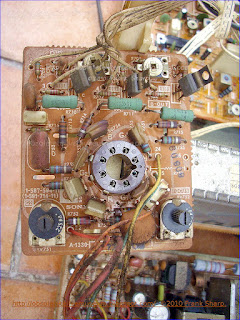

SONY KV-1842E CHASSIS SCC-191A-A

This Chassis SCC-191A-A is developed on 2 main panels boards. - Deflections + Supply board on the central bottom. - Signal board on the left side vertical mounted. Luminance and Chrominance combination ASIC VIF SIF - Chroma Processor Circuit - PAL Chrominance & Luminance Processor.

Above placed the commands for tunings and setups.

SONY KV-1842E CHASSIS SCC-191A-A CONTACTLESS

TOUCH SENSOR PROGRAM CHANGE KEYBOARD CIRCUIT ARRANGEMENT FOR

ESTABLISHING A CONSTANT POTENTIAL OF THE CHASSIS OF AN ELECTRICAL

DEVICE WITH RELATION TO GROUND :

Circuit arrangement for establishing a reference potential of a chassis of an electrical device such as a radio and/or TV receiver, such device being provided with at least one contactless touching switch operating under the AC voltage principle. The device is switched by touching a unipole touching field in a contactless manner so as to establish connection to a grounded network pole. The circuit arrangement includes in combination an electronic blocking switch and a unidirectional rectifier which separates such switch from the network during the blocking phase.

1.

A circuit arrangement for establishing, at the chassis of an

electrical device powered by a grounded AC supply network, a

reference potential with relation to ground, said device having

at least one contactless touching switch operating on the AC

voltage principle, the switch being operated by touching a

unipole touching field in a contactless manner, said arrangement

comprising an electronic switch for selectively blocking the

circuit of the device from the supply network, a half-wave

rectifier including a pair of diodes individually connected in

series-aiding relation between the terminals of the supply network

and the terminals of the device for separating the electronic

blocking switch from the supply network during a blocking phase

defined by a prescribed half period of the AC cycle, and a pair of

condensers individually connected in parallel with the respective

diodes. 2. A circuit

arrangement according to claim 1, wherein the capacitances of the

two condensers are of equal magnitude.

1.

A circuit arrangement for establishing, at the chassis of an

electrical device powered by a grounded AC supply network, a

reference potential with relation to ground, said device having

at least one contactless touching switch operating on the AC

voltage principle, the switch being operated by touching a

unipole touching field in a contactless manner, said arrangement

comprising an electronic switch for selectively blocking the

circuit of the device from the supply network, a half-wave

rectifier including a pair of diodes individually connected in

series-aiding relation between the terminals of the supply network

and the terminals of the device for separating the electronic

blocking switch from the supply network during a blocking phase

defined by a prescribed half period of the AC cycle, and a pair of

condensers individually connected in parallel with the respective

diodes. 2. A circuit

arrangement according to claim 1, wherein the capacitances of the

two condensers are of equal magnitude.

In electronic devices, for example TV and radio receivers, there are used in ever increasing numbers electronic touching switches for switching and adjusting the functions of the device. In one known embodiment of this type of touching switch, which operates on a DC voltage principle, the function of the electronic device, is contactlessly switched by touching a unipole touching field, the switching being carried out by means of an alternating current voltage. When using such a unipole touching electrode, one takes advantage of the fact that the AC current circuit is generally unipolarly grounded. In order to close the circuit by touching the touching surface via the body of the operator to ground, it is necessary to provide an AC voltage on the touching field. In one special known embodiment there is employed a known bridge current rectifier for the current supply. This type of arrangement has the drawback that the chassis of the device changes its polarity relative to the grounded network pole with the network frequency. With such construction considerable difficulties appear when connecting measuring instruments to the device, such difficulties possibly eventually leading to the destruction of individual parts of the electronic device.

In order to avoid these drawbacks, the present invention provides a normal combination of a unidirectional rectifier with an electronic blocking switch that separates the chassis of the electronic device from the network during the blocking phase. In accordance with the present invention, the polarity of the chassis of the electronic device does not periodically change, because the electronic device is practically separated from the network during the blocking phase of the unidirectional rectifier by means of the electronic blocking switch.

In a further embodiment of the invention a further rectifier is connected in series with the unidirectional rectifier in the connection between the circuit and the negative pole of the chassis. Such further rectifier is preferably a diode which is switched in the transfer direction of the unidirectional rectifier. According to another feature of the invention there are provided condensers, a respective condenser being connected parallel with each of the rectifiers. Preferably the two condensers have equal capacitances. Because of the use of such condensers, which are required because of high frequency reasons, during the blocking phase there is conducted to the chassis of the electronic device an AC voltage proportional to the order of capacitances of the condensers. Thus there is placed upon the touching field in a desired manner an AC voltage, and there is thereby assured a secure functioning of the adjustment of the device when such touching occurs.

I

n

the embodiment of the invention employing two rectifiers there

is the further advantage that over a bridging over of the minus

conduit of the rectifier that is connected between the network

and the negative pole of the chassis connection, no injuries can

be caused by a measuring instrument in the electronic device

itself and in the circuit arrangement connected thereto.

n

the embodiment of the invention employing two rectifiers there

is the further advantage that over a bridging over of the minus

conduit of the rectifier that is connected between the network

and the negative pole of the chassis connection, no injuries can

be caused by a measuring instrument in the electronic device

itself and in the circuit arrangement connected thereto.In the accompanying drawing:

The sole FIGURE of the drawing is a circuit diagram of a preferred embodiment of the invention.

In the illustrated embodiment the current supply part of the device, shown at the left, is connected via connecting terminals A and B to an AC voltage source, the terminal B being grounded at 8. The current supply part consists of a unidirectional rectifier in the form of a diode 1 with its anode connected to the terminal I, the cathode of diode 1 being connected to one input terminal 9 of an electronic device 2. In the device 2 there is also arranged a sensor circuit 3, shown here mainly as a block, circuit 3 being shown as including a pnp input transistor the emitter of which is connected to an output terminal 11 of the device 2. The collector of such transistor is connected to the other output terminal 12 of the device 2. The base of the transistor is connected by a wire 13 to a unipolar touching field 4 which may be in the form of a simple metal plate instead of the pnp transistor shown, the sensor circuit itself may consist of a standard integrating circuit which controls, among other things, the periodic sequential switching during the touching time of the touching field 4. All of the circuits of the electronic device 2 are isolated in a known manner from the chassis potential. Between the network terminal B and the negative pole 10 of the chassis there is arranged in the direction opposite that of diode 1 a further diode 5, the anode of diode 5 being connected to the terminal 10, and the cathode of diode 5 being connected to the terminal B of the current supply. To provide for HF type bridging of the diodes 1 and 5 there are arranged condensers 6 and 7 respectively, which are connected in parallel with such diodes.

The invention functions by reason of the fact that in an AC network separate devices radiate electromagnetic waves which produce freely traveling fields in the body of the person who is operating and/or adjusting the device, thereby producing an alternating current through his body to ground, as indicated by the - line at the right of the circuit diagram. If now the person operating the device touches the switching field 4, then the pnp type input transistor of the sensor circuit 3, which is placed on a definite reference potential (for example 12 Volts) and is connected with the negative halfwave of the AC voltage potential, is made conductive. There is thereby released a control command in the sequential switching, for example, for switching the electronic device to the next receiving channel. It is understood that the most suitable connection is formed between ground and the touching field 4 by means of a wire. By the use of such wires it would be assured that in all cases the base of the transistor in circuit 3 is connected to ground. This would, however, not permit anyone to operate the switch without the use of an auxiliary means such as a wire. It will be assumed that the touching almost always results directly via the almost isolated human body. For this reason the AC current fields are necessary, because otherwise there cannot always be provided a ground contact. Thus this connection is established via the body resistance of the person carrying out the touching of the switch.

