-

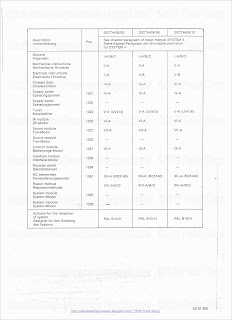

The PHILIPS CHASSIS KT4 is the "small brother" of the PHILIPS K40 but not isolated from mains and without AV SCART SOCKET, it's basically a basic K40 but with further diversity from K40.

WAS specifically designed for small sets like the 20" PHILIPS 20CT4426 /08Z SEGANTINI here shown.

- Deflection Board on the right called large signal board. Line deflection output (BU508A) + EHT, E/W

Correction, FRAME Deflection Output with IC TDA3650 (PHILIPS)

- Signal processing board + Tuning control drive TRD (Tuning Remote Digital)

Chrominance + Luminance with TDA3561A, Synchronization With TDA3576B.

PHILIPS TDA3576B SYNC COMBINATION WITH TRANSMITTER IDENTIFICATION

AND VERTICAL 625 DIVIDER SYSTEM.

GENERAL DESCRIPTION

The TDA3576B is a monolithic integrated circuit for use in colour television receivers. The circuit is

optimized for a horizontal and vertical frequency ratio of 625.

Features

• Horizontal sync separator (including noise inverter) with sliding bias such that the sync pulse is

always sliced between top sync level and blanking level

• Phase detector which compares the horizontal sync pulse with the oscillator voltage; this phase

detector is gated

• Phase detector which compares the horizontal flyback pulse with the oscillator voltage

• Horizontal oscillator (31,25 kHz)

• Time constant switching of the first control loop (short time constant during catching and reception

of VCR signals)

• Burst key pulse generator (sandcastle pulse with three levels)

• Very stable automatic vertical synchronization due to the 625 divider system, without delay after

channel change

• Vertical sync pulse separator

• Three voltage level sensor on coincidence detector circuit output

• Video transmitter identification circuit for sound muting and search tuning systems

• Inhibit of vertical sync pulse when no video transmitter is detected.

FUNCTIONAL DESCRIPTION

The video input voltage to drive the sync separator must have negative-going sync, which can be

obtained from synchronous demodulators such as TDA2540 and TDA2541.

The slicing level of the sync separator is determined by the value of the resistor between pins 6 and 7. A

4, 7 kr2 resistor provides a slicing level midway between the top sync level and the blanking level. Thus

the slicing level is independent of the amplitude of the sync pulse input at pin 5.

The nominal top sync level at pin 5 is 3 V, and the amplitude selective noise inverter is activated at

0,7 V.

To

obtain good stability the circuit contains three control loops. In the

first loop the phase of the horizontal sync pulse is compared with a

reference output pulse from the horizontal oscillator. In the second

loop the phase of the flyback pulse is compared with the same reference

output pulse. The first loop is designed for good noise immunity and the

second loop has a fast time constant to compensate quickly for storage

variations of the output stage. The second loop also generates a gating

signal of about 5,5 μs for use in the transmitter identification

circuit. The third control loop generates a second gating signal which

is used in the first phase detector. The pulse width is typically 14 μs.

For a short catching time the output current of the first phase

detector is not gated but is increased by 5 times during catching. This

is caused by the voltage of the coincidence detector at pin 9. For VCR

playback conditions the first control loop must be forced to a fast time

constant, this is achieved by applying an external voltage of~ 2,7 V to

pin 9.

The free running output frequency of the horizontal

oscillator is 31,25 kHz. The vertical frequency output is obtained by

dividing this double horizontal frequency by 625. The double horizontal

fre- quency is fed via a binary divider to provide the normal 15,625 kHz

horizontal output to pin 11. The sandcastle pulse is generated at pin 2

and has three levels. The burst key pulse is of short duration,

typically 4 μs, with an amplitude of 10 Vandis the highest level. The

second level has a pulse duration equal to the horizontal flyback pulse

with an amplitude of 4,5 Vandis used for horizontal blanking. The third

level, amplitude 2,5 V, is used for vertical blanking and has a pulse

duration of 1,34 ms. The last pulse is internal Iv generated by the

divider circuit and is only available when a standard video input signal

is received. An external vertical blanking pulse can be added to this

pin via a suitable series resistor. This pulse will be automatically

clamped to 2,5 V.

The automatic vertical sync block contains the following:

• 625 divider

• In/out-sync detector

• Direct/indirect sync switch

• Identification circuit

It

is fed by a signal obtained by integration of the composite video

signal and an internally generated, clipped video signal. The vertical

sync pulse is sliced out of this integrated signal by an automatically

biased clipper. The video part of the signal helps to build up a

vertical sync when heavy negative-going reflections (mountains) distort

the video signal. The in/out sync-detector considers a signal

out-of-sync when fourteen or more successive incoming vertical sync

pulses are not in phase with a reference signal from the 625 divider.

Therefore a distorted vertical sync signal needs only one

out-of-fourteen pulses to be in phase to keep the system in sync. When

the fifteenth successive out-of-sync pulse is detected, the

direct/indirect sync switch is activated to feed the vertical sync

signal directly out of the block at pin 3 (direct sync vertical output).

At the same time the 625 divider is reset by one of the sync pulses.

After the reset pulse, if the 7th sliced vertical sync pulse coincides

with a 625 divider window, the sync output pulse is presenteu again by

the divider system and switch-over to indirect mode occurs. In the

direct mode, every 7th non-coinciding sliced vertical sync pulse will

reset the counter. A non- standard video signal will result in

continuous reset pulses and the direct/indirect switch will remain in

the direct position.

To avoid delay in vertical synchronization, caused by waiting time of the divider circuit after channel

change or an unsynchronized camera change in the studio, information is fed from the horizontal

coincidence detector to the automatic switch for the vertical sync pulse. The loss of horizontal

synchronization sets the automatic switch to direct vertical sync.

When an external voltage between 2,7 V and 8,2 V is applied via pin 9 to the coincidence detector, the

horizontal phase detector is switched to a short time constant and the automatic switch to direct

vertical sync. A voltage level on pin 9 between 9,2 V and 12 V switches the horizontal phase detector

to a short time constant, without affecting the indirect/direct vertical sync system which remains

operational. Thus when standard signals are received vertical sync pulses are generated by the divider

system.

To avoid disturbance of the horizontal phase detector by the vertical sync pulse the 625 divider system

generates an anti-top-flutter pulse. This pulse is applied to the phase 1 detector when a standard video

signal is received. The anti-top-flutter pulse is also active for standard VCR signal conditions, voltage at

pin 9;;. 9,2 V.

The video transmitter identification circuit detects when a sync pulse occurs during the internal 5,5 μs

gating pulse. This indicates the presence of a video transmitter and results in the capacitor connected

to pin 1 being charged to 8,4 V. When no sync pulse is present the capacitor discharges to< 1 V. The

voltage at pin 1 is compared with an internal d.c. voltage. The identification output at pin 18 is active

when pin 1 is.;; 1,5 V (no video transmitter) and inactive (high impedance) when pin 1 is> 3,5 V,

this information can be used for search tuning.

The vertical sync output pulse at pin 3 is inhibited when no video transmitter is identified, which

prevents interference or noise affecting the frequency of the vertical output stage. This results in a

vertical stable picture, plus vertical stable position information for tuning systems.

RATINGS

Limiting values in accordance with the Absolute Maximum System (IEC 134)

Supply voltage (pin 17) Vp = V17-10 max. 13,2 v

Total power dissipation max. 1200 mW

Storage temperature range -55 to + 125 oc

Operating ambient temperature range -25 to +65 oc

THERMAL RESISTANCE From junction to ambient (in free air) Rthj-a 50 K/W

The function is described against the corresponding pin number.

