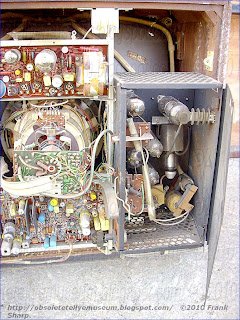

The PHILIPS CHASSIS K8 IS first PHILIPS COLOR CHASSIS developed for a 110° degree CRT Tube such as the A66-140X Delta gun type.

naturally it's tubes based but it has a hybrid technology in luminance chrominance parts and all generally around the chassis.

The Mainly Tubes based parts are power parts exception for power supply sections.

The PHILIPS CHASSIS K8 used in this set has a particular technology in Line deflection and EHT parts using 2 Line flyback transformers in a special circuit arrangement,

PHILIPS CHASSIS K8 TUBES:

- GY501

- PD510

- PL509

- PY500A

- PL509

- PY500A

- PL802

- PCL86

- PCF200

- PCF200

- PCF200

- PCF802

- PCF80

- PL508

The K8 was Philips last hybrid colour chassis. It was the first to sport a 110 degrees delta CRT. More deflection power was needed and convergence circuitry was mostly active using transistors instead of passive as before.

The K8 chassis is a further development of the K7 and K6 chassis. Tuner, IF and chroma circuits are solid state. The colour difference output unit, video output and sound are fitted with valves like in the K7 chassis. The large heat from the valves and the high power resistors burned the board of the chassis in the upper part.

It was made in 3 fundamentally different versions. The basic design was Dutch/Belgian as usual for the K series, and was designated K8, with variations K8B (for Belgian systems, 625 lines only) and K8L (tuner with separate push-buttons and a drawer instead of an integrated push-button/potmeter assembly). The K8L is never mentioned in the Model Number Survey but is marked as such on the schematic diagrams.

The picture tube with 110° deflection is much shorter than a 66 cm. picture tube with 90° deflection. As a result, the whole set has a shorter depth than the 90° colour tv sets before. Deflection circuits and convergence circuits are more complex due to the higher deflection angle.

The convergence board is placed behind a door on the right side of the set (viewed in front of the set). The convergence needs active parts with high-wattage transistors here in comparison to the total passive circuits in 90° colour tv sets to generate enough signal power for the correct geometry.

The German K8D used the same rather complex EHT cage as the K8 but the signal stages and controls were more advanced compared to the K8. It already used an IC in the colour decoder while touch controls and a wired remote were also available as options.

In the K6 and K7 chassis, one line output transformer was used for deflection and EHT. This transformer was driven by a PL 509 and a PL 504. In the K8 chassis, two transformers are used, one for deflection, and another one for EHT. Both transformers are driven by a PL 519 and a PY 500A each. EHT stabilizing is realized with a GY 501 and a PD 510 as a shunt regulator like in the K7 and the K6 chassis.

The A66-140X was the first 110° deflection delta shadow mask colour picture tube. The iron-brass cover for shielding geomagnetic effects is placed now in the inside of the picture tube. Philips used colour difference concept for the colour output units. The PL 802 is for luminance output, three PCF 200 are for colour difference signal output. White balance is realized with three VDRs on the crt board. The white balance use the black level niveau as a reference for white balance control.

A particular circuit arrangement is developed in Line deflection and EHT parts, see below.

PHILIPS X26K171 (PHILIPS K8) CHASSIS K8 CIRCUIT ARRANGEMENT FOR GENERATING A SAWTOOTH CURRENT IN A LINE DEFLECTION COIL FOR A DISPLAY TUBE CONVEYING A BEAM CURRENT AND FOR GENERATING AN EHT:A circuit for generating both line deflection current and final anode voltage that has main and auxiliary generators. The main generator supplies part of the deflection current and the anode voltage, while the auxiliary generator supplies the remaining part of the deflection current. The main generator is stabilized against anode voltage variations as a result of the beam current variations and component ageing, its operating line being located just above or at the limit of saturation. The auxiliary generator is stabilized against supply voltage variations and its stabilizing circuit can also be modulated by a parabola voltage of field frequency in order to correct the East-West pincushion distortion.

1. A circuit arrangement for generating from a power source a sawtooth current in a line deflection coil for a display tube conveying a beam current and for generating high voltage for said display tube, said circuit comprising means for deriving a supply voltage from said source, at least one generator having a control element with a saturation limit and a first stabilizing circuit means for stabilizing said generator against high voltage variations as a result of beam current variations and against variations caused by ageing of components, said control element in the generator being active just above or at the limit of saturation, said generator comprising a main generator means for providing a portion of the sawtooth current to be generated and the high voltage, an auxiliary generator means for providing the remaining portion of the sawtooth current, and a second stabilizing circuit means for stabilizing the auxiliary generator against variations in the supply voltage, said main and auxiliary generators being mutually decoupled, whereby the width of the picture displayed on the screen of the display tube is maintained constant. 2. A circuit arrangement as claimed in claim 1, wherein said auxiliary generator comprises a tube, and the nominal value of said supply voltage is set at a value which allows for a variation in the negative direction up to just above the limit of saturation of the control element in said auxiliary generator. 3. A circuit arrangement as claimed in claim 1 further comprising means for adjusting the ratio of the portions of the sawtooth currents supplied by said main and auxiliary generators, the portion of the sawtooth current supplied by the auxiliary generator being larger than zero and smaller than or equal to the portion of the sawtooth current supplied by the main generator. 4. A circuit arrangement as claimed in claim 3, wherein said main and auxiliary generators are adjusted in such a manner that the portion of the sawtooth current supplied by the main generator is equal to the portion which is supplied by the auxiliary generator. 5. A circuit arrangement as claimed in claim 4, further comprising a voltage source coupled only to the second stabilizing circuit. 6

. A circuit arrangement as claimed in claim 4, wherein the filament currents of the picture display tube and the high voltage are derived from the auxiliary generator. 7. A circuit arrangement as claimed in claim 1 further comprising first and second transformers coupled to said generators respectively, each of said transformers having a tap, an auxiliary coil coupled between said taps, said taps having the same potential when the supply voltage has decreased to its lowest occurring value. 8. A circuit arrangement as claimed in claim 1 further comprising means for applying pulses of line frequency to the second stabilizing circuit which pulses are the sum of pulses which are supplied by a source coupled to one generator and a source coupled to the other generator, the pulses supplied by the source of one generator relative to the pulses supplied by the source of the other generator being in the same ratio as the portions of the sawtooth currents supplied by the two generators. 9. A circuit arrangement as claimed in claim 1 further comprising means for deriving a bias from the supply voltage and for applying it to the second stabilizing circuit, means for deriving a direct voltage from a further source coupled to the main generator, which direct voltage is dependent on the beam current variations, and means for applying said direct voltage to said bias. 10. A circuit arrangement as claimed in claim 1 further comprising a field deflection generator, and means for deriving a parabola voltage from the field generator and for applying it to the second stabilizing circuit in order to modulate the sawtooth current supplied by the auxiliary generator for the purpose of the required East-West pincushion correction, the field generator being fed with a direct voltage which is proportional to the line deflection current. 11. A circuit arrangement as claimed in claim 10 wherein said deriving means comprises an integration network to which a sawtooth voltage originating from the field generator is applied, said integration network comprising an integration capacitor that also rapidly transfers the supply voltage fluctuations to the second stabilizing circuit. 12. A circuit arrangement as claimed in claim 9, wherein the second stabilizing circuit comprises a voltage dependent resistor.