The positive half wave of the alternating current travels to the terminal 9 of the electronic device 2 after such current has been rectified and smoothed by the devices 1, 6. Such positive halfwave is also conducted to the sensor circuit 3. The thus formed current circuit is closed by way of the chassis of the electronic device 3, the diode 5, and the terminal B. When there is a negative halfwave of the alternating current delivered by the current supply, both diodes 1 and 5 remain closed so that the chassis of the device 2 remains separated from the network during the blocking phase. Nevertheless, by means of condensers 6 and 7 the chassis is placed in a definite network potential, which depends on the relationship of the order of magnitude of the two condensers 6 and 7. When the capacitances of such condensers are equal, there is placed upon the chassis of the device 2 the constant reference potential, and simultaneously there is present via the sensor circuit 3 the required AC voltage at the touching field 4 for adjusting the function or functions of the device 2 upon the touching of the touching field 4.

The reference character 15 indicates a terminal or point at which the potential of the chassis of the device 2 may be measured. As above explained, the diode 5 causes the potential of the chassis at 15 to be separated from the network ground when a negative AC halfwave arrives. It will be noted that the return conduit of the circuit is held at a fixed chassis potential. The input transistor of the sensor circuit 3 remains, however, locked because it is subjected to a DC current of about 12 volts. If now, by means of touching the touching field 4, the chassis potential is connected to ground, then the transistor switches through and releases a switching function.

A suitable sensor which may be employed for the circuit 3 herein may be a sensor known as the "SAS 560 Tastatur IS," manufactured and sold by Siemens AG.

It is to be understood that the present invention is not limited to the illustrated environment. They can also be used in electronic blocking switch including a Thyristor circuit, which in the same manner separates the electronic device during the blocking phase from the network rectifier. With such Thyristor circuit the drawbacks described in the introductory portion of the specification of known circuit arrangements are also avoided.

Although the invention is illustrated and described with reference to a plurality of preferred embodiments thereof, it is to be expressly understood that it is in no way limited to the disclosure of such a plurality of preferred embodiments, but is capable of numerous modifications within the scope of the appended claims.

(AFC) Automatic frequency control circuit:

An

automatic frequency control (AFC) circuit is disclosed which

comprises an oscillating circuit for generating repetitive pulses, a

generator for generating comparison signals having a slope portion in

response to the repetitive pulses, and a phase comparison circuit which

compares the comparison signals, and synchronous (sync) signals and

based on the comparison supplies control signals to the oscillating

circuit. The AF circuit further comprises a limiting circuit connected

between the comparison signal generator and the phase comparison

circuit which limits the maximum and minimum levels of the comparison

signals to predetermined levels, and thereby predeterminedly limits

the control range of the AFC circuit.

1. An automatic frequency control signal generating circuit, comprising:

an oscillating circuit for generating repetitive pulses;

means for receiving said repetitive pulses and generating comparison

signals having sloped portions and maximum and minimum levels in

response to said repetitive pulses;

a source of reference signals;

phase comparison means having a first input terminal supplied with

said comparison signals, a second input terminal supplied with said

reference signals and an output terminal for supplying automatic

frequency control signals to said oscillating circuit for controlling

its frequency within a control range; and

limiting means connected between said comparison signal generating

means and said phase comparison means for limiting said maximum level

and said minimum level of said comparison signals to first and second

predetermined levels respectively, thereby limiting said control range

of said automatic frequency control signal generating circuit to a

predetermined range.

2. An automatic frequency control signal generating circuit according

to claim 1; wherein said comparison signal generating means comprises

integrating means for generating saw-tooth wave signals as said

comparison signals in response to said repetitive pulses.

3. An automatic frequency control signal

generating circuit according to claim 1; wherein said limiting means

comprises a series circuit including sources of first and second

reference potentials, first and second diodes connected together and

respectively connected to said first reference potential and said

second reference potential, the connecting point of said first and

second diodes being connected to an output terminal of said comparison

signal generating means. 4. An

automatic frequency control signal generating circuit for a television

receiver, comprising;

a source of reference signals;

an oscillator for generating control pulses;

an output circuit for producing repetitive pulses in response to said control pulses;

an integrating circuit for generating saw-tooth wave signals having

maximum and miniumum levels in response to said repetitive pulses from

said output circuit;

a phase comparator for comparing the phase of said saw-tooth waves and

the phase of said reference signals, and supplying output signals to

said oscillator as automatic frequency control signals; and

an amplitude limiting circuit connected between said integrating

circuit and said phase comparator, for limiting said maximum and

minimum levels of said saw-tooth wave signals to first and second

predetermined levels.

1. Field of the Invention

The present invention relates generally to an automatic frequency control (AFC) circuit and more particularly to an AFC circuit, preferably is used in a television receiver, which has a predeterminedly limited control range.

2. Description of the Prior Art

I

n

a prior art horizontal AFC circuit of a television receiver, as shown

in FIG. 1, the output from a horizontal oscillator 1 which can be,

for example, a control pulse is supplied to a horizontal output

circuit 2 and a flyback pulse therefrom is fed to a saw-tooth wave

generator 3. Though not shown, the horizontal output circuit 2

comprises a deflection circuit and a high voltage generating circuit.

The saw-tooth wave signal from saw-tooth wave generator 3 is supplied,

as a comparison signal, to a phase comparator 4 which is also

supplied with a horizontal synchronizing (sync) signal H through a

terminal 5. In phase comparator 4 the saw-tooth wave signal is

compared with the horizontal sync signal H to detect the phase

difference between the saw-tooth wave signal and the horizontal sync

signal. The detected phase difference is applied to horizontal

oscillator 1 as an AFC voltage e c . As shown in FIG. 2, when the horizontal sync signal H is coincident with the center φ 0

of the downward sloping portions of the comparison signal, that is,

when the phase difference between the comparison and sync signals is 0

(zero), the synchronization is maintained for phase differences of

which corresponds to the ends of the downward sloping portion of the

comparison signal. For phase differences of ±φ cm , the AFC output voltage e c has a maximum value of ±e cm .

n

a prior art horizontal AFC circuit of a television receiver, as shown

in FIG. 1, the output from a horizontal oscillator 1 which can be,

for example, a control pulse is supplied to a horizontal output

circuit 2 and a flyback pulse therefrom is fed to a saw-tooth wave

generator 3. Though not shown, the horizontal output circuit 2

comprises a deflection circuit and a high voltage generating circuit.

The saw-tooth wave signal from saw-tooth wave generator 3 is supplied,

as a comparison signal, to a phase comparator 4 which is also

supplied with a horizontal synchronizing (sync) signal H through a

terminal 5. In phase comparator 4 the saw-tooth wave signal is

compared with the horizontal sync signal H to detect the phase

difference between the saw-tooth wave signal and the horizontal sync

signal. The detected phase difference is applied to horizontal

oscillator 1 as an AFC voltage e c . As shown in FIG. 2, when the horizontal sync signal H is coincident with the center φ 0

of the downward sloping portions of the comparison signal, that is,

when the phase difference between the comparison and sync signals is 0

(zero), the synchronization is maintained for phase differences of

which corresponds to the ends of the downward sloping portion of the

comparison signal. For phase differences of ±φ cm , the AFC output voltage e c has a maximum value of ±e cm . If the AFC control sensitivity is taken as β, the maximum frequency range within which the f cm oscillating frequencies are controlled, hereinafter referred to as the control range, is: f cm =±2πβe cm

When the value of e cm in the above formula is need constant, regardless of frequency variation, then the value of f cm is constant.