1. Video transmitter identification

A 47 nF capacitor must be connected to this pin. It charges to a level of 8 V when a sync pulse is

detected, and discharges to a level of< 1 V when no sync pulse is detected.

2. Sandcastle output pulse

This output has three levels. The first and highest level (10 V) is the burst key pulse with a typical

duration of 4,0 μs. The second level, for the horizontal blanking, is typically 4,5 V with a pulse duration

equal to the horizontal flyback pulse. For the third level an external vertical flyback pulse must be

applied to this pin. This pulse will be clamped to 2,5 V by an internal clamping circuit. The input

current is typically 2 mA.

3. Vertical output pulse

This pulse is obtained from the 625 divider circuit when standard input signals are received or from the

sync separator when the signals are non-standard. The pulse is inhibited when no video transmitter is

detected. Both pulses have good stability and accuracy and are used to trigger the vertical oscillator.

4. Vertical sync pulse integrator biasing network

The vertical sync pulse is obtained by integrating the composite sync signal in an internal RC-network. An

external capacitor of 10 μF is required for biasing the vertical sync separator, this provides the vertical

sync output pulse with a delay of 37 μs. This value can be changed by an external resistor. A resistor of

470 kn between pin 3 and +12 V gives a delay of 45 μs.

5. Video input

The video input signal must have negative-going sync pulses. The top-sync level can vary between 1 V

and 3,5 V without affecting the sync separator operation. The slicing level is fixed at 50% for the

sync pulse amplitude range 0,1 to 1 V which provides good sync separation down to pulses with an

amplitude of 100 mV peak-to-peak. The slicing level is increased for sync pulses in excess of 1 V

peak-to-peak. The noise gate is activated at an input level< 1 V, thus when noise gating is required the

top sync level should be close to the minimum level of 1 V.

6. Sync separator slicing level output

The sync separator slicing level is determined on this pin. A slicing level of 50% is obtained by

comparing this level with the black level of the video signal, which is detected at pin 7.

7. Black level detector output

The black level of the input signal is detected on this pin. This is required to obtain good sync

separator operation. A 22 μF capacitor in series with a resistor of 82 n must be connected to this pin.

A 4,7 kU resistor connected between pins 6 and 7 results in a slicing level of 50%.

8. Horizontal phase detector output and control oscillator input

The flywheel filter must be connected to this pin. Typical values for the components are a capacitor of

100 nF in parallel with an RC-network of 1 kr2 and 10 μF. Furthermore, a resistor of 270 kH should

be connected between pins 8 and 13 to limit the free running frequency drift.

The output current of the phase detector depends on the condition of the coincidence detector. The

output current is high when the oscillator is out-of-sync. The result is a large catching range, and the

phase detector not gated. The output current is low when the oscillator is synchronized and the phase

detector is gated; this provides good noise immunity.

9. Coincidence detector output

A 1 μF capacitor must be connected to this pin. The output voltage depends on the oscillator condition

(synchronized or not) and on the video input signal. The following output voltages can occur:

• when in-sync

1,3 V

• when out-of-sync

2,7 V

• during noise at the input

2, 1 V

There are two switching levels at pin 9. At the first switching level when the output voltage is< 2, 1 V,

the phase detector output is low and the gating of the phase detector is switched on. When the output

voltage is> 2,7 V, the output current of the phase detector is high and the gating of the phase detector

is switched off. The result is a large catching range and a high dynamic steepness of the PLL. At the

second switching level when the output voltage is> 9,2 V the sync system is switched to a short time

constant while the indirect/direct vertical sync system remains fully operational. This condition is

suitable for VCR application.

10. Negative supply (ground)

11. Horizontal sync pulse output

This is an open collector output. The collector resistor mus be chosen such that sufficient current is

supplied

to the driver stage. The maximum current is 60 mA. The circuit is

designed such that the horizontal output transistor cannot be switched

on during flyback, but is switched on directly after flyback.

12. Control voltage second loop

This voltage controls the output pulse at pin 11 (positive-going edge). The capacitor connected to this

pin must have a minimum value of 6,8 nF. A higher value decreases the dynamic-loop gain in the second

control loop. When a high dynamic-loop gain is not required a capacitor value of 100 nF is recommended.

Horizontal shift is possible by applying an external current to pin 12.

13. Reference voltage control loops

The reference voltage must be decoupled by a capacitor of 10 μF.

14. Decoupling internal power supply

The IC has two power terminals. The main terminal (pin 17) supplies the output stages, the sync

separator and the divider circuit. The specially decoupled terminal (pin 14) supplies the horizontal

oscillator. The decoupling capacitor should be 22 μF.

15. Flyback input pulse

This pulse is required for the second phase control loop and for generating the horizontal blanking

pulse in the sandcastle output. The input current must be at least 0,2 mA and not exceed 3 mA.

16. RC-network horizontal oscillator

Stable components should be chosen for good frequency stability. For adjusting the frequency a part of

the total resistance must be variable. This part must be as small as possible, because of poor stability of

variable carbon resistors. The oscillator can be adjusted when pins 8 and 13 are short circuited (see Fig. 3).

17. Positive supply

The supply voltage may vary between 10,5 and 13,2 V. The current-draw is typ. 70 mA and the range is

50 to 85 mA.

·

18. Video transmitter identification output

This is an emitter-follower output which will be inactive (high-impedance) when the level at pin 1 is

> 4 V (video transmitter detected). The output will be active high when the level at pin 1 is< 1,7 V

(no videotransmitterdetected).This feature can be used for search-tuning and sound-muting.

GENERAL BASIC TRANSISTOR LINE OUTPUT STAGE OPERATION:

The basic essentials of a transistor line output stage are shown in Fig. 1(a). They comprise: a line output transformer which provides the d.c. feed to the line output transistor and serves mainly to generate the high -voltage pulse from which the e.h.t. is derived, and also in practice other supplies for various sections of the receiver; the line output transistor and its parallel efficiency diode which form a bidirectional switch; a tuning capacitor which resonates with the line output transformer primary winding and the scan coils to determine the flyback time; and the scan coils, with a series capacitor which provides a d.c. block and also serves to provide slight integration of the deflection current to compensate for the scan distortion that would otherwise be present due to the use of flat screen, wide deflection angle c.r.t.s. This basic circuit is widely used in small -screen portable receivers with little elaboration - some use a pnp output transistor however, with its collector connected to chassis.

Circuit Variations:

Variations to the basic circuit commonly found include: transposition of the scan coils and the correction capacitor; connection of the line output transformer primary winding and its e.h.t. overwinding in series; connection of the deflection components to a tap on the transformer to obtain correct matching of the components and conditions in the stage; use of a boost diode which operates in identical manner to the arrangement used in valve line output stages, thereby increasing the effective supply to the stage; omission of the efficiency diode where the stage is operated from an h.t. line, the collector -base junction of the line output transistor then providing the efficiency diode action without, in doing so, producing scan distortion; addition of inductors to provide linearity and width adjustment; use of a pair of series -connected line output transistors in some large -screen colour chassis; and in colour sets the addition of line convergence circuitry which is normally connected in series between the line scan coils and chassis. These variations on the basic circuit do not alter the basic mode of operation however.

Resonance

The most important fact to appreciate about the circuit is that when the transistor and diode are cut off during the flyback period - when the beam is being rapidly returned from the right-hand side of the screen to the left-hand side the tuning capacitor together with the scan coils and the primary winding of the line output transformer form a parallel resonant circuit: the equivalent circuit is shown in Fig. 1(b). The line output transformer primary winding and the tuning capacitor as drawn in Fig. 1(a) may look like a series tuned circuit, but from the signal point of view the end of the transformer primary winding connected to the power supply is earthy, giving the equivalent arrangement shown in Fig. 1(b).