. A circuit arrangement as claimed in claim 4, wherein the filament currents of the picture display tube and the high voltage are derived from the auxiliary generator. 7. A circuit arrangement as claimed in claim 1 further comprising first and second transformers coupled to said generators respectively, each of said transformers having a tap, an auxiliary coil coupled between said taps, said taps having the same potential when the supply voltage has decreased to its lowest occurring value. 8. A circuit arrangement as claimed in claim 1 further comprising means for applying pulses of line frequency to the second stabilizing circuit which pulses are the sum of pulses which are supplied by a source coupled to one generator and a source coupled to the other generator, the pulses supplied by the source of one generator relative to the pulses supplied by the source of the other generator being in the same ratio as the portions of the sawtooth currents supplied by the two generators. 9. A circuit arrangement as claimed in claim 1 further comprising means for deriving a bias from the supply voltage and for applying it to the second stabilizing circuit, means for deriving a direct voltage from a further source coupled to the main generator, which direct voltage is dependent on the beam current variations, and means for applying said direct voltage to said bias. 10. A circuit arrangement as claimed in claim 1 further comprising a field deflection generator, and means for deriving a parabola voltage from the field generator and for applying it to the second stabilizing circuit in order to modulate the sawtooth current supplied by the auxiliary generator for the purpose of the required East-West pincushion correction, the field generator being fed with a direct voltage which is proportional to the line deflection current. 11. A circuit arrangement as claimed in claim 10 wherein said deriving means comprises an integration network to which a sawtooth voltage originating from the field generator is applied, said integration network comprising an integration capacitor that also rapidly transfers the supply voltage fluctuations to the second stabilizing circuit. 12. A circuit arrangement as claimed in claim 9, wherein the second stabilizing circuit comprises a voltage dependent resistor.  13. A circuit arrangement as claimed in claim 10 wherein the second stabilizing circuit comprises a triode and a voltage dependent resistor coupled thereto, and means for applying a parabola voltage of field frequency to the cathode of said triode. 14. A circuit arrangement as claimed in claim 10 wherein the second stabilizing circuit comprises a triode and voltage dependent resistor coupled thereto, and means for applying a parabola voltage of field frequency to the grid of said triode. 15. A circuit arrangement as claimed in claim 10 wherein the second stabilizing circuit comprises a transistor having first and second input electrodes, a resistor, a reference voltage Zener diode coupled in series with said resistor and said first electrode, the resistances of the resistor and of the Zener diode at the nominal supply voltage being in the same proportion as are the contributions of the two generators to the deflection current, means for applying a voltage of line frequency which is proportional to the line deflection current to said second input electrode of said transistor, and means for applying a parabola voltage of field frequency to said first input electrode.

13. A circuit arrangement as claimed in claim 10 wherein the second stabilizing circuit comprises a triode and a voltage dependent resistor coupled thereto, and means for applying a parabola voltage of field frequency to the cathode of said triode. 14. A circuit arrangement as claimed in claim 10 wherein the second stabilizing circuit comprises a triode and voltage dependent resistor coupled thereto, and means for applying a parabola voltage of field frequency to the grid of said triode. 15. A circuit arrangement as claimed in claim 10 wherein the second stabilizing circuit comprises a transistor having first and second input electrodes, a resistor, a reference voltage Zener diode coupled in series with said resistor and said first electrode, the resistances of the resistor and of the Zener diode at the nominal supply voltage being in the same proportion as are the contributions of the two generators to the deflection current, means for applying a voltage of line frequency which is proportional to the line deflection current to said second input electrode of said transistor, and means for applying a parabola voltage of field frequency to said first input electrode. Such a circuit arrangement is known from French Pat. specification No. 1,146,166. This specification describes a circuit arrangement for generating a sawtooth current flowing through an inductor, generally the line deflection coil of a television receiver wherein the control element is a valve. This element is adjusted in such a manner that the operating line thereof in the I a - V a field is just above the limit of saturation. This has been made possible because a stabilizing circuit is provided employing a diode the cathode of which is connected through a winding of the inductor formed as a transformer to a supply voltage and whose purpose is to rectify the voltage peaks which are induced during the flyback in the said winding and which exceed the said supply voltage. The negative voltage produced on the anode of the diode then has a value which is proportional to the said voltage difference and is used as a control voltage for the first grid of the output valve of the sawtooth current. In this manner the purpose of stabilizing the operating line in the I a -V a field just above the limit of saturation (the so-called "knee") is achieved.

The circuit arrangement described above is often used as such or as some modification thereof. However, it has the following drawback. The supply voltage which serves as a reference for the amplitude of the voltage peaks to be rectified is generally derived from the mains directly so that this supply voltage proportionally varies with the inevitable fluctuations in the mains voltage. The result is that the width of the picture displayed and the EHT likewise vary as a function of the instantaneous value of the mains voltage. Therefore this is the reason why different stabilizing circuits are used wherein the picture width and the EHT are maintained constant independently of the variations in the mains voltage. Such a circuit arrangement is known, for example, from the U.S. Pat. No. 2,944,186.

In such a circuit arrangement the operating line in the I a -V a field must be chosen far above the "knee" at the nominal mains voltage if this line is not to come below the knee when the mains voltage has decreased to its lowest possible value. In other words the anode voltage of the line output valve must be much higher than in the case of the French patent specification mentioned above. Since the current which must flow through the inductor must be fairly large, this solution involves a considerable loss of power (greater dissipation). If a transistor is used as a control element this requirement is still more stringent because such transistors are immediately destroyed when the collector voltage increases too much during the flow of the comparatively large current.

In the case of color television wherein great powers for the deflection current and the EHT are required all this may cause an inadmissible additional dissipation also for valves. Thus, for example, a beam current of 2 mA (and even more) must be provided by the EHT source at an EHT of approximately 25 kV which is a power of approximately 50 W while corresponding numbers for monochrome television are: 0.5 mA, 18 kV that is to say 9 W. Therefore it is evident that it is not possible to meet all requirements simultaneously, to wit the supply of the deflection and EHT energy and the stabilization against variations in the EHT, ageing of the components and variations in the supply voltage derived from the mains.

An object of the present invention is to solve the problem described hereinbefore and to this end it is characterized in that the said generator is formed as a main generator which provides a portion of the sawtooth current to be generated and the EHT and that furthermore an auxiliary generator is provided which supplies the remaining portion of the sawtooth current, and a second stabilizing circuit which stabilizes the auxiliary generator against variations in the supply voltage, the two generators being mutually decoupled, all this for the purpose of maintaining the width of the picture displayed on the screen of the display tube constant under all circumstances. It is to be noted that since the main generator is stabilized just above or at the limit of saturation its own dissipation is always at a minimum.

Furthermore it is to be noted that the circuit arrangement according to the invention does not envisage a complete stabilization of the EHT and of the amplitude of the current flowing through the deflection coils. In fact, the internal impedance of the EHT source, although being reduced by the first stabilizing circuit, is not zero which as a matter of fact is not desirable due to evident reasons of safety. In addition as already stated the invention is based on the recognition of the fact that neither the part of the deflection current provided by the main generator nor the EHT are stabilized against variations in the supply voltage. Nevertheless it is possible to stabilize the width of the picture displayed. As is known this width can be maintained constant if the EHT varies at the same percentage as does the supply voltage and if the deflection current varies at half the percentage. If, for example, the mains voltage and hence also the supply voltage increase by 10 percent, the EHT must increase by 10 percent and the deflection current must increase by 5 percent.