Generally, the comparison signal, which is supplied by saw-tooth wave generator 3, is provided by integrating the flyback pulse. Both the width of the flyback pulse, which is determined by an LC resonance of horizontal output circuit, and the inclination of the rising portion of the comparison signal, which is determined by an RC time constant of the sawtooth generator, are constant. Therefore, the value of e cm varies with the frequency resulting in a variable value of f cm .

For example, as shown throughout FIGS. 3A, 3B, and 3C, both the width of the downward sloping portion and the inclination of the rising portion of the comparison signals are constant. As a result, when the frequency becomes high (FIG. 3A) as compared with its reference state (FIG. 3B), the value of e cm becomes small as represented by e' cm and when the frequency becomes low (FIG. 3C) as compared with the reference state (FIG. 3B), the value of e cm becomes large as represented by e" cm .

Therefore, when the frequency of the horizontal output signal is high, the differences between the minimum and maximum control signal amplitudes, hereinafter referred to as the amplitude range become smaller resulting in a reduced control range f cm . In contrast thereto, when the frequency of the horizontal oscillator signal is low, the amplitude range becomes larger resulting in an increase of control range f cm .

Typically for a variable control range as described heretofore, the AFC circuit is designed with the smaller control range, corresponding to high oscillating frequencies, as a reference. Such a reference, however, results in the control range at lower oscillating frequencies becoming either too large or at least larger than necessary.

When the control range at the lower oscillating frequencies is too large, the amplitudes of the control signals, that is, the values of ±e cm , are too high or low to be applied to horizontal oscillator 1 and thereby results in an unacceptable frequency correction. Such unacceptably high or low values of e cm can occur, for example, when the sync signal disappears during switching of television channels resulting in the oscillating frequency becoming too low and thereby creating a voltage in the horizontal output circuit that is abnormally high. Therefore, it is necessary that the control range of the AFC circuit be made as small as possible for lower frequencies.

Further, if the control range is too large, the AFC circuitry may unnecessarily adjust the oscillating frequency when noise is present on a weakly received signal.

Accordingly, an AFC circuit should necessarily have as small a control range as possible. Such a small control range is possible by providing maximum and minimum values of e cm irrespective of frequency variation.

OBJECTS AND SUMMARY OF THE INVENTION

Accordingly, it is an object of the present invention to provide an AFC circuit which avoids the drawbacks of the prior art.

More specifically, it is an object of the present invention to provide a new and improved AFC circuit whose control range is constant.

It is another object of the present invention to provide a new and improved AFC circuit which limits the maximum and minimum values of the amplitude range.

According to an aspect of the present invention, an AFC circuit comprises:

an oscillating circuit for generating repetitive pulses;

means for receiving said repetitive pulses and generating comparison signals having a slope portion and maximum and minimum levels in response to said repetitive pulses, said generating means having an output terminal;

a source of reference signals;

phase comparison means having a first input terminal supplied with said comparison signals, a second input terminal supplied with said reference signals and an output terminal for supplying said automatic frequency control signal to said oscillating circuit for controlling its frequency within a control range; and

limiting means connected between said comparison signal generating means and said phase comparison means for limiting said maximum level and said minimum level of said comparison signals to first and second predetermined levels respectively, thereby limiting said control range of said automatic frequency control signal generating circuit to a predetermined range.

The above, and other objects, features and advantages of the present invention will become apparent from the following description which is to be read in conjunction with the accompanying drawings, in which like reference numerals designate like elements and parts.

BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 is a block diagram showing a prior art AFC circuit;

FIG. 2 and FIGS. 3A to 3C are waveform diagrams used to explain the operation of the prior art circuit shown in FIG. 1;

FIG. 4 is an embodiment of saw-tooth wave generating and limiter circuitry in accordance with the present invention;

FIGS. 5A, 5B, and 5C illustrate respectively input and output waveforms of the saw-tooth wave generator and the output waveform of the limiter shown in FIG. 4;

FIG. 6 is an alternative embodiment of circuitry which replaces the circuitry of FIG. 4 and produces a comparison signal in accordance with the present invention; and

FIGS. 7A and 7B illustrate respectively an input waveform supplied to and an output waveform produced by the circuitry shown in FIG. 6.

DESCRIPTION OF THE PREFERRED EMBODIMENTS

The present invention will be hereinafter described with reference to the attached drawings.

FIG. 4 includes an in

put

terminal 11 connected to horizontal output circuit 2 (not shown) and

an input capacitor 12. Input capacitor 12 is connected to resistors 13

and 14. Capacitor 12 and resistors 13 and 14 form a bias circuit

which biases a base of an NPN-type transistor 15. Transistor 15 has a

grounded emitter and a collector connected through a resistor 16 to a

power supply terminal 17 which is at a voltage V cc and

through a series connection of a resistor 18 and a capacitor 19 to

ground. The connection point between resistor 18 and capacitor 19 is

connected to power supply terminal 17 through a series connection of a

capacitor 20 and a resistor 21. The connection point of capacitor 20

and resistor 21 is connected to power supply terminal 17 through a

resistor 22 and a diode 23 wherein the cathode and anode of diode 23

are respectively connected to terminal 17 and resistor 22. The

connection point of capacitor 20 and resistor 21 is also connected to

ground through resistor 22 and a series connection of a diode 24 and a

capacitor 25 which is grounded wherein the cathode and anode of diode

24 are respectively connected to the connection point of resistor 22

and diode 23 and to capacitor 25. The connection point of diode 24 and

capacitor 25 is connected to the connection point of voltage dividing

resistors 26 and 27. Resistors 26 and 27 are connected between

terminal 17 and ground. The connection point between diodes 23 and 24

is connected to a base of an NPN-type transistor 28 whose collector is

connected to power supply terminal 17 and whose emitter is grounded

through a resistor 29 and connected to an output terminal 30. Output

terminal 30 is connected to an input terminal of phase comparator 4 (not

shown).

put

terminal 11 connected to horizontal output circuit 2 (not shown) and

an input capacitor 12. Input capacitor 12 is connected to resistors 13

and 14. Capacitor 12 and resistors 13 and 14 form a bias circuit

which biases a base of an NPN-type transistor 15. Transistor 15 has a

grounded emitter and a collector connected through a resistor 16 to a

power supply terminal 17 which is at a voltage V cc and

through a series connection of a resistor 18 and a capacitor 19 to

ground. The connection point between resistor 18 and capacitor 19 is

connected to power supply terminal 17 through a series connection of a

capacitor 20 and a resistor 21. The connection point of capacitor 20

and resistor 21 is connected to power supply terminal 17 through a

resistor 22 and a diode 23 wherein the cathode and anode of diode 23

are respectively connected to terminal 17 and resistor 22. The

connection point of capacitor 20 and resistor 21 is also connected to

ground through resistor 22 and a series connection of a diode 24 and a

capacitor 25 which is grounded wherein the cathode and anode of diode

24 are respectively connected to the connection point of resistor 22

and diode 23 and to capacitor 25. The connection point of diode 24 and

capacitor 25 is connected to the connection point of voltage dividing

resistors 26 and 27. Resistors 26 and 27 are connected between

terminal 17 and ground. The connection point between diodes 23 and 24

is connected to a base of an NPN-type transistor 28 whose collector is

connected to power supply terminal 17 and whose emitter is grounded

through a resistor 29 and connected to an output terminal 30. Output

terminal 30 is connected to an input terminal of phase comparator 4 (not

shown). Diodes 23 and 24 form a limiter circuit and capacitor 25 and resistors 26 and 27 form a direct current (d.c.) voltage source having a voltage level of E.