The Flyback Period:

Since the operation of the circuit depends mainly upon what happens during the line flyback period, the simplest point at which to break into the scanning cycle is at the end of the forward scan, i.e. with the

beam deflected to the right-hand side of the screen, see Fig. 2. At

this point the line output transistor is suddenly switched off by the

squarewave drive applied to its base. Prior to this action a linearly

increasing current has been flowing in the line output transformer

primary winding and the scan coils, and as a result magnetic fields have

been built up around these components. When the transistor is switched

off these fields collapse, maintaining a flow of current which rapidly

decays to zero and returns the beam to the centre of the screen. This

flow of current charges the tuning capacitor, and the voltage at A rises

to a high positive value - of the order of 1- 2k V in large -screen

sets, 200V in the case of mains/battery portable sets. The e

beam deflected to the right-hand side of the screen, see Fig. 2. At

this point the line output transistor is suddenly switched off by the

squarewave drive applied to its base. Prior to this action a linearly

increasing current has been flowing in the line output transformer

primary winding and the scan coils, and as a result magnetic fields have

been built up around these components. When the transistor is switched

off these fields collapse, maintaining a flow of current which rapidly

decays to zero and returns the beam to the centre of the screen. This

flow of current charges the tuning capacitor, and the voltage at A rises

to a high positive value - of the order of 1- 2k V in large -screen

sets, 200V in the case of mains/battery portable sets. The e nergy

in the circuit is now stored in the tuning capacitor which next

discharges, reversing the flow of current in the circuit with the result

that the beam is rapidly deflected to the left-hand side of the screen -

see Fig. 3. When the tuning capacitor has discharged, the voltage at A

has fallen to zero and the circuit energy is once more stored in the

form of magnetic fields around the inductive components. One half -cycle

of oscillation has occurred, and the flyback is complete.

nergy

in the circuit is now stored in the tuning capacitor which next

discharges, reversing the flow of current in the circuit with the result

that the beam is rapidly deflected to the left-hand side of the screen -

see Fig. 3. When the tuning capacitor has discharged, the voltage at A

has fallen to zero and the circuit energy is once more stored in the

form of magnetic fields around the inductive components. One half -cycle

of oscillation has occurred, and the flyback is complete.Energy Recovery:

First Part of Forward Scan The circuit then tries to continue the cycle of oscillation, i.e. the magnetic fields again collapse, maintaining a current flow which this time would charge the tuning capacitor negatively (upper plate). When the voltage at A reaches about -0.6V however the efficiency diode becomes forward biased and switches on. This damps the circuit, preventing further oscillation, but the magnetic fields continue to collapse and in doing so produce a linearly decaying current flow which provides the first part of the forward s

can,

the beam returning towards the centre of the screen - see Fig. 4. The

diode shorts out the tuning capacitor but the scan correction capacitor

charges during this period, its right-hand plate becoming positive with

respect to its left-hand plate, i.e. point A. Completion of Forward Scan

When the current falls to zero, the diode will switch off. Shortly

before this state of affairs is reached however the transistor is

switched on. In practice this is usually about a third of the way

through the scan. The squarewave applied to its base drives it rapidly

to saturation, clamping the vol

can,

the beam returning towards the centre of the screen - see Fig. 4. The

diode shorts out the tuning capacitor but the scan correction capacitor

charges during this period, its right-hand plate becoming positive with

respect to its left-hand plate, i.e. point A. Completion of Forward Scan

When the current falls to zero, the diode will switch off. Shortly

before this state of affairs is reached however the transistor is

switched on. In practice this is usually about a third of the way

through the scan. The squarewave applied to its base drives it rapidly

to saturation, clamping the vol tage

at point A at a small positive value - the collector emitter saturation

voltage of the transistor. Current now flows via the transistor and the

primary winding of the line output transformer, the scan correction

capacitor discharges, and the resultant flow of current in the line scan

coils drives the beam to the right-hand side of the screen see Fig. 5.

tage

at point A at a small positive value - the collector emitter saturation

voltage of the transistor. Current now flows via the transistor and the

primary winding of the line output transformer, the scan correction

capacitor discharges, and the resultant flow of current in the line scan

coils drives the beam to the right-hand side of the screen see Fig. 5.Efficiency:

The transistor is then cut off again, to give the flyback, and the cycle of events recurs. The efficiency of the circuit is high since there is negligible resistance present. Energy is fed into the circuit in the form of the magnetic fields that build up when the output transistor is switched on. This action connects the line output transformer primary winding across the supply, and as a result a linearly increasing current flows through it. Since the width is

dependent on the supply voltage, this must be stabilised.

Harmonic Tuning:

There is another oscillatory action in the circuit during the flyback period. The considerable leakage inductance between the primary and the e.h.t. windings of the line output transformer, and the appreciable self -capacitance present, form a tuned circuit which is shocked into oscillation by the flyback pulse. Unless this oscillation is controlled, it will continue into and modulate the scan. The technique used to overcome this effect is to tune the leakage inductance and the associated capacitance to an odd harmonic of the line flyback oscillation frequency. By doing this the oscillatory actions present at the beginning of the scan cancel. Either third or fifth harmonic tuning is used. Third harmonic tuning also has the effect of increasing the amplitude of the e.h.t. pulse, and is generally used where a half -wave e.h.t. rectifier is employed. Fifth harmonic tuning results in a flat-topped e.h.t. pulse, giving improved e.h.t. regulation, and is generally used where an e.h.t. tripler is employed to produce the e.h.t. The tuning is mainly built into the line output transformer, though an external variable inductance is commonly found in colour chassis so that the tuning can be adjusted. With a following post I will go into the subject of modern TV line timebases in greater detail with other models and technology shown here at Obsolete Technology Tellye !

Simplified horizontal / line deflection circuit.

-------------------------------------------------------------------------------------------

A flyback transformer (FBT), also called a line output transformer (LOPT), is a special transformer, which is used for conversion of energy (current and voltage) in electronic circuits. It was initially designed to generate high current sawtooth signals at a relatively high frequency. In modern applications is used extensively in switched-mode power supplies for both low (3V) and high voltage (over 10 kV) supplies.

Flyback Transformer

It was invented as a means to control the horizontal movement of the electron beam in a cathode ray tube (CRT). Unlike conventional transformers, a flyback transformer is not fed with a signal of the same waveshape

as the intended output current. A convenient side effect of such a transformer is the considerable energy that is available in its magnetic circuit. This can be exploited using extra windings that can be used to provide power to operate other parts of the equipment. In particular, very high voltages are easily obtained using relatively few turns of winding which, once rectified, can provide the very high accelerating voltage for a CRT. Many more recent applications of such a transformer dispense with the need to produce high currents and just use the device as a relatively efficient means of producing a wide range of lower voltages using a transformer much smaller than a conventional mains transformer would be.

This GRUNDIG CHASSIS Series was featuring a Simplified BU208A based horizontal deflection section replacing all Thyristor horizontal timebase based circuits.

A horizontal deflection circuit makes a sawtooth

A horizontal deflection circuit makes a sawtoothcurrent flow through a deflection coil. The current

will have equal amounts of positive and negative

current. The horizontal switch transistor conducts

for the right hand side of the picture. The damper

diode conducts for the left side of the picture.

Current only flows through the fly back capacitor

during retrace time.

For time 1 the transistor is turned on. Current

ramps up in the yoke. The beam is moved from the

center of the picture to the right edge. Energy is

stored on the inductance of the yoke.

E=I2L/2

For time 2 the transistor is turned off. Energy

transfers from the yoke to the flyback capacitor. At

the end of time two all the energy from the yoke is

placed on the flyback capacitor. There is zero

current in the yoke and a large voltage on the

capacitor. The beam is quickly moved from the

right edge back to the middle of the picture.

