The CHASSIS CUC1837 DIGI-100 Is the last Digital chassis for the 100HZ digital scan feature from GRUNDIG officially developed and made.

All further products from 2002 with GRUNDIG brand name are BEKO (Crap) made, and are completely different.

Grundig's New Digi 100 chassis concept for increased comfort

1st February 2001 Nuremberg.With the new Digi 100 chassis, Grundig is setting another standard for television technology. In the 100-Hertz class

of the TV Elegance family, the Digi 100 concept offers not only more comfort, user-friendliness and future-oriented equipment, but is also master over the ever growing number of channels. Thanks to alphanumeric program selection, the Electronic Program Guide (EPG), Personal TV and the zapping button, selecting the correct channel number is child's play.

of the TV Elegance family, the Digi 100 concept offers not only more comfort, user-friendliness and future-oriented equipment, but is also master over the ever growing number of channels. Thanks to alphanumeric program selection, the Electronic Program Guide (EPG), Personal TV and the zapping button, selecting the correct channel number is child's play.In addition, Grundig has improved its already successful Easy Dialog electronic user guide and has made it even more straightforward to use. The integrated keyword index contains all the terms which the user needs to know. With a direct link between definition and execution, open questions are quickly answered. Moreover, a detailed graphical representation of the connections available makes it easy to add on peripheral devices such as video recorders, DVD players or personal digital recorders.

The qualities of the new Grundig Easy Dialog are best accessed with the ergonomically harmonized design concept developed by Alexander Neumeister for the Tele Pilot 100 C remote control. The "floating" remote control combines trend-setting design with intuitive touch functionality. Due to its unusual form, the Tele Pilot is not only easy to hold: the most important and often-used keys are in a practical place within thumb's reach, and are ideal for interaction with the Easy Dialog user guide.

The new alphanum

eric channel selection is one of the functional highlights of the Grundig Tele Pilot. In the same way as a mobile phone, the television viewer can enter letters that then take them to the desired channel at lightening speed. Several people can program their personal channel order using the "Personal TV" option, so that the channel sequence can be changed according to personal taste.

eric channel selection is one of the functional highlights of the Grundig Tele Pilot. In the same way as a mobile phone, the television viewer can enter letters that then take them to the desired channel at lightening speed. Several people can program their personal channel order using the "Personal TV" option, so that the channel sequence can be changed according to personal taste.A further innovation is the zapping button. The current channel is marked with a "bookmark" and, if the channel is changed, the marked channel can be immediately retrieved by pressing the Z key. The two channels viewed most recently can also be swapped at lightning speed with the touch of a key. The mode key with LED display completes the multi-faceted functionality of the Grundig Tele Pilot. Switching between the TV and external Grundig devices such as satellite receivers, video recorders or DVD players becomes child's play. The basic unit of the Grundig Digi 100 chassis can be expanded at any time thanks to an integrated interface. Thus, depending on the type of appliance, the equipment can be upgraded by a qualified dealer, for example with DVB, DVD, PDR, PIP, Dolby Digital or by increasing the teletext to 2000 pages.

The chassis GRUNDIG CUC1837 DIGI-100 is mainly based around ITT/MICRONAS Digital technology chipset (Micronas MEGAVISION® IC set) for the signal processing.

Other parts are based on Siemens/Infineon and PHILIPS and Thomson semiconductors techology.

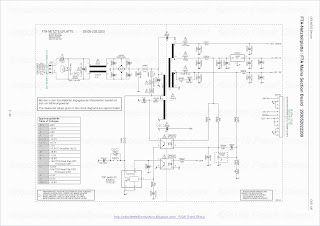

TDA 16846 Controller for Switch Mode Power Supplies Supporting Low Power Standby and Power Factor Correction

Description

The TDA 16846 is optimized to control free running or fixed frequency flyback converters

with or without Power Factor Correction (Current Pump). To provide low power

consumption at light loads, this device reduces the switching frequency continuously

with load, towards an adjustable minimum (e. g. 20 kHz in standby mode). Additionally,

the start up current is very low

. To avoid switching stresses of the power devices, the

. To avoid switching stresses of the power devices, thepower transistor is always switched on at minimum voltage. A special circuit is

implemented to avoid jitter. The device has several protection functions: VCC over- and

undervoltage, mains undervoltage, current limiting and 2 free usable fault comparators.

Regulation can be done by using the internal error amplifier or an opto coupler feedback

(additional input). The output driver is ideally suited for driving a power MOSFET, but it

can also be used for a bipolar transistor. Fixed frequency and synchronized operation

are also possible.

Short Description of the Pin Functions

Pin Function

1 A parallel RC-circuit between this pin and ground determines the ringing

suppression time and the standby-frequency.

2 A capacitor between this pin and ground and a resistor between this pin and

the positive terminal of the primary elcap quantifies the max. possible output

power of the SMPS.

3 This is the input of the error amplifier and the zero crossing input. The output

of a voltage divider between the control winding and ground is connected to

this input. If the pulses at pin 3 exceed a 5 V threshold, the control voltage at

pin 4 is lowered.

4 This is the pin for the control voltage. A capacitor has to be connected

between this pin and ground. The value of this capacitor determines the

duration of the softstart and the speed of the control.

5 If an opto coupler for the control is used, it’s output has to be connected

between this pin and ground. The voltage divider at pin 3 has then to be

changed, so that the pulses at pin 3 are below 5 V.

6 Fault comparator 2: If a voltage > 1.2 V is applied to this pin, the SMPS stops.

7 If fixed frequency mode is wanted, a parallel RC circuit has to be connected

between this pin and ground. The RC-value determines the frequency. If

synchronized mode is wanted, sync pulses have to be fed into this pin.

8 Not connected (TDA 16846). /

This is the power measurement output of the

This is the power measurement output of theTemporary High Power Circuit. A capacitor and a RC-circuit has to be

connected between this pin and ground (TDA 16847).

9 Output for reference voltage (5 V). With a resistor between this pin and ground

the fault comparator 2 (pin 6) is enabled.

10 Fault comparator 1: If a voltage > 1 V is applied to this pin, the SMPS stops.

11 This is the input of the primary voltage check. The voltage at the anode of the

primary elcap has to be fed to this pin via a voltage divider. If the voltage of

this pin falls below 1 V, the SMPS is switched off. A second function of this pin

is the primary voltage dependent fold back point correction (only active in free

running mode).

12 Common ground.

13 Output signal. This pin has to be connected across a serial resistor with the

gate of the power transistor.

14 Connection for supply voltage and startup capacitor. After startup the supply

voltage is produced by the control winding of the transformer and rectified by

an external diode.

Start Up Behaviour (Pin 14)

When power is applied to the chip and the voltage V14 at Pin 14 (VCC) is less than the

upper threshold (VON) of the Supply Voltage Comparator (SVC), input current I14 will be

less than 100 mA. The chip is not active and driver output (Pin 13) and control output

(Pin 4) will be actively held low. When V14 exceeds the upper SVC threshold (VON) the

chip starts working and I14 increases. When V14 falls below the lower SVC threshold

(VOFF) the chip starts again at his initial condition. Figure 4 shows the start-up circuit and

Figure 5 shows the voltage V14 during start up. Charging of C14 is done by resistor R2 of

the “Primary Current Simulation” (see later) and the internal diode D1, so no additional

start up resistor is needed. The capacitor C14 delivers the supply current until the

auxiliary winding of the transformer supplies the chip with current through the external

diode D14.

Protect

ion Functions

ion FunctionsThe chip has several protection functions:

Current Limiting

See “Primary Current Simulation PCS (Pin 2) / Current Limiting” and “Fold Back Point

Correction PVC (Pin 11)”.

Over- and Undervoltage Lockout OV/SVC (Pin 14)

When V14 at Pin 14 exceeds 16 V, e. g. due to a fault in the regulation circuit, the Error

Flip Flop ERR is set and the output driver is shut-down. When V14 goes below the lower

SVC threshold, ERR is reset and the driver output (Pin 13) and the soft-start (Pin 4) are

shut down and actively held low.

Primary Voltage Check PVC (Pin 11)

When the voltage V11 at Pin 11 goes below 1 V the Error Flip Flop (ERR) is set. E.g. a

voltage divider from the rectified mains at Pin 11 prevents from high input currents at too

low input voltage.

Free Usable Fault Comparator FC1 (Pin 10)

When the voltage at Pin 10 exceeds 1 V, the Error Flip Flop (ERR) is set. This can be

used e. g. for mains overvoltage shutdown.