When a repetitive pulse, such

as

a flyback pulse, as shown in FIG. 5A, is applied to input terminal

11, a saw-tooth wave (FIG. 5B) is generated at the connection point of

capacitor 20 and resistor 22 which in turn is fed to the limiter

circuit which produces a waveform as shown in FIG. 5C. That is, the

value e cm is limited to an upper level V cc +V D and a lower level E-V D (where V D is the forward voltage drop of diodes 23 and 24).

as

a flyback pulse, as shown in FIG. 5A, is applied to input terminal

11, a saw-tooth wave (FIG. 5B) is generated at the connection point of

capacitor 20 and resistor 22 which in turn is fed to the limiter

circuit which produces a waveform as shown in FIG. 5C. That is, the

value e cm is limited to an upper level V cc +V D and a lower level E-V D (where V D is the forward voltage drop of diodes 23 and 24). Since the value e cm is within a fixed range, the control range is constant resulting in a desired control range which is fixed regardless of frequency. That is, the present invention provides a control range which is constant irrespective of the frequency and thereby avoids the possibility of an unnecessary expansion of the control range at low frequencies and the resulting erroneous operation caused by the expanded control range.

An alternative embodiment of the present invention is shown in FIG. 6 which includes input terminal 11 connected through capacitor 12 to the base of a PNP-type transistor 31, which is biased by the resistors 13 and 14. Transistor 31 has an emitter connected to power supply terminal 17 and collector grounded through a parallel circuit of a resistor 32 and a capacitor 33. The collector of transistor 31 is also connected through a series connection of a capacitor 34 and a resistor 35 to an emitter of an NPN-type transistor 36. A base of transistor 36 is connected to a voltage dividing point of resistors 37 and 38 and a collector thereof is connected to power supply terminal 17 through a resistor 39. An emitter of transistor 36 is grounded through a resistor 40. Output terminal 30 is connected to the collector of transistor 36.

A

repetitive pulse, such as a flyback pulse as shown in FIG. 7A, is

supplied from the horizontal output circuit 2 and is applied to the

input terminal 11. During those periods of each cycle when there is no

flyback pulse, transistor 31 turns ON which charges capacitor 33

resulting in voltage at the emitter of transistor 36 rising and thereby

causing transistor 36 to turn OFF. During periods when transistor 36

is turned off, output terminal 30 is at a voltage level of V cc

as shown in FIG. 7B. During that portion of each cycle when a flyback

pulse occurs, transistor 31 turns OFF, allowing capacitor 33 to

discharge through resistor 32. As a result, the potential at the emitter

of transistor 36 gradually lowers and transistor 36 turns ON

resulting in the output voltage at output terminal 30 gradually

lowering to ground potential. When the period of the flyback pulse

terminates, once again transistors 31 turns ON, charging capacitor 33

immediately, turning transistor 36 OFF and charging the voltage at

output terminal 30 to V cc . That is, a signal is produced having a magnitude of V cc when the flyback pulse is absent and gradually lowering to ground potential during the flyback pulse period.

A

repetitive pulse, such as a flyback pulse as shown in FIG. 7A, is

supplied from the horizontal output circuit 2 and is applied to the

input terminal 11. During those periods of each cycle when there is no

flyback pulse, transistor 31 turns ON which charges capacitor 33

resulting in voltage at the emitter of transistor 36 rising and thereby

causing transistor 36 to turn OFF. During periods when transistor 36

is turned off, output terminal 30 is at a voltage level of V cc

as shown in FIG. 7B. During that portion of each cycle when a flyback

pulse occurs, transistor 31 turns OFF, allowing capacitor 33 to

discharge through resistor 32. As a result, the potential at the emitter

of transistor 36 gradually lowers and transistor 36 turns ON

resulting in the output voltage at output terminal 30 gradually

lowering to ground potential. When the period of the flyback pulse

terminates, once again transistors 31 turns ON, charging capacitor 33

immediately, turning transistor 36 OFF and charging the voltage at

output terminal 30 to V cc . That is, a signal is produced having a magnitude of V cc when the flyback pulse is absent and gradually lowering to ground potential during the flyback pulse period. Thus the comparison signal, e cm , magnitude is restricted to a range between V cc and ground potential and thereby provides a desired control range regardless of the frequency. More particularly, in either embodiment the present invention provides a predetermined control range.

The present invention, as described heretofore has used the downward sloping portion of the comparison signal during phase comparison with a reference signal. However, the present invention can be applied as well to circuitry which provides a comparison signal having a rising slope portion during flyback pulse periods wherein control signal e cm is selected from the rising slope portion.

Although illustrative embodiments of this invention have been described in detail herein with reference to the accompanying drawings, it is to be understood that the invention is not limited to those precise embodiments, and that various changes and modifications may be effected therein by one skilled in the art without departing from the spirit and scope of the invention, as defined in the appended claims.

A coil bobbin for a fly-back transformer or the like having a bobbin proper. A plurality of partition members or flanges are formed on the bobbin proper with a slot between adjacent ones. At least first and second coil units are formed in the bobbin proper, each having several slots, formed between the flanges, and first and second high voltage coils are wound on the first and second coil units in opposite directions, respectively. A rectifying means is connected in series to the first and second coil units, and a cut-off portion or recess is provided on each of the partition members. In this case, a wire lead of the coil units passes from one slot to an adjacent slot through the cut-off portion which is formed as a delta groove, and one side of the delta groove is corresponded to the tangent direction to the winding direction.

1. A fly-back transformer comprising a coil bobbin comprising a plurality of parallel spaced discs with a first adjacent plurality of said disc formed with delta shaped slots having first edges which extend tangentially to a first winding direction and a first winding wound on said first adjacent plurality of said discs in said first winding direction, a second adjacent plurality of said discs formed with delta shaped slots having first edges which extend tangentially to a second winding direction opposite said first winding direction and a second winding wound on said second adjacent plurality of said discs in said second winding direction, a third adjacent plurality of said discs formed with delta shaped slots having first edges which extend tangentially to said first winding direction and a third winding wound on said third adjacent plurality of said discs in said first winding direction and said second plurality of adjacent discs mounted between said first and third plurality of adjacent discs. 2. A fly-back transformer according to claim 1 wherein adjacent ones of said first adjacent plurality of discs are mounted such that their delta shaped slots are orientated 180 degrees relative to each other. 3. A fly-back transformer according to claim 2 including a first winding tur

ning

partition mounted between said first and second adjacent plurality of

discs and formed with grooves and notches for changing winding

direction between said first and second windings and a second winding

turning partition mounted between said second and third adjacent

plurality of discs and formed with grooves and notches for changing the

winding direction between said second and third windings.

4. A fly-back transformer according to

claim 3 wherein said first and second winding turning partitions are

formed with winding guiding slots for guiding the winding between the

first, second and third adjacent plurality of discs.

5. A fly-back transformer according to claim 2

including a first rectifying means connected between one end of said

first winding and one end of said second winding, and a second

rectifying means connected between the second end of said second

winding and one end of said third winding.

