

Supply current (pin 7) I7 — 125 — ‘ mA

Supply current (pin 11) ‘‘ V11 — 6.0 8.5 mA

Operating ambient temperature range Tamb -25 - + 65 °C

Storage temperature range Tstg -25 — + 150 °C

Total power dissipation Ptot — — 2.3 W

PACKAGE OUTLINE

28—lead DI L; plastic with internal heat spreader (SOT117).

TDA4502A

FUNCTIONAL DESCRIPTION

IF amplifier, synchronous demodulator and AFC

The IF amplifier (pins 8 and 9) has a symmetrical input, the impedance of which enables SAW-filtering

to be used. The synchronous demodulator and the AFC circuit share an external reference tuned

circuit (pins 20 and 21). An internal RC—network provides the necessary phase—shift for AFC operation.

The AFC circuit provides a control voltage output with a voltage swing greater than 9 V at pin 18.

In the internal and external mode the AFC can be switched OFF when pin 22 is connected to positive

supply.

AGC circuit

AGC gating is performed to reduce sensitivity of the IF amplifier to external noise. The AGC time

constant is provided by an RC<:ircuit 19.="" agc="" br="" connected="" from="" is="" pin="" supplied="" the="" to="" tuner="" voltage="">pin 5. The point of tuner takeover is preset by the voltage level at pin 1.

Video switch circuit

The IC has a video switch with two video inputs and one video output. One input is connected to the

demodulated IF signal which is also fed to the video output pin of the peritelevision connector. The

other input can be switched to an external signal which is applied to the video input of the

peritelevision connector. The video output signal of the switch is fed to pin 25 of the IC, which is

the wnchronization part and, to the colour decoder. When the video switch is in the external mode,

the synchronization circuit is switched to the external signal. The vision IF, AGC and AFC circuits

will not be affected by the switching action and will, therefore, operate in the normal mode. Gating

for the AGC detector is switched OFF when the switch is in the external mode. The first control

loop is not switched to a low time constant when weak signals are received.

Horizontal oscillator start function

The horizontal oscillator start function is achieved by applying a current of 8.5 mA to pin 11 during the

switch-on period. This current can be taken from the mains rectifier. The main supply, pin 7, can then

be obtained from the horizontal output stage. The load current of the driver has to be added to the

start current.

Horizontal synchronization

The positive video input signal is applied to pin 25. The horizontal synchronization has two control

loops which have been introduced to <:ircuit 19.="" agc="" br="" connected="" from="" is="" pin="" supplied="" the="" to="" tuner="" voltage=""> generate a sandcastle pulse. By using the oscillator sawtooth, an

generate a sandcastle pulse. By using the oscillator sawtooth, an

accurate timing of the burst-key pulse can be made. Therefore, the phase of this sawtooth pulse must

have a fixed relationship to the sync pulse.

Horizontal phase detector

The circuit has two operating conditions:

(a) Synchronized

The first loop has afixed time constant and a gated phase detector, this enables optimum

performance for co-channel interference. The VCR mode is obtained by an additional load on

pin 22.

(b) Non-synchronized

In this condition the time constant is the same as during the VCR mode.

Vertical sync pulse

The vertical sync pulse integrator will not be disturbed when the vertical sync pulses have a width of

10 ps and a separation of 22 us. This type of vertical sync pulse is generated by video tapes with

anti-copy guard.

Vertical divider system

A synchronized divider system generates the vertical sawtooth wavefonns at pin 2. The system uses an

internal frequency doubler circuit to enable the horizontal oscillator to operate at its normal line

frequency. One line period equals 2 clock pulses.

Using the divider system avoids the requirement for vertical frequency adjustment. The divider has a

discriminator window for automatic switching from 50 Hz to 60 Hz mode. When the trigger pulse

arrives before line 576 the 60 Hz mode is selected, if not, the 50 Hz mode is selected.

The divider system operates with two different reset windows to give maximum interferencel

disturbance protection. The windows are activated via an up/down counter.

The counter is increased by 1 each time the separated vertical sync pulse is within the narrow window.

When the sync pulse is not within the narrow window the counter is decreased by 1.

The operation modes of the divider system are as follows:

Mode A

Large (search) window (divider ratio between 488 and 722)

This mode is valid for the following con ditions:

ditions:

0 Divider is looking for a new transmitter

O Divider ratio found — not within the narrow window limits

0 A non—standard composite video signal is detected — when a double or enlarged vertical sync pulse is

detected after the internally generated anti-top~flutter pulse has ended. This means a vertical sync

pulse width > 10 clock pulses (50 Hz); > 12 clock pulses (60 Hz). This mode is normally activated

for video tape recorders operating in the feature trick mode

0 Up/down counter value of the divider system, operating in the narrow window mode, drops below

count 6

Mode B

Narrow window (divider ratio between 522 to 528 (60 Hz) or 622 to 628 (50 Hz))

The divider system switches over to this mode when the up/down counter has reached its maximum

value of 15 approved vertical sync pulses. When the divider operates in this mode and, a vertical sync

pulse is missing within the window, the divider is reset at the end of the window and the counter value

is decreased by 1. At a counter value below 6 the divider system switches over to the large window

mode.

The divider system also generates an anti—top-flutter pulse which inhibits the Phase 1 detector during

the vertical sync pulse. The pulse width is dependent on the divider mode. In ‘Mode A’ the start is

generated by resetting the divider. In ’Mode B’ the anti—top-flutter pulse starts at the beginning of the

first equalizing pulse. The anti—top-flutter pulse ends at count 10 for the 50 Hz mode and count 12 for

the 60 Hz mode.

The vertical blanking pulse is also generated via the divider system. The start is initiated by resetting

the divider while the blanking pulse width is at count 34, (17 lines), for the 60 Hz mode and at

count 42, (21 lines), for the 50 Hz mode. The vertical blanking pulse, at the sandcastle output

(pin 27), is generated by adding the anti—top-flutter pulse to the blanking pulse. When the divider

operates in ‘Mode B’, the vertical blanking pulse starts at the beginning of the first equalizing pulse.

The length of the vertical blanking in this condition is 21 lines in the 60 Hz mode and 25 lines in the

50 Hz mode.

RATINGS

Limiting values in accordance with the Absolute Maximum System llEC 134)

parameter symbol min. max. unit

Supply voltage Vp = V7.5 — 13.2 V

Total power dissipation Pmt - 2.3 W

Operating ambient temperature range Tamb -25 + 65 °C

Storage temperature ra nge Tstg -25 + 150 °C

nge Tstg -25 + 150 °C

CHARACTERISTICS

Vp = V7 = 12 V; Tamb = 25 °C; unless otherwise specified; all voltages are referenced to ground

(pin 6) unless otherwise specified

parameter conditions symbol min. typ. max. unit

Supplies

Supply voltage (pin 7) V7 9.5 12.0 13.2 V

Supply current (pin 7) I7 — 125 — mA

Supply current (pin 1 1) note 1 l 11 — 6 8.5 mA

Vision IF amplifier (pins 8 and 9)