During time 3 the energy on the capacitor flows

During time 3 the energy on the capacitor flowsback into the yoke. The voltage on the flyback

capacitor decreases while the current in the yoke

builds until there is no voltage on the capacitor. By

the end of time 3 the yoke current is at it's

maximum amount but in the negative direction.

The beam is quickly deflected form the center to the

left edge.

Time 4 represents the left hand half of the picture.

Yoke current is negative and ramping down. The

beam moves from the left to the center of the

picture.

The current that flows when the horizontal switch is

closed is approximately:

Ipk ≅ Vcc T / Ldy

Ipk = collector current

T = 1/2 trace time

Ldy = total inductance (yoke + lin coil + size coil)

note:The lin coil inductance varies with current.

______

Tr ≅ 3.14 √ L C

The current that flows during retrace is produced by

the C and L oscillation. The retrace time is 1/2 the

oscillation frequency of the L and C.

I2L /2 ≅ V2C /2 or I2L = V2C As stated earlier the energy in the yoke moves to the

flyback capacitor during time 2.

V= the amount of the flyback pulse that is above the

supply voltage.

D.C. annualizes is inductors are considered

D.C. annualizes is inductors are consideredshores, capacitors are open and generally

semiconductors are removed. The voltage at the

point “B+” is the supply voltage. The collector

voltage of Q1 is also at the supply voltage. The

voltage across C2 is equal to the supply voltage.

When we A.C. annualize this circuit we will find

that the collector of Q1 has a voltage that ranges

from slightly negative to 1000 volts positive. The

average voltage must remain the same as the D.C.

value.

In the A.C. annualizes of the circuit, the

inductance of the yoke (DY) and the inductance of

the flyback transformer are in parallel. The

inductance of T2 is much larger than that if the

DY. This results is a total system inductance of

about 10% to 20% less than that of the DY it’s

self.

The voltage across the Q1 is a half sinusoid pulse during the flyback or retrace period and close to zero at

all other times. It is not possible or safe to observe this point on an oscilloscope without a proper high

frequency high voltage probe. Normally use a 100:1 probe suitable for 2,000V peak. The probe must have

been high frequency calibrated recently.

HORIZONTAL SIZE / E/W AMPLITUDE - CORRECTION CIRCUIT:

There are several different methods of adjusting horizontal size.

SIZE COIL

SIZE COILAdd a variable coil to the yoke current path

causes the total inductance to vary with the coils

setting.

The yoke current is related to supply voltage,

trace time and total inductance. This method

has a limited range!

The horizontal section uses a PWM to set the

horizontal size. One DAC sets the horizontal

size and another DAC sets the pincushion and

trap.

The Raster Centering (D.C. centering) is

controlled by a DAC.

On small monitors the retrace time is fixed. On

large monitors or wide frequency range monitors

two different retrace times are available. The flyback time is set by the micro computer by selecting two

different flyback capacitors. At slow frequencies the longer retrace time is selected.

Different S corrector capacitor values are selected by the micro computer. At the highest frequency the

smallest capacitor is selected.

SPLIT DIODE MODULATOR

SPLIT DIODE MODULATORThis horizontal circuit consists of two parts. D1, C1, C2 and DY are the components as described above.

D2, C3, C4 and L1 are a second “dummy” horizontal section that does not cause deflection current. By the

D.C. analyzing this circuit the voltage across C2 + C4 must equal the supply voltage (B+). Deflection

current in the DY is related to the supply voltage minus the voltage across C4. For a maximum horizontal

size the control point must be held at ground. This causes the dummy section to not operate and the DY

section will get full supply voltage. If the control point is at 1/3 supply then the DY section will be

operating at 2/3 supply.

Note: The impedance of (D1,C1,C2 and DY) and (D2,C3,C4 and L1) makes a voltage divider. If the

control point is not connected then there is some natural voltage on C4. Most split diode monitors are built

to pull power from the dummy section through L2 to ground. A single power transistor shunts from the

control point to ground. It is true that power can be supplied from some other supply through L2 to rise the voltage on C4. For maximum range a bi-directional power amplifier can drive the control point.

The most exciting feature if the split diode modulator is that the flyback pulse, as seen by the flyback

transformer, is the same size at all horizontal size settings.

HORIZONTAL SWITCH/DAMPER DIODE

HORIZONTAL SWITCH/DAMPER DIODEOn the right hand side of the screen, the H. switch transistor conducts current through the deflection yoke.

This current comes from the S correction capacitors, which have a charge equal to the effective supply

voltage. The damper diode allows current for the left hand side of the screen to flow back through the

deflection yoke to the S capacitors.

FLYBACK CAPACITOR

The flyback capacitor connects the hot side of the yoke to ground. This component determines the size and

length of the flyback pulse. ‘Tuning the flyback capacitor’ is done to match the timing of the flyback pulse

to the video blanking time of the video signal. The peak flyback voltage on the horizontal switch must be

set to less that 80% if the Vces specification. The two conditions of time and voltage can be set by three

variables (supply voltage, retrace capacitor and yoke inductance) .

S CAPACITOR

The S capacitors corrects outside versus center linearity in the horizontal scan. The voltage on the S cap

has a parabola plus the DC horizontal supply. Reducing the value of S cap increases this parabola thus

reducing the size of the outside characters and increasing the size of the center characters.

S Capacitor value: Too low: picture will be squashed towards edges.

Too high: picture will be stretched towards edges.

By simply putting a capacitor in series with each coil, the sawtooth waveform is

modified into a slightly sine-wave shape. This reduces the scanning speed near the

edges where the yoke is more sensitive. Generally the deflection angle of the electron

beam and the yoke current are closely related. The problem is the deflection angle

verses the distance of movement on the CRT screen does not have a linear effect.

BASE DRIVE CURRENT

The base drive resistor determines the amount of

base drive. If the transistor is over driven the Vsat

looks very good, but the current fall time is poor.

If the base current is too small the current fall time is very fast. The problem is that the transistor will have many volts across C-E when closed.

The best condition is found by placing the transistor in the heaviest load condition. Adjust the base resistor for the least power consumption then increase the base drive a small amount. This will slightly over drive the base.

BU508(A)

Silicon NPNnpn transistors,pnp transistors,transistors

Category: NPN Transistor, Transistor

MHz: <1 MHz

Amps: 5A

Volts: 1500V

HIGH VOLTAGE CAPABILITY

JEDEC TO-3 METAL CASE.

DESCRIPTION

The BU208A, BU508A and BU508AFI are

manufactured using Multiepitaxial Mesa

technology for cost-effective high performance

and use a Hollow Emitter structure to enhance

switching speeds.

APPLICATIONS:

* HORIZONTAL DEFLECTION FOR COLOUR TV With 110° or even 90° degree of deflection angle.

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

VCES Collector-Emit ter Voltage (VBE = 0) 1500 V

VCEO Collector-Emit ter Voltage (IB = 0) 700 V

VEBO Emitter-Base Voltage (IC = 0) 10 V

IC Collector Current 8 A

ICM Collector Peak Current (tp < 5 ms) 15 A

TO - 3 TO - 218 ISOWATT218

Ptot Total Dissipation at Tc = 25 oC 150 125 50 W

Tstg Storage Temperature -65 to 175 -65 to 150 -65 to 150 oC

Tj Max. Operating Junction Temperature 175 150 150 °C

----------------------------------------------------------------------------------

FRAME Deflection Output with IC TDA3650 (PHILIPS)

FRAME Deflection Output with IC TDA3650 (PHILIPS)GENERAL DESCRIPTION

TDA3650 is a monolithic integrated circuit for vertical deflection in large screen colour television

receivers.

The circuit incorporates the following functions:

• Oscillator

• Synchronization circuit

• Blanking pulse generator

• Sawtooth generator

• $-correction and linearity control

• Comparator and drive circuit

• Output stage

• Flyback generator

• Voltage stabilizer

• Thermal protection circuit

• Guard circuit

• Output stage protection

APPLICATION INFORMATION

The function is described against the corresponding pin number.