Free Usable Fault Comparator FC2 (Pin 6)

When the voltage at Pin 6 exceeds 1.2 V, the Error Flip Flop (ERR) is set. A resistor

between Pin 9 (REF) and ground is necessary to enable this fault comparator.

Voltage dependent Ringing Suppression Time

During start-up and short-circuit operation, the output voltage of the converter is low and

parasitic zero crossings are applied for a longer time at Pin 3. Therefore the Ringing

Suppression Time TC1 (see “Off-Time Circuit OTC (Pin 1)”) is made longer with

factor 2.5 at low output voltage. To ensure start-up of the circuit, the value of resistor R1

(Pin 1, Figure 6) must be higher than 20 kW.

TDA8145 TV EAST/WEST CORRECTION CIRCUIT FOR SQUARE TUBES

FEATURES SUMMARY

■ L

OW DISSIPATION

OW DISSIPATION■ SQUARE GENERATOR FOR PARABOLIC

CURRENT SPECIALLY DESIGNED FOR

SQUARE C.R.T. CORRECTION

■ EXTERNAL KEYSTONE ADJUSTMENT

(symmetry of the parabola)

■ INPUT FOR DYNAMIC FIELD CORRECTION

(beam current change)

■ STATIC PICTURE WIDTH ADJUSTMENT

■ PULSE-WIDTH MODULATOR

■ FINAL STAGE D-CLASS WITH ENERGY

REDELIVERY

■ PARASITIC PARABOLA SUPPRESSION,

DURING FLYBACK TIME OF THE VERTICAL

SAWTOOTH

DESCRIPTION

The TDA8145 is a monolithic integrated circuit in a

8 pin minidip plastic package designed for use in

the square C.R.T. east-west pin-cushion correction

by driving a diode modulator in TV and monitor

applications.

CIRCUIT OPERATION

(see the shematic diagram)

A differential amplifier OP1 is driven by a vertical

frequency sawtooth current of ± 33µA which is

produced via an external resistor fromthe sawtooth

voltage. The non–inverting input of this amplifier

is connected with a reference voltage

corresponding to the DC level of the sawtooth voltage.

This DC voltage should be adjustable for the

keystone correction. The rectified output current of

this amplifier drives the parabola networkwhich

provides a parabolic output current.

This output current produces the corresponding

voltage due to the voltage drop across the external

resistor at pin 7.

If the input is overmodulated (> 40µA) the internal

current is limited to 40µA. This limitation can be

used for suppressing the parasitic parabolic current

generated during the flyback time of the frame

sawtooth.

A comparator OP2 is driven by the parabolic current.

The second input of the comparator is connected

with a horizontal frequency sawtooth

voltage the DC level of which can be changed by

the external circuitry for the adjustment of the picture

width.

The horizontal frequency pulse–width modulated

output signal drives the final stage. It consists of a

class D push–pull output amplifier that drives, via

an external inductor, the diode modulator.

TDA8177 VERTICAL DEFLECTION BOOSTER

DESCRIPTION

Designed for monitors and high performance TVs,

the TDA8177 vertical deflection booster delivers

flyback voltages up to 70V.

The TDA8177 operates with supplies up to 35V and

provides up to 3APP output current to drive the yoke.

The TDA8177 is offered in HEPTAWATT package.

---------------------------------------------------------------------------

SIGNAL BAUSTEIN UNIT: 29504-202.21

TEA6425 VIDEO CELLULAR MATRIX

DESCRIPTION

This device is intended for switching between video

and chroma signals such as CVBS, SVHS,

baseband CVBS, MAC. Each input clamp mode,

each output gain, all switching are controlled

through the I2C bus. The 8 outputs can be set separately

in high impedance state, to enable parallel

DC connection of several devices (up to 4).

FUNCTIONAL DESCRIPTION

This device is controlled via the I2C bus. 4 addresses

can be selected by a 4-level detector on Pin 7,

thus enabling parallel connection of 4 devices.

Via the I2C bus :

– The input signals can be clamped at their negative

peak (top sync).

– The gain factor of the outputs can be selected

between 0.5 and 6.5dB.

– Each of the 6 inputs can be connected to the 8

outputs.

– Each output can individually be set in a high impedance

state.

Two internal SVHS mixers will add the selected Y

and C inputs. Two dedicated outputs will have the

option to select this added signal also.

. 6 Video Inputs - 8 Video Outputs

. 2 Internal Selectable YC Adders

. 15MHz Bandwidth @ -3dB

. Selectable 0.5/6.5dB Gain FOR EACH Output

. High Impedance Switch for each Output (3-

state operation)

. Programmable Clamp Mode on each Input (sync bottom or average value)

. -60dB Crosstalk @ 5MHz

. 4 Sub-address Capability

. I2C Bus Control

TDA9885; TDA9886 ,I2C-bus controlled single and multistandard alignment-free IF-PLL demodulators:

FEATURES

· 5 V supply voltage

· Gain controlled wide-band Vision Intermediate

Frequency (VIF) amplifier, AC-coupled

· Multistandard true synchronous demodulation with

active carrier regeneration: very linear demodulation,

good intermodulation figures, reduced harmonics, and

excellent pulse response

· Gated phase detector for L and L-accent standard

· Fully integrated VIF Voltage Controlled Oscillator

(VCO), alignment-free, frequencies switchable for all

negative and positive modulated standards via I2C-bus

· Digital acquisition help, VIF frequencies of 33.4, 33.9,

38.0, 38.9, 45.75, and 58.75 MHz

· 4 MHz reference frequency input: signal from

Phase-Locked Loop (PLL) tuning system or operating

as crystal oscillator

· VIF Automatic Gain Control (AGC) detector for gain

control, operating as peak sync detector for negative

modulated signals and as a peak white detector for

positive modulated signals

· External AGC setting via pin OP1

· Precise fully digital Automatic Frequency Control (AFC)

detector with 4-bit digital-to-analog converter, AFC bits

readable via I2C-bus

· TakeOver Point (TOP) adjustable via I2C-bus or

alternatively with potentiometer

· Fully integrated sound carrier trap for 4.5, 5.5,

6.0, and 6.5 MHz, controlled by FM-PLL oscillator

· Sound IF (SIF) input for single reference Quasi Split

Sound (QSS) mode, PLL controlled

· SIF-AGC for gain controlled SIF amplifier, single

reference QSS mixer able to operate in high

performance single reference QSS mode and in

intercarrier mode, switchable via I2C-bus

· AM demodulator without extra reference circuit

· Alignment-free selective FM-PLL demodulator with high

linearity and low noise

· Four selectable I2C-bus addresses

· I2C-bus control for all functions

· I2C-bus transceiver with pin programmable Module

Address (MAD).

2 GENERAL DESCRIPTION

The TDA9885 is an alignment-free multistandard

(PAL and NTSC) vision and sound IF signal PLL

demodulator for negative modulation only and

FM processing.

The TDA9886 is an alignment-free multistandard

(PAL, SECAM and NTSC) vision and sound IF signal PLL

demodulator for positive and negative modulation,

including sound AM and FM processing.

3 APPLICATIONS

· TV, VTR, PC, and STB applications.

FUNCTIONAL DESCRIPTION

Figure 1 shows the simplified block diagram of the device

which comprises the following functional blocks:

· VIF amplifier

· Tuner AGC and VIF-AGC

· VIF-AGC detector

· Frequency Phase-Locked Loop (FPLL) detector

· VCO and divider

· AFC and digital acquisition help

· Video demodulator and amplifier

· Sound carrier trap

· SIF amplifier

· SIF-AGC detector

· Single reference QSS mixer

· AM demodulator

· FM demodulator and acquisition help

· Audio amplifier and mute time constant

· Internal voltage stabilizer

· I2C-bus transceiver and MAD (module address).

8.1 VIF amplifier

The VIF amplifier consists of three AC-coupled differential

stages. Gain control is performed by emitter degeneration.

The total gain control range is typically 66 dB. The

differential input impedance is typically 2 kWin parallel with

3 pF.

8.2 T

uner AGC and VIF-AGC

uner AGC and VIF-AGCThis block adapts the voltages, generated at the VIF-AGC

and SIF-AGC detectors, to the internal signal processing

at the VIF and SIF amplifiers and performs the tuner AGC

control current generation. The onset of the tuner AGC

control current generation can be set either via the I2C-bus

(see Table 13) or optionally by a potentiometer at pin TOP

(in case that the I2C-bus information cannot be stored,

related to the device). The presence of a potentiometer is

automatically detected and the I2C-bus setting is disabled.