Input sensitivity at 38.9 MHz note 2 V8 40 80 120 uV

Input sensitivity at 45.75 MHz note 2 V3 — 100 ~ uV

Differential input resistance

(pin 8 to pin 9) note 3 R3_g 0.8 1.3 1.8 kfl

Differential input capacitance

(pin 8 to pin 9) note 3 C39 — 5 —- pF

Gain control range G3_g — 62 — dB

Maximum input signal V3.9 50 100 — mV

Expansion of output signal for

50 dB variation of input signal note 4 AV17 — 1 — dB

Video amplifier note 5

Output level for zero signal input note 6 V17 3.3 3.7 4.1 V

Output signal top sync level V17 1.5 1.7 1.9 V

Amplitude of video output signal

(peak-to-peak value) note 7 V17(p_p) 1.4 1.8 2.2 V

Internal bias current of output

transistor (npn emitter

follower) l17(int) 1.4 2.0 — mA

Bandwidth of demodulated

output signal B 4.0 5.0 — M Hz

Differential gain note 8 G 17 — 5 10 %

Differential phase note 8 lp — 5 10 %

PHILIPS TDA3653B TDA3653C Vertical deflection and guard circuit (90°):

GENERAL DESCRIPTION

The TDA3653B/C is a vertical deflection output circuit for drive of various deflection systems with currents up to

1.5 A peak-to-peak.

Features

· Driver

· Output stage

· Thermal protection and output stage protection

· Flyback generator

· Voltage stabilizer

· Guard circuit

QUICK REFERENCE DATA

Note to the quick reference data

1. The maximum supply voltage should be chosen such that during flyback the voltage at pin 5 does not exceed 60 V.

FUNCTIONAL DESCRIPTION

Output stage and protection circuit

Pin 5 is the output pin. The supply for the output stage is fed to pin 6 and the output stage ground is connected to pin 4.

The output transistors of the class-B output stage can each deliver 0.75 A maximum.

The maximum voltage for pin 5 and 6 is 60 V.

The output power transistors are protected such that their operation remains within the SOAR area. This is achieved by

the co-operation of the thermal protection circuit, the current-voltage detector, the short-circuit protection and the special

measures in the internal circuit layout.

Driver and switching circuit

Pin 1 is the input for the driver of the output stage. The signal at pin 1 is also applied via external resistors to pin 3 which

is the input of a switching circuit. When the flyback starts, this switching circuit rapidly turns off the lower output stage

and so limits the turn-off dissipation. It also allows a quick start of the flyback generator.

External connection of pin 1 to pin 3 allows for applications in which the pins are driven separately.

Flyback generator

During scan the capacitor connected between pins 6 and 8 is charged to a level which is dependent on the value of the

resistor at pin 8 (see Fig.1).

When the flyback starts and the voltage at the output pin (pin 5) exceeds the supply voltage, the flyback generator is

activated.

The supply voltage is then connected in series, via pin 8, with the voltage across the capacitor during the flyback period.

This implies that during scan the supply voltage can be reduced to the required scan voltage plus saturation voltage of

the output transistors.

The amplitude of the flyback voltage can be chosen by changing the value of the external resistor at pin 8.

It

should be noted that the application is chosen such that the lowest

voltage at pin 8 is > 2.5 V, during normal operation.

Guard circuit

When there is no deflection current and the flyback generator is not activated, the voltage at pin 8 reduces to less than

1.8 V. The guard circuit will then produce a DC voltage at pin 7, which can be used to blank the picture tube and thus

prevent screen damage.

Voltage stabilizer

The internal voltage stabilizer provides a stabilized supply of 6 V to drive the output stage, which prevents the drive

current of the output stage being affected by supply voltage variations.

PACKAGE OUTLINES

TDA3653B: 9-lead SIL; plastic (SOT110B); SOT110-1; 1996 November 25.

TDA3653C: 9-lead SIL; plastic power (SOT131); SOT131-2 November 25.

PARAMETER SYMBOL MIN. TYP. MAX. UNIT

Supply (note 1)

Supply voltage range

pin 9 VP = V9-4 10 - 40 V

pin 6 V6-4 - - 60 V

Output (pin 5)

Peak output voltage during flyback V5-4M - - 60 V

Output current I5(p-p) - 1.2 1.5 A

Operating junction temperature range Tj -25 - +150 °C

Thermal resistance junction to mounting base

(SOT110B) Rth j-mb - 10 - K/W

(SOT131) Rth j-mb - 3.5 - K/W.

--------------------------------------------------

- Video chrominance and Luminance with TDA3562A,

TDA3562A

TDA3562A (Philips)PAL/NTSC ONE-CHIP DECODER, DESCRIPTION

The TDA3562A is a monolithic IC designed as

decode PAL and/or NTSC colour television standards

and it combines all functions required for the

identification and demodulation of PAL and NTSC

signals.

.CHROMINANCE SIGNAL PROCESSOR

.LUMINANCE SIGNAL PROCESSING WITH

CLAMPING

.HORIZONTAL AND VERTICAL BLANKING

.LINEAR TRANSMISSION OF INSERTED

RGB SIGNALS

.LINEAR CONTRAST AND BRIGHTNESS

CONTROL ACTING ON INSERTED AND MATRIXED

SIGNALS

.AUTOMATIC CUT-OFF CONTROL

.NTSC HUE CONTROL

FEATURES:

· A black-current stabilizer which

controls the black-currents of the

three electron-guns to a level low

enough to omit the black-level

adjustment

· Contrast control of inserted RGB

signals

· No black-level disturbance when

non-synchronized external RGB

signals are available on the inputs

· NTSC capability with hue control.

APPLICATIONS

· Teletext/broadcast antiope

· Channel number display.

GENERAL DESCRIPTION

It follows that the

external switches and filters which

are required for the TDA3562A are

not required for the TDA3566A.

There is no difference between the

amplitudes of the colour output

signals in the PAL or NTSC mode.

· The clamp capacitor at pins 10, 20

and 21 in the black-level

stabilization loop can be reduced to

100 nF provided the stability of the

loop is maintained. Loop stability

depends on complete application.

The clamp capacitors receive a

pre-bias voltage to avoid coloured

background during switch-on.

· The crystal oscillator circuit has

been changed to prevent parasitic

oscillations on the third overtone of

the crystal. Consequently the

optimum tuning capacitance must

be reduced to 10 pF.

· The hue control has been improved

(linear)

.CHROMINANCE SIGNALPROCESSOR .LUMINANCE SIGNAL PROCESSING WITH

CLAMPING .HORIZONTAL AND VERTICAL BLANKING .LINEAR TRANSMISSION OF INSERTED

RGB SIGNALS .LINEAR CONTRAST AND BRIGHTNESS

CONTROL ACTING ON INSERTED AND MATRIXED

SIGNALS .AUTOMATIC CUT-OFF CONTROL .NTSC HUE CONTROL

DESCRIPTION

The TDA3562A is a monolithic IC designed as

decode PAL and/or NTSC colour television standards

and it combines all functions required for the

identification and demodulation of PAL and NTSC

signals.

THE PHILIPS TDA3562A Circuit arrangement for the control of a picture tube :

1. Circuit arrangement for the control of at least one beam current in a picture tube by a picture comprising

a control loop which in one sampling interval obtains a measuring

signal from the value of the beam current on the occurrence of a given

reference level in the picture signal, stores a control signal derived

therefrom until th

e next sampling interval and thereby adjusts the beam

current to a value preset by a reference signal.

and a trigger

circuit which suppresses auxiliary pulses used to generate the beam

current after the picture tube has been started up and issues a

switching signal for the purpose of closing the control loop during the

sampling intervals and for releasing the control of the beam current by

the picture signal after the measuring signal has exceeded the threshold

value,

a change detection arrangement which delivers a change

signal when the stored signal has assumed a largely constant value, and

a logic network which does not release the control of the beam current

by the picture signal outside the sampling intervals until the change

signal has also been issued after the switching signal.

