INTRODUCTION:

This PHILIPS CRT type the 45AX FST TUBE BY PHILIPS WAS WIDELY USED AROUND THE WORLD and fabricated form more than 22 YEARS.

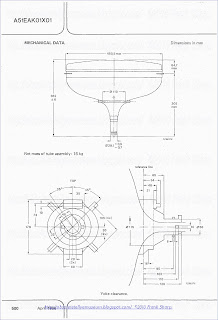

FLAT SQUARE Hi-Bri COLOUR PICTURE TUBE

• Flat and square screen

• 110° deflection

• Shadow mask of NiFe alloy with low thermal expansion

• In-line, hi-bi potential A RT* gun with quadrupole cathode le11s

• 29, 1 mm neck diameter

• Mask with corner suspension

• Hi-Bri technology

• Pigmented phosphors

• Quick-heating low-power cathodes

• Soft-flash

• Slotted shadow mask optimized for minimum moin! at 625 lines systems

• Internal magnetic shield

• Internal multipole

• Reinforced envelope for push-through mounting

• Anti-crackle coating.

Remaining guns adjusted for spot cut-off by means of cathode voltage

Vg2 range 575 to 825 V;

Vk range 105 to 130 V.

Adjustment procedure:

Set the cathode voltage (Vk) for each gun at 130 V; increase the grid 2 voltage (Vg2) from approx.

550 V to the value at which one of the colours become just visible. Now decrease the cathode voltage

of the remaining guns so that the other colours also become visible.

Notes

1. Absolute maximum rating system.

2. The X-ray dose rate remains below the acceptable value of 36 pA/kg (0,5 m R/h). measured with

ionization chamber when the tube is used within its limiting values.

3. During adjustment on the production line this value is likely to be surpassed considerably. It is

therefore strongly recommended to first make the necessary adjustments for normal operation with-

out picture tube.

4. Operating of the tube at lower voltages impairs the luminance and resolution, and could impair

convergence.

5. The short-term average anode current should be limited by circuitry to 1500 μA.

6. During adjustment on the production line max. 1500 V is permitted.

7. For maximum cathode life it is recommended that the heater supply be designed for 6,3 Vat zero

beam current.

Picture display system including a deflection unit with a double saddle coil system

PHILIPS 45AX SYSTEM

1. A picture display system including a colour display tube having a neck accommodating an electron gun assembly for generating three electron beams, and an electromagnetic deflection unit surrounding the paths of the electron beams which have left the electron assembly, said deflection unit comprising

a field deflection coil of the saddle type having a front and a rear end for deflecting electron beams generated in the display tube in a vertical direction;

a line deflection coil of the saddle type likewise having a front and a rear end for deflecting electron beams generated in the display tube in a horizontal direction, and a yoke ring of ferromagnetic material surrounding the two deflection coils and having front and rear end faces extending transversely to the tube axis, the electron beam traversing the coils in the direction from the rear to the front ends when the deflection unit is arranged on a display tube, characterized in that the deflection unit also has first and second magnetically permeable portions arranged symmetrically with respect to the plane of symmetry of the field deflection coil on either side of the tube axis, each magnetically permeble portion having a first end located opposite the rear end face of the yoke ring and a second end located at the neck of the display tube in the proximity of the location where the electron beams leave the electron gun assembly, the length of the first and second magnetically permeable portions and their distance to the yoke ring being dimensioned for providing a self-convergent picture display system.

2. A picture display system as claimed in claim 1 characterized in that regions of the rear end of the yoke ring located on either side of the plane of symmetry of the line deflection coil are left free by the rear end of the field deflection coil and in that the first ends of the magnetically permeable portions are located opposite said regions.

3. A picture display system as claimed in claim 1 characterized in that the field deflection coil and the line deflection coil are directly wound on a support.

4. Apparatus for adapting a self-convergent deflection unit of the type mountable on the neck of a display tube and including a saddle type field deflection coil screen end and a gun end extending away from said tube in a plane disposed at an angle to a tube axis, and a yoke ring having a screen end and a gun end, for use with display tubes having different screen formats comprising:

format adjustment means disposed adjacent to the gun end of the yoke ring for coupling flux from the yoke ring to the neck of the tube to supplement the field produced by the vertical deflection coil to uniformly increase the vertical deflection field to produce a raster having a different format from the raster produced by said deflection unit alone.

6. The apparatus of claim 5 wherein each of said first and second magnetically permeablel members comprises a first end located opposite a gun end face of the yoke ring, and a second end located at the neck of the display tube adjacent the location where the electron beams leave the electron gun assembly.

7. The apparatus of claim 6 wherein said first end comprises a portion of said permeable member disposed parallel to the neck of the displaya tube and said second end comprises a portion of said magnetically permeable member located perpepndicular to the neck of the display tube.

8. The apparatus of claim 7 wherein said second endsn of said magnetically permeable members have inwardly extending arms subending a first angle.

9. The appaaratus of claim 8 wherein said angle is large so that the supplemental field has a positive sixpole component.

11. Apparatus for adapting a self-convergent deflection unit of the type used on the neck of a display tube having an electron gun disposed in a neck of said tube, said deflection unit including a field deflection coil of the saddle type having a rear end portion disposed at an angle to the axis of said tube, comprising means disposed adjacent to said neck between said electron gun and said deflection unit, and coupled to said deflection unit for changing the distance between the line and field deflection points for causing said deflection unit to produce a different screen format.

BACKGROUND OF THE INVENTION The

invention relates to a picture display system including a colour

display tube having a neck accommodating an electron gun assembly for

generating three electron beams, and an electromagnetic deflection unit

including a field

deflection coil of the saddle type having a front and a rear end for

deflecting electron beams generated in the display tube in a vertical

direction and a line

deflection coil of the saddle type likewise having a front and a rear

end for deflecting electron beams generated in the display tube in a

horizontal direction and yoke ring of ferromagnetic material

surrounds the two deflection coils and has front and rear end faces

extending transversely to the tube axis, the electron beam traversing

the coils in the direction from the rear to the front ends when the

deflection unit is arranged on a display tube. FOr

some time a colour display tube has become the vogue in which three

electron beams are used in one plane; the type of such a cathode ray

tube is sometimes referred to as "in-line". In this case, for

decreasing convergence errors of the electron beams, a deflection

unit is used having a line deflection coil generating a horizontal

deflection field of the pincushion type and a field deflection coil

generating a vertical deflection field of the barrel-shaped type. Deflection

units for in-line colour display tube systems can in principle be

made to be entirely self-convergent, that is to say, in a design of

the deflection unit which ensures convergence of the three electron

beams on the axes, anisotropic y-astigmatism errors, if any, can

simultaneously be made zero in the corners without this requiring

extra correction means. While it would be interesting from a point of

view of manufacture to have a deflection unit which is selfconvergent

for a family of display tubes of the same deflection angle and neck

diameter, but different screen formats, the problem exists, however,

that a deflection unit of given main dimensions can only be used for

display tubes of one screen format. This means that only one screen

format can be found for a fixed maximum deflection angle in which aa

given deflection unit is self-convergent without a compromise (for

example, the use of extra correction means).