Furthermore, derived from the AGC detector voltage, a

comparator is used to test if the corresponding VIF input

voltage is higher than 200 mV. This information can be

read out via the I2C-bus (bit VIFLEV = 1).

8.3 VIF-AGC detector

Gain control is performed by sync level detection (negative

modulation) or peak white detection (positive modulation).

For negative modulation, the sync level voltage is stored at

an integrated capacitor by means of a fast peak detector.

This voltage is compared with a reference voltage

(nominal sync level) by a comparator which charges or

discharges the integrated AGC capacitor for the

generation of the required VIF gain. The time constants for

decreasing or increasing the gain are nearly equal and the

total AGC reaction time is fast to cope with ‘aeroplane

fluttering’.

For positive modulation, the white peak level voltage is

compared with a reference voltage (nominal white level)

by a comparator which charges (fast) or discharges (slow)

the external AGC capacitor directly for the generation of

the required VIF gain. The need of a very long time

constant for VIF gain increase is because the peak white

level may appear only once in a field. In order to reduce

this time constant, an additional level detector increases

the discharging current of the AGC capacitor (fast mode)

in the event of a decreasing VIF amplitude step controlled

by the detected actual black level voltage. The threshold

level for fast mode AGC is typically -6 dB video amplitude.

The fast mode state is also transferred to the SIF-AGC

detector for speed-up. In case of missing peak white

pulses, the VIF gain increase is limited to typically +3 dB

by comparing the detected actual black level voltage with

a corresponding reference voltage.

8.4 FPLL detector

The VIF amplifier output signal is fed into a frequency

detector and into a phase detector via a limiting amplifier

for removing the video AM.

During acquisition the frequency detector produces a

current proportional to the frequency difference between

the VIF and the VCO signals. After frequency lock-in the

phase detector produces a current proportional to the

phase difference between the VIF and the VCO signals.

The currents from the frequency and phase detectors are

charged into the loop filter which controls the VIF VCO and

locks it to the frequency and phase of the VIF carrier.

For a positive modulated VIF signal, the charging currents

are gated by the composite sync in order to avoid signal

distortion in case of overmodulation. The gating depth is

switchable via the I2C-bus.

VCO and divider

The VCO of the VIF-FPLL operates as an integrated low

radiation relaxation oscillator at double the picture carrier

frequency. The control voltage, required to tune the VCO

to double the picture carrier frequency, is generated at the

loop filter by the frequency phase detector. The possible

frequency range is 50 to 140 MHz (typical value).

The oscillator frequency is divided-by-two to provide two

differential square wave signals with exactly 90 degrees

phase difference, independent of the frequency, for use in

the FPLL detectors, the video demodulator and the

intercarrier mixer.

8.6 AFC and digital acquisition help

Each relaxation oscillator of the VIF-PLL and FM-PLL

demodulator has a wide frequency range. To prevent false

locking of the PLLs and with respect to the catching range,

the digital acquisition help provides an individual control,

until the frequency of the VCO is within the preselected

standard dependent lock-in window of the PLL.

The in-window and out-window control at the FM-PLL is

additionally used to mute the audio stage (if auto mute is

selected via the I2C-bus).

The working principle of the digital acquisition help is as

follows. The PLL VCO output is connected to a down

counter which has a predefined start value (standard

dependent). The VCO frequency clocks the down counter

for a fixed gate time. Thereafter, the down counter stop

value is analysed. In case the stop value is higher (lower)

than the expected value range, the VCO frequency is

lower (higher) than the wanted lock-in window frequency

range. A positive (negative) control current is injected into

the PLL loop filter and consequently the VCO frequency is

increased (decreased) and a new counting cycle starts.

The gate time as well as the control logic of the acquisition

help circuit is dependent on the precision of the reference

signal at pin REF. Operation as a crystal oscillator is

possible as well as connecting this input via a serial

capacitor to an external reference frequency, e.g. the

tuning system oscillator.

The AFC signal is derived from the corresponding down

counter stop value after a counting cycle. The last four bits

are latched and can be read out via the I2C-bus

(see Table 7). Also the digital-to-analog converted value is

given as current at pin AFC.

8.7 Video demodulator and amplifier

The video demodulator is realized by a multiplier which is

designed for low distortion and large bandwidth. The VIF

signal is multiplied with the ‘in phase’ signal of the VIF-PLL

VCO.

The demodulator output signal is fed into the video

preamplifier via a level shift stage with integrated low-pass

filter to achieve carrier harmonics attenuation.

The output signal of the preamplifier is fed to the VIF-AGC

detector (see Section 8.3) and in the sound trap mode also

fed internally to the integrated sound carrier trap

(see Section 8.8). The differential trap output signal is

converted and amplified by the following postamplifier.

The video output level at pin CVBS is 2 V (p-p).

In the bypass mode the output signal of the preamplifier is

fed directly through the postamplifier to pin CVBS. The

output video level is 1.1 V (p-p) for using an external sound

trap with 10 % overall loss.

Noise clipping is provided in both cases.

8.8 Sound carrier trap

The sound carrier trap consists of a reference filter, a

phase detector and the sound trap itself.

A sound carrier reference signal is fed into the reference

low-pass filter and is shifted by nominal 90 degrees. The

phase detector compares the original reference signal with

the signal shifted by the reference filter and produces a

DC voltage by charging or discharging an integrated

capacitor with a current proportional to the phase

difference between both signals, respectively to the

frequency error of the integrated filters. The DC voltage

controls the frequency position of the reference filter and

the sound trap. So the accurate frequency position for the

different standards is set by the sound carrier reference

signal.

The sound trap itself is constructed of three separate traps

to realize sufficient suppression of the first and second

sound carriers.

8.9 SIF amplifier

The SIF amplifier consists of three AC-coupled differential

stages. Gain control is performed by emitter degeneration.

The total gain control range is typically 66 dB. The

differential input impedance is typically 2 kWin parallel with

3 pF.

SIF-AGC detector

SIF gain control is performed by the detection of the

DC component of the AM demodulator output signal. This

DC signal corresponds directly to the SIF voltage at the

output of the SIF amplifier so that a constant SIF signal is

supplied to the AM demodulator and to the single

reference QSS mixer.

By switching the gain of the input amplifier of the SIF-AGC

detector via the I2C-bus, the internal SIF level for

FM sound is 5.5 dB lower than for AM sound. This is to

adapt the SIF-AGC characteristic to the VIF-AGC

characteristic. The adaption is ideal for a picture-to-sound

FM carrier ratio of 13 dB.

Via a comparator, the integrated AGC capacitor is charged

or discharged for the generation of the required SIF gain.

Due to AM sound, the AGC reaction time is slow

(fc < 20 Hz for the closed AGC loop). For reducing this

AM sound time constant in the event of a decreasing

IF amplitude step, the load current of the AGC capacitor is

increased (fast mode) when the VIF-AGC detector (at

positive modulation mode) operates in the fast mode too.

An additional circuit (threshold approximately 7 dB)

ensures a very fast gain reduction for a large increasing

IF amplitude step.

8.11 Single reference QSS mixer

With the present system a high performance Hi-Fi stereo

sound processing can be achieved. For a simplified

application without a SIF SAW filter, the single reference

QSS mixer can be switched to the intercarrier mode via the

I2C-bus.

The single reference QSS mixer generates the 2nd FM

TV sound intercarrier signal. It is realized by a linear

multiplier which multiplies the SIF amplifier output signal

and the VIF-PLL VCO signal (90 degrees output) which is

locked to the picture carrier. In this way the QSS mixer

operates as a quadrature mixer in the intercarrier mode

and provides suppression of the low frequency video

signals.

The QSS mixer output signal is fed internally via a

high-pass and low-pass combination to the

FM demodulator as well as via an operational amplifier to

the intercarrier output pin SIOMAD.

8.12 AM demodulator

The amplitude modulated SIF amplifier output signal is fed

both to a two-stage limiting amplifier that removes the AM

and to a linear multiplier. The result of the multiplication of

the SIF signal with the limiter output signal is

AM demodulation (passive synchronous demodulator).

The demodulator output signal is fed via a low-pass filter

that attenuates the carrier harmonics and via the input

amplifier of the SIF-AGC detector to the audio amplifier.