2. Circuit arrangement as set forth in claim 1, in

which the picture signal comprises several color signals for the control

of a corresponding number of beam currents for the display of a color

picture in the picture tube and the control loop stores a part measuring

signal or a part control signal derived therefrom for each color

signal, characterized in that the change detection arrangement includes a

change detector for each color signal which delivers a part change

signal when the relevant stored signal has assumed a largely constant

value, and the logic network does not release the control of the beam

currents by the color signals outside the sampling intervals until the

part change signals have been delivered by all change detectors.

3. Circuit arrangement as set forth in claim 1,

including a comparator arrangement which compares the measuring signal

with the reference signal and derives the control signal from this

comparison, characterized in that the change detection arrangement

detects a change in the control signal with respect to time and issues

the change signal when the control signal has assumed a largely constant

value.

4. Circuit arrangement as set forth in claims 1, 2, 3

including a control signal memory which contains at least one

capacitor, characterized in that the change detection arrangement

delivers the change signal when a charge-reversing current of the

capacitor occuring during the starting up of the picture tube falls

below a limit value.

5. Circuit arrangement as set forth in claim 2,

including a comparator arrangement which compares the measuring signal

with the reference signal and derives the control signal from this

comparison, characterized in that the change detection arrangement

detects a change in the control signal with respect to time and issues

the change signal when the control signal has assumed a largely constant

value.

Description:

BACKGROUND OF THE INVENTION

The invention

relates to a circuit arrangement for the control of at least one beam

current in a picture tube by a picture signal with a control loop which

in one sampling interval obtains a measuring signal from the value of

the beam current on the occurrence of a given reference level in the

picture signal, stores a control signal derived therefrom until the next

sampling interval and by this means adjusts the beam current to a value

preset by a reference signal, and with a trigger circuit which

suppresses auxiliary pulses used to generate the beam current after the

picture tube is turned on and issues a switching signal for the purpose

of closing the control loop during the sampling intervals and releasing

the control of the beam current by the picture signal after the

measuring signal has exceeded a threshold value.

Such a circuit

arrangement has been described in Valvo Technische Information 820705

with regard to the integrated color decoder circuit PHILIPS TDA3562A and is

used in this as a so-called cut-off point control. In the known circuit

arrangement, such a cut-off point control provides automatic

compensation of the so-called cut-off point of the picture tube, i.e. it

regulates the beam current in the picture tube in such a way that for a

given reference level in the picture signal the beam current has a

constant value despite tolerances and changes with time (aging, thermal

modifications) in the picture tube and the circuit arrangement, thereby

ensuring correct picture reproduction.

Such a blocking point

control is particularly advantageous for the operation of a picture tube

for the display of color pictures because in this case there are

several beam currents for different color components of the color

picture which have to be in a fixed ratio with one another. If this

ratio changes, for example, as the result of manufacturing tolerances or

ageing processes, distortions of the colors occur in the reproduction

of the color picture. The beam currents, therefore, have to be very

accurately balanced. The said cut-off point control prevents expensive

adjustment and maintenance time which is otherwise necessary.

Conventional

picutre tubes are constructed as cathode-ray tubes with hot cathodes

which require a certain time after being turned on for the hot cathodes

to heat up. Not until a final operating temperature has been reached do

these hot cathodes emit the desired beam currents to the full extent,

while gradually rising beam currents occur in the time interval when the

hot cathodes are heating up. The instantaneous values of these beam

currents depend on the instantaneous temperatures of the hot cathodes

and on the accelerating voltages for the picture tube which build up

simultaneously with the heating process and are undefined until the end

of the heating time. After the picture tube is turned on, these values

initially produce a highly distorted picture until the beam currents

have attained their final value. These picture distortions after the

picture tube is turned on are even further intensified by the fact that

the cut-off point control is not yet adjusted to the beam currents which

flow after the heating time is over.

For the purpose of

suppressing distorted pictures during the heating time of the hot

cathodes, the known circuit arrangement has a turn-on delay element

o

perating as a trigger circuit which, in essence, contains a bistable

flip-flop. When the picture tube and the circuit arrangement controlling

the beam currents flowing in it are turned on, the flip-flop is

switched into a first state in which it interrupts the supply of the

picture signal to the picture tube. Thus, during the heating time the

beam currents are suppressed, and the picture tube does not yet display

any picture. In sampling intervals which are provided subsequent to

flybacks of the cathode beam into an initial position on the changeover

from the display of one picture to the display of a subsequent picture

and even within the changeover, that is outside the display of pictures,

the picture tube is controlled for a short time in such a way that beam

currents occur when the hot cathodes are sufficiently heated up and an

accelerating voltage is resent. If these currents exceed a certain

threshold value, the flip-flop circuit switches into a second state and

releases the picture signal for the control of the beam currents and the

cut-off point control.

It is found, however, that the picture

displayed in the picture tube immediately after the switching over of

the flip-flop is still not fault-free. Because, in fact, the beam

currents are supported during the heating time of the hot cathodes, the

cut-off point control cannot respond yet. This response of the cut-off

point control takes place only after the beam currents are switched on,

i.e. after the flip-flop is switched into the second state and therefore

at a time in which the picture signal already controls the beam

currents. In this way the response of the blocking point control makes

its presence felt in the picture displayed.

With the known

circuit arrangement the brightness of the picture gradually increases,

during the response of the cut-off point control, from black to the

final value.

This slow increase in the picture brightness after

the tube is turned on is disturbing to the eyes of the viewer not only

in the case of the black-and-white picture tubes with one hot cathode,

but especially so in the case of colour picture tubes which usually have

three hot cathodes. With a color picture tube, color purity errors can

also occur in addition to the change in the picture brightness if, as a

result of different speeds of response of the cut-off point control for

the three beam currents, there are found to be intermittent variations

from the interrelation between the beam currents required for a correct

picture reproduction.

SUMMARY OF THE INVENTION

The

aim of the invention is to create a circuit arrangement which

suppresses the above-described disturbances of brightness and color of

the displayed picture when the picture tube is being started.

The

invention achieves this aim in that a circuit arrangement of the type

mentioned in the preamble contains a change detection arrangement which

emits a change signal when the stored signal has assumed an essentially

constant value, and a logic network which does not release the control

of the beam current by the picture signal until the change signal has

also been emitted after the switching signal.

In the circuit

arrangement according to the invention, therefore, the display of the

picture is suppressed after the picture tube is turned on until the

cut-off point control has responded. If the picture signal then starts

to control the beam current, a perfect picture is displayed immediately.

In this way, all the disturbances of the picture which affect the

viewer's pleasure are suppressed. The circuit arrangement of the

invention is of simple design and can be combined on one semiconductor

wafer with the existing picture signal processing circuits and also, for

example, with the known circuit arrangement for cut-off point control.

Such an integrated circuit arrangement not only requires very little

space on the semiconductor wafer, but also needs no additional external

leads. Thus the circuit arrangement of the invention can be arranged,

for example, in an integrated circuit which has precisely the same

external connections as known integrated circuits. This means that an

integrated circuit containing the circuit arrangement of the invention

can be directly incorporated in existing equipment without the need for

additional measures.

In one embodiment of the said circuit

arrangement, in which the picture signal contains several color signals

for the control of a corresponding number of beam currents for

representing a color picture in the picture tube and, for each color

signal, the control loop stores a part measuring signal or a part

control signal derived from it, the change detection arrangement

contains a change detector for each color signal which emits a part

change signal when the relevant stored signal has assumed an essentially

constant value, and the logic network does not release the control of

the beam currents by the color signals outside the sampling intervals

until the part change signals have been emitted from all change

detectors.