BACKGROUND OF THE INVENTION The

invention relates to a picture display system including a colour

display tube having a neck accommodating an electron gun assembly for

generating three electron beams, and an electromagnetic deflection unit

including a field

deflection coil of the saddle type having a front and a rear end for

deflecting electron beams generated in the display tube in a vertical

direction and a line

deflection coil of the saddle type likewise having a front and a rear

end for deflecting electron beams generated in the display tube in a

horizontal direction and yoke ring of ferromagnetic material

surrounds the two deflection coils and has front and rear end faces

extending transversely to the tube axis, the electron beam traversing

the coils in the direction from the rear to the front ends when the

deflection unit is arranged on a display tube. FOr

some time a colour display tube has become the vogue in which three

electron beams are used in one plane; the type of such a cathode ray

tube is sometimes referred to as "in-line". In this case, for

decreasing convergence errors of the electron beams, a deflection

unit is used having a line deflection coil generating a horizontal

deflection field of the pincushion type and a field deflection coil

generating a vertical deflection field of the barrel-shaped type. Deflection

units for in-line colour display tube systems can in principle be

made to be entirely self-convergent, that is to say, in a design of

the deflection unit which ensures convergence of the three electron

beams on the axes, anisotropic y-astigmatism errors, if any, can

simultaneously be made zero in the corners without this requiring

extra correction means. While it would be interesting from a point of

view of manufacture to have a deflection unit which is selfconvergent

for a family of display tubes of the same deflection angle and neck

diameter, but different screen formats, the problem exists, however,

that a deflection unit of given main dimensions can only be used for

display tubes of one screen format. This means that only one screen

format can be found for a fixed maximum deflection angle in which aa

given deflection unit is self-convergent without a compromise (for

example, the use of extra correction means).  The

Netherlands Patent Specification 174 198 provides a solution to this

problem which is based on the fact that, starting from field and

line deflection coils having given main dimensions, selfconvergent

deflection units for a family of display tubes having different screen

formats can be assembled by modifying the effective lengths of the

field and line deflection coils with respect to each other. This

solution is based on the recognition that, if selfconvergence on the

axes has been reached, the possibly remaining anisotropic

y-astigmatism error (particularly the y-convergence error halfway the

diagonals) mainly depends on the distance between the line deflection

point and the field deflection point and to a much smaller extent on

the main dimensions of the deflection coils used. If deflection

units for different screen formats are to be produced while using

deflection coils having the same main dimensions, the distance

between the line and field deflection points may be used as a

parameter to achieve self-convergence for a family of display tubes

having different screen formats but the same maximum deflection

angle. The variation in the

distance between the line and field deflection points necessary for

adaption to different screen formaats is achieved in the prior art by

either decreasing or increasing the effective coil length of the

line deflection coil or of the field deflection coil, or of both -

but then in the opposite sense - with the maiin dimensions of the

deflection coils remaining the same and with the dimensions of the

yoke ring remaining the same, for example, by mechanically making the

coil or coils on the rear side smaller and longer, respectively, by a

few millimeters, or by positioning, with the coil length remaining

the same, the coil window further or less far to the rear (so thata

the turns on the rear side are more or less compressed). To achieve

this, saddle-shaped line and field deflection coils of the shell type

were used. These are coils having ends following the contour of the

neck of the tube at least on the gun side. This is in contrast to the

conventional saddle coils in which the gun-sided ends, likewise as

the screen-sided ends, are flanged and extend transversely to the

tube surface. When using saddle coils of the shell type it is

possible for the field deflection coil (and hence the vertical

deflection field) to extend further to the electron gun assembly than

the line deflection coil, if the field design so requires. However,

there are also deflection units with deflection coils of the

conventional saddle type, which means that - as stated - they have

front and rear ends located in planes extending at an angle

(generally of 90.degree. ) to the tube axis. (A special type of such a

deflection unit with conventional saddle coils is, for exam

The

Netherlands Patent Specification 174 198 provides a solution to this

problem which is based on the fact that, starting from field and

line deflection coils having given main dimensions, selfconvergent

deflection units for a family of display tubes having different screen

formats can be assembled by modifying the effective lengths of the

field and line deflection coils with respect to each other. This

solution is based on the recognition that, if selfconvergence on the

axes has been reached, the possibly remaining anisotropic

y-astigmatism error (particularly the y-convergence error halfway the

diagonals) mainly depends on the distance between the line deflection

point and the field deflection point and to a much smaller extent on

the main dimensions of the deflection coils used. If deflection

units for different screen formats are to be produced while using

deflection coils having the same main dimensions, the distance

between the line and field deflection points may be used as a

parameter to achieve self-convergence for a family of display tubes

having different screen formats but the same maximum deflection

angle. The variation in the

distance between the line and field deflection points necessary for

adaption to different screen formaats is achieved in the prior art by

either decreasing or increasing the effective coil length of the

line deflection coil or of the field deflection coil, or of both -

but then in the opposite sense - with the maiin dimensions of the

deflection coils remaining the same and with the dimensions of the

yoke ring remaining the same, for example, by mechanically making the

coil or coils on the rear side smaller and longer, respectively, by a

few millimeters, or by positioning, with the coil length remaining

the same, the coil window further or less far to the rear (so thata

the turns on the rear side are more or less compressed). To achieve

this, saddle-shaped line and field deflection coils of the shell type

were used. These are coils having ends following the contour of the

neck of the tube at least on the gun side. This is in contrast to the

conventional saddle coils in which the gun-sided ends, likewise as

the screen-sided ends, are flanged and extend transversely to the

tube surface. When using saddle coils of the shell type it is

possible for the field deflection coil (and hence the vertical

deflection field) to extend further to the electron gun assembly than

the line deflection coil, if the field design so requires. However,

there are also deflection units with deflection coils of the

conventional saddle type, which means that - as stated - they have

front and rear ends located in planes extending at an angle

(generally of 90.degree. ) to the tube axis. (A special type of such a

deflection unit with conventional saddle coils is, for exam ple, the

deflection unit described in EP 102 658 with field and line

deflection coils directly wound on a support). In this case it has

until now been impossible to extend the vertical deflection field

further to the electron gun assembly than the horizontal deflection

field, because the field deflection coil is enclosed between the

flanges of the line deflection coil. SUMMARY OF THE INVENTION The

deflection unit has first and second magnetically permeable portions

arranged symmetrically with respect to the plane of symmetry of the

field deflection coil on either side of the tube axis, each

magnetically permeable portion having a first end located opposite

the rear end face of othe yoke ring and a second end located at the

neck of the display tube in the proximity of the location where the

electron beams leave the electron gun assembly. The length of the

first and second magnetically permeable portions and their distance

to the yoke ring are dimensioned for providing a self-convergent

picture display system. The

invention is based on the recognition that the first ends of the

magnetically permeable portions draw a field deflection flux flux which

is taken up is adjusted by means of the distance between the first

ends and the yoke ring, and the length of the magnetically permeable

portions determines how far the vertical deflection field is extended

to the rear. A practical

embodiment of the picture display system according to the invention is

characterized in that regions of the rear end of the yoke ring

located on either side of the plane of symmetry of the line

deflection coil are left free by the rear end of the field deflection

coil and in that the first ends of the magnetically permeable

portions are located opposite said regions. The

invention can particularly be used to advanatage if the field

deflection coil and the line deflection coil are directly wound on a

support. The invention also

relates to an electromagnetic deflection unit suitable for use in a

picture display system as described hereinbefore. For

use in a display tube having a larger screen format than the display

tube for which it is designed, the invention provides the

possibility of moving apart the deflection points of the horizontal

deflection field and the vertical deflection field generated by a

given deflection unit having saddle coils and of moving them towards

each other for use in a display tube having a smaller screen format. The

great advantage of the invention is that only a modification of the

length of the magnetically permeable portions (providing or omitting

them, respectively) is required to adapt a deflection unit to

different screen formats of a display tube family.