8.13 FM demodulator and acquisition help

The narrow-band FM-PLL detector consists of:

· Gain controlled FM amplifier and AGC detector

· Narrow-band PLL.

The intercarrier signal from the intercarrier mixer is fed to

the input of an AC-coupled gain controlled amplifier with

two stages. The gain controlled output signal is fed to the

phase detector of the narrow-band FM-PLL

(FM demodulator). For good selectivity and robustness

against disturbance caused by the video signal, a high

linearity of the gain controlled FM amplifier and of the

phase detector as well as a constant signal level are

required. The gain control is done by means of an ‘in

phase’ demodulator for the FM carrier (from the output of

the FM amplifier). The demodulation output is fed into a

comparator for charging or discharging the integrated

AGC capacitor. This leads to a mean value AGC loop to

control the gain of the FM amplifier.

The FM demodulator is realized as a narrow-band PLL

with an external loop filter, which provides the necessary

selectivity (bandwidth approximately 100 kHz). To achieve

good selectivity, a linear phase detector and a constant

input level are required. The gain controlled intercarrier

signal from the FM amplifier is fed to the phase detector.

The phase detector controls via the loop filter the

integrated low radiation relaxation oscillator. The designed

frequency range is from 4 to 7 MHz.

The VCO within the FM-PLL is phase-locked to the

incoming 2nd SIF signal, which is frequency modulated.

As well as this, the VCO control voltage is superimposed

by the AF voltage. Therefore, the VCO tracks with the FM

of the 2nd SIF signal. So, the AF voltage is present at the

loop filter and is typically 5 mV (RMS) for 27 kHz

FM deviation. This AF signal is fed via a buffer to the audio

amplifier.

Audio amplifier and mute time constant

The audio amplifier consists of two parts:

· AF preamplifier

· AF output amplifier.

The AF preamplifier used for FM sound is an operational

amplifier with internal feedback, high gain and high

common mode rejection. The AF voltage from the

PLL demodulator is 5 mV (RMS) for a frequency deviation

of 27 kHz and is amplified by 30 dB. By the use of a

DC operating point control circuit (with external

capacitor CAF), the AF preamplifier is decoupled from the

PLL DC voltage. The low-pass characteristic of the

amplifier reduces the harmonics of the sound intercarrier

signal at the AF output terminal.

For FM sound a switchable de-emphasis network (with

external capacitor) is implemented between the

preamplifier and the output amplifier.

The AF output amplifier provides the required AF output

level by a rail-to-rail output stage. A preceding stage

makes use of an input selector for switching between

FM sound, AM sound and mute state. The gain can be

switched between 10 dB (normal) and 4 dB (reduced).

Switching to the mute state is controlled automatically,

dependent on the digital acquisition help in case the VCO

of the FM-PLL is not in the required frequency window.

This is done by a time constant: fast for switching to the

mute state and slow (typically 40 ms) for switching to the

no-mute state.

All switching functions are controlled via the I2C-bus:

· AM sound, FM sound and forced mute

· Auto mute enable or disable

· De-emphasis off or on with 50 or 75 ms

· Audio gain normal or reduced.

8.15 Internal voltage stabilizer

The band gap circuit internally generates a voltage of

approximately 2.4 V, independent of supply voltage and

temperature. A voltage regulator circuit, connected to this

voltage, produces a constant voltage of 3.55 V which is

used as an internal reference voltage.

8.16 I2C-bus transceiver and module address

The device can be controlled via the 2-wire I2C-bus by a

microcontroller. Two wires carry serial data (SDA) and

serial clock (SCL) info

rmation between the devices

rmation between the devicesconnected to the I2C-bus.

The device has an I2C-bus slave transceiver with

auto-increment. The circuit operates up to clock

frequencies of 400 kHz.

A slave address is sent from the master to the slave

receiver. To avoid conflicts in a real application with other

devices providing similar or complementing functions,

there are four possible slave addresses available. These

Module Addresses (MADs) can be selected by connecting

resistors on pin SIOMAD and/or pins SIF1 and SIF2 (see

Fig.23). Pin SIOMAD relates with bit A0 and pins SIF1

and SIF2 relate with bit A3. The slave addresses of this

device are given in Table 1.

The power-on preset value is dependent on the use of

pin SIOMAD and can be chosen for 45.75 MHz NTSC as

default (pin SIOMAD left open-circuit) or 58.75 MHz NTSC

(resistor on pin SIOMAD). In this way the device can be

used without the I2C-bus as an NTSC only device.

MSP 3411G Multistandard Sound Processor Family with Virtual Dolby Surround

1. Introduction

1. IntroductionThe MSP 34x1G family of single-chip Multistandard

Sound Processors covers the sound processing of all

analog TV-Standards worldwide, as well as the NICAM

digital sound standards. The full TV sound processing,

starting with analog sound IF signal-in, down to processed

analog AF-out, is performed on a single chip.

Figure 1–1 shows a simplified functional block diagram

of the MSP 34x1G.

The MSP 34x1G has all functions of the MSP 34x0G

with the addition of Virtual Dolby Surround.

Surround sound can be reproduced to a certain extent

with two loudspeakers. The MSP 34x1G includes the

Micronas virtualizer 3D-PANORAMA® which has been

approved by the Dolby1) Laboratories for compliance

with the "Virtual Dolby Surround" technology. In addition,

the MSP 34x1G includes the “PANORAMA” algorithm.

These TV sound processing ICs include versions for

processing the multichannel television sound (MTS)

signal conforming to the standard recommended by

the Broadcast Television Systems Committee (BTSC).

The DBX noise reduction, or alternatively, Micronas

Noise Reduction (MNR) is performed alignment free.

Other processed standards are the Japanese FM-FM

multiplex standard (EIA-J) and the FM Stereo Radio

standard.

Current ICs have to perform adjustment procedures in

order to achieve good stereo separation for BTSC and

EIA-J. The MSP 34x1G has optimum stereo performance

without any adjustments.

All MSP 34xxG versions are pin compatible to the

MSP 34xxD. Only minor modifications are necessary

to adapt a MSP 34xxD controlling software to the

MSP 34xxG. The MSP 34x1G further simplifies controlling

software. Standard selection requires a single

I2C transmission only.

The MSP 34x1G has built-in automatic functions: The

IC is able to detect the actual sound standard automatically

(Automatic Standard Detection). Furthermore,

pilot levels and identification signals can be evaluated

internally with subsequent switching between mono/

stereo/bilingual; no I2C interaction is necessary (Automatic

Sound Selection).

The ICs are produced in submicron CMOS technology.

2.1. Architecture of the MSP 34x1G Family

Fig. 2–1 on page 9 shows a simplified block diagram of

the IC. The block diagram contains all features of the

MSP 3451G. Other members of the MSP 34x1G family

do not have the complete set of features: The

demodulator handles only a subset of the standards

presented in the demodulator block; NICAM processing

is only possible in the MSP 3411G and

MSP 3451G.

2.2. Sound IF Processing

2.2.1. Analog Sound IF Input

The input pins ANA_IN1+, ANA_IN2+, and ANA_IN−

offer the possibility to connect two different sound IF

(SIF) sources to the MSP 34x1G. The analog-to-digital

conversion of the preselected sound IF signal is done

by an A/D-converter. An analog automatic gain circuit

(AGC) allows a wide range of input levels. The highpass

filters formed by the coupling capacitors at pins

ANA_IN1+ and ANA_IN2+ see Section 7.2. “Application

Circuit” on page 107 are sufficient in most cases to

suppress video components. Some combinations of

SAW filters and sound IF mixer ICs, however, show

large picture components on their outputs. In this case,

further filtering is recommended.

2.2.2. Demodulator: Standards and Features

The MSP 34x1G is able to demodulate all TV-sound

standards worldwide including the digital NICAM system.

Depending on the MSP 34x1G version, the following

demodulation modes can be performed:

A2 Systems: Detection and demodulation of two separate

FM carriers (FM1 and FM2), demodulation and

evaluation of the identification signal of carrier FM2.

NICAM Systems: Demodulation and decoding of the

NICAM carrier, detection and demodulation of the analog

(FM or AM) carrier. For D/K-NICAM, the FM carrier

may have a maximum deviation of 384 kHz.

Very high deviation FM-Mono: Detection and robust

demodulation of one FM carrier with a maximum deviation

of 540 kHz.