In principle, therefore, such a circuit arrangement

has three cut-off point controls for the three beam currents controlled

by the individual color signals. To reduce the cost of the circuitry,

the measuring stage is common to all the cut-off point controls, as in

the known circuit arrangement. All three beam currents are then measured

successively by this measuring stage. In this way, a part measuring

signal or a part control signal derived from it is obtained for each

beam current and is stored sesparately according to which of the beam

currents it belongs. Changes in the part measuring signal or part

control signal are detected for each beam current by one of the change

detectors each time. Each of these change detectors issues a part change

signal to the logic network. The latter does not release the control of

the beam currents by the picture signal outside the sampling intervals

until all the part change signals indicate that the part measuring

signal or the part control signal, as the case may be, remains constant.

This ensures that the cut-off point controls for the beam currents of

all color signals have responded when the picture appears in the picture

tube.

In a further embodiment of the circuit arrangement

according to the invention with a comparator arrangement which compares

the measuring signal with the reference signal and derives the control

signal from this comparison, the change detection arrangement detects a

change in the control signal with respect to time and issues the change

signal when the control signal has assumed an essentially constant

value. In the case of the representation of a color signal the

comparator arrangement derives several part control signals, whose

changes with time are detected by the change detectors, from a

corresponding comparison of the part measuring signals with the

reference signal. In this embodiment of the circuit arrangement of the

invention, preference is given to storage of only the control signal or

the part control signals for the purpose of controlling the beam

currents.

In another embodiment of the circuit arrangement of t

he

invention which includes a control signal memory which contains at

least one capacitor in which a charge or voltage corresponding to the

control signal is stored, the change detection arrangement issues the

change signal when a charge-reversing current of the capacitor occurring

during the turning on of the picture tube has fallen below a limit

value and has thus at least largely decayed. Such a detection of the

steady state of the cut-off point control is independent of the actual

magnitude of the control signal and therefore independent of, for

example, the level of the picture tube cut-off voltage, circuit

tolerances or ageing processes in the circuit arrangement or the picture

tube.

Detection of whether or not the charge-reversing current

exceeds the limit value is performed preferentially by a current

detector which is designed with a current mirror system which is

arranged in a supply line to a capacitor acting as a control signal

store. A current mirror arrangement of this kind supplies a current

which coincides very precisely with the charging current of the

capacitor. This current is then compared, preferably in a further device

contained in the change detection arrangement, with a current

representing a limit value or, after conversion into a voltage, with a

voltage representing the limit value. The change signal is obtained from

the result of this comparison.

On the other hand, digital

memories may also be used as control signal memories, especially when

the picture signal is supplied as a digital signal and the blocking

point control is constructed as a digital control loop. In such a case,

the comparator arrangement, the change detection arrangement and the

trigger circuit are also designed as digital circuits. Then, the change

detection arrangement advantageously forms the difference of the signals

stored in the control signal memory in two successive sampling

intervals and compares this with the limit value formed by a digital

value. If the difference falls short of the limit value, the change

signal is issued.

BRIEF DESCRIPTION OF THE DRAWINGS

An embodiment of the invention is described in greater detail below with the aid of the drawings in which:

FIG. 1 shows a block circuit diagram of the embodiment,

FIG. 2 shows a somewhat more detailed block circuit diagram of the embodiment,

FIG. 3 shows time-dependency diagrams of some signals occurring in the circuit diagram shown in FIG. 2, and

FIG. 4 shows a somewhat moredetailed block circuit diagram of a part of the circuit diagram shown in FIG. 2.

DETAILED DESCRIPTION OF THE INVENTION

FIG.

1 shows a block circuit diagram of a circuit arrangement to which a

picture signal is fed via a first input 1 of a combinatorial stage 2.

From the output 3 of the combinatorial stage 2 the picture signal is fed

to the picture signal input of a controllable amplifier 5 which at an

output 6 issues a current controlled by the picture signal. This current

is fed via a measuring stage 7 to a hot cathode 8 in a picture tube 9

and forms therein a beam current of a cathode ray by means of which a

picture defined by the picture signal is displayed on a fluorescent

screen of the picture tube 9.

The measuring stage 7 measures the

current fed to the hot cathode 8, i.e. the the beam current in the

picture tube 9, and at a measuring signal output 10, issues a measuring

signal corresponding to the magnitude of this current. This is fed to a

measuring signal input 11 of a comparator arrangement 12 to which a

reference signal is supplied at a reference signal input 13. In a

preferably periodically recurring sampling interval during the

occurrence of a given reference level in the picture signal, the

comparator arrangement 12 forms a control signal from the value of the

measuring signal fed to the measuring signal input 11 at this time, on

the one hand, and the reference signal, on the other, by means of

substraction and delivers this at a control signal output 14. From there

the control signal is fed to an input 15 of a control signal memory 16

and is stored in the latter. The control signal is fed via an output 17

of the control signal memory 16 to a second input 18 of combinatorial

stage 2 in which it is combined with the picture signal, e.g. added to

it.

The combinatorial stage 2, the controllable amplifier 5, the

measuring stage 7, the comparator arrangement 12 and the control signal

memory 16 form a control loop with which the beam current is guided

towards the reference signal in the sampling interval during the

occurrence of the reference level in the picture signal. For the

reference level, use is made in particular of a black level or a level

with small, fixed distance from the black level, i.e. a value in the

picture signal which produces a black or almost back picture area in the

displayed picture in the picture tube. In this case the control loop,

as described, forms a cut-off point control for the picture tube. If the

reference level is away from the black level, the control loop is also

designated as quasi-cut-off-point control.

The circuit

arrangement as shown in FIG. 1 also has a trigger circuit 19 to which

the measuring signal from the measuring signal output 10 of measuring

stage 7 is fed at a measuring signal input 20. When the circuit

arrangement and therefore the picture tube are turned on, the trigger

circuit 19 is set in a first state in which by means of a first

connection 21 it blocks the comparator arrangement 12 in such a way that

the latter delivers no control signal or a control signal with the

value zero at its control signal output 14. This prevents the control

signal memory 16 from storing undefined values for the control signal at

the moment of turning on or immediately thereafter.

The circuit

arrangement shown in FIG. 1 also has a logic network 22 which is

connected via a second connection 23, by means of which a switching

signal is supplied, with the trigger circuit 10 and via a third

connection 24 with the controllable amplifier 5. Like the trigger

circuit 19, the logic network 22 also finds itself controlled, when the

circuit arrangement is being turned on, by the switching signal in a

first stage in which by way of the third connection 24 it blocks the

controllable amplifier 5 with a blocking signal in such a way that no

beam currents controlled by the picture signal can yet flow in the

picture tube 9. Thus the picture tube 9 is blanked; no picture is

displayed yet.

When picture tube 9 is turned on, the hot cathode 8

is still cold so that no beam current can flow anyhow. The hot cathode 8

is then heated up and, after a certain time, begins gradually to emit

electrons as the result of which a cathode ray and therefore a beam

current can form. However, during the heating up of the hot cathode 8,

and because the cut-off point control has not yet responded, this would

be undefined and is therefore suppressed by the controllable amplifier

5. Only in time intervals which are provided immediately subsequent to

flybacks of the cathode rays into an initial position at the changeover

from the display of one image to that of a subsequent image, but even

before the start of the display of the subsequent image, the

controllable amplifier 5 delivers a voltage in the form of an auxiliary

pulse for a short time at its output 6, and when the hot cathode 8 in

the picture tube 9 is heated up sufficiently, this voltage produces a

beam current. The time interval for the delivery of this voltage is

selected in such a way that a cathode ray produced by its does not

produce a visible image in the picture tube 9, and coincides for example

with the sampling interval.