6. A fly-back transformer according to claim 5 wherein the

second end of said first winding is grounded and a third rectifying

means connected between the second end of said third winding and an

output terminal.

ning

partition mounted between said first and second adjacent plurality of

discs and formed with grooves and notches for changing winding

direction between said first and second windings and a second winding

turning partition mounted between said second and third adjacent

plurality of discs and formed with grooves and notches for changing the

winding direction between said second and third windings.

4. A fly-back transformer according to

claim 3 wherein said first and second winding turning partitions are

formed with winding guiding slots for guiding the winding between the

first, second and third adjacent plurality of discs.

5. A fly-back transformer according to claim 2

including a first rectifying means connected between one end of said

first winding and one end of said second winding, and a second

rectifying means connected between the second end of said second

winding and one end of said third winding.

6. A fly-back transformer according to claim 5 wherein the

second end of said first winding is grounded and a third rectifying

means connected between the second end of said third winding and an

output terminal.

1. Field of the Invention

The present invention relates generally to a bobbin structure for high voltage transformers, and is directed more particularly to a bobbin structure for high voltage transformer suitable for automatically winding coils thereon.

2. Description of the Prior Art

In the art, when a wire lead is reversely wound on a bobbin separately at every winding block, a boss is provided at every winding block and the wire lead is wound on one block, then one end of the wire lead is tied to the boss where it will be cut off. The end of the wire lead is tied to another boss, and then the wire lead is wound in the opposite direction. Therefore, the prior art winding method requires complicated procedures and the winding of the wire lead cannot be rapidly done and also the winding can not be performed automatically. Further, the goods made by the prior art method are rather unsatisfactory and have a low yield.

OBJECTS AND SUMMARY OF THE INVENTION

Accordingly an object of the invention is to provide a coil bobbin for a fly-back transformer or the like by which a wire lead can be automatically wound on winding blocks of the coil bobbin even though the winding direction is different among the different winding blocks.

Another object of the invention is to provide a coil bobbin for a fly-back transformer or the like in which a bridge member and an inverse engaging device for transferring a wire lead from one wiring block to an adjacent wiring block of the coil bobbin and wiring the wire lead in opposite wiring directions between adjacent wiring blocks, and a guide member for positively guiding the wire lead are provided.

According to an aspect of the present invention, a coil bobbin for a fly-back transformer or the like is provided which comprises a plurality of partition members forming a plurality of slots, a first coil unit having several slots on which a first high voltage coil is wound in one winding direction, a second coil unit having several slots on which a second high voltage coil is wound in the other direction, a rectifying means connected in series to the first and second coil units, and a cut-off portion provided on each of the partition members, a wire lead passing from one slot to an adjacent slot through the cut-off portions, each of the cut-off portions being formed as a delta groove, and one side of the delta groove corresponding to a tangent to the winding direction.

The other objects, features and advantages of the present invention will become apparent from the following description taken in conjunction with the accompanying drawings through which the like reference numerals and letters designate the same elements and parts, respectively.

BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 is a schematic diagram showing the construction of a fly-back transformer;

FIG. 2 is a connection diagram showing an example of the electrical connection of the fly-back transformer shown in FIG. 1;

FIG. 3 is a schematic diagram showing an example of a device for automatically winding a wire lead of the fly-back transformer on its bobbin;

FIG. 4 is a perspective view showing an example of the coil bobbin according to the present invention;

FIG. 5 is a plan view of FIG. 4;

FIGS. 6 and 7 are views used for explaining recesses or cut-off portions shown in FIGS. 4 and 5; and FIGS. 8A and 8B cross-sectional views showing an example of the inverse engaging means according to the present invention.

DESCRIPTION OF THE PREFERRED EMBODIMENT

When the high voltage winding of a fly-back transformer used in a high voltage generating circuit of a television receiver is divided into plural ones and then wound on a bobbin, the divided windings (divided coils) are connected in serie

s through a plurality of rectifying diodes.

s through a plurality of rectifying diodes. When the winding is divided into, for example, three portions, such as divided coils La, Lb and Lc, they are wound on a bobbin proper 1 from, for example, left to right sequentially in this order as shown in FIG. 1. In this case, if the divided coils La and Lc are selected to have the same sense of turn and the middle coil Lb is selected to have the opposite sense of turn from the coils La and Lc, the distance between the terminal end of coil La and the start of coil Lb and the distance between the terminal end of coil Lb and the start of coil Lc can be got relatively long. Therefore, diodes Da and Db can be mounted by utilizing the space above the block on which the middle coil Lb is wound as shown in FIG. 1, so that it becomes useless to provide spaces for diodes between the divided coils La and Lb and between the divided coils Lb and Lc and hence the bobbin proper 1 can be made compact.

FIG. 2 is a connection diagram showing the connection of the above fly-back transformer. In FIG. 2, reference numeral 2 designates a primary winding (Primary coil) of the fly-back transformer, reference letter L designates its high voltage winding (secondary coil), including divided coils La, Lb and Lc, 3 an output terminal, and 4 a lead wire connected to the anode terminal of a cathode ray tube (not shown), respectively.

An example of the bobbin structure according to the invention, which is suitable to automatically wind coils, which are different in sense of turn in each winding block as shown in FIG. 1, on the bobbin, will be hereinafter described with reference to the drawings.

FIG. 3 is a diagram showing an automatic winding apparatus of a wire lead on a coil bobbin. If it is assumed that the wire lead is wound in the order of w

inding

blocks A, B and C in FIG. 1 and the wire lead is wound on the block A

with the bobbin proper 1 being rotated in the counter-clockwise

direction as shown in FIG. 3, the relation between the bobbin proper 1

and the wire lead becomes as shown in FIG. 3. In this figure, reference

numeral 6 designates a bobbin for feeding the wire lead.

inding

blocks A, B and C in FIG. 1 and the wire lead is wound on the block A

with the bobbin proper 1 being rotated in the counter-clockwise

direction as shown in FIG. 3, the relation between the bobbin proper 1

and the wire lead becomes as shown in FIG. 3. In this figure, reference

numeral 6 designates a bobbin for feeding the wire lead. Turning to FIG. 4, an example 10 of the bobbin structure or coil bobbin according to the present invention will be described now. In this example, the winding blocks A, B and C for the divided coils La, Lb and Lc are respectively divided into plural slots or sections by plural partition members or flanges 11, and a cut-off portion or recess 12 is formed on each of the flanges 11 through which the wire lead in one section is transferred to the following winding section.

As shown in FIG. 6, each recess 12 is so formed that its one side extends in the direction substantially coincident with the tangent to the circle of the bobbin proper 1 and its direction is selected in response to the sense of turn of the winding or wire lead. In this case, the direction of recess 12 means the direction of the opening of recess 12, and the direction of recess 12 is selected opposite to the sense of turn of the wi

nding in the present invention.

nding in the present invention. Now, recesses 12A, which are formed in the winding block A, will be now described by way of example. The positions of recesses 12A formed on an even flange 11Ae and an odd flange 11A 0 are different, for example, about 180° as shown in FIGS. 6A and 6B. Since the bobbin proper 1 is rotated in the counter-clockwise direction in the winding block A and hence the sense of turn of the wire lead is in the clockwise direction, the recess 12A is formed on the even flange 11Ae at the position shown in FIG. 6A. That is, the direction of recess 12A is inclined with respect to the rotating direction of bobbin proper 1 as shown in FIG. 6A. In this case, one side 13a of recess 12A is coincident with the tangent to the circle of bobbin proper 1, while the other side 13b of recess 12A is selected to have an oblique angle with respect to the side 13a so that the recess 12A has a predetermined opening angle.