This object can be achieved in a very simple manner by means of a special embodiment of a circuit arrangement according to the invention and to this end the circuit arrangement is characterized in that the two generators are adjusted in such a manner that the part of the sawtooth current provided by the main generator is equal to the part which is provided by the auxiliary generator.

Furthermore the invention is based on the recognition of the fact that the second stabilizing circuit (that of the auxiliary generator) is used for performing the so-called East-West raster correction of the pincushion distortion. If the lengths of the lines displayed on the screen are to remain constant during the sweep of one field period, the amplitude of the sawtooth line deflection current must vary in accordance with a parabola function during this sweep and this in such a manner that a maximum value is reached substantially in the middle of the sweep. This East-West correction is obtained by modulating the sawtooth line deflection current by a parabola function of field frequency. This may in principle be achieved in a simple manner by applying a parabola voltage of field frequency to the grid of the line output valve to which the control pulse of the line frequency is applied. However, it will be readily evident that the desired object cannot quite be achieved in that case since the introduced amplitude variation is counteracted by the first stabilizing circuit which in fact attempts to maintain the amplitude of the line deflection current constant. A special embodiment of the circuit arrangement according to the invention is characterized in that a parabola voltage derived from the field generator is applied to the second stabilizing circuit in order to modulate the sawtooth current provided by the auxiliary generator for the purpose of the required East-West pincushion correction, the field generator being fed with a direct voltage which is proportional to the line deflection current.

In this connection a further particular advantage of the circuit arrangement according to the invention becomes manifest. If the main generator had been chosen for this modulation, the EHT would also have varied due to the modulation. On the one hand this would somewhat detrimentally influence the East-West correction to be performed and on the other hand it would cause a variation in brightness during one field period. These drawbacks are obviated by modulating the auxiliary generator only.

In order that the invention may be readily carried into effect a few embodiments thereof will not be described in detail by way of example with reference to the accompanying diagrammatic drawings in which:

FIG. 1 shows the general principle of coupling the main generator and the auxiliary generator to the line deflection coils.

FIG. 2 shows an embodiment of a line deflection circuit employing valves wherein the line deflection coils are connected in parallel.

FIG. 3 and FIG. 4 show the operating line in the I a -V a and the I c -V c fields of the main generator and the auxiliary generator, respectively.

FIGS. 5, 6, 7 and 8 show a few other embodiments of the second stabilizing circuit of FIG. 2.

FIGS. 9 and 10 show a circuit arrangement according to the invention wherein the line deflection coils are arranged in series.

FIG. 11 shows a circuit arrangement wherein the control elements are transistors.

In FIG. 1 the reference numerals 1 and 2 denote the main and auxiliary generators, respectively, whi

ch are coupled through transformers 3 and 4 to the line deflection coil 5. Main generator 1 is directly coupled by means of winding 6 to transformer 3 while line deflection coil 5 is coupled to the same transformer by means of winding 7 (n 7 turns). Furthermore a winding 8 (n 8 turns) is wound on transformer 3 and a winding 9 (n 9 turns) is wound on transformer 4 which windings are connected together through an auxiliary coil 10 which coil 10 is exclusively provided to decouple generators 1 and 2. Windings 11 and 12 (n 12 turns) on transformer 4 correspond to windings 6 and 7 on transformer 3. Both generators contribute to the sawtooth deflection current i Y which flows through line deflection coil 5 while a compensation current i k flows through auxiliary coil 10.

ch are coupled through transformers 3 and 4 to the line deflection coil 5. Main generator 1 is directly coupled by means of winding 6 to transformer 3 while line deflection coil 5 is coupled to the same transformer by means of winding 7 (n 7 turns). Furthermore a winding 8 (n 8 turns) is wound on transformer 3 and a winding 9 (n 9 turns) is wound on transformer 4 which windings are connected together through an auxiliary coil 10 which coil 10 is exclusively provided to decouple generators 1 and 2. Windings 11 and 12 (n 12 turns) on transformer 4 correspond to windings 6 and 7 on transformer 3. Both generators contribute to the sawtooth deflection current i Y which flows through line deflection coil 5 while a compensation current i k flows through auxiliary coil 10.It must not be possible for auxiliary generator 2 to exert influence on main generator 1, that is to say, the deflection current originating from auxiliary generator 2 must not induce a flux in transformer 3, in other words the voltages V 7 and V 8 which are produced by generator 2 at the terminals of windings 7 and 8 must be zero. This may be calculated when generator 1 is switched off and in that case the following relations apply:

i Y /i k = n 8 / n 7 and V 12 /V 9 = n 12 /n 9 = (i Y ωL 5 )/(i k ωL 10 )

wherein L 5 and L 10 are the inductances of coils 5 and 10, respectively. The ratio of the inductances L 5 and L 10 can be calculated therefrom:

Conversely it must not be possible for generator 1 to exert influence on generator 2, in other words when generator 2 is disconnected the voltages V 12 and V 9 must be zero. In that case the following relations apply:

i k / i Y = n 12 /n 9 and V 7 /V 8 = n 7 /n 8 = (i Y ω L 5 )/(i k ωL 10 )

from which follows

This is the same condition as the one above, in other words, if these conditions are satisfied the two generators are mutually completely decoupled. As is evident from FIG. 1 this is achieved by coupling windings 8 and 9, as it were, oppositely to windings 7 and 12.

In practice, the principal circuit diagram described may be formed in different manners. A first embodiment is sho

wn in FIG. 2 where corresponding elements have the same reference numerals as those in FIG. 1. In this figure the reference numerals 1 and 2 denote line deflection generators which may be formed in known manner and which are provided with a shunt or series booster circuit; in this embodiment they are both provided with a series booster circuit. Main generator 1 is controlled by a control signal 13 and is formed as a flyback driven high voltage generator for generating the EHT V H , EHT winding 14 being wound on transformer 3. The purpose of this transformer is to step up the high peaks occurring during the flyback so as to obtain the EHT V H after rectification. The transformer 3 is tuned in known manner by means of circuit 16 to two parallel resonance one of which has the flyback frequency and the other is substantially an odd harmonic of the first, capacitor 15 representing an interconnection with respect to alternating current between the primary and the secondary. Auxiliary generator 2 is controlled by the same control signal 13 as is main generator 1 or without any objection by a source other than 1 provided that an equivalent control signal of line frequency is applied to its control grid. Coil 10 represents the auxiliary coil while the two half line deflection coils 5 are arranged in parallel in this embodiment. Transformer 17 serves to modulate the line deflection current through the two half coils 5 (the so-called difference current control) in order to eliminate the effect of the anisotropic astigmatism in the corners of the picture display tube as described in the U.S. Pat. application Ser. No. 832,957, filed on June 13, 1969. Since transformer 17 is bifilarly wound and forms a bridge circuit with the half deflection coils which circuit is in balance it does not represent an impedance for the deflection current i Y . The adjustable and damped inductor 18 through which current i Y flows serves for the usual linearity correction. The points in FIG. 2 at windings 12 and 9 on transformer 4 show that the flux generated by current i Y in winding 12 is opposite to the flux which is generated by current i k in winding 9. This corresponds to the manner of decoupling as described with reference to FIG. 1. Since transformer 4 is not used to produce an EHT, a non-tuned transformer would be sufficient. It is, however, found to be advantageous to tune it anyway in the above-described known manner because also transformer 4 has leakage inductance. Without the said tuning ringing might occur, but in addition the flyback periods of the two generators might become unequal.