BTSC-Stereo: Detection and FM demodulation of the

aural carrier resulting in the MTS/MPX signal. Detection

and evaluation of the pilot carrier, AM demodulation

of the (L−R)-carrier and detection of the SAP subcarrier.

Processing of DBX noise reduction or

Micronas Noise Reduction (MNR).

BTSC-Mono + SAP: Detection and FM demodulation

of the aural carrier resulting in the MTS/MPX signal.

Detection and evaluation of the pilot carrier, detection

and FM demodulation of the SAP subcarrier. Processing

of DBX noise reduction or Micronas Noise Reduction

(MNR).

Japan Stereo: Detection and FM demodulation of the

aural carrier resulting in the MPX signal. Demodulation

and evaluation of the identification signal and FM

demodulation of the (L−R)-carrier.

FM-Satellite Sound: Demodulation of one or two FM

carriers. Processing of high-deviation mono or narrow

bandwidth mono, stereo, or bilingual satellite sound

according to the ASTRA specification.

FM-Stereo-Radio: Detection and FM demodulation of

the aural carrier resulting in the MPX signal. Detection

and evaluation of the pilot carrier and AM demodulation

of the (L−R)-carrier.

The demodulator blocks of all MSP 34x1G versions

have identical user interfaces. Even completely different

systems like the BTSC and NICAM systems are

controlled the same way. Standards are selected by

means of MSP Standard Codes. Automatic processes

handle standard detection and identification without

controller interaction. The key features of the

MSP 34x1G demodulator blocks are

Standard Selection: The controlling of the demodulator

is minimized: All parameters, such as tuning frequencies

or filter bandwidth, are adjusted automatically

by transmitting one single value to the

STANDARD SELECT register. For all standards, specific

MSP standard codes are defined.

Automatic Standard Detection: If the TV sound standard

is unknown, the MSP 34x1G can automatically

detect the actual standard, switch to that standard, and

respond the actual MSP standard code.

Automatic Carrier Mute: To prevent noise effects or

FM identification problems in the absence of an FM

carrier, the MSP 34x1G offers a configurable carrier

mute feature, which is activated automatically if the TV

sound standard is selected by means of the STANDARD

SELECT register. If no FM carrier is detected at

one of the two MSP demodulator channels, the corresponding

demodulator

output is muted. This is indicated

output is muted. This is indicatedin the STATUS register.

2.2.3. Preprocessing of Demodulator Signals

The NICAM signals must be processed by a deemphasis

filter and adjusted in level. The analog demodulated

signals must be processed by a deemphasis filter,

adjusted in level, and dematrixed. The correct

deemphasis filters are already selected by setting the

standard in the STANDARD SELECT register. The

level adjustment has to be done by means of the FM/

AM and NICAM prescale registers. The necessary

dematrix function depends on the selected sound standard

and the actual broadcasted sound mode (mono,

stereo, or bilingual). It can be manually set by the FM

Matrix Mode register or automatically by the Automatic

Sound Selection.

2.2.4. Automatic Sound Select

In the Automatic Sound Select mode, the dematrix

function is automatically selected based on the identification

information in the STATUS register. No I2C

interaction is necessary when the broadcasted sound

mode changes (e.g. from mono to stereo).

The demodulator supports the identification check by

switching between mono-compatible standards (standards

that have the same FM-Mono carrier) automatically

and non-audible. If B/G-FM or B/G-NICAM is

selected, th

e MSP will switch between these standards.

e MSP will switch between these standards.The same action is performed for the standards:

D/K1-FM, D/K2-FM, D/K3-FM and D/K-NICAM.

Switching is only done in the absence of any stereo or

bilingual identification. If identification is found, the

MSP keeps the detected standard.

In case of high bit-error rates, the MSP 34x1G automatically

falls back from digital NICAM sound to analog

FM or AM mono.

Table 2–1 summarizes all actions that take place when

Automatic Sound Select is switched on.

To provide more flexibility, the Automatic Sound Select

block prepares four different source channels of

demodulated sound (Fig. 2–2). By choosing one of the

four demodulator channels, the preferred sound mode

can be selected for each of the output channels (loudspeaker,

headphone, etc.). This is done by means of

the Source Select registers.

The following source channels of demodulated sound

are defined:

– “FM/AM” channel: Analog mono sound, stereo if

available. In case of NICAM, analog mono only

(FM or AM mono).

– “Stereo or A/B” channel: Analog or digital mono

sound, stereo if available. In case of bilingual broadcast,

it contains both languages A (left) and B

(right).

– “Stereo or A” channel: Analog or digital mono

sound, stereo if available. In case of bilingual broadcast,

it contains language A (on left and right).

– “Stereo or B” channel: Analog or digital mono

sound, stereo if available. In case of bilingual broadcast,

it contains language B (on left and right).

2.4. Source Selection and Output Channel Matrix

The Source Selector makes it possible to distribute all

source signals (one of the demodulator source channels,

SCART, or I2S input) to the desired output channels

(loudspeaker, headphone, etc.). All input and output

signals can be processed simultaneously. Each

source channel is identified by a unique source

address.

For each output channel, the sound mode can be set

to sound A, sound B, stereo, or mono by means of the

output channel matrix.

If Automatic Sound Select is on, the output channel

matrix can stay fixed to stereo (transparent) for

demodulated signals.

2.5.4. Automatic Volume Correction (AVC)

Different sound sources (e.g. terrestrial channels, SAT

channels, or SCART) fairly often do not have the same

volume level. Advertisements during movies usually

have a higher volume level than the movie itself. This

results in annoying volume changes. The AVC solves

this problem by equalizing the volume level.

To prevent clipping, the AVC’s gain decreases quickly

in dynamic boost conditions. To suppress oscillation

effects, the gain increases rather slowly for low level

inputs. The decay time is programmable by means of

the AVC register (see page 34).

For input signals ranging from −24 dBr to 0 dBr, the

AVC maintains a fixed output level of −18 dBr. Fig. 2–4

shows the AVC output level versus its input level. For

prescale and volume registers set to 0 dB, a level of

0 dBr c

orresponds to full scale input/output. This is

orresponds to full scale input/output. This is– SCART input/output 0 dBr = 2.0 Vrms

– Loudspeaker output 0 dBr = 1.4 Vrms

2.5.5. Loudspeaker and Headphone Outputs

The following baseband features are implemented in

the loudspeaker and headphone output channels:

bass/treble, loudness, balance, and volume. A square

wave beeper can be added to the loudspeaker and

headphone channel. The loudspeaker channel additionally

performs: equalizer (not simultaneously with

bass/treble), spatial effects, and a subwoofer crossover

filter.

2.5.6. Subwoofer Output

The subwoofer signal is created by combining the left

and right channels directly behind the loudness block

using the formula (L+R)/2. Due to the division by 2, the

D/A converter will not be overloaded, even with full

scale input signals. The subwoofer signal is filtered by

a third-order low-pass with programmable corner frequency

followed by a level adjustment. At the loudspeaker

channels, a complementary high-pass filter

can be switched on. Subwoofer and loudspeaker output

use the same volume (Loudspeaker Volume Register).

GRUNDIG ELEGANCE 63 ST63-300 DOLBY CHASSIS CUC1837 DIGI-100 FEATURE BAUSTEIN UNIT: 29504-203.2200

VPC 3215C Video Processor Family

The VPC 32x5 is a high-quality, single-chip video

front-end, which is targeted for 4:3 and 16:9, 50/60 and

100/120 Hz TV sets. It can be combined with other

members of the DIGIT3000 IC family (such as CIP

3250A, DDP 3300A, TPU 3040) and/or it can be used

with 3rd-party products.

The main features of the VPC 32x5 are

– all-digital video processing

– high-performance adaptive 4H comb filter Y/C separator

with adjustable vertical peaking

– multi-standard color decoder PAL/NTSC/SECAM

including all substandards

– 4 composite, 1 S-VHS input, 1 composite output

– integrated high-quality A/D converters and associated

clamp and AGC circuits

– multi-standard sync processing

– linear horizontal scaling (0.25 ... 4), as well as

non-linear horizontal scaling ‘panorama vision’

– PAL+ preprocessing (VPC 3215)

– line-locked clock, data and sync output (VPC 3215)

– display/deflection control (VPC 3205)

– submicron CMOS technology

– I2C-Bus Interface

– one 20.25 MHz crystal, few external components

– 68-pin PLCC package

1.1. System Architecture

Fig. 1–1 shows the block diagram of the video processor.