ple, the

deflection unit described in EP 102 658 with field and line

deflection coils directly wound on a support). In this case it has

until now been impossible to extend the vertical deflection field

further to the electron gun assembly than the horizontal deflection

field, because the field deflection coil is enclosed between the

flanges of the line deflection coil. SUMMARY OF THE INVENTION The

deflection unit has first and second magnetically permeable portions

arranged symmetrically with respect to the plane of symmetry of the

field deflection coil on either side of the tube axis, each

magnetically permeable portion having a first end located opposite

the rear end face of othe yoke ring and a second end located at the

neck of the display tube in the proximity of the location where the

electron beams leave the electron gun assembly. The length of the

first and second magnetically permeable portions and their distance

to the yoke ring are dimensioned for providing a self-convergent

picture display system. The

invention is based on the recognition that the first ends of the

magnetically permeable portions draw a field deflection flux flux which

is taken up is adjusted by means of the distance between the first

ends and the yoke ring, and the length of the magnetically permeable

portions determines how far the vertical deflection field is extended

to the rear. A practical

embodiment of the picture display system according to the invention is

characterized in that regions of the rear end of the yoke ring

located on either side of the plane of symmetry of the line

deflection coil are left free by the rear end of the field deflection

coil and in that the first ends of the magnetically permeable

portions are located opposite said regions. The

invention can particularly be used to advanatage if the field

deflection coil and the line deflection coil are directly wound on a

support. The invention also

relates to an electromagnetic deflection unit suitable for use in a

picture display system as described hereinbefore. For

use in a display tube having a larger screen format than the display

tube for which it is designed, the invention provides the

possibility of moving apart the deflection points of the horizontal

deflection field and the vertical deflection field generated by a

given deflection unit having saddle coils and of moving them towards

each other for use in a display tube having a smaller screen format. The

great advantage of the invention is that only a modification of the

length of the magnetically permeable portions (providing or omitting

them, respectively) is required to adapt a deflection unit to

different screen formats of a display tube family.1. A method of manufacturing a color display tube in which magnetic poles are provided in or around the neck of said tube and around the paths of the electron beams, which poles generate a permanent static multipole magnetic field for the correction of errors in convergence, color purity and frame of the display tube, which magnetic poles are formed by the magnetisation of a configuration of magnetisable material provided around the paths of the electron beams, the method comprising energizing a magnetisation device with a combination of direct currents with which a static multipole magnetic field is generated, and superimposing a decaying alternating magnetic field over said static multipole magnetic field which initially drives said magnetisable material into saturation on either side of the hysteresis curve thereof, said decaying alternating magnetic field being generated by a decaying alternating current. 2. The method as claimed in claim 1, 6 or 7, wherein the decaying alternating magnetic field is generated by means of a separate system of coils in the magnetisation device. 3. The method as claimed in claim 2, wherein the decaying alternating magnetic field varies its direction continuously. 4. The method as claimed in claim 3 wherein the frequency of the decaying alternating current is approximately the standard line frequency. 5. A colour display tube manufactured by means of the method as claimed in claim 4. 6. The method as claime

d

in claim 1 which further comprises erasing any residual magnetism in

said configuration, prior to said magnetisation, with an alternating

magnetic field. 7. The method as claimed in claim 6 which further

comprises correcting the errors in convergence, color purity and frame

of the display picture with a combination of direct currents applied

to said magnetisation device and then reversing said direct currents

while increasing the magnitudes thereof and applying these adjusted

direct currents to said magnetisation device for the magnetisation of

said configuration.

d

in claim 1 which further comprises erasing any residual magnetism in

said configuration, prior to said magnetisation, with an alternating

magnetic field. 7. The method as claimed in claim 6 which further

comprises correcting the errors in convergence, color purity and frame

of the display picture with a combination of direct currents applied

to said magnetisation device and then reversing said direct currents

while increasing the magnitudes thereof and applying these adjusted

direct currents to said magnetisation device for the magnetisation of

said configuration. The invention relates to a method of manufacturing a color display tube in which magnetic poles are provided in or around the neck of the envelope and around the paths of the electron beams, which poles generate a permanent multipole magnetic field for the correction of the occurring errors in convergence, color purity and frame of the color display tube, which magnetic poles are formed by the magnetisation of a configuration of magnetisable material provided around the paths of the electron beams, which configuration is magnetized by energising a magnetising device with a combination of currents with which a static multipole magnetic field is generated.

The invention also relates to a color display tube manufactured according to said method.

In a color display tube of the "delta" type, three electron guns are accommodated in the neck of the tube in a triangular arrangement. The points of intersection of the axes of the guns with a plane perpendicular to the tube axis constitute the corner points of an equilateral triangle.

In a color display tube of the "in-line" type three electron guns are arranged in the tube neck in such manner that the axes of the three guns are situated mainly in one plane while the axis of the central electron gun coincides substantially with the axis of the display tube. The two outermost electron guns are situated symmetrically with respect to the central gun. As long as the electron beams generated by the electron guns are not deflected, the three electron beams, both in tubes of the "delta" type and of the "in-line" type, must coincide in the center of the display screen (static convergence). Because, however, as a result of defects in the manufacture of the display tube, for example, the electron guns are not sealed quite symmetrically with respect to the tube axis, deviations of the frame shape, the color purity and the static convergence occur. It should be possible to correct said deviations.

Such a color display tube of the "in-line" type in which this correction is possible, is disclosed in Netherlands Pat. application No. 7,503,830 laid open to public inspection. Said application describes a color display tube in which the deviations are corrected by the magnetisation of a ring of magnetisable material, as a result of which a static magnetic multipole is formed around the paths of the electron beams. Said ring is provided in or around the tube neck. In the method described in said patent application, the color display tube is actuated after which data, regarding the value and the direction of the convergence errors of the electron guns, are established, with reference to which the polarity and strength of the magnetic multipole necessary to correct the frame, color purity and convergence errors are determined. The magnetisation of the configuration, which may consist of a ring, a ribbon or a number of rods or blocks grouped around the electron paths, may be carried out in a number of manners. It is possible, for example, first to magnetise the configuration to full saturation, after which demagnetisation to the desired value is carried out with an opposite field. A disadvantage of this method is that, with a combination of, for example, a 2, 4, and 6-pole field, the polarity and strength of the demagnetisation vary greatly and frequently, dependent on the place on the ring, and hence also the polarity and strength of the full magnetisation used in this method. Moreover it appears that the required demagnetising field has no linear relationship with the required correction field. Due to this non-linearity it is not possible to use a combined 2, 4 and 6-pole field for the demagnetisation. It is impossible to successively carry out the 2, 4 and 6-pole magnetisation since, for each magnetisation, the ring has to be magnetised fully, which results in the preceding magnetisation being erased again. The possibility of successively magnetising various places on the ring is very complicated and is not readily possible if the ring is situated in the tube neck since the stray field of the field necessary for the magnetisation again demagnetizes, at least partly, the already magnetised places.

SUMMARY OF THE INVENTION

It is therefore an object of the invention to provide a method with which a combined multipole can be obtained by one total magnetisation.