wn in FIG. 2 where corresponding elements have the same reference numerals as those in FIG. 1. In this figure the reference numerals 1 and 2 denote line deflection generators which may be formed in known manner and which are provided with a shunt or series booster circuit; in this embodiment they are both provided with a series booster circuit. Main generator 1 is controlled by a control signal 13 and is formed as a flyback driven high voltage generator for generating the EHT V H , EHT winding 14 being wound on transformer 3. The purpose of this transformer is to step up the high peaks occurring during the flyback so as to obtain the EHT V H after rectification. The transformer 3 is tuned in known manner by means of circuit 16 to two parallel resonance one of which has the flyback frequency and the other is substantially an odd harmonic of the first, capacitor 15 representing an interconnection with respect to alternating current between the primary and the secondary. Auxiliary generator 2 is controlled by the same control signal 13 as is main generator 1 or without any objection by a source other than 1 provided that an equivalent control signal of line frequency is applied to its control grid. Coil 10 represents the auxiliary coil while the two half line deflection coils 5 are arranged in parallel in this embodiment. Transformer 17 serves to modulate the line deflection current through the two half coils 5 (the so-called difference current control) in order to eliminate the effect of the anisotropic astigmatism in the corners of the picture display tube as described in the U.S. Pat. application Ser. No. 832,957, filed on June 13, 1969. Since transformer 17 is bifilarly wound and forms a bridge circuit with the half deflection coils which circuit is in balance it does not represent an impedance for the deflection current i Y . The adjustable and damped inductor 18 through which current i Y flows serves for the usual linearity correction. The points in FIG. 2 at windings 12 and 9 on transformer 4 show that the flux generated by current i Y in winding 12 is opposite to the flux which is generated by current i k in winding 9. This corresponds to the manner of decoupling as described with reference to FIG. 1. Since transformer 4 is not used to produce an EHT, a non-tuned transformer would be sufficient. It is, however, found to be advantageous to tune it anyway in the above-described known manner because also transformer 4 has leakage inductance. Without the said tuning ringing might occur, but in addition the flyback periods of the two generators might become unequal.Capacitor 19 for the S correction must be arranged in series with winding 7 on transformer 3 of main generator 1. In fact, the current which flows through winding 8 is not the deflection current i Y , but i Y + i k - i p , wherein i k is the compensation current flowing through auxiliary coil 10 and i p is the primary current of transformer 3. Since the cathode current of pentode 20 in generator 1 is not proportional to the deflection current i Y , this current cannot be used for centration which must be performed by means of circuit 21 in order that the shift remains exactly correlated with the deflection current. The current taken up by circuit 21 has a value which relative to that of deflection current i Y is so low that the current flowing through capacitor 19 and resistor 22 is substantially equal to i Y . Furthermore a resistor 22 of small value is incorporated in series with capacitor 19. Because the current flowing through capacitor 19 has a sawtooth form the voltage across resistor 22 is the combination of a sawtooth voltage and a parabola voltage. If resistor 22 is formed as a potentiometer the voltage between the wiper on potentiometer 22 and the junction 19-22 can be used for adjustment of the dynamic convergence if the circuit arrangement acco

rding to FIG. 2 is used in a color television receiver.

rding to FIG. 2 is used in a color television receiver.Main generator 1 is provided with a stabilizing circuit which stabilizes this generator in known manner against variations in the EHT as a result of beam current variations as a function of the brightness (= the load on winding 14) and against variations caused by ageing of components. In FIG. 2 the voltage dependent resistor (VDR) 23 is included by way of example which resistor rectifies line flyback pulses producing a negative voltage which serves as a control voltage for the control grid of pentode 20 in generator 1. The lower end of VDR 23 is connected to the wiper on a potentiometer 24' one end of which is connected to earth and the other end of which is connected through a resistor of large value to the series booster capacitor. If the wiper on potentiometer 24' is provided at the lower end, main generator 1 is not stabilized against variations in the mains voltage; in case of a different position of this wiper the extent of stabilization against mains voltage variations is optionally adjustable.

Since the pulses included in winding 6 of transformer 3 during the line flyback are substantially proportional to the instantaneous value of the supply voltage, it is advantageous to rectify the pulses produced on a tapping of winding 6 by means of rectifier 25 in order to generate a voltage for a second grid of the display tube. In fact, the voltages on the cathodes and the Wehnelt cylinders of this display tube vary proportionally to the supply voltage. Furthermore the main generator 1 is adjusted by means of potentiometers 24' and 24" in such manner that its operating line in the I a - V a field of pentode 20 may be represented by line PQ in FIG. 3. As already described in the preamble the line PQ is placed as closely as possible to the limit of saturation which is represented by the line section NO in order to maintain the natural dissipation of t

his pentode as small as possible.

his pentode as small as possible.Auxiliary generator 2 is provided with a second stabilizing circuit which stabilizes this generator in known manner against supply voltage variations. In FIG. 2 the combination of a triode 26 and a further voltage dependent resistor (VDR) 27 which is included in the cathode line of the triode serves for this purpose. As is known a negative voltage which serves as a control voltage for the control grid of pentode 28 in generator 2 is produced on the anode of the triode. The adjustment of this pentode is chosen to be such (see FIG. 4) that the operating line thereof in the I a -V a field is placed sufficiently far above the "knee" so that the envisaged stabilization against supply voltage variations can be carried into effect. It is a recognition of the invention to choose the operating line at the nominal supply voltage such that the largest occurring variation in the supply voltage in negative direction causes the operating line to be displaced just above the "knee. " In fact, in such a case the same contribution to deflection current i Y is still provided by auxiliary generator 2 while the dissipation is maintained at a minimum. The foregoing may be explained with reference to the following figures. If, for example, pentode 20 is a PL 509 and if the control voltage 13 thereof has a sawtooth form, the anode current of this pentode may increase during the scan period from zero to approximately 800 mA at the nominal supply voltage which represents a mean value of approximately 360 mA throughout the line period while the mean anode voltage is approximately 50 V. The natural dissipation is 360 × 50 × 10 -3 = 18 W at an average. If the supply voltage variations had been taken into account, an anode voltage of, for example, 70 V should have been chosen at the nominal mains voltage which is an additional increase of 360 × 20 × 10 -3 = 7.2 W. For a maximum mains voltage of 240 V an additional power of 7.2 W must be supplied.

On account of the same reason the number of turns on windings 8 and 9 must be chosen to be such that there does not flow any compensation current i k through balancing auxiliary coil 10 when the supply voltage has decreased to its lowest occurring value: since the two generators supply exclusively deflection energy the circuit arrangement then has its maximum efficiency and since the two valves are then adjusted just above their "knees" the overall dissipation is at a minimum under these circumstances. If necessary auxiliary coil 10 may be arranged between tappings on windings 8 and 9.