The measuring stage 7 measures the

short-time cathode current pro

duced in the manner described and, at its

measuring signal output 10, delivers a corresponding measuring signal

which is passed via measuring signal output 20 to the trigger circuit

19. If the measuring signal exceeds a definite preset threshold value,

the trigger circuit 19 is switched into a second state in which it

releases the comparator arrangement 12 via the first connection 12 and,

by means of the second connection 23, uses the switching signal to also

bring the logic network 22 into a second state. The comparator

arrangement 12 now evaluates the measuring signal supplied to it via the

measuring signal input 11, i.e. it forms the control signal as the

difference between the measuring signal and the reference signal

supplied via the reference signal input 13. The control signal is

transferred via the control signal output 14 and the input 15 into the

control signal memory 16. It is subsequently fed via the output 17 of

the control signal memory 16 to the second input 18 of the combinatorial

stage 2 and is there combined with the picture signal at the first

input 1, e.g. is superimposed on it by addition. This superimposed

picture signal is fed to the picture signal input 4 of the controllable

amplifier 5 via the output 3 of the combinatorial stage 2.

In the

second state of the logic network 22 the controllable amplifier 5 is

switched via the third connection 24 by the blocking signal in such a

way that the picture signal controls the beam currents only during the

sampling intervals and that, for the rest, no image appears yet in the

picture tube. The cut-off point control now gebins to respond, i.e. the

value of the control signal is changed by the control loop comprising

the combinatorial stage 2, the controllable amplifier 5, the measuring

stage 7, the comparator arrangement 12 and the control signal memory 16

until such time as the beam current in the picture tube 9 at the

blocking point or at a fixed level with respect to it is adjusted to a

value preset by the reference signal. For this purpose the sampling

interval, in which the picture signal controls the beam current via the

controllable amplifier 5 is selected in such a way that within it the

picture signal just assumes a value corresponding to the cut-off point

or to a fixed level with respect to it.

During the response of

the cut-off point control the control signal fed to the control signal

memory 16 changes continuously. Between the control signal output 14 of

the comparator arrangement 12 and the input 15 of the control signal

memory 16 is inserted a changed detection arrangement 25 which detects

the variations of the control signal. When the cut-off point control has

responded, i.e. the control signal has assumed a constant value, the

change detection arrangement 25 delivers a change signal at an output 26

which indicates that the steady stage of the cut-off point control is

achieved and the said signal is fed to a change signal input 27 of the

logic network 22. The logic network then switches into a third state in

which via the third connection 24 it enables the controllable amplifier 5

in such a way that the beam currents are now controlled without

restriction by the picture signal. Thus a correctly represented picture

appears in the picture tube 9.

A shadow-like representation of

individual constituents of the circuit arrangement in FIG. 1 is used to

indicate a modification by which this circuit arrangement is equipped

for the representation of color pictures in the picture tube 9. For

example, three color signals are fed in this case as the picture signal

via the input 1 to the combinatorial stage 2. Accordingly, the input 1

is shown in triplicate, and the combinatorial stage 2 has a logic

element, e.g. an adder, for example of these color signals. The

controllable amplifier 5 now has three amplifier stages, one for each of

the color signals, and the picture tube now contains three hot cathodes

8 instead of one so that three independent cathode rays are available

for the three color signals.

However, to simplify the circuit

arrangement and to save on components, only one measuring stage 7 is

provided which measures all three beam currents successively. Also, the

comparator arrangement 12 forms part control signals from the

successively arriving part measuring signals for the individual beam

currents with the reference signal, and these part control signals are

allocated to the individual color signals and passed on to three storage

units which are contained in the control signal memory 16. From there,

the part control signals are sent via the second input 18 of the

combinatorial stage 2 to the assigned logic elements.

The circuit

arrangement thus forms three independently acting control loops for the

cut-off point control of the individual color signals, in which case

only the measuring stage 7 and to some extent at least the comparator

arrangement 12 are common to these control loops.

The change

detection arrangement 25 now has three change detectors each of which

detects the changes with time of the part control signals relating to a

color signal. Then via the output 26 each of these change detectors

delivers a part change signal to the change signal input 27 of the logic

network 22. These part change signals occur independently of one

another when the relevent control loop has responded. The logic network

22 evaluates all three part change signals and does not switch into its

third stage until all part change signals indicate a steady state of the

control loops. Only then, in fact, is it ensured that all the color

signals from the beam currents controlled by them are correctly

reproduced in the picture tube, and thus no distortions of the displayed

image, especially no color purity errors, occur. The color picture

displayed then immediately has the correct brightness and color on its

appearance when the picture tube is turned on.

FIG. 2 shows a

somewhat more detailed block circuit diagram of an embodiment of a

circuit arrangement equipped for the processing of a picture signal

containing three colour signals. Three color signals for the

representation of the colors red, green and blue are fed to this circuit

arrangement via three input terminals 101, 102, 103. A red color signal

is fed via the first input terminal 101 to a first adder 201, a green

colour signal is fed via the second input terminal to a second adder

202, and a blue colour signal is fed via the third input terminal 103 to

a third adder 203. From outputs 301, 302 and 303 of the adders 201,

202, 203 the color signals are fed to amplifier stages 501, 502 and 503

respectively. Each of the amplifier stages contains a switchable

amplifier 511, 512 and 513, an output amplifier 521, 522 and 523 as well

as a measuring transistor 531, 532 and 533 respectively. The emitters

of these measuring transistors 531, 532, 533 are each connected to a hot

cathode 801, 802, 803 of the picture tube 9 and deliver the cathode

currents, whereas the collectors of measuring transistors 521, 532, 533

are connected to one another and to a first terminal 701 of a measuring

resistor 702 the second terminal of which 703 is connected to earth. The

current gain of the measuring transistors 531, 532 and 533 is so great

that the

ir collector currents coincide almost with the cathode currents.

By measuring the voltage drop produced by the cathode currents at the

measuring resistor 802 it is then possible to measure the cathode

currents and therefore the beam currents in the picture tube 9 with

great accuracy.

The falling voltage at the measuring resistor 702

is fed as a measuring signal to an input 121 of a buffer amplifier 120

with a gain factor of one, at the output 122 of which the unchanged

measuring signal is therefore available at low impedance. From there it

is fed to a first terminal 131 of a reference voltage source 130 which

is connected with its second terminal 132 to inverting inputs 111, 112

and 113 of three differential amplifiers 123, 124, 125 respectively. The

differential amplifiers 123, 124, 125 also each have a non-inverting

input 114, 115, and 116 respectively. These are connected to each other

at a junction 117, to earth via a leakage current storage capacitor 126

and to the output 122 of the buffer amplifier 120 via decoupling

resistor 118 and a leakage current sampling switch 119. In addition, the

input 121 of the buffer amplifier 120 can be connected to earth via a

short-circuiting switch 127.

From outputs 141, 142, and 143

respectively of the differential amplifiers 123, 124 and 125, part

control signals relating to the individual color signals are fed in the

form of electrical voltages (or, in some cases, charge-reversing

currents) via control signal sampling switches 154, 155 and 156, in the

one instance, to first terminals 151, 152 and 153 respectively of

control signal storage capacitors 161, 162, 163 which form the storage

units of the control signal memory 16 and store inside them charges

corresponding to these voltages (or formed by the charge-reversing

currents). In the other instance, the part control signals are fed to

second inputs 181, 182 and 183 of the first, second or third adders 201,

202, 203 respectively and are added therein to the color signals from

the first, second or third input terminals 101, 102 or 103 respectively.