According to the invention, a method, of the kind described in the first paragraph with which this is possible, is characterized in that the magnetisation is effected by means of a decaying alternating magnetic field which initially drives the magnetisable material on either side of the hysteresis curve into saturation. After the decay of the alternating m

agnetic

field, a hard magnetisation remains in the material of the

configuration which neutralizes the externally applied magnetic field

and is, hence, directed oppositely thereto. After switching off the

externally applied magnetic field, a magnetic multipole field remains

as a result of the configuration magnetized as a multipole. The

desired magnetisation may be determined in a number of manners. By

observing and/or measuring the deviations in the frame shape, color

purity and convergence, the desired multipole can be determined

experimentally and the correction may be carried out by magnetisation of

the configuration. If small deviations are then still found, the

method is repeated once or several times with corrected currents. In

this manner, by repeating the method according to the invention, it is

possible to produce a complete correction of the errors in frame,

color purity and convergence. Preceding the magnetisation, residual

magnetism, if any, in the configuration is preferably erased by means

of a magnetic field.

agnetic

field, a hard magnetisation remains in the material of the

configuration which neutralizes the externally applied magnetic field

and is, hence, directed oppositely thereto. After switching off the

externally applied magnetic field, a magnetic multipole field remains

as a result of the configuration magnetized as a multipole. The

desired magnetisation may be determined in a number of manners. By

observing and/or measuring the deviations in the frame shape, color

purity and convergence, the desired multipole can be determined

experimentally and the correction may be carried out by magnetisation of

the configuration. If small deviations are then still found, the

method is repeated once or several times with corrected currents. In

this manner, by repeating the method according to the invention, it is

possible to produce a complete correction of the errors in frame,

color purity and convergence. Preceding the magnetisation, residual

magnetism, if any, in the configuration is preferably erased by means

of a magnetic field. The method is preferably carried out by determining the required correction field prior to the magnetisation and, after the erasing of the residual magnetism, by correcting the errors in the convergence, the color purity and the frame of the displayed picture by means of a combination of currents through the magnetising device, after which the magnetisation is produced by reversing the direction of the combination of currents, increasing the current strength and simultaneously producing the said decaying alternating magnetic field.

The correction field, obtained with the magnetizing device and measured along the axis of the electron beams, is generally longer than the multipole correction field generated by the configuration. So the correction of the deviations will have to be carried out over a shorter distance along the axis of the tube, which is possible only with a stronger field. During the magnetisation, a combination of currents, which in strength and direction is in the proportion of m:1 to the combination of currents which is necessary to generate a correction multipole field with the device, where m is, for example, -3, should flow through the magnetisation device. The value of m depends on the ratio between the length of the correction multipole field, generated by the

magnetizing

device, to the effective field length of the magnetized

configuration. This depends upon a number of factors, for example, the

diameter of the neck, the kind of material, the shape and the place

of the configuration, etc., and can be established experimentally. If

it proves, upon checking, that the corrections with the magnetized

configuration are too large or too small, the magnetisation process

can be repeated with varied magnetisation currents.

magnetizing

device, to the effective field length of the magnetized

configuration. This depends upon a number of factors, for example, the

diameter of the neck, the kind of material, the shape and the place

of the configuration, etc., and can be established experimentally. If

it proves, upon checking, that the corrections with the magnetized

configuration are too large or too small, the magnetisation process

can be repeated with varied magnetisation currents. The decaying alternating magnetic field can be generated by superimposing a decaying alternating current on the combination of currents through the magnetisation device (for example, a device as disclosed in Netherlands Pat. application No. 7,503,830 laid open to public inspection). The decaying alternating magnetic field is preferably generated in the magnetisation device by means of a separate system of coils. In order to obtain a substantially equal influence of all parts of the configuration by the decaying alternating field, it is recommendable not only to cause the alternating field to decay but also to cause it to vary its direction continuously. The system of coils therefore consists preferably of at least two coils and the decaying alternating currents through the coils are shifted in phase with respect to each other. Standard line frequency (50 or 60 Hz) has proven to give good results. The phase shift, when using coils or coil pairs, the axes of which enclose angles of 120° with each other, can simply be obtained from a three-phase line.

DESCRIPTION OF THE DRAWINGS

The invention will now be described in greater detail with reference to a drawing, in which

FIG. 1 is a diagrammatic sectional view of a known color display tube of the "in-line" type having an external static convergence unit,

FIG. 2 shows the pinion transmission used therein,

FIGS. 3 and 4 are two diagrammatic perpendicular cross-sectional views of the color display tube with a ring, which has not yet been magnetized, and in which the outermost electron beams do not converge satisfactorily,

FIGS. 5 and 6 are two diagrammatic perpendicular sectional views of a color display tube in which convergence by means of the magnetisation device has been obtained,

FIGS. 7 and 8 show the magnetisation of a ring arranged in the system of electron guns,

FIGS. 9 and 10 show two diagrammatic perpendicular sectional views of a color display tube with a magnetized ring with which the convergence error, as shown in FIG. 4, is removed,

FIGS. 11 and 12 show two types of devices suitable for magnetisation according to the invention, and

FIGS. 13 to 18 show parts of another type of magnetisation unit.

DESCRIPTION OF THE PREFERRED EMBODIMENTS

FIG.

1 is a diagrammatic sectional view of a known color display tube of

the "in-line" type. Three electron guns 5, 6 and 7, generating the

electron beams 8, 9 and 10, respectively, are accommodated in the neck 4

of a glass envelope 1 which is composed of a display window 2, a

funnel-shaped part 3 and a neck 4. The axes of the electron guns 5, 6

and 7 are situated in one plane, the plane of the drawing. The axis of

the central electron gun 6 coincides substantially with the tube axis

11. The three electron guns are seated in a sleeve 16 which is

situated coaxially in the neck 4. The display window 2 has on the

inner surface thereof a large number of triplets of phosphor lines.

Each triplet comprises a line of a phosphor luminescing green, a line

of a phosphor luminescing blue, and a line of a phosphor luminescing

red. All of the triplets together constitute a display screen 12.

The phosphor lines are normal to the plane of the drawing. A shadow

mask 12, in which a very large number of elongate apertures 14 are

provided through which the electron beams 8, 9 and 10 pass, is

arranged in front of the display screen 12. The electron beams 8, 9

and 10 are deflected in the horizontal direction (in the plane of the

drawing) and in the vertical direction (at right angles thereto) by a

system 15 of deflection coils. The three electron guns 5, 6 and 7

are assembled so that the axes thereof enclose a small angle with

respect to each other. As a result of this, the generated electron

beams 8, 9 and 10 pass through each of the apertures 14 at said

angle, the so-called color selection angle, and each impinge only

upon phosphor lines of one color.

FIG.

1 is a diagrammatic sectional view of a known color display tube of

the "in-line" type. Three electron guns 5, 6 and 7, generating the

electron beams 8, 9 and 10, respectively, are accommodated in the neck 4

of a glass envelope 1 which is composed of a display window 2, a

funnel-shaped part 3 and a neck 4. The axes of the electron guns 5, 6

and 7 are situated in one plane, the plane of the drawing. The axis of

the central electron gun 6 coincides substantially with the tube axis

11. The three electron guns are seated in a sleeve 16 which is

situated coaxially in the neck 4. The display window 2 has on the

inner surface thereof a large number of triplets of phosphor lines.

Each triplet comprises a line of a phosphor luminescing green, a line

of a phosphor luminescing blue, and a line of a phosphor luminescing

red. All of the triplets together constitute a display screen 12.