As already described in the preamble the second stabilizing circuit is modulated by a parabola voltage of field frequency so as to correct the East-West pincushion distortion. This may be achieved in accordance with the embodiment of FIG. 2 by integrating a sawtooth voltage 29 originating from the field generator by means of an RC network 30-31 and to apply the resultant parabola voltage 32 to the grid of triode 26. It is alternatively possible (see FIG. 5) to arrange this parabola voltage of field frequency 32 in series with VDR 27, but then at a polarity which is reversed relative to that of the previous case. It is true that the advantage of the higher input impedance of the grid is then lost so that the parabola voltage must have slightly greater amplitude, but is should be taken into account that a sawtooth voltage of field frequency is not always available at the desired polarity in the television receiver in which the circuit arrangement is used.

In the embodiment of FIG. 2 in which the second stabilizing circuit receives the voltage of field frequency at the grid of triode 26, integration capacitor 31 of the RC integration network is arranged between said grid and the supply voltage. In this simple manner capacitor 31 also serves to transfer the fluctuations in the supply voltage quickly to the second stabilizing circuit. The same applies to the embodiment of FIG. 5.

In FIG. 2 the second stabilizing circuit is formed as the combination of a triode and a VDR. It is evident that any other known stabilizing circuit for the line deflection is likewise suitable for this purpose. Thus said stabilizing circuit may be formed as a VDR 33 to which the parabola voltage is also applied provided that this voltage is high enough because the amplification of the triode is no longer available (see FIG. 6).

Since the second stabilizing circuit is modulated by the parabola voltage in one of the manners described, the following problem presents itself. The current provided by auxiliary generator 2 is rendered independent of variations in the supply voltage or, in other words, the contribution of auxiliary generator 2 to the overall deflection current is dependent on the value of this supply voltage, for if α i Y and β i Y are the contributions of the first and second generators to the deflection current, then α varies with the supply voltage while β remains constant from which is apparent that the ratio β : α is a function of the supply voltage. If the amplitude of the modulating parabola voltage 32 is constant this results in over- or undermodulation in case of variations in the supply voltage. If, for example, the two generators each supply half the deflection current i Y at the nominal supply voltage and if the amplitude of the modulating current is 20 percent of i Y , the two generators provide 0.5 i Y and (0.5 + 0.2)i Y , respectively. If the supply voltage decreases by 10 percent the main generator, which is not stabilized against this variation, provides 0.45 i Y while the auxiliary generator continues to provide (0.5 + 0.2) i Y which means that the modulating current has become 20 : 95 = 21 percent of the new deflection current. Consequently, an overcompensation occurs.

The problem can be solved in an elegant manner when the applied parabola voltage does not remain constant, but when it varies by the same factor as does the line deflection current, that is to say, as already previously described, by a factor which is 50 percent of the factor by which the supply voltage varies. In the above-mentioned example of calculation the modulating current then decreases by a factor of 5 percent and and hence the auxiliary generator provides (0.5 + 0.19) i Y . The amplitude of the modulating current is 19 : 95 = 20 percent of the deflection current so it has proportionally remained constant. The same reasoning applies when the supply voltage would increase. The step described may be carried into effect by feeding the field generator with a direct voltage which is proportional to the line deflection current, which direct voltage can be generated by rectifying, with the aid of diode 34 of FIG. 2, the parabola voltage which is produced across capacitor 19 for the S correction. The direct voltage derived from point 35 may be applied to the field generator, for the current flowing through capacitor 19 is nothing but deflection current i Y since the current flowing through circuit arrangement 21 is negligibly small relative thereto. It is alternatively possible to provide an additional winding on the two transformers 3 and 4 in such a manner that the voltages induced therein are in the same properties as are the contributions of the two generators to deflection current i Y . These voltages may be added together and the resultant voltage may be rectified by means of diode 34.

A winding 36 across which line flyback pulses are produced is provided on transformer 3 of main generator 1 which pulses are applied through potentiometer 37 to the second stabilizing circuit while also flyback pulses from winding 38 on transformer 4 of auxiliary generator 2 are applied to the same stabilizing circuit. In fact, this stabilizing circuit must receive information regarding the instantaneous value of the deflection current. Potentiometer 37 then serves to give the pulses applied to the second stabilizing circuit a ratio which is equal to the ratio of the contributions of the two generators to the deflection current. However, since the amplitude of the pulses generated across winding 36 is also dependent on the variations in the EHT V H as a result of its internal impedance, which is not negligible, the part of the deflection current provided by auxiliary generator 2 would also vary which would cause a variation in the picture width. Therefore the second stabilizing circuit must also receive information regarding these EHT variations. In the embodiment of FIG. 2 this purpose is achieved by connecting the lower end of potentiometer 39 not to earth but to an RC parallel network 40 which is provided at the lower end of winding 14. In fact, an adjustable direct voltage which is directly proportional to the beam current is produced across this network 40. In this manner the deflection current provided by auxiliary generator 2 slightly decreases as the beam current increases. As a matter of fact the direct voltage produced across network 40 may be used elsewhere in the display device so as to prevent the beam current from exceeding a given value.

As described hereinbefore according to the recognition of the invention the deflection current must vary by a percentage which is equal to half that of the variation in the supply voltage. The second stabilizing circuit thus must have a stabilization factor relative to the supply voltage which is equal to 2. This is adjusted by means of potentiometer 39.

However, the previously described stabilizing circuit for the auxiliary generator 2 has the drawback that it provides two adjusting possibilities, to wit potentiometers 37 and 39. Associated with each position of one potentiometer is a position of the other by which the series booster voltage of the auxil

iary generator can be adjusted, but there is only one position at which the width of the picture does not vary with the supply voltage. This is not very practical. This drawback can be obviated with the aid of the circuit arrangement shown in FIG. 7. In this circuit arrangement the second stabilizing circuit is formed as a transistor 41 whose base line includes a resistor 42 in series with an element 43 supplying a reference voltage, for example a Zener diode, in such a manner that the voltages across resistor 42 and Zener diode 43 have the same proportion in case of nominal supply voltage as do the contributions of the two generators to the deflection current. Then the variation of the base voltage is half the variation in the supply voltage. The emitter of transistor 41 is controlled by a voltage of line frequency which is proportional to the deflection current i Y which voltage can be obtained by arranging, for example, a resistor 44 of small value in series with the parallel arrangement of the two deflection coil halves 5 or by providing a few windings on the yoke of the deflection unit or by means of an auxiliary transformer on the line deflection coils while the parabola voltage 32 is applied to the base. The same purpose as the one described above is now achieved with the aid of only one adjustment, to wit the adjustment of transistor 41. It is alternatively possible without any objection to incorporate resistor 42 and Zener diode 43 in the emitter line of transistor 41 and the information proportional to the line deflection current in the base line.