The opening angle of recess 12A is important but the angle between the side 13a of recess 12A and the tangent to the circle of bobbin proper 1 is also important in the invention. When the wire lead is bridged or transferred from one section to the following section through the recess 12A, the wire lead in one section advances to the following section in contact with the side 13a of recess 12A since the bobbin proper 1 is rotated. In the invention, if the side 13a of recess 12A is selected to be extended in the direction coincident with the tangent to the circle of bobbin proper 1, the wire lead can smoothly advance from one section to the next section without being bent.

In the invention, since the middle divided coil Lb is wound opposite to the divided coil La, a recess 12B provided on each of flanges 11B of the winding block B is formed to have an opening opposite to that of recess 12A formed in the winding block A as shown in FIGS. 6C and 6D.

As shown in FIG. 5, terminal attaching recesses 14 are provided between the winding blocks A and B to which diodes are attached respectively. In the illustrate

d example of FIG. 5, a flange 15AB is formed between the flanges 11A 0 and 11B 0 of winding blocks A and B, and the recesses 14 are formed between the flanges 11A 0 and 15AB and between 15AB and 11B 0

at predetermined positions. Then, terminal plates 16, shown in FIG.

4, are inserted into the recesses 14 and then fixed there to,

respectively. The terminal plates 16 are not shown in FIG. 5. Between

the winding blocks B and C and between the blocks A and B, similar

terminal attaching recesses 14 are formed, and terminal plates 16 are

also inserted thereinto and then fixed thereto.

d example of FIG. 5, a flange 15AB is formed between the flanges 11A 0 and 11B 0 of winding blocks A and B, and the recesses 14 are formed between the flanges 11A 0 and 15AB and between 15AB and 11B 0

at predetermined positions. Then, terminal plates 16, shown in FIG.

4, are inserted into the recesses 14 and then fixed there to,

respectively. The terminal plates 16 are not shown in FIG. 5. Between

the winding blocks B and C and between the blocks A and B, similar

terminal attaching recesses 14 are formed, and terminal plates 16 are

also inserted thereinto and then fixed thereto. As described above, since the divided coil Lb is wound opposite to the divided coils La and Lc, it is necessary that the winding direction of the wire lead be changed when the wire lead goes from the block A to block B and also from the block B to block C, respectively.

Turning to FIG. 7, an example of the winding or wire lead guide means according to the present invention will be now described. In FIG. 7, there are mainly shown a bridge member for the wire lead and an inve

rse

member or means for the wire lead which are provided between the

winding blocks A and B. At first, a bridge means 20 and its guide means

21, which form the bridge member, will be described. The bridge means

20 is provided by forming a cut-out portion or recess in the middle

flange 15AB located between the winding blocks A and B. In close

relation to the bridge means or recess 20, the guide means 21 is

provided on a bridge section X A at the side of block A.

This guide means 21 is formed as a guide piece which connects an edge

portion 20a of recess 20 at the winding direction side to the flange

11A 0 of block A in the oblique direction along the winding direction through the section X A .

rse

member or means for the wire lead which are provided between the

winding blocks A and B. At first, a bridge means 20 and its guide means

21, which form the bridge member, will be described. The bridge means

20 is provided by forming a cut-out portion or recess in the middle

flange 15AB located between the winding blocks A and B. In close

relation to the bridge means or recess 20, the guide means 21 is

provided on a bridge section X A at the side of block A.

This guide means 21 is formed as a guide piece which connects an edge

portion 20a of recess 20 at the winding direction side to the flange

11A 0 of block A in the oblique direction along the winding direction through the section X A . Next, an inverse engaging means 22 will be now described with reference to FIGS. 7 and 8. If the flange 11B 0 of FIG. 7 is viewed from the right side, the inverse engaging means 22 can be shown in FIG. 8A. In this case, the tip end of one side 13a of recess 12B 1 is formed as a projection which is extended outwards somewhat beyond the outer diameter of flange 11B 0 . The inverse engaging means 22 may take any configuration but it is necessary that when the rotating direction of the bobbin proper 1 is changed to the clockwise direction, the wire lead can be engaged with the recess 12B 1 or projection of one side 13a and then suitably transferred to the next station.

Another guide means 23 is provided on a bridge section X B at the side of winding block B in close relation to the inverse engaging means 22. The guide means 23 is formed as a guide surface which is a projected surface from the bottom surface of section X B and extended obliquely in the winding direction. This guide means or guide surface 23 is inclinded low into the means 22 and has an edge 23a which is continuously formed between the middle flange 15AB and the flange 11B 0 .

In this case, it is possible that the guide means 21 and guide surface 23 are formed to be the same in construction. That is, both the guide means 21 and 23 can be made of either the guide piece, which crosses the winding section or guide surface projected upwards from the bottom surface of the winding section. It is sufficient if the guide means 21 and 23 are formed to smoothly transfer the wire lead from one section to the next section under the bobbin proper 1 being rotated.

Although not shown, in connection with the middle flange 15BC between the winding blocks B and C, there are provided similar bridge means 20, guide means 21, inverse engaging means 22 and another guide means 23, respectively. In this case, since the winding direction of the wire lead is reversed, the forming directions of the means are reverse but their construction is substantially the same as that of the former means. Therefore, their detailed description will be omitted.

According to the bobbin structure of the invention with the construction set forth above, the wire lead, which is transferred from the block A to the section X A by the rotation of bobbin proper 1, is wound on the section X B from the section X A after being guided by the guide piece 21 to the recess 20 provided on the middle flange 15AB, and then transferred to the recess 22 provided on the flange 11B 0 guide surface 23, bridged once to the first section of winding block B through the recess 22 (refer to dotted lines b in FIG. 7). Then, if the rotating direction of the bobbin proper 1 is reversed, the wire lead is engaged with the bottom of recess 22 (refer to solid lines b in FIG. 7). Thus, if the above reverse rotation of bobbin proper 1 is maintained, the wire lead is wound on the block B in the direction reverse to that of block

A. When the wire lead is transferred from the block B to block C, the

same effect as that above is achieved. Therefore, according to the

present invention, the wire lead can be automatically and continuously

wound on the bobbin proper 1.

A. When the wire lead is transferred from the block B to block C, the

same effect as that above is achieved. Therefore, according to the

present invention, the wire lead can be automatically and continuously

wound on the bobbin proper 1. After the single wire lead is continuously wound on blocks A, B and C of bobbin proper 1 as set forth above, the wire lead is cut at the substantially center of each of its bridging portions. Then, the cut ends of the wire lead are connected through diodes Da, Db and Dc at the terminal plates 16, respectively by solder.

In the present invention, the projection piece, which has the diameter greater than that of the flange 11B, is provided in the bridge recess 12 to form the inverse engaging means 22 as described above, so that when the winding direction is changed, the wire lead engages with the inverse engaging means 22 without errors when reversing the winding direction of the wire lead.

If the diameter of the projection piece of means 22 is selected, for example, to be the same as that of the flange 11B, it will not be certain that the wire lead engages with the means 22 because it depends upon the extra length of the wire lead and hence errors in winding cannot be positively avoided.

Further, in this invention, the bridge means is provided on the flange positioned at the bridging portion of the bobbin which has a number of dividing blocks separated by flanges, and the inverse engaging means is provided and also the guide means is provided at the former winding section to cooperate with the inverse engaging means. Therefore, the wire lead can be positively fed to the bridge means, and the transfer of the wire lead to the following winding section can be carried out smoothly.