1. Comparator and drive circuit

The current flowing through the deflection coils is measured across an external series resistor. The signal

across this resistor is fed to the comparator via pin 1, where it is compared with the internally generated

sawtooth signal. The output of the comparator drives.the output stage. Pin 1 is also used for d.c. feed-

back of the output stage (mid-point setting).

2. Negative supply (ground) for the output stage

3. Output stage

The output stage provides the current to the deflection coils. The vertical deflection coil is connected

to this pin, via a series connection of a coupling capacitor and a feedback resistor to ground. The

output stage is protected against over-voltages and over-currents by a SOAR-protection circuit. When

one of the transistors exceeds its operational threshold the drive current is reduced to a safe level.

Temperature protection reduces the drive of the output stage when the junction temperature exceeds

170 oc.

4. Positive supply of output stage

This supply is obtained from the flyback generator. An electrolytic capacitor between pins 4 and 6, a

diode between pins 4 and 13, and a resistor between pins 6 and ground must be connected for correct

operation of the flyback generator.

5. Synchronization input

When the voltage applied to pin 5 reaches a level of 0, 7 V the lower switching level is increased thus

initiating the charge cycle of the oscillator capacitor. The synchronization circuit is inhibited during

oscillator flyback time.

6. Flyback generator

The flyback generator reduces power dissipation in the vertical stage. As a result a lower power supply

can be chosen (26 V for 30AX application). Whereas the voltage during flyback is increased to 45 V

(depending on the design of external components), the maximum increase of the voltage during fly back

is nearly factor 2.

The capacitor between pins 6 and 4 is charged via the external diode during the scan period. Then,

when the flyback generator is.activated by the oscillator flyback pulse, the voltage across the capacitor

is connected in series with the supply voltage to provide the required flyback voltage. At the end of the

oscillator pulse the drive of the flyback generator is maintained by the flyback voltage of the deflection

circuit.

7. Oscillator

The oscillator frequency is determined by the val.ues of the external resistor and capacitor connected

in parallel to pin 7. The capacitor is discharged via the resistor which is connected to ground. The

voltage on the capacitor is compared with an internal voltage from the voltage stabilizer (lower switching

level). When this loviter switching level is reached the capacitor is charged via an internal 500 n resistor.

At the same time the comparator voltage is increased (higher switching level). When the voltage on the

capacitor reaches the higher switching level the charge current is switched off and the capacitor is

discharged again.

8. S-correction and linearity circuit

From pin 8 an adjustable parabolic current is fed back to the mid-point of the sawtooth generator

capacitors at pin 9 to provide linearity control. The external components connected between pins 8

and 9 together with the d.c. feedback circuitry at pin 1 define the S-shape of the deflection current.

9. Sawtooth generator

The sawtooth signal is obtained by charging the capacitors connected to pin 9 via an external resistorVariation of the charge current will vary the amplitude of the signal. During oscillator flyback time

the capacitors are discharged to an internally fixed voltage level.

10. Output stage decoupling

A low value capacitor must be connected to pin 10 for decoupling of the output driver stage.

11. Blanking pulse generator

The blanking pulse duration is determined by the oscillator sawtooth signal. The guard circuit providcontinuous blanking when the vertical deflection current is absent.

12. Negative supply (ground) of small-signal part

13. Positive supply

The supply voltage at this pin is used to supply the flyback generator, the voltage stabilizer and the

protection circuits.

Chrominance + Luminance with PHILIPS TDA3561A,

PAL decoder TDA3561A

GENERAL DESCRIPTION

The PHILIPS TDA3561A is a decoder for the PAL colour television standard. It combines all functions required for the identification

and demodulation of PAL signals.

Furthermore it contains a luminance amplifier, an RGB-matrix and amplifier. These

amplifiers supply output signals up to 5 V peak-to-peak (picture information) enabling direct drive of the discrete output

stages.

The circuit also contains separate inputs for data insertion, analogue as well as digital, which can be used for text display systems (e.g. (Teletext/broadcast antiope), channel number display, etc. Additional to the TDA3560, the

circuit includes the following features:

· The peak white limiter is only active during the time that the 9,3 V level at the output is exceeded.

The start of the

limiting function is delayed by one line period. This avoids peak white limiting by test patterns which have abrupt transitions from colour to white signals.

· The brightness

control is obtained by inserting a variable pulse in the luminance

channel. Therefore the ratio of brightness variation and signal

amplitude at the three outputs will be identical and independent of the

difference in gain of the three channels. Thus discolouring due to

adjustment of contrast and brightness is avoided.

· The brightness

control is obtained by inserting a variable pulse in the luminance

channel. Therefore the ratio of brightness variation and signal

amplitude at the three outputs will be identical and independent of the

difference in gain of the three channels. Thus discolouring due to

adjustment of contrast and brightness is avoided.· Improved suppression of the internal RGB signals when the device is switched to external signals, and vice versa.

· Non-synchronized external RGB signals do not disturb the black level of the internal signals.

· Improved suppression of the residual 4,4 MHz signal in the RGB output stages.

· Cascoded stages in the demodulators and burst phase detector minimize the radiation of the colour demodulator

inputs.

· High current capability of the RGB outputs and the chrominance output.

APPLICATION INFORMATION

The function is described against the corresponding pin

number.

1. + 12 V power supply

The circuit gives good operation in a supply voltage range

between 8 and 13,2 V provided that the supply voltage for

the controls is equal to the supply voltage for the

TDA3561A. All signal and control levels have a linear

dependency on the supply voltage. The current taken by

the device at 12 V is typically 85 mA. It is linearly

dependent on the supply voltage.

2. Control voltage for identification

This pin requires a detection capacitor of about 330 nF for

correct operation. The voltages available under various

signal conditions are given in the specification.

signal conditions are given in the specification.3. Chrominance input

The chroma signal must be a.c.-coupled to the input.

Its amplitude must be between 55 mV and 1100 mV

peak-to-peak (25 mV to 500 mV peak-to-peak burst

signal). All figures for the chroma signals are based on a

colour bar signal with 75% saturation, that is the

burst-to-chroma ratio of the input signal is 1 : 2,25.

4. Reference voltage A.C.C. detector

This pin must be decoupled by a capacitor of about 330

nF. The voltage at this pin is 4,9 V.

5. Control voltage A.C.C.

The A.C.C. is obtained by synchronous detection of the

burst signal followed by a peak detector. A good noise

immunity is obtained in this way and an increase of the

colour for weak input signals is prevented. The

recommended capacitor value at this pin is 2,2 µF.

6. Saturation control

The saturation control range is in excess of 50 dB.

The control voltage range is 2 to 4 V. Saturation control is

a linear function of the control voltage.

When the colour killer is active, the saturation control

voltage is reduced to a low level if the resistance of the

external saturation control network is sufficiently high.

Then the chroma amplifier supplies no signal to the

demodulator. Colour switch-on can be delayed by proper

choice of the time constant for the saturation control

setting circuit.

When the saturation control pin is connected to the power

supply the colour killer circuit is overruled so that the colour

signal is visible on the screen. In this way it is possible to

adjust the oscillator frequency without using a frequency

counter (see also pins 25 and 26).

7. Contrast control

The contrast control range is 20 dB for a control voltage

change from + 2 to + 4 V. Contrast control is a linear

function of the control voltage. The output signal is

suppressed when the control voltage is 1 V or less. If one

or more output signals surpasses the level of 9 V the peak

white limiter circuit becomes active and reduces the out

put

putsignals via the contrast control by discharging C2 via an

internal current sink.