iary generator can be adjusted, but there is only one position at which the width of the picture does not vary with the supply voltage. This is not very practical. This drawback can be obviated with the aid of the circuit arrangement shown in FIG. 7. In this circuit arrangement the second stabilizing circuit is formed as a transistor 41 whose base line includes a resistor 42 in series with an element 43 supplying a reference voltage, for example a Zener diode, in such a manner that the voltages across resistor 42 and Zener diode 43 have the same proportion in case of nominal supply voltage as do the contributions of the two generators to the deflection current. Then the variation of the base voltage is half the variation in the supply voltage. The emitter of transistor 41 is controlled by a voltage of line frequency which is proportional to the deflection current i Y which voltage can be obtained by arranging, for example, a resistor 44 of small value in series with the parallel arrangement of the two deflection coil halves 5 or by providing a few windings on the yoke of the deflection unit or by means of an auxiliary transformer on the line deflection coils while the parabola voltage 32 is applied to the base. The same purpose as the one described above is now achieved with the aid of only one adjustment, to wit the adjustment of transistor 41. It is alternatively possible without any objection to incorporate resistor 42 and Zener diode 43 in the emitter line of transistor 41 and the information proportional to the line deflection current in the base line.A drawback of the previously described stabilizing circuit is that that the voltage which is present at the control grid of pentode 28 must remain negative throughout the line period, that is to say, a mean grid voltage of approximately -30 to -60 V dependent on the waveform, the amplitude of the control voltage and on the negative voltage which is required at the end of the scan. Since this grid voltage serves as a collector voltage for transistor 41 this mean value is fairly high, at least so for many transistors. FIG. 8 shows an embodiment which is more suitable in this respect. In this embodiment the collector voltage of transistor 41 is laid down at a fixed level, for example, -20 V and control signal 13 is clamped against this level by means of a diode. This embodiment provides the advantage that the action of stabilization has become more effective because variations in the amplitude of control signal 13 as a result of variations in the supply voltage are rectified by the clamping diode which is a contribution to the negative voltage for the control grid. This contribution need not then be provided by the control circuit. A diode is provided in the base circuit of transistor 41 in order to rectify the peaks of the voltage present on the wiper of potentiometer 39 so that the admissible reverse voltage for the base-emitter diode of transistor 41 is not exceeded. Furthermore, the emitter voltage changes to a small extent because the current derived from the supply voltage and flowing through Zener diode 43 and resistor 42 also flows through the resistor in network 40: this has no influence when the base of transistor 41 undergoes a proportional variation which may be effected by choosing the correct value for the resistor between potentiometer 39 and the supply voltage.

So far nothing has been stated about the ration of the contributions of the deflection currents provided by the two generators and all ratios are in principle possible. It will, however, be readily evident that the contribution of auxiliary generator 2 must at any rate not decrease to zero, for generator 2 in FIG. 1 may be considered a voltage source parallel to a circuit (= winding 11 and the parasitic capacitances). If generator 2 provides a current the two generators do not "see" each other as has been proved, but if this current is zero, that is to say, if the line between voltage source 2 and the circuit is interrupted, windings 12 and 9 are only coupled together and the transformed inductor 10 is in

series with deflection coil 5. This may cause heavy free oscillations which become visible as a velocity modulation of the dot of light on the screen of the display tube. The contribution provided by generator 2 may therefore not become smaller than approximately 2 percent of the overall supplied current. In addition it would make little sense to have auxiliary generator 2 supply more current than main generator 1 since the dissipation in the auxiliary generator would become greater without discharging the main generator considerably thereby, since this generator must provide the (great) EHT power anyway.

series with deflection coil 5. This may cause heavy free oscillations which become visible as a velocity modulation of the dot of light on the screen of the display tube. The contribution provided by generator 2 may therefore not become smaller than approximately 2 percent of the overall supplied current. In addition it would make little sense to have auxiliary generator 2 supply more current than main generator 1 since the dissipation in the auxiliary generator would become greater without discharging the main generator considerably thereby, since this generator must provide the (great) EHT power anyway.It will now be proved that a ratio of 1 : 1 that is the same contribution of the two generators (at nominal supply voltage) is preferred to some extent. If i Y and i Y are the contributions of the two generators at an arbitrary supply voltage, while i Y and i Y represent the same values at nominal supply voltage, the following relations apply when this supply voltage has varied by a factor of 1 + s and when the main generator 1 is not stabilized at all against mains voltage variations, that is to say, when the wiper on potentiometer 24' is connected to earth:

wherein n is the stabilization factor of auxiliary generator 2 against mains voltage variations. In order that the width of the picture remains constant there must apply that:

that is to say, the overall deflection current varies by the percentage s/2 . From this follows: ##SPC1##

Since the position of the wiper on potentiometer 24' may vary, the first stabilizing circuit may have a mains voltage stabilization factor of m which, likewise as n, is smaller that 1; the last formula then becomes:

It can be seen that n = 0 when i Y = i Y for any value of m, or in words: at the ratio of 1 : 1 of the deflection currents supplied at nominal mains voltage the auxiliary generator is completely stabilized against mains voltage variations independently of the stabilization factor m of the main generator, in other words the two stabilizing circuits can now be fully independent of each other.

The ratio 1 : 1 permits of writing that the deflection current must be

when the supply voltage is multiplied by a factor of 1 + s. The term

is then the current provided by main generator 1 which entirely follows the supply voltage fluctuations. The second term i Y /2 represents the current provided by auxiliary generator 2 which current remains constant. The advantage of this ratio of 1 : 1 is then evident. A variation in the mains voltage does not cause any variation in the picture width, but only a variation in the EHT (for this varies with the supply voltage variations) while auxiliary generator 2 does not exert any influence on the EHT. Thus the two functions of the line output generator are separated from each other, that is to say, they have been made independent of each other. Such an independency was not possible with the circuit arrangements known so far.

It is allowed to optionally stabilize or not stabilize main generator 1 against supply voltage variations while the second stabilizing circuit does stabilize auxiliary generator 2 completely. This second stabilizing circuit then need no longer receive information regarding the value of the overall deflection current. Winding 36 in FIG. 2 can then be omitted while resistor 44 in FIGS. 7 and 8 may be replaced by, for example, a winding on transformer 4. In addition resistor 42 is now omitted.

It is true that it must be possible for pentode 28 in auxiliary generator 2 to supply a comparatively large power at the ratio of 1 : 1. However, the advantage of an independent EHT generation and picture width stabilization is so important that a pentode for generator 2 suitable for a greater dissipation may be accepted. Since generator 2 need not supply any EHT power, its pentode may nevertheless be a valve which is suitable for a smaller dissipation than is pentode 20 in main generator 1. This means that the cathode of pentode 28 may be smaller and the insulation between this cathode and the filament for heating thereof may be thinner resulting in the heating period of auxiliary generator 2 being shorter upon switching on than that of main generator 1. It is then advantageous to provide additional windings on transformer 4 so as to provide the picture tube, the EHT rectifier and optionally the series booster diode of main generator 1 with filament power. Not only are the relevant filament voltages constant independently of the mains voltage variations but due to the shorter heating period of auxiliary generator 2 the picture tube has already completely heated up at the instant when main generator 1 starts to operate. If one generator were present and if the filament voltage for the picture tube were derived from its output transformer, the heating period of the picture tube cathode would not commence until this single generator would start to operate after it was switched on. Consequently, this is a longer period than when this filament supply would be effected by auxiliary generator 2.