The phosphor lines are normal to the plane of the drawing. A shadow

mask 12, in which a very large number of elongate apertures 14 are

provided through which the electron beams 8, 9 and 10 pass, is

arranged in front of the display screen 12. The electron beams 8, 9

and 10 are deflected in the horizontal direction (in the plane of the

drawing) and in the vertical direction (at right angles thereto) by a

system 15 of deflection coils. The three electron guns 5, 6 and 7

are assembled so that the axes thereof enclose a small angle with

respect to each other. As a result of this, the generated electron

beams 8, 9 and 10 pass through each of the apertures 14 at said

angle, the so-called color selection angle, and each impinge only

upon phosphor lines of one color. A display tube has a good static convergence if the three electron beams, when they are not being deflected, intersect each other substantially in the center of the display screen. It has been found, however, that the static convergence often is not good, no more than the frame shape and the color purity, which may be the result of an insufficiently accurate assembly of the guns, and/or sealing of the electron guns, in the tube neck. In order to produce the static convergence, so far, externally adjustable correction units have been added to the tube. They consist of a number of pairs of multipoles consisting of magnetic rings, for example four two-poles (two horizontal and two vertical), two four-poles and two six-poles. The rings of each pair are coupled together by means of a pinion transmission (see FIG. 2), with which the rings are rotatable with respect to each other to an equal extent. By rotating the rings with respect to each other and/or together, the strength and/or direction of the two-, four- or six-pole field is adjusted. It will be obvious that the control of a display tube with such a device is complicated and time-consuming. Moreover, such a correction unit is material-consuming since, for a combination of multipoles, at least eight rings are necessary which have to be provided around the neck so as to be rotatable with respect to each other.

In the Netherlands Pat. application No. 7,503,830, laid open to public inspection, the complicated correction unit has, therefore, been replaced by one or more magnetized rings, which rings are situated in or around the tube neck or in or around the electron guns.

However, it has proved difficult with the magnetising methods known so far to provide a combination of multipoles in the ring by magnetisation.

The method according to the invention provides a solution.

For clarity, identical components in the following figures will be referred to by the same reference numerals as in FIG. 1.

FIG.

3 is a diagrammatic sectional view of a display tube in which the

electron beams do not converge in the horizontal direction. As is

known, the outermost electron beams can be deflected more or less in

the opposite direction by means of a four-pole, for example, towards

the central beam or away therefrom. It is also possible to move the

beams upwards and downwards. By means of a six-pole the beams can be

deflected more or less in the same direction. For simplicity, the

invention will be described with reference to a display tube which

requires only a four-pole correction. The convergence errors in the

horizontal direction of the electron beams 8 and 10 are in this case

equally large but opposite.

FIG.

3 is a diagrammatic sectional view of a display tube in which the

electron beams do not converge in the horizontal direction. As is

known, the outermost electron beams can be deflected more or less in

the opposite direction by means of a four-pole, for example, towards

the central beam or away therefrom. It is also possible to move the

beams upwards and downwards. By means of a six-pole the beams can be

deflected more or less in the same direction. For simplicity, the

invention will be described with reference to a display tube which

requires only a four-pole correction. The convergence errors in the

horizontal direction of the electron beams 8 and 10 are in this case

equally large but opposite. FIG. 4 is a sectional view of FIG. 3. On the bottom of sleeve 16, a ring 18 is provided of an alloy of Fe, Co, V and Cr (known as Vicalloy) which can be readily magnetized. It will be obvious that the ring may alternatively be provided in other places around the guns or in or around the tube neck. Instead of a ring it is alternatively possible to use a ribbon or a configuration of rods or blocks of magnetisable material.

In FIG. 5 a device 19 for generating a controllable multipole magnetic field is provided around the neck 4 and the ring 18 according to the method of the invention. 2-, 4- or 6-poles and co

mbinations

thereof can be generated by means of the device 19. For the tube

shown in FIG. 3, only a four-pole correction is necessary. The coils

of the device 19, which device will be described in detail

hereinafter, are in this case energized as four-poles until the point

of intersection S of the three electron beams 8, 9 and 10, which in

FIG. 3 was situated outside the tube 1, lies on the display screen 12.

The current I through the coils of the device originates from a

direct current source B which supplies a current -mI 1 (m

being an experimentally determined constant >1) to the coils

via a current divider and commutator A. The current can be adjusted

per coil so as to generate the desired multipole. In this phase of the

method, an alternating current source C does not yet supply current

(i=0).

mbinations

thereof can be generated by means of the device 19. For the tube

shown in FIG. 3, only a four-pole correction is necessary. The coils

of the device 19, which device will be described in detail

hereinafter, are in this case energized as four-poles until the point

of intersection S of the three electron beams 8, 9 and 10, which in

FIG. 3 was situated outside the tube 1, lies on the display screen 12.

The current I through the coils of the device originates from a

direct current source B which supplies a current -mI 1 (m

being an experimentally determined constant >1) to the coils

via a current divider and commutator A. The current can be adjusted

per coil so as to generate the desired multipole. In this phase of the

method, an alternating current source C does not yet supply current

(i=0). FIG. 6 is a perpendicular sectional view of FIG. 5. The current I 1 is a measure of the strength of the required correction field. The correction field of the multipole of the device 19 extends over a larger length of the electron paths than the magnetic field generated later by the magnetized ring. Therefore the field of the ring is to be m-times stronger.

FIG.

7 shows the step of the method in which the ring 18 is magnetized as

a four-pole. As follows from the above, in this preferred embodiment

of the method, the current through the coils of the device must be

-mI 1 during the magnetisation, so must traverse in the

reverse direction and be m-times as large as the current through the

coils during the correction. Moreover, the alternating current source

C supplies a decaying alternating current (i=i 1

>0) to the device 19, with which current the decaying

alternating field is generated. When the alternating current is

switched on, it must be so large that the ring 18 is fully magnetized

on either side of the hysteresis curve. When the alternating field

has decayed, the ring 18 is magnetized, in this case as a four-pole.

It is, of course, alternatively possible to magnetise the ring 18 as a

six-pole or as a two-pole or to provide combinations of said

multipoles in the ring 18 and to correct therewith other convergence

errors or color purity and frame errors. It is also possible to use

said corrections in color display tubes of the "delta" type.

FIG.

7 shows the step of the method in which the ring 18 is magnetized as

a four-pole. As follows from the above, in this preferred embodiment

of the method, the current through the coils of the device must be

-mI 1 during the magnetisation, so must traverse in the

reverse direction and be m-times as large as the current through the

coils during the correction. Moreover, the alternating current source

C supplies a decaying alternating current (i=i 1

>0) to the device 19, with which current the decaying

alternating field is generated. When the alternating current is

switched on, it must be so large that the ring 18 is fully magnetized

on either side of the hysteresis curve. When the alternating field

has decayed, the ring 18 is magnetized, in this case as a four-pole.

It is, of course, alternatively possible to magnetise the ring 18 as a

six-pole or as a two-pole or to provide combinations of said

multipoles in the ring 18 and to correct therewith other convergence

errors or color purity and frame errors. It is also possible to use

said corrections in color display tubes of the "delta" type.  FIG.

9 shows the display tube 1 shown in FIG. 3, but in this case

provided with a ring 18 magnetized according to the method of the

invention as shown in FIGS. 5 and 7. The convergence correction takes

place only by the magnetized ring 18 present in sleeve 16. The

provision of the required multipole takes place at the display tube 1

factory and complicated adjustments and adjustable convergence units

(FIG. 2) may be omitted.