8. Sandcastle and field blanking input

The output signals are blanked if the amplitude of the input

pulse is between 2 and 6,5 V. The burst gate and clamping

circuits are activated if the input pulse exceeds a level of

7,5 V.

The higher part of the sandcastle pulse should start just

after the sync pulse to prevent clamping of video signal on

the sync pulse. The width should be about 4 µs for proper

A.C.C. operation.

9. Video-data switching

The insertion circuit is activated by means of this input by

an input pulse between 1 V and 2 V. In that condition, the

internal RGB signals are switched off and the inserted

signals are supplied to the output amplifiers. If only normal

operation is wanted this pin should be connected to the

negative supply. The switching times are very short

(< 20 ns) to avoid coloured edges of the inserted signals

on the screen.

10. Luminance signal input

The input signal should have a peak-to-peak amplitude of

0,45 V (peak white to sync) to obtain a black-white output

signal to 5 V at nominal contrast. It must be a.c.-coupled to

the input by a capacitor of about 22 nF. The signal is

clamped at the input to an internal reference voltage.

A 1 kΩ luminance delay line can be applied because the

luminance input impedance is made very high.

Consequently the charging and discharging currents of the

coupling capacitor are very small and do not influence the

signal level at the input noticeably. Additionally the

coupling capacitor value may be small.

11. Brightness control

The black level of the RGB outputs can be set by the

voltage on this pin (see Fig.5). The black level can be set

higher than 4 V however the available output signal

amplitude is reduced (see pin 7). Brightness control also

operates on the black level of the inserted signals.

12, 14, 16. RGB outputs

The output circuits for red, green and blue are identical.

Output signals are 5,25 V (R, G and B) at nominal input

signals and control settings. The black levels of the three

outputs have the same value. The blanking level at the

outputs is 2,1 V. The peak white level is limited to 9,3 V.

When this level exceeded the output signal amplitude is

reduced via the contrast control (see pin 7).

13, 15, 17. Inputs for external RGB signals

The external signals must be a.c.-coupled to the inputs via

a coupling capacitor of about 100 nF. Source impedance

should not exceed 150 Ω. The input signal required for

a 5 V peak-to-peak output signal is 1 V peak-to-peak.

At the RGB outputs the black level of the inserted signal is

identical to that of normal RGB signals. When these inputs

are not used the coupling capacitors have to be connected

are not used the coupling capacitors have to be connectedto the negative supply.

18, 19, 20. Black level clamp capacitors

The black level clamp capacitors for the three channels are

connected to these pins. The value of each capacitor

should be about 100 nF.

21, 22. Inputs (B-Y) and (R-Y) demodulators

The input signal is automatically fixed to the required level

by means of the burst phase detector and A.C.C.

generator which are connected to pin 21 and pin 22. As the

burst (applied differentially to those pins) is kept constant

by the A.C.C., the colour difference signals automatically

have the correct value.

23, 24. Burst phase detector outputs

At these pins the output of the burst phase detector is

filtered and controls the reference oscillator. An adequate

catching range is obtained with the time constants given in

the application circuit (see Fig.6).

25, 26. Reference oscillator

The frequency of the oscillator is adjusted by the variable

capacitor C1. For frequency adjustment interconnect pin

21 and pin 22. The frequency can be measured by

connecting a suitable frequency counter to pin 25.

28. Output of the chroma amplifier

Both burst and chroma signals are available at the output.

The burst-to-chroma ratio at the output is identical to that

at the input for nominal control settings. The burst signal is

not affected by the controls. The amplitude of the input

signal to the demodulator is kept constant by the A.C.C.

Therefore the output signal at pin 28 will depend on the

signal loss in the delay line.

Synchronization With TDA3576B.12V 70mA sync combination with transmitter identification and vertical 625 divider system

- Line deflection synchronized Power supply on the bottom of the cabinet !

TDA2541 IF AMPLIFIER WITH DEMODULATOR AND AFC

DESCRIPTION

The TDA2540 and 2541 are IF amplifier and A.M.

demodulator circuits for colour and black and white

television receivers using PNP or NPN tuners. They

are intended for reception of negative or positive

modulation CCIR standard.

They incorporate the following functions : .Gain controlled amplifier .Synchronous demodulator .White spot inverter .Video preamplifier with noise protection .Switchable AFC .AGC with noise gating .Tuner AGC output (NPN tuner for 2540)-(PNP

tuner for 2541) .VCR switch for video output inhibition (VCR

play back).

.SUPPLYVOLTAGE : 12V TYP

.SUPPLYCURRENT : 50mATYP

.I.F. INPUT VOLTAGE SENSITIVITY AT

F = 38.9MHz : 85mVRMS TYP

.VIDEO OUTPUT VOLTAGE (white at 10% of

top synchro) : 2.7VPP TYP

.I.F. VOLTAGE GAIN CONTROL RANGE :

64dB TYP .SIGNAL TO NOISE RATIO AT VI = 10mV :

58dB TYP

.A.F.C. OUTPUT VOLTAGE SWING FOR

Df = 100kHz : 10V TYP.

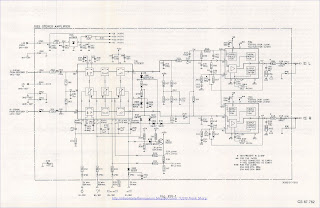

PHILIPS 20CT4426 /08Z SEGANTINI CHASSIS KT4 CIRCUIT ARRANGEMENT IN A PICTURE DISPLAY DEVICE UTILIZING A STABILIZED SUPPLY VOLTAGE CIRCUIT:CHASSIS KT4 Line synch Switched Mode Power Supply with Line deflection output Transistor Drive Circuit:

A

stabilized supply voltage circuit for a picture display device

comprising a chopper wherein the switching signal has the line frequency

and is duration-modulated. The coil of the chopper constitutes the

primary winding of a transformer a secondary winding of which drives

the line output transistor so that the switching transistor of the

chopper also functions as a driver for the line output stage. The

oscillator generating the switching signal may be the line oscillator.

In a special embodiment the driver and line output transistor

conduct simultaneously and in order to limit the base current of the

line output transistor a coil shunted by a diode is incorporated in

the drive line of the line output transistor. Other secondary

windings of the transformer drive diodes which conduct simultaneously

with the efficiency diode of the chopper so as to generate further

stabilized supply voltages.

A

stabilized supply voltage circuit for a picture display device

comprising a chopper wherein the switching signal has the line frequency

and is duration-modulated. The coil of the chopper constitutes the

primary winding of a transformer a secondary winding of which drives

the line output transistor so that the switching transistor of the

chopper also functions as a driver for the line output stage. The

oscillator generating the switching signal may be the line oscillator.

In a special embodiment the driver and line output transistor

conduct simultaneously and in order to limit the base current of the

line output transistor a coil shunted by a diode is incorporated in

the drive line of the line output transistor. Other secondary

windings of the transformer drive diodes which conduct simultaneously

with the efficiency diode of the chopper so as to generate further

stabilized supply voltages.

The

invention relates to a circuit arrangement in a picture display

device wherein the input direct voltage between two input terminals,

which is obtained be rectifying the mains alternating voltage, is

converted into a stabilized output direct voltage by means of a

switching transistor and a coil and wherein the transistor is connected

to a first input terminal and an efficiency diode is connected to the

junction of the transistor and the coil. The switching transistor is

driven by a pulsatory voltage of line frequency which pulses are

duration-modulated in order to saturate the switching transistor during

part of the period dependent on the direct voltage to be stabilized

and to cut off this transistor during the remaining part of the

period. The pulse duration modulation is effected by means of a

comparison circuit which compares the direct voltage to be stabilized

with a substantially constant voltage, the coil constituting the

primary winding of a transformer.