Further, in this invention since one side of the recess 12 is selected coincident with the tangent of the outer circle of the bobbin proper 1 and also with the winding direction, the wire lead can be smoothly bridged to the following section. Due to the fact that the direction of recess 12 is changed in response to the winding direction, even if there is a block on which the wire lead is wound in the opposite direction to that of the other block, the wire lead can be continuously and automatically wound through the respective blocks.

The above description is given for the case where the present invention is applied to the coil bobbin for the high voltage winding of a fly-back transformer, but it will be clear that the present invention can be applied to other coil bobbins which require divided windings thereon with the same effects.

It will be apparent that many modifications and variations could be effected by one skilled in the art without departing from the spirits or scope of the novel concepts of the present invention, so that the spirits or scope of the invention should be determined by the appended claims only.

Side, or left and right pin-cushion distortions in the raster of a cathode ray tube, for example, of a color television receiver having an in-line arrangement of its electron beams, are corrected by connecting the horizontal deflection winding of t

he

cathode ray tube, the collector-emitter path of a transistor and the

output winding of a saturable reactor, in series, to a power supply

source, and by applying to the base or control electrode of the

transistor and to the input winding of the saturable reactor a

correction signal having a parabolic waveform of the vertical scanning

rate or frequency so that correction of the side pin-cushion

distortions is effected satisfactorily at all portions of the raster.

he

cathode ray tube, the collector-emitter path of a transistor and the

output winding of a saturable reactor, in series, to a power supply

source, and by applying to the base or control electrode of the

transistor and to the input winding of the saturable reactor a

correction signal having a parabolic waveform of the vertical scanning

rate or frequency so that correction of the side pin-cushion

distortions is effected satisfactorily at all portions of the raster. 1.

A raster distortion correcting circuit for a television receiver

including a cathode ray tube in which at least one electron beam is

directed against a screen, a deflection yoke associated with said tube

and having horizontal and vertical deflection windings, and horizontal

and vertical deflection circuits for supplying horizontal and

vertical deflection currents to said horizontal and vertical

deflection windings, respectively, so that the resulting magnetic

fields cause each said beam to scan horizontally and vertically for

forming a raster on the screen: said raster distortion correcting

circuit comprising a power supply source for supplying a power supply

voltage to said horizontal deflection circuit; an active element

having first and second electrodes and a control electrode for varying

the effective resistance between said first and second electrodes in

dependence on a control signal applied to said control electrode; a

saturable reactor having input and output windings, means for

generating a correction signal at the vertical scanning rate of said

vertical deflection current; circuit means for connecting said first

and second electrodes of the active element between said power supply

source and said horizontal deflection circuit to connect said active

element, said horizontal deflection winding of the yoke and said

output winding of the saturable reactor in a series circuit connected

to said power supply source; and circuit means for applying said

correction signal to said control electrode of the active element as

the control signal for the latter and to said input winding of said

saturable reactor so that said active element and saturable reactor

combine to correct a distortion of said raster over all portions of the

latter. 2. A raster distortion

correcting circuit according to claim 1; in which said correction

signal is generated with a parabolic waveform at said vertical

scanning rate for correcting side pin cushion distortions of said

raster. 3. A raster distortion

correcting circuit according to claim 1; in which said means for

generating the correction signal includes a capacitor connected in

series with said vertical deflection winding of the yoke, and said

circuit means for applying said correction signal extends from between

said vertical deflection winding and said capacitor.

4. A raster distortion correcting circuit

according to claim 1; in which said active element is a transistor

having collector, emitter and base electrodes which constitute said

first, second and control electrodes, respectively.

5. A raster distortion correcting circuit according

to claim 1; in which said horizontal deflection current is supplied

from said horizontal deflection circuit to said series circuit at a

location in the latter between said first and second electrodes of

said active element and said horizontal deflection winding of the

yoke. 6. In a horizontal

deflection circuit for a cathode ray tube, including a horizontal

deflection current output circuit for supplying horizontal deflection

current to a horizontal deflection winding and a source of operating

voltage adapted to be supplied to said output circuit, a raster

distortion correcting circuit comprising a saturable reactor having an

input winding to receive a correction signal whose frequency is equal

to the vertical deflection frequency of said cathode ray tube, and an

output winding connected in series with said horizontal deflection

winding; an active element for supplying said operating voltage to

said output circuit; and means for supplying said correction signal to

said active element to thereby vary said operating voltage supplied

to said output circuit as a function of said correction signal.

7. A raster distortion correcting

circuit in accordance with claim 6 wherein said correction signal is

generated with a parabolic waveform.

1.

A raster distortion correcting circuit for a television receiver

including a cathode ray tube in which at least one electron beam is

directed against a screen, a deflection yoke associated with said tube

and having horizontal and vertical deflection windings, and horizontal

and vertical deflection circuits for supplying horizontal and

vertical deflection currents to said horizontal and vertical

deflection windings, respectively, so that the resulting magnetic

fields cause each said beam to scan horizontally and vertically for

forming a raster on the screen: said raster distortion correcting

circuit comprising a power supply source for supplying a power supply

voltage to said horizontal deflection circuit; an active element

having first and second electrodes and a control electrode for varying

the effective resistance between said first and second electrodes in

dependence on a control signal applied to said control electrode; a

saturable reactor having input and output windings, means for

generating a correction signal at the vertical scanning rate of said

vertical deflection current; circuit means for connecting said first

and second electrodes of the active element between said power supply

source and said horizontal deflection circuit to connect said active

element, said horizontal deflection winding of the yoke and said

output winding of the saturable reactor in a series circuit connected

to said power supply source; and circuit means for applying said

correction signal to said control electrode of the active element as

the control signal for the latter and to said input winding of said

saturable reactor so that said active element and saturable reactor

combine to correct a distortion of said raster over all portions of the

latter. 2. A raster distortion

correcting circuit according to claim 1; in which said correction

signal is generated with a parabolic waveform at said vertical

scanning rate for correcting side pin cushion distortions of said

raster. 3. A raster distortion

correcting circuit according to claim 1; in which said means for

generating the correction signal includes a capacitor connected in

series with said vertical deflection winding of the yoke, and said

circuit means for applying said correction signal extends from between

said vertical deflection winding and said capacitor.

4. A raster distortion correcting circuit

according to claim 1; in which said active element is a transistor

having collector, emitter and base electrodes which constitute said

first, second and control electrodes, respectively.

5. A raster distortion correcting circuit according

to claim 1; in which said horizontal deflection current is supplied

from said horizontal deflection circuit to said series circuit at a

location in the latter between said first and second electrodes of

said active element and said horizontal deflection winding of the

yoke. 6. In a horizontal

deflection circuit for a cathode ray tube, including a horizontal

deflection current output circuit for supplying horizontal deflection

current to a horizontal deflection winding and a source of operating

voltage adapted to be supplied to said output circuit, a raster

distortion correcting circuit comprising a saturable reactor having an

input winding to receive a correction signal whose frequency is equal

to the vertical deflection frequency of said cathode ray tube, and an

output winding connected in series with said horizontal deflection

winding; an active element for supplying said operating voltage to

said output circuit; and means for supplying said correction signal to

said active element to thereby vary said operating voltage supplied

to said output circuit as a function of said correction signal.

7. A raster distortion correcting

circuit in accordance with claim 6 wherein said correction signal is

generated with a parabolic waveform.

1. Field of the Invention

This invention relates generally to a raster distortion correcting circuit for a cathode ray tube, for example, of a color television receiver.