The operation of the comparator arrangement 12 which consists

mainly of the buffer amplifier 120, the reference voltage source 130 and

differential amplifiers 123, 124, 125 will be explained below with the

aid of the pulse diagrams in FIG. 3. FIG. 3a shows a horizontal blanking

signal for a television signal which, as the picture signal, controls

the beam currents in the picture tube 9. In this diagram, H represents

horizontal blanking pulses which follow one another in the picture

signal at the time interval of one line duration and by means of which

the beam currents are switched off during line flyback between the

display of the individual picture lines in the picture tube. FIG. 3b

shows a vertical blanking pulse V by means of which the beam currents

are switched off during the change ober from the display of one picture

to the display of the next picture. FIG. 3c shows a measuring signal

control pulse VH which is formed from a vertical blanking pulse

lengthened by three line duration.

The short-circuiting switch

127 is now controlled in such a way that it is non-conducting only

throughout the duration of the measuring signal control pulse VH and

during the remaining time short-circuits the input 121 of the buffer

amplifier 120 to earth. This means that a measuring signal only reaches

the comparator arrangement 12 during frame change so that the parts of

the picture signal which control the beam currents producing the picture

in the picture tube exert no influence on comparator arrangement 12 and

therefore on the blocking point control.

Throughout the duration

of the measuring signal control pulse VH, the measuring signal from

output 122, reduced by a reference voltage issued by the reference

voltage source 130 between its first 131 and its second terminal 132, is

present at the inverting inputs 111, 112, 113 of differential

amplifiers 123, 124, 125. If the differential amplifiers 123, 124, 125

were not present, this difference would be fed directly as part control

signals to the control signal storage capacitors 161, 162, 162. The

differential amplifiers 123, 124, 125 amplify the difference and thus

form the control amplifiers of the control loops.

The comparator

arrangement 12 further contains a device for compensation of the

influence of any leakage currents occurring in the picture tube 9. For

this purpose, a voltage to which the leakage current storage capacitor

126 is charg

ed is fed to the non-inverting inputs 114, 115, 116 of the

three differential amplifiers 123, 124 and 125. The charging is

performed by the measuring signal from output 122 of the buffer

amplifier 120 via the decoupling resistor 118 and the leakage current

sampling switch 119 which is closed only within the period of the

vertical blanking pulse V, and in certain cases only during part of the

latter. Within this time the beam currents are, in fact, totally

switched off by the picture signal so that in certain cases only a

leakage current flows through the measuring resistor 702. Consequently,

throughout the duration of the vertical blanking pulse V the measuring

signal corresponds to this leakage current. Because the leakage current

also flows during the remaining time, even outside the duration of the

vertical blanking pulse the measuring signal contains a component

originating from the leakage current which therefore is also contained

in the voltage fed to the inverting inputs 111, 112, 113 of differential

amplifiers 123, 124, 125 and is subtracted out in the differential

amplifiers 123, 124, 125.

The part control signal is fed from

output 141 of differential amplifier 123 by the first control signal

sampling switch 154 to the first terminal 151 of the first control

signal storage capacitor 161 during the period of a storage pulse L1 and

is stored in the said capacitor. Similarly, the part control signal

from output 143 of differential amplifier 125 is fed to the third

control signal storage capacitor 163 during the period of a storage

pulse L2 and the part control signal from output 142 of differential

amplifier 124 is fed to the second control signal storage capacitor 162

during a storage pulse L3. The storage pulses L1, L2 and L3 are

illustrated in FIGS. 3d, e and f. They lie in sequence in one of the

three line periods by which the measuring signal control pulse VH is

longer than the vertical blan

king pulse V. These three line periods form

the sampling interval for the measuring signal or the part measuring

signals, as the case may be. During the remaining periods the outputs,

141, 152, 143 of the differential amplifiers 123, 124, 125 are isolated

from the control signal storage capacitors 161, 162, 163 so that no

interference can be transmitted from there and any distortion of the

stored part control signals caused thereby is eliminated. For the

duration of storage pulses L1, L2 and L3 the color signals at the input

terminals 101, 102, 103 are at their reference level i.e. in the present

embodiment at a level, corresponding to the blocking point or at a

fixed level with respect to it so that the control loops can adjust to

this level.

The switchable amplifiers 511, 512, and 513 each

receive at each input 241, 242, 243 a blanking signal BL1, BL2, BL3

respectively, the curves of which are shown in FIGS. 3g, h, i. These

blanking signals interrupt the supply of the color signals during line

flybacks and frame change, i.e. during the period of the measuring

signal control pulse VH, and thus the beam currents in these time

intervals are switched off. Naturally, the red color signal is let

through during the first line period after the end of the vertical

blanking pulse V, the blue color signal during the second line period

after the end of the vertical blanking pulse V and the green color

signal during the third line period after the end of the vertical

blanking pulse V by the switchable amplifiers 511, 512, 513 respectively

so that they can control the beam currents. Blanking signals BL1, BL2

and BL3 also provide for interruptions in the frame change blanking

pulse, which corresponds to the measuring signal control pulse, in the

corresponding time intervals. In these time intervals the beam currents

are measured and part control signals are determined from the part

measuring signals and stored in the control signal storage capacitors

161, 162, 163.

The circuit arrangement shown in FIG. 2 further

contains a trigger circuit 19 to which a supply voltage is fed via a

supply terminal 190. Via a reset input 191 a voltage is also

supplied to

the trigger circuit 19 from a third terminal 133 of the reference

voltage source 130. When the circuit arrangement is turned on, this

voltage is designed so as to be delayed with respect to the supply

voltage so that when the circuit arrangement is brought into operation

the interplay of the two voltages produces a switch-on reset signal such

that a low-value voltage pulse occurs at the reset input 191 during

turn on, which means that the trigger circuit 19 is set in its first

state. The reset input 191 can also be connected to another circuit of

any configuration which generates a switch-on reset signal when the

picture tube is turned on.

The trigger circuit 19 is further

connected via a second connection 23 to a logic network 22 which, when

the circuit arrangement is turned on, is also set into a first state via

the second connection 23. In this first state the logic network 22

delivers a blocking signal at a blocking output 240 which is fed to the

three switchable amplifiers 511, 512, 513. By this means the supply of

the color signals to the output amplifiers 521, 522, 523 is interrupted

completely so that no beam currents can be generated by these. No

picture is therefore displayed.

An insertion signal EL which

extends over the three line periods by which the measuring signal

control pulse VH is longer than the vertical blanking pulse V, i.e. over

the sampling interval, is also fed via a line 233 to the trigger

circuit 19 and the logic netw

ork 22. As long as the trigger circuit 19

is in its first state, this insertion pulse EL is issued via a control

output 192 from the trigger circuit 19 and fed to the pulse generator

244. During the period of the insertion pulse EL this generator produces

a voltage pulse of a definite magnitude and passes this to output

amplfiiers 521, 522, 523 as an auxiliary pulse via switching diodes 245,

246, 247. By this means the beam currents are switched on for a short

time so as to receive a measuring signal despite the disconnected color

signals as soon as at least one of the hot cathodes 801, 802, 803

delivers a beam current.