1.2. Video Processor Family

The VPC video processor family supports 15/32 kHz

systems and is available with different comb filter

options. The 50 Hz/single scan versions provide controlling

for the display and the vertical/east west deflection

of DDP 3300A. The 100 Hz/double scan versions

have a line-locked clock output interface and the

PAL+ preprocessing option. Table 1–1 gives an overview

of the VPC video processor family.

VPC Applications

Fig. 1–2 depicts several VPC applications. Since the

VPC functions as a video front-end, it must be complemented

with additional functionality to form a complete

TV set.

The DDP 33x0 contains the video back-end with video

postprocessing (contrast, peaking, DTI,...), H/V-deflection,

RGB insertion (SCART, Text, PIP,...) and tube

control (cutoff, white drive, beam current limiter). It

generates a beam scan velocity modulation output

from the digital YCrCb and RGB signals. Note that this

signal is not generated from the external analog RGB

inputs.

The CIP 3250A provides a high quality analog RGB

interface with character insertion capability. This allows

appropriate processing of external sources, such as

MPEG2 set-top boxes in transparent (4:2:2) quality.

Furthermore, it translates RGB/Fastblank signals to

the common digital video bus and makes those signals

available for 100 Hz upconversion or double scan processing.

In some European countries (Italy), this feature

is mandatory.

The IP indicates memory based image processing,

such as scan rate conversion, vertical processing

(Zoom), or PAL+ reconstruction.

Examples:

– Europe: 15 kHz/50 Hz → 32 kHz/100 Hz interlaced

– US: 15 kHz/60 Hz → 32 kHz/60 Hz non-interlaced

Note that the VPC supports memory based applications

through line-locked clocks, syncs, and data. CIP

may run either with the native DIGIT3000 clock but

also with a line-locked clock system.

Functional Description

2.1. Analog Front-End

This block provides the analog interfaces to all video

inputs and mainly carries out analog-to digital conversion

for the following digital video processing. A block

diagram is given in Fig. 2–1.

Most of the functional blocks in the front-end are digitally

controlled (clamping, AGC, and clock-DCO). The

control loops are closed by the Fast Processor (‘FP’)

embedded in the decoder.

2.1.1. Input Selector

Up to five analog inputs can be connected. Four inputs

are for input of composite video or S-VHS luma signal.

These inputs are clamped to the sync back porch and are

amplified by a variable gain amplifier. One input is for

connection of S-VHS carrier-chrominance signal. This

input is internally biased and has a fixed gain amplifier.

2.1.2. Clamping

The composite video input signals are AC coupled to

the IC. The clamping voltage is stored on the coupling

capacitors and is generated by digitally controlled current

sources. The clamping level is the back porch of

the video signal. S-VHS chroma is also AC coupled.

The input pin is internally biased to the center of the

ADC input range.

2.1.3. Automatic Gain Control

A digitally working automatic gain control adjusts the

magnitude of the selected baseband by +6/–4.5 dB in

64 logarithmic steps to the optimal range of the ADC.

The gain of the video input stage including the ADC is

213 steps/V with the AGC set to 0 dB.

2.1.4. Analog-to-Digital Converters

Two ADCs are provided to digitize the input signals.

Each converter runs with 20.25 MHz and has 8 bit resolution.

An integrated bandgap circuit generates the

required reference voltages for the converters. The

two ADCs are of a 2-stage subranging type.

2.1.5. Digitally Controlled Clock Oscillator

The clock generation is also a part of the analog front

end. The crystal oscillator is controlled digitally by the

control processor; the clock frequency can be adjusted

within ±150 ppm.

2.1.6. Analog Video Output

Th

e input signal of the Luma ADC is available at the

e input signal of the Luma ADC is available at theanalog video output pin. The signal at this pin must be

buffered by a source follower. The output voltage is

2 V, thus the signal can be used to drive a 75 Ω line.

The magnitude is adjusted with an AGC in 8 steps

together with the main AGC.

Adaptive Comb Filter

The 4H adaptive comb filter is used for high-quality

luminance/chrominance separation for PAL or NTSC

composite video signals. The comb filter improves the

luminance resolution (bandwidth) and reduces interferences

like cross-luminance and cross-color. The adaptive

algorithm eliminates most of the mentioned errors

without introducing new artifacts or noise.

A block diagram of the comb filter is shown in Fig. 2–2.

The filter uses four line delays to process the information

of three video lines. To have a fixed phase relationship

of the color subcarrier in the three channels,

the system clock (20.25 MHz) is fractionally locked to

the color subcarrier. This allows the processing of all

color standards and substandards using a single crystal

frequency.

The CVBS signal in the three channels is filtered at the

subcarrier frequency by a set of bandpass/notch filters.

The output of the three channels is used by the

adaption logic to select the weighting that is used to

reconstruct the luminance/chrominance signal from

the 4 bandpass/notch filter signals. By using soft mixing

of the 4 signals switching artifacts of the adaption

algorithm are completely suppressed.

The comb filter uses the middle line as reference,

therefore, the comb filter delay is two lines. If the comb

filter is switched off, the delay lines are used to pass

the luma/chroma signals from the A/D converters to

the luma/chroma outputs. Thus, the processing delay

is always two lines.

In order to obtain the best-suited picture quality , the

user has the possibility to influence the behaviour of

the adaption algorithm going from moderate combing

to strong combing. Therfore, the following three parameters

may be adjusted:

– HDG ( horizontal difference gain )

– VDG ( vertical difference gain )

– DDR ( diagonal dot reducer )

HDG typically defines the comb strength on horizontal

edges. It determines the amount of the remaining

cross-luminance and the sharpness on edges respectively.

As HDG increases, the comb strength, e. g.

cross luminance reduction and sharpness, increases.

VDG typically determines the comb filter behaviour on

vertical edges. As VDG increases, the comb strength,

e. g. the amount of hanging dots, decreases.

After selecting the combfilter performance in horizontal

and vertical direction, the diagonal picture performance

may further be optimized by adjusting DDR. As

DDR increases, the dot crawl on diagonal colored

edges is reduced.

To enhance the vertical resolution of the the picture,

the VPC 32x5 provides a vertical peaking circuitry. The

filter gain is adjustable between 0 – +6 dB and a coring

filter suppresses small amplitudes to reduce noise artifacts.

In relation to the comb filter, this vertical peaking

widely contributes to an optimal two-dimensional resolution

homogeneity.

2.3. Color Decoder

In this block, the standard luma/chroma separation

and multi-standard color demodulation is carried out.

The color demodulation uses an asynchronous clock,

thus allowing a unified architecture for all color standards.

If the adaptive comb filter is used for luma chroma

separation, the color decoder uses the S-VHS mode

processing. The output of the color decoder is YCrCb

in a 4:2:2 format.

2.3.1. IF-Compensation

With off-air or mistuned reception, any attenuation at

higher frequencies or asymmetry around the color subcarrier

is compensated. Four different settings of the

IF-compensation are possible (see Fig. 2–3):

– flat (no compensation)

– 6 dB/octave

– 12 dB/octave

– 10 dB/MHz

The last setting gives a very large boost to high frequencies.

It is provided for SECAM signals that are

decoded using a SAW filter specified originally for the

PAL standard.

Frequency response of chroma IF-compensation

2.3.2. Demodulator

The entire signal (which might still contain luma) is

quadrature-mixed to the baseband. The mixing frequency

is equal to the subcarrier for PAL and NTSC,

thus achieving the chroma demodulation. For SECAM,

the mixing frequency is 4.286 MHz giving the quadrature

baseband components of the FM modulated

chroma. After the mixer, a lowpass filter selects the

chroma components; a downsampling stage converts

the color difference signals to a multiplexed half rate

data stream.

The subcarrier frequency in the demodulator is generated

by direct digital synthesis; therefore, substandards

such as PAL 3.58 or NTSC 4.43 can also be

demodulated.

2.3.3. Chrominance Filter

The demodulation is followed by a lowpass filter for the

color difference signals for PAL/NTSC. SECAM requires

a modified lowpass function with bell-filter characteristic.

At the output of the lowpass filter, all luma

information is eliminated.

The lowpass filters are calculated in time multiplex for

the two color signals. Three bandwidth settings (narrow,

normal, broad) are available for each standard

(see Fig. 2–5). For PAL/NTSC, a wide band chroma filter

can be selected. This filter is intended for high

bandwidth chroma signals, e.g. a nonstandard wide

bandwidth S-VHS signal.