FIG. 2 described so far related to a line deflection circuit in which the two halves of deflection coils 5 are arranged in parallel. The foregoing will of course also apply when the said halves are arranged in series. In this respect reference is made to FIG. 9 in which only the important elements

of FIG. 2 are shown and denoted by the same reference numerals. Since the two halves 5' and 5" of the deflection coil are arranged in series the entire circuit arrangement must be symmetric which is apparent from FIG. 9. For this reason coil 18 for the linearity control must have a bifilar winding and capacitor 19 for the S correction must be split up into two equal parts 19', 19". Since capacitors 19' and 19" should exactly be equal for a satisfactory symmetry, only one capacitor is used and an electric center is made by means of a bifilarly wound coil 45', 45" (see FIG. 10). This coil may alternatively be formed as a transformer wherein the secondary serves for generating (21) the centering current which is smoothed by capacitors 46' and 46".

of FIG. 2 are shown and denoted by the same reference numerals. Since the two halves 5' and 5" of the deflection coil are arranged in series the entire circuit arrangement must be symmetric which is apparent from FIG. 9. For this reason coil 18 for the linearity control must have a bifilar winding and capacitor 19 for the S correction must be split up into two equal parts 19', 19". Since capacitors 19' and 19" should exactly be equal for a satisfactory symmetry, only one capacitor is used and an electric center is made by means of a bifilarly wound coil 45', 45" (see FIG. 10). This coil may alternatively be formed as a transformer wherein the secondary serves for generating (21) the centering current which is smoothed by capacitors 46' and 46".FIG. 11 shows by way of example a circuit arrangement according to the invention wherein transistors are employed as control elements and in which the ratio between the sawtooth currents is 1 : 1 and wherein the deflection coils are arranged in series. The corresponding components of the previous Figures have the same reference numerals. The paramount difference from a circuit arrangement employing valves resides in the fact that it is not possible to control a transistor, which actually functions as a switch, in the same way as a valve. It is possible to use a so-called "knee stabilization" in contrast to what is effected with valves for the reasons explained in the French Pat. specification No. 1,146,166. If it is ensured that the control currents of transistors 20' and 28' of FIG. 11 are sufficiently large, the operating line of the two transistors in the I c -V c field will substantially always extend under any circumstances in accordance with the line ON in FIG. 3 (wherein I c and V c should be read instead of I a and V a , respectively). If in addition the operating point would be above the "knee," the dissipation, as already stated, might become inadmissibly high.

In FIG. 11 main generator 1 is not stabilized against variations in the supply voltage V B whereas auxiliary generator 2 is stabilized, namely by means of transistor 26'. Transistor 26' receives a parabola voltage 32 of field frequency from a circuit arrangement 17 (not further described) for the purpose of correcting the East-West pincushion distortion as well as a direct voltage which has a variation such that the variation in the collector voltage of transistor 26' is always equal to that of supply voltage V B . The voltage across auxiliary generator 2 then remains constant which means that the part i Y of the sawtooth current supplied by auxiliary generator 2 is constant.

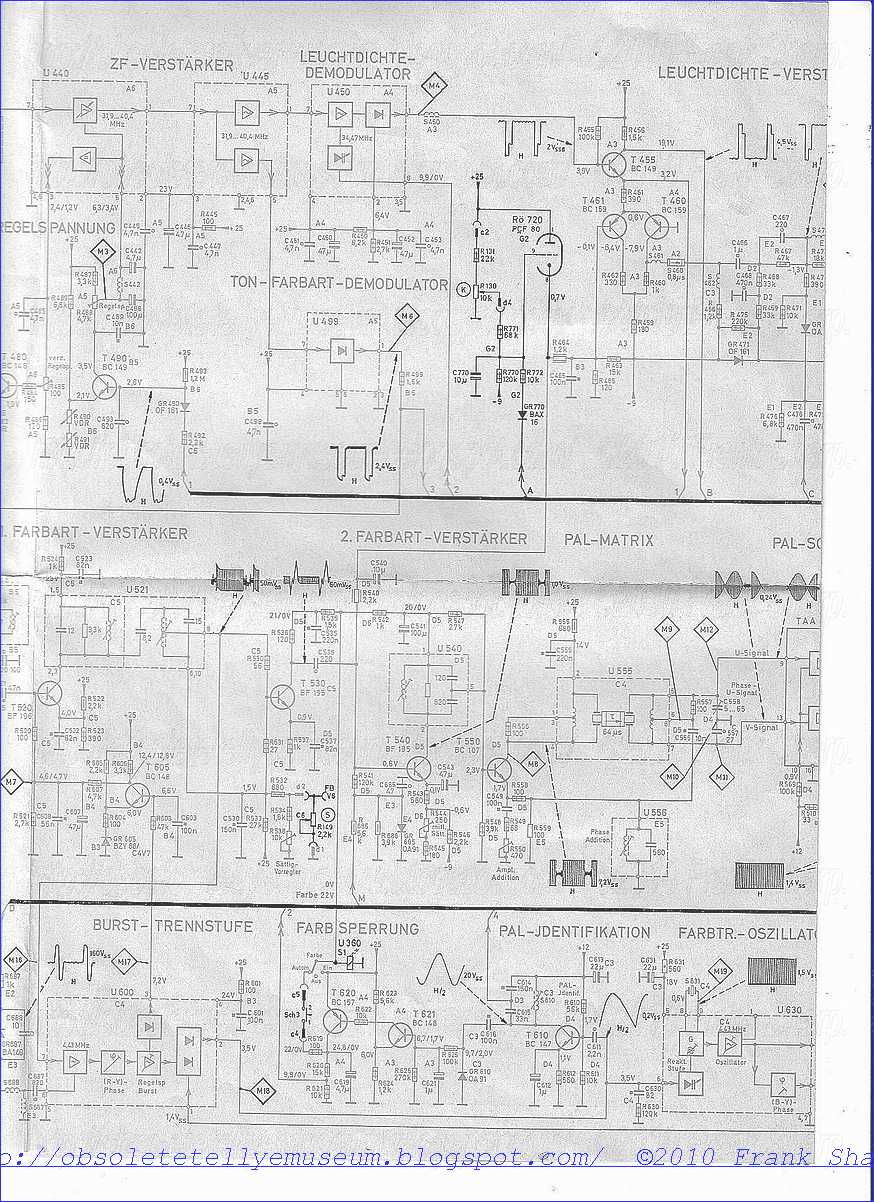

PHILIPS X26K171 (PHILIPS K8) CHASSIS K8 PAL-TYPE COLOR SIGNAL PROCESSING

Burst components of PAL-type encoded signal are retained with modulated subcarrier components as they are processed in 1H delay line assembly and delivered to respective demodulators. Reference oscillation phase to which R-Y demodulator responds is effectively reversed every other line, in response to PAL switch apparatus, in order to provide desired R-Y output in successive lines. Reference oscillation phase to which B-Y demodulator responds is alternated by quadrature switch apparatus between B-Y phase (applied throughout each line interval) and R-Y phase (applied during each inter-line blanking interval). A first gating circuit, coupled to the output of the B-Y demodulator, selects that portion of the B-Y demodulator output developed during the burst interval for passage to integrating and amplifying means in order to develop an AFPC voltage for phase control of the local reference oscillator. A second gating circuit, coupled to the output of the R-Y demodulator, selects that portion of the R-Y demodulator output developed during the burst interval for passage to ACC and color killer circuitry. During color operation (enabled state of bandpass chrominance amplifier) the ACC circuiry develops a control current from the second gating circuit output that adjusts the chrominance amplifier g

ain in a direction appropriate to maintaining burst amplitude substantially constant at a level set by a manual chroma control. The color killer enables the chrominance amplifier for color operation only when the gated R-Y output indicates by its amplitude the presence of a burst in the received signal and by its polarity the correct switching mode for the PAL switch. Unless such circumstances are present, the color killer disables the chrominance amplifier during each line interval; the killer is keyed, however, to enable the chrominance amplifier during each burst interval so that recovery from the disable state may be effected when appropriate. The color killer circuitry also passes a reset pulse to the PAL switch in the absence of a correct mode indication in the gated R-Y output. The color killer circuitry further serves to control the effectiveness of a subcarrier trap for the receiver's luminance channel, removing the trap during line intervals of monochrome operation.