In its first state the trigger circuit

19 also delivers a signal via a control line 211, and this signal is

used to switch the outputs 141, 142, 143 of the differential amplifiers

123, 124, 125 to earth potential or practically to earth potential. This

suppresses effects of voltages at the inputs 111 to 116 of the

differential amplifiers 123, 124, 125, especially effects of the

reference voltage source 130 which may in some cases initiate incorrect

charging of the control signal storage capacitors 161, 162, 163.

The

measuring signal produced by means of the pulse generator 244 at the

input 121 of the buffer amplifier 120 is also fed to the trigger circuit

19 via a measuring signal input 20. If it exceeds a preset threshold

value, the trigger circuit 19 switched into its second state. The logic

network 22 is then also switched into its second state via the second

connection 23. The differential amplifiers 123, 124, 125, too, are

triggered by the signal along the control line 211 into issuing a

control signal defined by the difference in the voltages at its inputs

111 to 116. The pulse generator 244 is blocked by the control output

192. The blocking signal issued from the blocking output 240 of the

logic network 22 now turns on the switchable amplifiers 511, 512, 513 in

the time intervals defined by the storage pulses L1, L2, L3 in such a

way that in these time intervals the color signals can produce beam

currents to form a measuring signal by which the control loops respond.

However, the display of the picture is still suppressed. The control

signal storage capacitors 161, 162, 163 are charged up in this process.

In the leads to the first terminals 151, 152, 153 there are change

detectors 251, 252, 253 which detect the changes of the charging

currents of the control signal storage capacitors 161, 162, 163 and at

their outputs 261, 262, 263 in each case deliver a part change signal

when the charging current of the control signal storage capacitor in

question has decayed and thus the relevant control loop has responded.

The part change signals are fed to three terminals 271, 272, 273 of the

change signal input 27 of the logic network 22.

When part change

signals are present from all change detectors 251, 252, 253, when

therefore all control loops have responded, the logic network 22

switches from its second to its third state. The blocking signal from

the blocking output 240 is now completely disconnected such that the

switchable amplifiers 511, 512, 513 are now switched only by the

blanking signals BL1, BL2, BL3. The colour signals are then switched

through to the output amplifiers 521, 522, 523 and the picture is

displayed in the picture tube.

FIG. 4 shows an embodiment for a

trigger circuit 19 and a logic network 22 of the circuit arrangements as

shown in FIGS. 1 or 2. The trigger circuit 19 contains a flip-flop

circuit formed from two NAND-gates 194, 195 to which the switch-on reset

signal, by which the trigger circuit 19 is returned to its first stage,

is fed via the reset input 191. All the elements of the circuit

arrangement in FIG. 4 are shown in positive logic. Thus, a short-time

low voltage at the reset input 191 immediately after the circuit

arrangement is started up is used to set the flip-flop circuit 194, 195

in such a way that a high voltage occurs at the output of the second

NAND gate 194 and a low voltage at the output of the second NAND gate

195. The low voltage at the output of the second NAND gate 195 blocks

differential amplifiers 123, 124, 125 via the control line 211 in the

manner described.

The insertion pulse EL is fed via the line 233

to the trigger circuit 19, is combined via an AND gate 196 with the

signal from the output of the first NAND gate 194 and is delivered at

the control output 192 for the purpose of controlling the pulse

generator 244.

The signals from the outputs of the NAND-gates

194, 195 are fed via a first line 231 and a second line 232 of the

second connection 23 as a switching signal to the logic network 22. The

first line 231 is connected to reset inputs R of three part change

signal memories 221, 222, 223 in the form of bistable flip-flop circuits

which when the circuit arrangement is

started up are reset via the

first line 231 in such a way that they carry a low voltage at their

outputs Q. The second line 232 of the second connection 23 leads via

three AND gates 224, 225, 226 to setting inputs S of the three part

change signal memories 221, 222, 223. By means of the AND gates 224,

225, 226 the signal on the second line 232 of the second connection 23

is combined each time with one of the part change signals supplied via

the terminals 271, 272, 273. The signals from the outputs Q of the part

change signal memories 221, 222, 223 are combined by means of a

collecting gate 227 in the form of an NAND gate and are held ready at

its output 228.

The measuring signal is fed to the trigger

circuit 19 via the measuring signal input 20 and passed to a first input

197 of a threshold detector 198 to which at a second input a threshold

value, in the form of a threshold voltage for example, produced by a

threshold generator 199 is also supplied. When the voltage at the first

input 197 of the threshold detector 198 is smaller than the voltage

delivered by the threshold generator 199, the threshold detector 198

delivers a high voltage at its output 200. When, on the other hand, the

voltage at the first input 197 is greater than the voltage of the

threshold generator 199, the voltage at the output 200 jumps to a low

value. This voltage is supplied as the setting signal of the flip-flop

circuit 194, 195, reverses the latter and thereby switches the trigger

circuit 19 into its second state when the voltage at the first input 197

exceeds the voltage of the threshold generator 199.

Between the

output 200 and the flip-flop circuit 194, 195 in the circuit arrangem

ent

shown in FIG. 4 there is inserted an inquiry gate 181 in the form of an

OR gate to which an inquiry pulse is fed via an inquiry input 193 of

the trigger circuit 19. This ensures that the flip-flop circuit 194, 195

is switched over only at a time fixed by the inquiry pulse--in the

present case a negative voltage pulse--and not at any other times due to

disturbances. As such an inquiry pulse it is possible to use, for

example, a pulse which occurs in the second line period after the end of

the vertical blanking pulse V, i.e. one which largely corresponds to

the storage pulse L2.

After the switching over of the flip-flop

circuit 194, 195 corresponding to the setting of the trigger circuit 19

into the second state, appropriately modified signals are supplied via

the control line 211 and the output 192 for the purpose of controlling

the pulse generator 244 and the differential amplifiers 123, 124, 125.

Modified voltages also appear on the lines 231, 232 of the second

connection 23, and these voltages release the part change signal

memories 221, 222, 223 such that they can each be set when the part

change signals reach the terminals 271, 272, 273.

In certain

cases, a further flip-flop circuit 234 is inserted in the lines 231, 232

to delay the signals passing along these lines; this is reset via the

first line 231 when the circuit arrangement is started up and thus it

also resets the part change signal memories 221, 222, 223. However,

after the trigger circuit 19 is switched into the second state the

further flip-flop circuit 234 is not set via the second line 232 of the

second connection 23 until a release pulse arrives via a release input

235 and another AND gate 236, for example a period of approximately the

interval of two vertical blanking pulses V after the switching of the

trigger circuit 19 into the second state. In this way it is possible to

bridge a period of time in which no defined signal values are present at

the terminals 271, 272, 273.

The signal at the output 228 of the

collecting gate 227 changes its state when the last of the three part

change signals has also arrived and has set the last of the three part

change signal memories. The signal is then combined via a gate

arrangement 229 of two NAND gates and one AND gate with the insertion

pulse EL of line 223 and with the signal on the second line 232 of the

second connection 23 or from the output Q of the further flip-flop

circuit 234 to the blocking signal delivered at the blocking output 24

which is fed to the switchable amplifiers 511, 512, 513.

FIGS.

31, m, n show the combinations of the blocking signal with the blanking

signals BL1, BL2, and BL3 at the blanking inputs 241, 242, 243 of the

switchable amplifiers 511, 512, 513 in the form of logic AND operations.