The

invention relates to a circuit arrangement in a picture display

device wherein the input direct voltage between two input terminals,

which is obtained be rectifying the mains alternating voltage, is

converted into a stabilized output direct voltage by means of a

switching transistor and a coil and wherein the transistor is connected

to a first input terminal and an efficiency diode is connected to the

junction of the transistor and the coil. The switching transistor is

driven by a pulsatory voltage of line frequency which pulses are

duration-modulated in order to saturate the switching transistor during

part of the period dependent on the direct voltage to be stabilized

and to cut off this transistor during the remaining part of the

period. The pulse duration modulation is effected by means of a

comparison circuit which compares the direct voltage to be stabilized

with a substantially constant voltage, the coil constituting the

primary winding of a transformer.Such a circuit arrangement is known from German "Auslegeschrift" 1.293.304. wherein a circuit arrangement is described which has for its object to convert an input direct voltage which is generated between two terminals into a different direct voltage. The circuit employs a switch connected to the first terminal of the input voltage and periodically opens and closes so that the input voltage is converted into a pulsatory voltage. This pulsatory voltage is then applied to a coil. A diode is arranged between the junction of the switch and the coil and the second terminal of the input voltage whilst a load and a charge capacitor in parallel thereto are arranged between the other end of the coil and the second terminal of the input voltage. The assembly operates in accordance with the known efficiency principle i.e., the current supplied to the load flows alternately through the switch and through the diode. The function of the switch is perform

ed

by a switching transistor which is driven by a periodical pulsatory

voltage which saturates this transistor for a given part of the

period. Such a configuration is known under different names in the

literature; it will be referred to herein as a "chopper." A known

advantage thereof, is that the switching transistor must be able to

stand a high voltage or provide a great current but it need not

dissipate a great power. The output voltage of the chopper is

compared with a constant reference voltage. If the output voltage

attempts to vary because the input voltage and/or the load varies, a

voltage causing a duration modulation of the pulses is produced at

the output of the comparison arrangement. As a result the quantity of

the energy stored in the coil varies and the output voltage is

maintained constant. In the German "Auslegeschrift" referred to it is

therefore an object to provide a stabilized supply voltage device.

ed

by a switching transistor which is driven by a periodical pulsatory

voltage which saturates this transistor for a given part of the

period. Such a configuration is known under different names in the

literature; it will be referred to herein as a "chopper." A known

advantage thereof, is that the switching transistor must be able to

stand a high voltage or provide a great current but it need not

dissipate a great power. The output voltage of the chopper is

compared with a constant reference voltage. If the output voltage

attempts to vary because the input voltage and/or the load varies, a

voltage causing a duration modulation of the pulses is produced at

the output of the comparison arrangement. As a result the quantity of

the energy stored in the coil varies and the output voltage is

maintained constant. In the German "Auslegeschrift" referred to it is

therefore an object to provide a stabilized supply voltage device.In the circuit arrangement according to the mentioned German "Auslegeschrift" the frequency of the load variations or a harmonic thereof is chosen as the frequency for the switching voltage. Particularly when the load fed by the chopper is the line deflection circuit of a picture display device, wherein thus the impedance of the load varies in the rhythm of the line frequency, the frequency of the switching voltage is equal to or is a multiple of the line frequency.

It

is to be noted that the chopper need not necessarily be formed as

that in the mentioned German "Auslegeschrift." In fact, it is known

from literature that the efficiency diode and the coil may be

exchanged. It is alternatively possible for the coil to be provided at

the first terminal of the input voltage whilst the switching

transistor is arranged between the other end and the second terminal

of the input voltage. The efficiency diode is then provided between

the junction of said end and the switching transistor and the load. It

may be recognized that for all these modifications a voltage is

present across the connections of the coil which voltage has the same

frequency and the same shape as the pulsatory switching voltage. The

control voltage of a line deflection circuit is a pulsatory voltage

which causes the line output transistor to be saturates and cut off

alternately. The invention is based on the recognition that the

voltage present across the connections of the coil is suitable to

function as such a control voltage and that the coil constitutes the

primary of a transformer. To this end the circuit arrangement

according to the invention is characterized in that a secondary

winding of the transformer drives the switching element which applies a

line deflection current to line deflection coils and by which the

voltage for the final anode of a picture display tube which forms part

of the picture display device is generated, and that the ratio

between the period during which the switching transistor is saturated

and the entire period, i.e., the switching transistor duty cycle is

between 0.3 and 0.7 during normal operation.

It

is to be noted that the chopper need not necessarily be formed as

that in the mentioned German "Auslegeschrift." In fact, it is known

from literature that the efficiency diode and the coil may be

exchanged. It is alternatively possible for the coil to be provided at

the first terminal of the input voltage whilst the switching

transistor is arranged between the other end and the second terminal

of the input voltage. The efficiency diode is then provided between

the junction of said end and the switching transistor and the load. It

may be recognized that for all these modifications a voltage is

present across the connections of the coil which voltage has the same

frequency and the same shape as the pulsatory switching voltage. The

control voltage of a line deflection circuit is a pulsatory voltage

which causes the line output transistor to be saturates and cut off

alternately. The invention is based on the recognition that the

voltage present across the connections of the coil is suitable to

function as such a control voltage and that the coil constitutes the

primary of a transformer. To this end the circuit arrangement

according to the invention is characterized in that a secondary

winding of the transformer drives the switching element which applies a

line deflection current to line deflection coils and by which the

voltage for the final anode of a picture display tube which forms part

of the picture display device is generated, and that the ratio

between the period during which the switching transistor is saturated

and the entire period, i.e., the switching transistor duty cycle is

between 0.3 and 0.7 during normal operation.The invention is also based on the recognition that the duration modulation which is necessary to stabilize the supply voltage with the switching transistor does not exert influence on the driving of the line output transistor. This resides in the fact that in case of a longer or shorter cut-off period of the line output transistor the current flowing through the line deflection coils thereof is not influenced because of the efficiency diode current and transistor current are taken over or, in case of a special kind of transistor, the collector-emitter current is taken over by the base collector current and conversely. However, in that case the above-mentioned ratios of 0.3 : 0.7 should be taken into account since otherwise this take-over principle is jeopardized.

As will be furth

er explained the use of the switching transistor as a driver for

the line output transistor in an embodiment to be especially

described hereinafter has the further advantage that the line output

transistor automatically becomes non-conductive when this switching

transistor is short circuited so that the deflection and the EHT for

the display tube drop out and thus avoid damage thereof.

er explained the use of the switching transistor as a driver for

the line output transistor in an embodiment to be especially

described hereinafter has the further advantage that the line output

transistor automatically becomes non-conductive when this switching

transistor is short circuited so that the deflection and the EHT for

the display tube drop out and thus avoid damage thereof.Due to the step according to the invention the switching transistor in the stabilized supply functions as a driver for the line deflection circuit. The circuit arrangement according to the invention may in addition be equipped with a very efficient safety circuit so that the reliability is considerably enhanced, which is described in the U.S. Pat. No. 3,629,686. The invention is furthermore based on the recognition of the fact that the pulsatory voltage present across the connections of the coil is furthermore used and to this end the circuit arrangement according to the invention is characterized in that secondary windings of the transformer drive diodes which conduct simultaneously with the efficiency diode so as to generate further stabilized direct voltages, one end of said diodes being connected to ground.

In order that the invention may be readily carried into effect, a few embodiments thereof will now be described in detail by way of example with reference to the accompanying diagrammatic drawings in which:

FIG. 1 shows a principle circuit diagram wherein the chopper and the line deflection circuit are further shown but other circuits are not further shown.

FIGS. 2a, 2b and 2c show the variation as a function of time of two currents and of a voltage occurring in the circuit arrangement according to FIG. 1.

FIGS. 3a 3b, 3c and 3d show other embodiments of the chopper.

FIGS. 4a and 4b show modifications of part of the circuit arrangement of FIG. 1.