FIG.

9 shows the display tube 1 shown in FIG. 3, but in this case

provided with a ring 18 magnetized according to the method of the

invention as shown in FIGS. 5 and 7. The convergence correction takes

place only by the magnetized ring 18 present in sleeve 16. The

provision of the required multipole takes place at the display tube 1

factory and complicated adjustments and adjustable convergence units

(FIG. 2) may be omitted. FIG. 10 is a cross-sectional view perpendicular to FIG. 9. FIG. 11 shows a magnetisation device 19 comprising eight coils 20 with which the convergence (see FIG. 5) and the magnetisation (see FIG. 7) are carried out. For generating the decaying alternating magnetic field, two pairs of coils 21 and 22, extending in this case at right angles to each other, are incorporated in the device 19. The current i a through the pair of coils 21 is shifted in phase through 90° with respect to the current i b through the other pair of coils 22, so that the decaying alternating magnetic field changes its direction during the decay and is a field circulating through the ring 18. FIG. 12 shows a magnetisation device known from Netherlands Pat. application No. 7,503,830 laid open to public inspection. In t

his

case, the decaying alternating current may be superimposed on the

direct current through the coils 23 so that extra coils are not

necessary in the device. The coils 23 are wound around a yoke 24.

his

case, the decaying alternating current may be superimposed on the

direct current through the coils 23 so that extra coils are not

necessary in the device. The coils 23 are wound around a yoke 24. The magnetisation device 19 may alternatively be composed of a combination of electrical conductors and coils, as is shown diagrammatically in FIGS. 13 to 18.

FIG. 13 is a sectional view of the neck 4 of a display tube 1 at the area of a ring 18 to be magnetised. A two-pole field for corrections in the horizontal direction is generated in this case by causing currents to flow through the conductors 25, 26, 27 and 28 in the direction as shown in the figure. Said conductors may be single wires or wire bundles forming part of one or more coils or turns, and extending parallel to the tube axis at the area of the ring 18.

FIG. 14 shows how, in an analogous manner, a four-pole field for corrections of the outermost beams 8 and 10 in the horizontal direction can be generated by electrical conductors 29, 30, 31 and 32. A four-pole field for corrections of the outermost beams 8 and 10 in the vertic

al

direction is substantially the same. However, the system of

conductors 29, 30, 31 and 32 is rotated through 45° with respect to

the neck 4 and the axis of the tube 1.

al

direction is substantially the same. However, the system of

conductors 29, 30, 31 and 32 is rotated through 45° with respect to

the neck 4 and the axis of the tube 1. FIG. 15 shows, in an analogous manner, a six-pole for corrections in the horizontal direction with conductors 33 to 38. By means of a combination of conductors (wires or wire bundles) with which 2-, 4- and 6-poles can be generated, all combinations of two-, four- and six-pole fields with the desired strength can be obtained by variations of the currents through said conductors 33 to 38.

The decaying alternating magnetic field in a magnetisation unit with conductors as shown in FIGS. 13, 14 and 15 can be obtained by means of coils positioned symmetrically around the neck 4 and the conductors as shown in FIGS. 16 and 17 or 18. By energizing the coils 3

9

and 40, shown in FIG. 16, with a decaying alternating current, a

decaying alternating magnetic field is generated. A better influencing

of the ring 18 by the decaying alternating field is obtained when a

system of coils having coils 41 and 42 in FIG. 17 is provided which is

rotated 90° with respect to the coils 39. In this case, 40 and the

decaying alternating current through the coils 41 and 42 should then

preferably be shifted 90° in phase with respect to the decaying

alternating current through the coils 39 and 40.

9

and 40, shown in FIG. 16, with a decaying alternating current, a

decaying alternating magnetic field is generated. A better influencing

of the ring 18 by the decaying alternating field is obtained when a

system of coils having coils 41 and 42 in FIG. 17 is provided which is

rotated 90° with respect to the coils 39. In this case, 40 and the

decaying alternating current through the coils 41 and 42 should then

preferably be shifted 90° in phase with respect to the decaying

alternating current through the coils 39 and 40. It is alternatively possible to generate the decaying al

ternating

magnetic field with one or more systems of coils as shown in FIG.

18. The coils 43, 44 and 45 are situated symmetrically around the

tube axis and are energized with decaying alternating currents which

are shifted 120° in phase with respect to each other (for example

from a three-phase line).

ternating

magnetic field with one or more systems of coils as shown in FIG.

18. The coils 43, 44 and 45 are situated symmetrically around the

tube axis and are energized with decaying alternating currents which

are shifted 120° in phase with respect to each other (for example

from a three-phase line).

CRT TUBE PHILIPS 45AX TECHNOLOGY Method of manufacturing a static convergence unit, and a color display tube comprising a convergence unit manufactured according to the method, PHILIPS 45AX INTERNAL STATIC CONVERGENCE SYSTEM Application technology:

IMACO RING (Integrated Magnetic Auto Converging )

The method according to the invention consists in the determination of data of the convergence errors of a color display tube, data being derived from the said determinations for determining the polarity and the intensity of magnetic poles of a structure. The structure thus obtained generates a static, permanent, multipole magnetic field adapted to the convergence errors occurring, so that the errors are connected.

nstructing said annular permanent magnetic convergence structure

having a desired magnetic field strength from a set of previously

magnetized structural parts. 6. A method as claimed in claim 1,

further comprising forming the convergence structure from a

magnetizable mass which is annularly arranged on at least one wall of

the neck of the color display tube. 7. A method as claimed in claim 1,

further comprising forming the convergence structure from a

magnetizable ring which is arranged on the neck of the color display

tube. 8. A method as claimed in claim 1, wherein the convergence

structure comprises a non-magnetizable support and a number of

permanent magnetic dipoles. 9. A method as claimed in claim 4, wherein

said magnetizing step cofmprises polarizing the magnetizable

material of the annular convergence structure at one location after

the other by means of the magnetizing unit. 10. A method as claimed

in claim 4, further comprising assemblying the auxiliary device and

the magnetizing unit in one construction, and then enclosing a

convergence structure to be magnetized with said magnetizing unit.

11. A method as claimed in claim 10, further comprising displacing

said construction with respect to said tube after said determining

step.

nstructing said annular permanent magnetic convergence structure

having a desired magnetic field strength from a set of previously

magnetized structural parts. 6. A method as claimed in claim 1,

further comprising forming the convergence structure from a

magnetizable mass which is annularly arranged on at least one wall of

the neck of the color display tube. 7. A method as claimed in claim 1,

further comprising forming the convergence structure from a

magnetizable ring which is arranged on the neck of the color display

tube. 8. A method as claimed in claim 1, wherein the convergence

structure comprises a non-magnetizable support and a number of

permanent magnetic dipoles. 9. A method as claimed in claim 4, wherein

said magnetizing step cofmprises polarizing the magnetizable

material of the annular convergence structure at one location after

the other by means of the magnetizing unit. 10. A method as claimed

in claim 4, further comprising assemblying the auxiliary device and

the magnetizing unit in one construction, and then enclosing a

convergence structure to be magnetized with said magnetizing unit.