2. Description of the Prior Art

In a television receiver having a cathode ray tube, a deflection yoke is positioned about the neck of the cathode ray tube, and deflection circuits associated with such deflection yoke cyclically vary currents which are made to flow through windings of the yoke so that the windings generate varying electromagnetic fields by which each electron beam of the cathode ray tube is deflected vertically and horizontally to scan a respective raster on the screen of the cathode ray tube. In general, the raster formed by each electron beam is desired to be substantially rectangular. However, various types of scanning distortions may occur so as to cause the configuration of the generated raster to deviate from the desired rectangular shape. One of the types of raster distortions that may occur is the so-called "pin-cushion" distortion which may appear in respect to the top and bottom or left- and right-hand sides of the raster, and this invention is particularly concerned with providing corrections for the side, or left and right pin-cushion distortions.

Heretofore, such side, or left and right pin-cushion distortions in the raster of a cathode ray tube have been corrected by one or the other of several methods. One of the most frequently employed methods for achieving correction of side pin-cushion raster distortion involves varying or modulating the power supply voltage for the horizontal deflection circuit of the cathode ray tube in accordance with a parabolic wave having the vertical scanning rate or frequency. Another frequently employed method for achieving the foregoing raster correction involves the use of a saturable reactor having an output winding connected in series with the horizontal deflection winding of the yoke and an input winding to which there is applied a correction signal in the form of a parabolic wave having the vertical scanning rate or frequency so that the horizontal deflection current is again varied or modulated by such parabolic wave. Each of the foregoing methods that are frequently employed for correcting side, or left and right pin-cushion distortions in the raster of a cathode ray tube has its inherent advantages and disadvatages, as hereinafter described.

In the case where the power supply voltage for the horizontal deflection circuit is varied or modulated, as aforesaid, the horizontal deflection current I h flowing through the horizontal deflection winding of the yoke is expressed by the following equation: ##EQU1## in which V cc is the power supply voltage, L is the inductance value of the deflection winding, and t is time.

It will be apparent from the above equation that, when the power supply voltage V cc is varied or modulated in accordance with a correction signal having a parabolic waveform at the vertical scanning rate, the amplitude of the horizontal deflection current is varied in accordance with such parabolic waveform so that correction of side pin-cushion distortions in the raster is achieved. Such correction of side pin-cushion distortions in the raster is advantageous in that the circuit required therefor is very simple and inexpensive. However, with this method, the horizontal deflection current is varied only at the vertical scanning rate, and not within each horizontal or line scanning period, so that, if a single horizontal scanning line is considered, the same correction is effected adjacent the center and adjacent the opposite or left- and right-hand sides of the screen. The foregoing characteristic of the described method is disadvantageous, particularly when applied to a color cathode ray tube having a wide deflection angle, and the disadvantage, as hereinafter described, is most serious in the case of a color cathode ray tube having an electron gun structure with a so-called in-line arrangement of the plural electron beams issuing therefrom.

In a color cathode ray tube having an electron gun structure with an in-line arrangement of the plural electron beams issuing therefrom, it is desirable that the

electromagnetic

field for effecting horizontal deflection or scanning of the beams

have a pin-cushion shape and that the electromagnetic field for

effecting vertical deflection or scanning of the beams have a barrel

shape, that is, that the horizontal and vertical deflection fields be

non-uniform, so as to correct or compensate for misconvergence of the

plural electron beams as the latter are deflected horizontally and

vertically from the center of the screen, for example, as disclosed in

U.S. Pat. No. 3,500,114, issued Mar. 10, 1970, and having a common

assignee herewith. When such non-uniform deflection fields are

employed so as to correct or compensate for misconvergence of the

electron beams, it has been determined experimentally that correction

of side pin-cushion distortions of the raster by means of varying the

power supply voltage for the horizontal deflection circuit as

mentioned above, is insufficient, particularly in respect to the

extent of the correction effected at the central portion of each

horizontal scanning line. Therefore, in the case being described, a

side pin-cushion distortion may still remain adjacent the central

portion of the raster.

electromagnetic

field for effecting horizontal deflection or scanning of the beams

have a pin-cushion shape and that the electromagnetic field for

effecting vertical deflection or scanning of the beams have a barrel

shape, that is, that the horizontal and vertical deflection fields be

non-uniform, so as to correct or compensate for misconvergence of the

plural electron beams as the latter are deflected horizontally and

vertically from the center of the screen, for example, as disclosed in

U.S. Pat. No. 3,500,114, issued Mar. 10, 1970, and having a common

assignee herewith. When such non-uniform deflection fields are

employed so as to correct or compensate for misconvergence of the

electron beams, it has been determined experimentally that correction

of side pin-cushion distortions of the raster by means of varying the

power supply voltage for the horizontal deflection circuit as

mentioned above, is insufficient, particularly in respect to the

extent of the correction effected at the central portion of each

horizontal scanning line. Therefore, in the case being described, a

side pin-cushion distortion may still remain adjacent the central

portion of the raster. On the other hand, when a saturable reactor is employed for correcting side pin-cushion distortions, as aforesaid, such distortions are fully eliminated even near the central portion of the raster by reason of the fact that the inductance value of the output winding of the saturable reactor is varied in response to the correction signal applied to the input winding of the reactor and having a parabolic waveform at the vertical scanning rate, and the inductance value of the output winding of the saturable reactor is also varied at the horizontal scanning rate in response to the horizontal deflection current flowing through such output winding. However, when the side pin-cushion distortions are corrected only by means of the described saturable reactor, the apparatus required for correction of side pin-cushion distortions becomes bulky, heavy and expensive, particularly when applied to a color cathode ray tube having a relatively large deflection angle. Further, when side pin-cushion distortions of the raster are corrected only by means of the described saturable reactor in the case of a color cathode ray tube having a relatively wide deflection angle, it has been found that the desired linearity of the horizontal deflection of the beam or beams if seriously deteriorated.

SUMMARY OF THE INVENTION

Accordingly, it is an object of this invention to provide an improved circuit for correcting side pin-cushion raster distortions which avoids the above mentioned disadvantages inherent in the arrangements previously employed for that purpose.

More specifically, it is an object of this invention to provide a side pin-cushion raster distortion correcting circuit which is relatively small in size and weight and also inexpensive, and which is effective to fully eliminate such distortions near the central portion of the raster as well as near the opposite sides thereof.

Another object is to provide an improved side pin-cushion raster distortion correcting circuit, as aforesaid, which is suitable for a color cathode ray tube with a relatively wide deflection angle.

Still another object is to provide an improved side pin-cushion raster distortion correcting circuit which is particularly adapted for use with a color cathode ray tube having an electron gun structure with a so-called in-line arrangement of the plural electron beams emitted thereby.

In accordance with an aspect of this invention, side pin-cushion distortions in the raster of a cathode ray tube are eliminated by varying or modulating the power supply voltage for the horizontal deflection circuit in accordance with a correction signal having a parabolic waveform at the vertical scanning rate, and by simultaneously applying such correction signal to the input winding of a saturable reactor which has its output winding connected in series with the horizontal deflection winding of the cathode ray tube. By reason of the foregoing arrangement, the horizontal deflection current is modulated in accordance with the parabolic waveform at the vertical scanning rate by the combined action of a transistor or other active element employed for varying or modulating the power supply voltage and of the saturable reactor, and the horizontal deflection current is further modulated in response to the flow of such current through the output winding of the saturable reactor which varies its inductance in accordance with the horizontal deflection current flowing therethrough.

The above, and other objects, features and advantages of the invention, will be apparent in the following detailed description of illustrative embodiments which is to be read in connection with the accompanying drawings.

BRIEF DESCRIPTION OF THE DRAWINGS