In

FIG. 1 the reference numeral 1 denotes a rectifier circuit which

converts the mains voltage supplied thereto into a non-stabilized direct

voltage. The collector of a switching transistor 2 is connected to

one of the two terminals between which this direct voltage is

obtained, said transistor being of the npn-type in this embodiment and

the base of which receives a pulsatory voltage which originates

through a control stage 4 from a modulator 5 and causes transistor 2

to be saturated and cut off alternately. The voltage waveform 3 is

produced at the emitter of transistor 2. In order to maintain the

output voltage of the circuit arrangement constant, the duration of

the pulses provided is varied in modulator 5. A pulse oscillator 6

supplies the pulsatory voltage to modulator 5 and is synchronized by a

signal of line frequency which originates from the line oscillator

6' present in the picture display device. This line oscillator 6' is

in turn directly synchronized in known manner by pulses 7' of line

frequency which are present in the device and originate for example

from a received television signal if the picture display device is a

television receiver. Pulse oscillator 6 thus generates a pulsatory

voltage the repetition frequency of which is the line frequency.

In

FIG. 1 the reference numeral 1 denotes a rectifier circuit which

converts the mains voltage supplied thereto into a non-stabilized direct

voltage. The collector of a switching transistor 2 is connected to

one of the two terminals between which this direct voltage is

obtained, said transistor being of the npn-type in this embodiment and

the base of which receives a pulsatory voltage which originates

through a control stage 4 from a modulator 5 and causes transistor 2

to be saturated and cut off alternately. The voltage waveform 3 is

produced at the emitter of transistor 2. In order to maintain the

output voltage of the circuit arrangement constant, the duration of

the pulses provided is varied in modulator 5. A pulse oscillator 6

supplies the pulsatory voltage to modulator 5 and is synchronized by a

signal of line frequency which originates from the line oscillator

6' present in the picture display device. This line oscillator 6' is

in turn directly synchronized in known manner by pulses 7' of line

frequency which are present in the device and originate for example

from a received television signal if the picture display device is a

television receiver. Pulse oscillator 6 thus generates a pulsatory

voltage the repetition frequency of which is the line frequency.The emitter of switching transistor 2 is connected at one end to the cathode of an efficiency diode 7 whose other end is connected to the second input voltage terminal and at the other end to primary winding 8 of a transformer 9. Pulsatory voltage 3 which is produced at the cathode of efficiency diode 7 is clamped against the potential of said second terminal during the intervals when this diode conducts. During the other intervals the pulsatory voltage 3 assumes the value V i . A charge capacitor 10 and a load 11 are arranged between the other end of winding 8 and the second input voltage terminal. The elements 2,7,8,10 and 11 constitute a so-called chopper producing a direct voltage across charge capacitor 10, provided that capacitor 10 has a sufficiently great value for the line frequency and the current applied to load 11 flowing alternately through switching transistor 2 or through efficiency diode 7. The output voltage V o which is the direct voltage produced across charge capacitor 10 is applied to a comparison circuit 12 which compares the voltage V o with a reference voltage. Comparison circuit 12 generates a direct voltage which is applied to modulator 5 so that the duration of the effective period δ T of switching transistor 2 relative to the period T of pulses 3 varies as a function of the variations of output voltage V 0 . In fact, it is readily evident that output voltage V o is proportional to the ratio δ :

V o = V i . δ

Load 11 of the chopper consists in the consumption of parts of the picture display device which are fed by output voltage V 0 .

In a practical embodiment of the circuit arrangement according to

FIG. 1 wherein the mains alternating voltage has a nominal effective

value of 220 V and the rectified voltage V i is approximately 270 V, output voltage V o

for δ = 0.5 is approximately 135 V. This makes it also possible, for

example, to feed a line deflection circuit as is shown in FIG. 1

wherein load 11 then represents different parts which are fed by the

chopper. Since voltage V o is maintained constant due to

pulse duration modulation, the supply voltage of this line deflection

circuit remains constant with the favorable result that the line

amplitude(= the width of the picture displayed on the screen of the

picture display tube) likewise remains constant as well as the EHT

required for the final anode of the picture display tube in the same

circuit arrangement independent of the variations in the mains voltage

and the load on the EHT generator (= variations in brightness).

Load 11 of the chopper consists in the consumption of parts of the picture display device which are fed by output voltage V 0 .

In a practical embodiment of the circuit arrangement according to

FIG. 1 wherein the mains alternating voltage has a nominal effective

value of 220 V and the rectified voltage V i is approximately 270 V, output voltage V o

for δ = 0.5 is approximately 135 V. This makes it also possible, for

example, to feed a line deflection circuit as is shown in FIG. 1

wherein load 11 then represents different parts which are fed by the

chopper. Since voltage V o is maintained constant due to

pulse duration modulation, the supply voltage of this line deflection

circuit remains constant with the favorable result that the line

amplitude(= the width of the picture displayed on the screen of the

picture display tube) likewise remains constant as well as the EHT

required for the final anode of the picture display tube in the same

circuit arrangement independent of the variations in the mains voltage

and the load on the EHT generator (= variations in brightness). However,

variations in the line amplitude and the EHT may occur as a result

of an insufficiently small internal impedance of the EHT generator.

Compensation means are known for this purpose. A possibility within

the scope of the present invention is to use comparison circuit 12

for this purpose. In fact, if the beam current passes through an

element having a substantially quadratic characteristic, for example,

a voltage-dependent resistor, then a variation for voltage V o

may be obtained through comparison circuit 12 which variation is

proportional to the root of the variation in the EHT which is a known

condition for the line amplitude to remain constant.

However,

variations in the line amplitude and the EHT may occur as a result

of an insufficiently small internal impedance of the EHT generator.

Compensation means are known for this purpose. A possibility within

the scope of the present invention is to use comparison circuit 12

for this purpose. In fact, if the beam current passes through an

element having a substantially quadratic characteristic, for example,

a voltage-dependent resistor, then a variation for voltage V o

may be obtained through comparison circuit 12 which variation is

proportional to the root of the variation in the EHT which is a known

condition for the line amplitude to remain constant.In addition this facilitates smoothing of voltage V o since the repetition frequency of pulsatory voltage 3 is many times higher than that of the mains and a comparatively small value may be sufficient for charge capacitor 10. If charge capacitor 10 has a sufficiently high value for the line frequency, voltage V o is indeed a direct voltage so that a voltage having the same form as pulsatory voltage 3 is produced across the terminals of primary winding 8. Thus voltages which have the same shape as pulsatory voltage 3 but have a greater or smaller amplitude are produced across secondary windings 13, 14 of transformer 9 (FIG. 1 shows only 2 secondary windings but there may be more). The invention is based on the recognition that one end of each secondary winding is connected to earth while the other end thereof drives a diode, the winding sense of each winding and the direction of conductance of each diode being chosen to be such that these diodes conduct during the same period as does efficiency diode 7. After smoothing, stabilized supply voltages, for example, at terminal 15 are generated in this manner at the amplitudes and polarities required for the circuit arrangements pre

sent

in the picture display device. In FIG. 1 the voltage generated at

terminal 15 is, for example, positive relative to earth. It is to be

noted that the load currents of the supply voltages obtained in this

manner cause a reduction of the switching power which is economized by

efficiency diode 7. The sum of all diode currents including that of

diode 7 is in fact equal to the current which would flow through

diode 7 if no secondary winding were wound on transformer 9 and if no

simultaneous diode were used. This reduction may be considered an

additional advantage of the circuit arrangement according to the

invention, for a diode suitable for smaller powers may then be used.

However, it will be evident that the overall secondary load must not

exceed the primary load since otherwise there is the risk of

efficiency diode 7 being blocked so that stabilization of the

secondary supply voltages would be out of the question.

sent

in the picture display device. In FIG. 1 the voltage generated at