11. A method as claimed in claim 10, further comprising displacing

said construction with respect to said tube after said determining

step.  extend

approximately in one plane in a neck of a colour display tube, and

to a colour display tube provided with a permanent magnetic device

for the static convergence of electron beams in the colour display

tube. A known device, described in U.S. Pat. No. 3,725,831, consists

of at least four permanent magnetic rings arranged in pairs which

generate a magnetic field that can be adjusted as regards position

and intensity. The adjustability is obtained by turning the two rings

of a pair in the same direction with respect to the electron beams

and by turning the one ring in the opposite direction with respct to

the other ring. The adjustability necessitates that the rings be

arranged on a support which is arranged about the neck of the colour

display tube and which should include facilities such that the

adjustability of each pair of rings, independent of the position of

the other rings, is ensured. The invention has for its object to

provide a method whereby a device for converging electron beams can

be manufactured which need not be mechanically adjustable, so that it

can have a very simple construction, and to provide a colour display

tube including such a device.

extend

approximately in one plane in a neck of a colour display tube, and

to a colour display tube provided with a permanent magnetic device

for the static convergence of electron beams in the colour display

tube. A known device, described in U.S. Pat. No. 3,725,831, consists

of at least four permanent magnetic rings arranged in pairs which

generate a magnetic field that can be adjusted as regards position

and intensity. The adjustability is obtained by turning the two rings

of a pair in the same direction with respect to the electron beams

and by turning the one ring in the opposite direction with respct to

the other ring. The adjustability necessitates that the rings be

arranged on a support which is arranged about the neck of the colour

display tube and which should include facilities such that the

adjustability of each pair of rings, independent of the position of

the other rings, is ensured. The invention has for its object to

provide a method whereby a device for converging electron beams can

be manufactured which need not be mechanically adjustable, so that it

can have a very simple construction, and to provide a colour display

tube including such a device.  ce

errors can be eliminated by this method. The convergence errors

visible on the screen can be measured and expressed in milimeters of

horizontal and vertical errors. The errors thus classified represent

data whereby, using magnetic poles of an intensity to be derived from

the errors, there can be determined a structure of a magnetic

multi-pole which generates a permanent magnetic field adapted to the

determined convergence errors.

ce

errors can be eliminated by this method. The convergence errors

visible on the screen can be measured and expressed in milimeters of

horizontal and vertical errors. The errors thus classified represent

data whereby, using magnetic poles of an intensity to be derived from

the errors, there can be determined a structure of a magnetic

multi-pole which generates a permanent magnetic field adapted to the

determined convergence errors.  er by means of the

magnetizing unit. A suitable alternative of the method for which use

can be made of the described construction of the magnetizing unit is

characterized in that the device consists of a non-magnetizable

support and a number of permanent magnetic bipoles. It was found that

any feasible magnetic field required for the static convergence of

electron beams in a neck of a colour display tube can be

comparatively simply generated using at least one eight-pole

electromagnetic convergence unit. Similarly, any desired magnetic

field can be generated using a twelve-pole electromagnetic

convergence unit. It is to be noted that electromagnetic convergence

units have already been proposed in U.S. Pat. No. 4,027,219.

er by means of the

magnetizing unit. A suitable alternative of the method for which use

can be made of the described construction of the magnetizing unit is

characterized in that the device consists of a non-magnetizable

support and a number of permanent magnetic bipoles. It was found that

any feasible magnetic field required for the static convergence of

electron beams in a neck of a colour display tube can be

comparatively simply generated using at least one eight-pole

electromagnetic convergence unit. Similarly, any desired magnetic

field can be generated using a twelve-pole electromagnetic

convergence unit. It is to be noted that electromagnetic convergence

units have already been proposed in U.S. Pat. No. 4,027,219.  tromagnetic

auxiliary device 5 is arranged around the neck 3 of the colour

display tube 1. The auxiliary device 5 will be described in detail

with reference to FIG. 3. Electrical currents which generate a

magnetic field are applied to the auxiliary device 5. When the

electrical currents are adjusted to the correct value, a magnetic

field adapted to the colour display tube 1 as regards position and

intensity is generated. The electrical currents are measured by means

of the measuring unit 9. The electrical currents represent data which

completely describe the magnetic field generated by the auxiliary

device 5. The data are stored in a memory 19 (for example, a ring core

memory) in an adapted form (digitally). The data can be extracted

from the memory 19 again for feeding a control unit 11. The control

unit 11 actuates a magnetizing unit 13. A magnetic field is impressed

on the device 15 arranged inside the magnetizing unit 13 (shown to be

arranged outside this unit in FIG. 1), the said magnetic field

equalling the magnetic field generated by the auxiliary device 5 at

the area of the electron beams. The auxiliary device 5 is then removed

from the neck 3 and replaced by the device 15.

tromagnetic

auxiliary device 5 is arranged around the neck 3 of the colour

display tube 1. The auxiliary device 5 will be described in detail

with reference to FIG. 3. Electrical currents which generate a

magnetic field are applied to the auxiliary device 5. When the

electrical currents are adjusted to the correct value, a magnetic

field adapted to the colour display tube 1 as regards position and

intensity is generated. The electrical currents are measured by means

of the measuring unit 9. The electrical currents represent data which

completely describe the magnetic field generated by the auxiliary

device 5. The data are stored in a memory 19 (for example, a ring core

memory) in an adapted form (digitally). The data can be extracted

from the memory 19 again for feeding a control unit 11. The control

unit 11 actuates a magnetizing unit 13. A magnetic field is impressed

on the device 15 arranged inside the magnetizing unit 13 (shown to be

arranged outside this unit in FIG. 1), the said magnetic field

equalling the magnetic field generated by the auxiliary device 5 at

the area of the electron beams. The auxiliary device 5 is then removed

from the neck 3 and replaced by the device 15.  The

method shown in FIG. 2 is an alternative to the method described

with reference to FIG. 1. The auxiliary device 5 and the magnetizing

unit 13 are accommodated together in one construction 6. Before the

auxiliary device 5 and the magnetizing unit 13 are arranged around the

neck 3 of the colour display tube 1, the as yet unmagnetized device

15 is arranged in a desired position. The auxiliary device 5 is

activated and adjuste so that a magnetic field converging the electron

beams is produced. Subsequently, the measuring unit 9 determines the

necessary data whereby the control unit 11 is adjusted. The

auxiliary device 5 may be shifted so that the magnetizing unit 13

encloses the device 15. After the current to the auxiliary device 5

has been interrupted, the magnetizng unit 13 is activated by the

control unit 11. After magnetization of the device 15, the auxiliary

device 5 and the magnetizing unit 13 are removed. A convergence unit

which has been exactly adjusted as regards position and strength has

then been arranged on the neck 3 of the tube 1.