2.3.4. Frequency Demodulator

The frequency demodulator for demodulating the SECAM

signal is implemented as a CORDIC-structure. It

calculates the phase and magnitude of the quadrature

components by coordinate rotation.

The phase output of the CORDIC processor is differentiated

to obtain the demodulated frequency. After

the deemphasis filter, the Dr and Db signals are scaled

to standard CrCb amplitudes and fed to the crossover-

switch.

2.3.5. Burst Detection

In the PAL/NTSC-system the burst is the reference for

the color signal. The phase and magnitude outputs of

the CORDIC are gated with the color key and used for

controlling the phase-lock-loop (APC) of the demodulator

and the automatic color control (ACC) in PAL/NTSC.

The ACC has a control range of +30 ... –6 dB.

For SECAM decoding, the frequency of the burst is

measured. Thus, the current chroma carrier frequency

can be identified and is used to control the SECAM

processing. The burst measurements also control the

color killer operation; they can be used for automatic

standard detection as well.

2.3.6. Color Killer Operation

The color killer uses the burst-phase/burst-frequency

measurement to identify a PAL/NTSC or SECAM color

signal. For PAL/NTSC, the color is switched off (killed)

as long as the color subcarrier PLL is not locked. For

SECAM, the killer is controlled by the toggle of the

burst frequency. The burst amplitude measurement is

used to switch-off the color if the burst amplitude is

below a programmable threshold. Thus, color will be

killed for very noisy signals. The color amplitude killer

has a programmable hysteresis.

2.3.7. PAL Compensation/1-H Comb Filter

The color decoder uses one fully integrated delay line.

Only active video is stored.

The delay line application depends on the color standard:

– NTSC: 1-H comb filter or color compensation

– PAL: color compensation

– SECAM: crossover-switch

In the NTSC compensated mode, Fig. 2–6 c), the color

signal is averaged for two adjacent lines. Thus,

cross-color distortion and chroma noise is reduced. In

the NTSC 1-H comb filter mode, Fig. 2–6 d), the delay

line is in the composite signal path, thus allowing

reduction of cross-color components, as well as

cross-luminance. The loss of vertical resolution in the

luminance channel is compensated by adding the vertical

detail signal with removed color information. If the

4H adaptive comb filter is used, the 1-H NTSC comb

filter has to be deselected.

2.4. Horizontal Scaler

The 4:2:2 YCrCb signal from the color decoder is processed

by the horizontal scaler. The scaler block

allows a linear or nonlinear horizontal scaling of the

input video signal in the range of 0.25 to 4. Nonlinear

scaling, also called “panorama vision”, provides a

geometrical distortion of the input picture. It is used to

fit a picture with 4:3 format on a 16:9 screen by stretching

the picture geometry at the borders. Also, the

inverse effect can be produced by the scaler. A summary

of scaler modes is given in Table 2–1.

The scaler contains a programmable decimation filter,

a 1-line FIFO memory, and a programmable interpolation

filter. The scaler input filter is also used for pixel

skew correction, see 2.3.9. The decimator/interpolator

structure allows optimal use of the FIFO memory. The

controlling of the scaler is done by the internal Fast

Processor.

2.5. Blackline Detector

In case of a letterbox format input video, e.g. Cinemascope,

PAL+ etc., black areas at the upper and lower

part of the picture are visible. It is suitable to remove or

reduce these areas by a vertical zoom and/or shift

operation.

The VPC 32xx supports this feature by a letterbox

detector. The circuitry detects black video lines by

measuring the signal amplitude during active video.

For every field the number of black lines at the upper

and lower part of the picture are measured, compared

to the previous measurement and the minima are

stored in the I2C-register BLKLIN. To adjust the picture

amplitude, the external controller reads this register,

calculates the vertical scaling coefficient and transfers

the new settings, e.g. vertical sawtooth parameters,

horizontal scaling coefficient etc., to the VPC.

Letterbox signals containing logos on the left or right

side of the black areas are processed as black lines,

while subtitles, inserted in the black areas, are processed

as non-black lines. Therefore the subtitles are

visible on the screen. To suppress the subtitles, the

vertical zoom coefficient is calculated by selecting the

larger number of black lines only. Dark video scenes

with a low contrast level compared to the letterbox

area are indicated by the BLKPIC bit.

2.6. Control and Data Output Signals

The VPC 32x

x supports two output modes: In

x supports two output modes: InDIGIT3000 mode, the output interfaces run at the main

system clock, in line-locked mode, the VPC generates

an asynchronous line-locked clock that is used for the

output interfaces.

2.6.1. Line-Locked Clock Generation

An on-chip rate multiplier will be used to synthesize

any desired output clock frequency of 13.5/16/18 MHz.

A double clock frequency output is available to support

100 Hz systems. The synthesizer is controlled by the

embedded RISC controller, which also controls all

front-end loops (clamp, AGC, PLL1, etc.). This allows

the generation of a line-locked output clock regardless

of the system clock (20.25 MHz) which is used for

comb filter operation and color decoding. The control

of scaling and output clock frequency is kept independent

to allow aspect ratio conversion combined with

sample rate conversion. The line-locked clock circuity

generates control signals, e.g. horizontal/vertical sync,

active video output, it is also the interface from the

internal (20.25 MHz) clock to the external line-locked

clock system.

If no line-locked clock is required, i.e. in the DIGIT3000

mode, the system runs at the 20.25 MHz main clock.

The horizontal timing reference in this mode is provided

by the front-sync signal. In this case, the

line-locked clock block and all interfaces run from the

20.25 MHz main clock. The synchronization signals

from the line-locked clock block are still available, but

for every line the internal counters are reset with the

main-sync signal. A double clock signal is not available

in DIGIT3000 mode.

Sync Signals

The front end will provide a number of sync/control signals

which are output with the output clock. The sync

signals are generated in the line-locked clock block.

– Href : horizontal sync

– AVO: active video out (programmable)

– HC: horizontal clamp (programmable)

– Vref : vertical sync

– INTLC: interlace

– HELPER: PAL+ helper lines

All horizontal signals are not qualified with field information,

i.e. the signals are present on all lines.

2.6.3. DIGIT3000 Output Format

The picture bus format between all DIGIT3000 ICs is

4:2:2 YCrCb with 20.25 MHz samples/s. Only active

video is transferred, synchronized by the system main

sync signal (MSY) which indicates the start of valid

data for each scan line and which initializes the color

multiplex. The video data is orthogonally sampled

YCrCb, the output format is given in Table 2–2. The

number of active samples per line is 1080 for all standards

(525 and 625).

The output can be switched to 4:1:1 mode with the output

format according to Table 2–3.

Via the MSY line, serial data is transferred which contains

information about the main picture such as current

line number, odd/even field etc.). It is generated

by the deflection circuitry and represents the orthogonal

timebase for the entire system.

2.6.4. Line-Locked 4:2:2 Output Format

In line-locked mode, the VPC 32xx will produce the

industry standard pixel stream for YCrCb data. The difference

to DIGIT3000 native mode is only the number

of active samples, which of course, depends on the

chosen scaling factor. Thus, Table 2–2 is valid for both

4:2:2 modes.

2.6.5. Line-Locked 4:1:1 Output Format

The orthogonal 4:1:1 output format is compatible to the

industry standard. The YCrCb samples are skew-corrected

and interpolated to an orthogonal sampling raster

(see Table 2–3).

note: C*x

Y (x = pixel number and y = bit number)

2.6.6. Output Code Levels

Output Code Levels correspond to ITU-R code levels:

Y = 16...240

Black Level = 16

CrCb = 128±112

An overview over the output code levels is given in

Table 2–4.

2.6.7. Output Signal Levels

All data and sync lines operate at TTL compliant levels.

With an optional external 3.3 V supply for the output

pins, reduced voltage swings can be obtained.

2.6.8. Test Pattern Generator

The YCrCb outputs can be switched to a test mode

where YCrCb data are generated digitally in the

VPC32xx. Test patterns include luma/chroma ramps,

flat field, and a pseudo color bar.

Video Sync Processing

To extract the sync information from the

To extract the sync information from thevideo signal, a linear phase lowpass filter eliminates all

noise and video contents above 1 MHz. The sync is

separated by a slicer; the sync phase is measured. A

variable window can be selected to improve the noise

immunity of the slicer. The phase comparator measures

the falling edge of sync, as well as the integrated

sync pulse.