The dot-dash lines show resulting insertion signals A1, A2, A3 formed

by these operations after the starting up of the circuit arrangement and

before the occurrence of a beam current, i.e. in the first state of the

logic network 22. Here the resulting insertion signals A1, A2, A3 are

constant at low level. The dash curves show the resulting insertion

signals A1, A2, A3 after the appearance of a beam current and before the

steady state of the cut-off point control is reached, i.e. in the

second state of the logic network 22, while the continuous curves

represent the resulting insertion signals A1, A2, A3 in the steady state

of the cut-off point control, i.e. in the third state of logic network

22. The dash curves have similar shapes to storage pulses L1, L2, L3,

whereas the continuous curves correspond in shape to the inverses of the

blanking signals BL1, BL2, BL3. In this case a high level of the

resulting insertion signals A1, A2 or A3 means that the switchable

amplifier 511, 512 or 513 feeds the colour signal to the relevant output

amplifier 521, 522 or 523 respectively, whereas a low level in the

resulting insertion signal A1, A2 or A3 means that the relevant

switchable amplifier 511, 512 or 513 is blocked for the color signal.

The

circuit arrangement described is designed in such a way that the

trigger circuit 19 remains in its second state and logic network 22

remains in its third state even if charging currents reappear at the

difference signal storage cpacitors 161, 162, 163 due to disturbances

during the operation of the circuit arrangement. The cutoff point

control then makes readjustments without the displayed picture being

disturbed.

In the circuit arrangement shown in F

IG. 2, the green

color signal can also be let through during the second line period after

the end of the vertical blanking pulse V and the blue color signal

during the third line period after the end of the vertical blanking

pulse V by the switchable amplifiers 511, 512, 513 for the purpose of

controlling the beam currents. The storage pulses L2 and L3 at the

control signal sampling switches 155 and 156 and the second and third

blanking signals BL2 and BL3 at the blanking inputs 242 and 243 are then

to be interchanged. The resulting insertion signals A2 and A3 as shown

in FIGS. 3m and n are also interchanged then accordingly.

In FIG.

2 a dashed line is used to indicate which components of the circuit

arrangement can be combined advantageously to form an integrated

circuit. The first terminals 151, 152, 153 of the difference signal

storage capacitors 161, 162, 163, one terminal 128 of leakage current

storage capacitor 126, three terminals 524, 525, 526 in the leads to the

output amplifiers 521, 522, 523 as well as a line connection 704

between the first terminal 701 of the measuring resistor 702 and the

input 121 of the buffer amplifier 120 will then form the connecting

contacts of this integrated circuit

-----------------------------------------------------

CHASSIS F8 Power supply Description based on TDA4601d (SIEMENS)

TDA4601 Operation. * The TDA4601 device is a single in line, 9 pin chip. Its predecessor was the TDA4600 device, the TDA4601 however has improved switching, better protection and cooler running. The (SIEMENS) TDA4601 power supply is a fairly standard parallel chopper switch mode type, which operates on the same basic principle as a line output stage. It is turned on and off by a square wave drive pulse, when switched on energy is stored in the chopper transformer primary winding in the form of a magnetic flux; when the chopper is turned off the magnetic flux collapses, causing a large back emf to be produced. At the secondary side of the chopper transformer this is rectified and smoothed for H.T. supply purposes. The advantage of this type of supply is that the high chopping frequency (20 to 70 KHz according to load) allows the use of relatively small H.T. smoothing capacitors making smoothing easier. Also should the chopper device go short circuit there is no H.T. output. In order to start up the TDA4601 I.C. an initial supply of 9v is required at pin 9, this voltage is sourced via R818 and D805 from the AC side of the bridge rectifier D801, also pin 5 requires a +Ve bias for the internal logic block. (On some sets pin 5 is used for standby switching). Once the power supply is up and running, the voltage on pin 9 is increased to 16v and maintained at this level by D807 and C820 acting as a half wave rectifier and smoothing circuit. PIN DESCRIPTIONS Pin 1 This is a 4v reference produced within the I.C. Pin 2 This pin detects the exact point at which energy stored in the chopper transformer collapses to zero via R824 and R825, and allows Q1 to deliver drive volts to the chopper transistor. It also opens the switch at pin 4 allowing the external capacitor C813 to charge from its external feed resistor R810. Pin 3 H.T. control/feedback via photo coupler D830. The voltage at this pin controls the on time of the chopper transistor and hence the output voltage. Normally it runs at Approximately 2v and regulates H.T. by sensing a proportion of the +4v reference at pin 1, offset by conduction of the photo coupler D830 which acts like a variable resistor. An increase in the conduction of transistor D830 and therefor a reduction of its resistance will cause a corresponding reduction of the positive voltage at Pin 3. A decrease in this voltage will result in a shorter on time for the chopper transistor and therefor a lowering of the output voltage and vice versa, oscillation frequency also varies according to load, the  higher the load the lower the frequency etc. should the voltage at pin 3 exceed 2.3v an internal flip flop is triggered causing the chopper drive mark space ratio to extend to 244 (off time) to 1 (on time), the chip is now in over volts trip condition. Pin 4 At this pin a sawtooth waveform is generated which simulates chopper current, it is produced by a time constant network R810 and C813. C813 charges when the chopper is on and is discharged when the chopper is off, by an internal switch strapping pin 4 to the internal +2v reference, see Fig 2. The amplitude of the ramp is proportional to chopper drive. In an overload condition it reaches 4v amplitude at which point chopper drive is reduced to a mark-space ratio of 13 to 1, the chip is then in over current trip. The I.C. can easily withstand a short circuit on the H.T. rail and in such a case the power supply simply squegs quietly. Pin 4 is protected by internal protection components which limit the maximum voltage at this pin to 6.5v. Should a fault occur in either of the time constant components, then the chopper transistor will probably be destroyed. Pin 5 This pin can be used for remote control on/off switching of the power supply, it is normally held at about +7v and will cause the chip to enter standby mode if it falls below 2v. Pin 6 Ground. Pin 7 Chopper switch off pin. This pin clamps the chopper drive voltage to 1.6v in order to switch off the chopper. Pin 8 Chopper base current output drive pin. Pin 9 L.T. pin, approximately 9v under start-up conditions and 16v during normal running, Current consumption of the I.C. is typically 135mA. The voltage at this pin must reach 6.7v in order for the chip to start-up.

higher the load the lower the frequency etc. should the voltage at pin 3 exceed 2.3v an internal flip flop is triggered causing the chopper drive mark space ratio to extend to 244 (off time) to 1 (on time), the chip is now in over volts trip condition. Pin 4 At this pin a sawtooth waveform is generated which simulates chopper current, it is produced by a time constant network R810 and C813. C813 charges when the chopper is on and is discharged when the chopper is off, by an internal switch strapping pin 4 to the internal +2v reference, see Fig 2. The amplitude of the ramp is proportional to chopper drive. In an overload condition it reaches 4v amplitude at which point chopper drive is reduced to a mark-space ratio of 13 to 1, the chip is then in over current trip. The I.C. can easily withstand a short circuit on the H.T. rail and in such a case the power supply simply squegs quietly. Pin 4 is protected by internal protection components which limit the maximum voltage at this pin to 6.5v. Should a fault occur in either of the time constant components, then the chopper transistor will probably be destroyed. Pin 5 This pin can be used for remote control on/off switching of the power supply, it is normally held at about +7v and will cause the chip to enter standby mode if it falls below 2v. Pin 6 Ground. Pin 7 Chopper switch off pin. This pin clamps the chopper drive voltage to 1.6v in order to switch off the chopper. Pin 8 Chopper base current output drive pin. Pin 9 L.T. pin, approximately 9v under start-up conditions and 16v during normal running, Current consumption of the I.C. is typically 135mA. The voltage at this pin must reach 6.7v in order for the chip to start-up.