The

method shown in FIG. 2 is an alternative to the method described

with reference to FIG. 1. The auxiliary device 5 and the magnetizing

unit 13 are accommodated together in one construction 6. Before the

auxiliary device 5 and the magnetizing unit 13 are arranged around the

neck 3 of the colour display tube 1, the as yet unmagnetized device

15 is arranged in a desired position. The auxiliary device 5 is

activated and adjuste so that a magnetic field converging the electron

beams is produced. Subsequently, the measuring unit 9 determines the

necessary data whereby the control unit 11 is adjusted. The

auxiliary device 5 may be shifted so that the magnetizing unit 13

encloses the device 15. After the current to the auxiliary device 5

has been interrupted, the magnetizng unit 13 is activated by the

control unit 11. After magnetization of the device 15, the auxiliary

device 5 and the magnetizing unit 13 are removed. A convergence unit

which has been exactly adjusted as regards position and strength has

then been arranged on the neck 3 of the tube 1. situated

in one plane and radially orientated. Each pole shoe has provided

thereabout a winding wherethrough a direct current I to be adjusted is

to be conducted.

situated

in one plane and radially orientated. Each pole shoe has provided

thereabout a winding wherethrough a direct current I to be adjusted is

to be conducted.  portion

and the adjoining display screen not being shown. At the end of the

neck 3 there are provided contact pins 33 to which cathodes and

electrodes of the system of electron guns 35 are connected. The device

15 for the static convergence of the electron beams generated by the

system of guns 35 consists of a support 15A of synthetic material and a

ferrite ring 15B. On the jacket surface of the support 15A is

provided a ridge 15c which extends in the longitudinal direction; the

ferrite ring 15B is provided with a slot which co-operates therewith

and which opens into the edge of the ring on only one side, so that

the ring 15B can be secured to the carrier 15A in only one way. FIG. 5

is a cross-sectional view which clearly shows the ridge 15C and the

slot of the device 15. The references used in FIG. 5 correspond to

those used in FIG. 4.

portion

and the adjoining display screen not being shown. At the end of the

neck 3 there are provided contact pins 33 to which cathodes and

electrodes of the system of electron guns 35 are connected. The device

15 for the static convergence of the electron beams generated by the

system of guns 35 consists of a support 15A of synthetic material and a

ferrite ring 15B. On the jacket surface of the support 15A is

provided a ridge 15c which extends in the longitudinal direction; the

ferrite ring 15B is provided with a slot which co-operates therewith

and which opens into the edge of the ring on only one side, so that

the ring 15B can be secured to the carrier 15A in only one way. FIG. 5

is a cross-sectional view which clearly shows the ridge 15C and the

slot of the device 15. The references used in FIG. 5 correspond to

those used in FIG. 4.  shoes

47 and 49 preferably are shaped to follow the curved faces 51 and 53

of the device substantially completely. In order to enable easy

arrangement and displacement of the device between the pole shoes 47

and 49, the core portions 43 and 45 are provided with ground contact

faces 55 and 57 which are perpendicular to each other. The pole shoes

47 and 49 can be moved away from and towards each other, the core

portions 43 and 45 always returning to the same position relative to

each other due to the faces 55 and 57 perpendicularly extending to each

other. At the same time, the magnetic contact resistance at the

faces 55 snd 57 is low and constant, so that the necessary

unambiguous relationship between the current Im and the magnetic

field generated in the core is ensured.

shoes

47 and 49 preferably are shaped to follow the curved faces 51 and 53

of the device substantially completely. In order to enable easy

arrangement and displacement of the device between the pole shoes 47

and 49, the core portions 43 and 45 are provided with ground contact

faces 55 and 57 which are perpendicular to each other. The pole shoes

47 and 49 can be moved away from and towards each other, the core

portions 43 and 45 always returning to the same position relative to

each other due to the faces 55 and 57 perpendicularly extending to each

other. At the same time, the magnetic contact resistance at the

faces 55 snd 57 is low and constant, so that the necessary

unambiguous relationship between the current Im and the magnetic

field generated in the core is ensured.  5

consists of a support 61 of synthetic material, for example,

polycarbonate, wherein eight ferromagnetic discs (or "inserts") 63 are

equidistantly arranged along the circumference. It will be obvious

that this embodiment is particularly suitable for being actuated in a

magnetizing unit as shown in FIG. 8. The holes 65 provided in the

support 61 are slightly elliptical so as to lock the capsules 63 firmly

in the holes 65. To this end, the width b is chosen to be slightly

smaller than the height h which equals the diameter d of the round

discs (or "inserts") 63. The narrow portions 67 of the support 61

with clamp the disc 63 in the hole 65 due to their elastic action. It

is, of course, possible to magnetize the disc 63 before they are

arranged in the support 61; the sequence in which the disc 63 are

arranged in the support 61 should then be carefully checked.

5

consists of a support 61 of synthetic material, for example,

polycarbonate, wherein eight ferromagnetic discs (or "inserts") 63 are

equidistantly arranged along the circumference. It will be obvious

that this embodiment is particularly suitable for being actuated in a

magnetizing unit as shown in FIG. 8. The holes 65 provided in the

support 61 are slightly elliptical so as to lock the capsules 63 firmly

in the holes 65. To this end, the width b is chosen to be slightly

smaller than the height h which equals the diameter d of the round

discs (or "inserts") 63. The narrow portions 67 of the support 61

with clamp the disc 63 in the hole 65 due to their elastic action. It

is, of course, possible to magnetize the disc 63 before they are

arranged in the support 61; the sequence in which the disc 63 are

arranged in the support 61 should then be carefully checked. Color television display tube with coma correction ELECTRON GUN STRUCTURE PHILIPS CRT TUBE 45AX

A color television display tube including an electron gun system (5) in an evacuated envelope for generating three electron beams whose axes are co-planar. The beams converge on a display screen (10) provided on a wall of the envelope and are deflected in the operative display tube across the display screen into two orthogonal directions. The electron gun system (5) has correction elements for causing the rasters scanned on the display screen by the electron beams to coincide as much as possible. The correction elements include annular elements (34) of a material having a high magnetic permeability which are positioned around the two outer beams. In addition a further correction element (38, 38", 38"') of a material having a high magnetic permeability is provided around the central beam in a position located further from the screen in order to correct field coma errors at the ends of the vertical axis and in the corners to an equal extent. The further element is preferably positioned in, or on the screen side of, the area of the focusing gap of the electron gun.

1. A color display

tube comprising an envelope containing a display screen, and an

electron gun system for producing a central electron beam and first

and second outer electron beams having respective axes which lie in a

single plane and converge toward a point on the screen, the

electron gun system including an end from which the electron beams

exit into a deflection field region of the envelope where a field

deflection field effects deflection of the beams in a direction

perpendicular to said plane and a line deflection field effects

deflection of the beams in a direction parallel to said plane, said

line deflection field producing a positive lens action;

tube comprising an envelope containing a display screen, and an

electron gun system for producing a central electron beam and first

and second outer electron beams having respective axes which lie in a

single plane and converge toward a point on the screen, the

electron gun system including an end from which the electron beams

exit into a deflection field region of the envelope where a field

deflection field effects deflection of the beams in a direction

perpendicular to said plane and a line deflection field effects

deflection of the beams in a direction parallel to said plane, said

line deflection field producing a positive lens action;  l

to the outer-electron-beam-produced rasters.

l

to the outer-electron-beam-produced rasters. elates

to a colour television display tube comprising an electron gun

system of the "in-line" type in an evacuated envelope for generating

three electron beams. The beam axes are co-planar and converge on a

display screen provided on a wall of the envelope while the beams are

deflected across the display screen into two orthogonal directions

by means of a first and a second deflection field. The electron gun

system is provided with field shapers for causing the rasters

scanned on the display screen by the electron beams to coincide as

much as possible. The field shapers comprise elements of a

magnetically permeable material positioned around the two outer beams

and placed adjacent the end of the electron gun system closest to

the screen.

elates

to a colour television display tube comprising an electron gun

system of the "in-line" type in an evacuated envelope for generating

three electron beams. The beam axes are co-planar and converge on a

display screen provided on a wall of the envelope while the beams are

deflected across the display screen into two orthogonal directions

by means of a first and a second deflection field. The electron gun

system is provided with field shapers for causing the rasters