The sync phase error is filtered by a phase-locked loop

that is computed by the FP. All timing in the front-end is

derived from a counter that is part of this PLL, and it

thus counts synchronously to the video signal.

A separate hardware block measures the signal back

porch and also allows gathering the maximum/minimum

of the video signal. This information is processed

by the FP and used for gain control and clamping.

For vertical sync separation, the sliced video signal is

integrated. The FP uses the integrator value to derive

vertical sync and field information.

The information extracted by the video sync processing

is multiplexed onto the hardware front sync signal

(FSY) and is distributed to the rest of the video processing

system. The format of the front sync signal is

given in Fig. 2–13.

The data for the vertical deflection, the sawtooth, and

the East-West correction signal is calculated by the

VPC 32xx. The data is buffered in a FIFO and transferred

to the back-end IC DDP 3300A by a single wire

interface.

Frequency and phase characteristics of the analog

video signal are derived from PLL1. The results are fed

to the scaler unit for data interpolation and orthogonalization

and to the clock synthesizer for line-locked

clock generation. Horizontal and vertical syncs are

latched with the line-locked clock.

Pin Descriptions

(pin numbers for PLCC68 package)

Pin 1 – Ground, Analog Front-End GNDF

Pin 2 – Ground, Analog Front-End GNDF

Pin 3 – CCU 5 MHz Clock Output CLK5 (Fig. 4–11)

This pin provides a clock frequency for the TV microcontroller,

e.g. a CCU 3000 controller. It is also used

by the DDP 3300A display controller as a standby

clock.

Pin 4 – Standby Supply Voltage VSTDBY

In standby mode, only the clock oscillator is active,

GNDF should be ground reference. Please activate

RESQ before powering-up other supplies

Pins 6 and 5 – XTAL1 Crystal Input and XTAL2 Crystal

Output (Fig. 4–8)

These pins are connected to an 20.25 MHz crystal

oscillator which is digitally tuned by integrated shunt

capacitances. The CLK20 and CLK5 clock signals are

derived from this oscillator. An external clock can be

fed into XTAL1. In this case, clock frequency adjustment

must be switched off.

Pin 7 – Ground, Analog Front-End GNDF

Pin 9 – Ground, Output Pad Circuitry GNDP

Pin 10 – Interlace Output, INTLC (Fig. 4–4)

This pin supplies the interlace information, 0 indicates

first field, 1 indicates second field.

Pin 12 – Vertical Sync Pulse, VS (Fig. 4–4)

This pin supplies the vertical sync signal.

Pin 13 – Front Sync Pulse, FSY (Fig. 4–4)

This pin supplies the front sync information.

Pin 14 – Main Sync/Horizontal Sync Pulse MSY/HS

(Fig. 4–4)

This pin supplies the horizontal sync pulse information

in line-locked mode. In DIGIT3000 mode, this pin is the

main sync input.

Pin 15 – Helper Line Output, Helper (Fig. 4–4)

This signal indicates a helper line in PAL+ mode.

Pin 16 – Horizontal Clamp Pulse, HC (Fig. 4–4)

This signal can be used to clamp an external video signal,

that is synchronous to the input signal. The timing

is programmable.

Pin 17 – Active Video Output, AVO (Fig. 4–4)

This pin indicates the active video output data. The

signal is clocked with the LLC1 clock.

Pin 18 – Double Output Clock, LLC2 (Fig. 4–6)

Pin 19 – Output Clock, LLC1 (Fig. 4–6)

This is the clock reference for the luma, chroma, and

status outputs.

Pin 26 – Ground, Output Pad Circuitry GNDP

Pins 20 to 25,28,29 – Luma Outputs Y0 – Y7 (Fig. 4–4)

These output pins carry the digital luminance data. The

data are clocked with the LLC1 clock.

Pin 30 – Main Clock Output CLK20 (Fig. 4–5)

This is the 20.25 MHz main clock output.

Pin 31 – Supply Voltage, Digital Circuitry VSUPD

Pin 34 – Ground, Digital Circuitry GNDD

Pin 35 – Ground, Output Pad Circuitry GNDP

Pin 36 – Supply Voltage, Output Pad Supply VSUPP

Pins 38 to 43,46,47 – Chroma Outputs C0–C7 (Fig. 4–4)

These outputs carry the digital CrCb chrominance data.

The data are clocked with the LL1 clock. The data are

sampled at half the clock rate and multiplexed. The

CrCb multiplex is reset for each TV line.

Pins 48 to 50 – Picture Bus Priority PR0–PR2 (Fig. 4–6)

The Picture Bus Priority lines carry the digital priority

selection signals. The priority interface allows digital

switching of up to 8 sources to the back-end processor.

Switching for different sources is prioritized and can be

on a per pixel basis.

Pin 51 – Ground, Output Pad Circuitry GNDP

Pin 52 – VGAV-Input. (Fig. 4–3)

This pin is connected to the vertical sync signal of a VGA

signal.

Pin 53 – Front-End/Back-End Data FPDAT (Fig. 4–6)

This pin interfaces to the DDP 3300A back-end processor.

The information for the deflection drives and

for the white drive control, i.e. the beam current limiter,

is transmitted by this pin.

Pin 54 – Reset Input RESQ (Fig. 4–3)

A low level on this pin resets the VPC 32xx.

Pin 55 – I2C Bus Data SDA (Fig. 4–13)

This pin connects to the I2C bus data line.

Pin 56 – I2C Bus Clock SCL (Fig. 4–3)

This pin connects to the I2C bus clock line.

Pin 57 – Test Input TEST (Fig. 4–3)

This pin enables factory test modes. For normal operation,

it must be connected to ground.

Pin 59 – Ground, Analog Front-End GNDF

Pins 62,61,60,58 – Video Input 1–4 (Fig. 4–12)

These are the analog video inputs. A CVBS or S-VHS

luma signal is converted using the luma (Video 1) AD

converter. The VIN1 input can also be switched to the

chroma (Video 2) ADC. The input signal must be

AC-coupled.

Pin 63 – Chroma Input CIN (Fig. 4–10)

This pin is connected to the S-VHS chroma signal. A

resistive divider is used to bias the input signal to the

middle of the converter input range. CIN can only be

connected to the chroma (Video 2) A/D converter. The

signal must be AC-coupled.

Pin 64 – Analog Video Output, VOUT (Fig. 4–7)

The analog video signal that is selected for the main

(luma, CVBS) ADC is output at this pin. An emitter follower

is required at this pin.

Pin 65 – Ground, Analog Shield Front-End GNDF

Pin 66 – Supply Voltage, Analog Front-End VSUPF

(Fig. 4–9)

Pin 67 – Signal GND for Analog Input ISGND (Fig. 4–

11) This is the high quality ground reference for the

video input signals.

Pin 68 – Reference Voltage Top VRT (Fig. 4–9)

Via this pin, the reference voltage for the A/D converters

is decoupled. The pin is connected with 10 µF/47 nF to

the Signal Ground Pin

SDA 9401 SCARABAEUS Scan Rate Converter using Embedded DRAM Technology Units

1 General description

1 General descriptionThe SDA 9401 is a new component of the Micronas MEGAVISION® IC set in a 0.35 µm embedded

DRAM technology (field memory embedded). The SDA 9401 is pin compatible to the SDA 9400

(frame memory embedded). The SDA 9401 comprises all main functionalities of a digital featurebox

in one monolithic IC.

The SDA 9401 does a simple 100/120 Hz interlaced (50/60 Hz progressive) scan rate conversion.

The scan rate converted picture can be vertically expanded. The SDA 9401 has a freerunning

mode, therefore features like multiple picture display (e.g. tuner scan) are possible.

The noise reduction is field based. Furthermore separate motion detectors for luminance and

chrominance have been implemented. For automatic controlling of the noise reduction parameters a

noise measurement algorithm is included, which measures the noise level in the picture or in the

blanking period. In addition a spatial noise reduction is implemented, which reduces the noise even

in the case of motion. The input signal can be compressed horizontally and vertically with a certain

number of factors. Therefore split screen modes are supported too.

Beside these additional functions like coloured background, windowing and flashing are

implemented.

2 Features

• Two input data formats

- 4:2:2 luminance and chrominance parallel (2 x 8 wires)

- ITU-R 656 data format (8 wires)

• Two different representations of input chrominance data

- 2‘s complement code

- Positive dual code

• Flexible input sync controller

• Flexible compression of the input signal