ain in a direction appropriate to maintaining burst amplitude substantially constant at a level set by a manual chroma control. The color killer enables the chrominance amplifier for color operation only when the gated R-Y output indicates by its amplitude the presence of a burst in the received signal and by its polarity the correct switching mode for the PAL switch. Unless such circumstances are present, the color killer disables the chrominance amplifier during each line interval; the killer is keyed, however, to enable the chrominance amplifier during each burst interval so that recovery from the disable state may be effected when appropriate. The color killer circuitry also passes a reset pulse to the PAL switch in the absence of a correct mode indication in the gated R-Y output. The color killer circuitry further serves to control the effectiveness of a subcarrier trap for the receiver's luminance channel, removing the trap during line intervals of monochrome operation.1. In apparatus for processing PAL-type encoded color television signals, the combination comprising: 2. Apparatus in accordance with claim 1, also including: 3. Apparatus in accordance with claim 2, also including: 4. Apparatus in accordance with claim 2, also including 5. Apparatus in accordance with claim 2, wherein said second reference oscillation supplying means includes means for reversing the phase of the supplied reference oscillation in alternate line intervals, and wherein said apparatus also includes: 6. Apparatus in accordance with claim 5, also including a source of line rate triggering pulses; and 7. Apparatus in accordance with claim 6, also including:

In a widely used approach to the processing of such detector PAL signals, the following functions are performed: A bandpass chromina

nce channel provides frequency selective amplification of the subcarrier sideband components, to the exclusion of low frequency luminance signals. The selectively amplified signals are applied to a 1H delay line assembly to develop two outputs respectively corresponding to an additive combination of undelayed and delayed signals, and a subtractive combination of undelayed and delayed signals. One output (in which the B-Y components for successive line intervals reinforce, whereas the R-Y components for successive line intervals mutually cancel) is supplied to a B-Y demodulator, while the other output (in which the R-Y components for successive line intervals reinforce, whereas the B-Y components for successive line intervals mutually cancel) is supplied to a R-Y demodulator. Each demodulator functions as a synchronous detector, controlled by the application of the appropriate phase of subcarrier frequency oscillations of fixed amplitude from a local reference oscillator. The reference phase applied to the B-Y demodulator is constant line-to-line, whereas the reference phase applied to the R-Y demodulator is shifted by 180° in successive line intervals. A takeoff for the burst component of the received signal is provided at a point in the chrominance channel prior to the delay line assembly, with appropriately gated apparatus extracting the burst component alone for amplification and delivery to a phase detector for comparison with an output of the local reference oscillator. An AFPC control voltage derived from the phase detector serves to lock the oscillator in a fixed phase relationship to the average phase of the "swinging" burst. Information derived from the separated burst is also used in performance of color killer and automatic chroma control (ACC) functions (determining the enabling or disabling of the chrominace channel, and the relative gain thereof when enabled). The burst component is eliminated from the chrominance signal delivered to the delay line assembly.

nce channel provides frequency selective amplification of the subcarrier sideband components, to the exclusion of low frequency luminance signals. The selectively amplified signals are applied to a 1H delay line assembly to develop two outputs respectively corresponding to an additive combination of undelayed and delayed signals, and a subtractive combination of undelayed and delayed signals. One output (in which the B-Y components for successive line intervals reinforce, whereas the R-Y components for successive line intervals mutually cancel) is supplied to a B-Y demodulator, while the other output (in which the R-Y components for successive line intervals reinforce, whereas the B-Y components for successive line intervals mutually cancel) is supplied to a R-Y demodulator. Each demodulator functions as a synchronous detector, controlled by the application of the appropriate phase of subcarrier frequency oscillations of fixed amplitude from a local reference oscillator. The reference phase applied to the B-Y demodulator is constant line-to-line, whereas the reference phase applied to the R-Y demodulator is shifted by 180° in successive line intervals. A takeoff for the burst component of the received signal is provided at a point in the chrominance channel prior to the delay line assembly, with appropriately gated apparatus extracting the burst component alone for amplification and delivery to a phase detector for comparison with an output of the local reference oscillator. An AFPC control voltage derived from the phase detector serves to lock the oscillator in a fixed phase relationship to the average phase of the "swinging" burst. Information derived from the separated burst is also used in performance of color killer and automatic chroma control (ACC) functions (determining the enabling or disabling of the chrominace channel, and the relative gain thereof when enabled). The burst component is eliminated from the chrominance signal delivered to the delay line assembly.In accordance with the principles of the present invention, novel approaches to PAL color signal processing are contemplated which depart, in many regards, from the above-described widely used approach. Pursuant to the principles of the present invention, burst separation prior to delay is not effected, a separate burst amplifying channel and separate AFPC phase detector are not employed, and burst suppression is not effected for the signal delivered to the 1H delay line assembly. Rather, the burst is retained in the signal delivered to the 1H delay line assembly, and the respective B-Y and R-Y components of the burst pass to the respective demodulators. The B-Y demodulator then serves a dual function: as the B-Y demodulator during line intervals, and as an AFPC Phase detector during interline burst intervals. The phase of reference oscillations supplied to the B-Y demodulator is switched from its normal B-Y phase to an R-Y phase between line intervals, so that the polarity of the demodulator output during a burst interval is indicative of the direction of departure from correct phase relationship between local oscillator and incoming signal. A gating circuit, coupled to the output of the B-Y demodulator, selects that portion of the B-Y demodulator output developed during the burst interval for passage to an integrating and amplifying means in order to develop an AFPC voltage to control the local reference oscillator.

In accordance with further aspects of the present invention, the R-Y demodulator also serves a dual function: as the R-Y demodulator during line intervals, and as a synchronous in-phase detector of burst amplitude during the inter-line burst intervals. A second gating circuit, coupled to the output of the R-Y demodulator, selects that portion of the R-Y demodulator output developed during the burst interval for passage to automatic chroma control (ACC) and color killer circuitry. During color operation (enabled state of bandpass chrominance amplifier) the ACC circuitry develops a control current from the second gating circuit output that adjusts the chrominance amplifier gain in a direction appropriate to maintaining burst amplitude substantially constant at a level set by a manual chroma control. The color killer enables the chrominance amplifier for color operation only when the gated R-Y output indicates by its amplitude the presence of a burst in the received signal and by its polarity the correct switching mode for the PAL switch (i.e., for the reference phase reversing switch associated with the R-Y demodulator). Unless such circumstances are present, the color killer disables the chrominance amplifier during each line interval; the killer is keyed, however, to enable the chrominance amplifier during each inter-line interval so that recovery from the disabled state may be effected when appropriate.

In accordance with still further aspects of the present invention, the color killer circuitry may serve several additional functions, viz.: (a) passing a reset pulse to the PAL switch apparatus, in the absence of a correct mode indication in the gated R-Y output (so that PAL switching mode synchronization may be realized; and (b) controlling the effectiveness of a subcarrier trap for the receiver's luminance channel, removing the trap during line intervals of monochrome operation.

Other objects and advantages of the present invention will be readily apparent to those skilled in the art upon a reading of the following detailed description and an inspection of the accompanying drawings in which:

FIG. 1 is a block diagram illustration of a portion of a color television receiver incorporating color signal processing apparatus embodying the principles of the present invention;

FIG. 2 depicts schematically illustrative apparatus for performing the AFPC function in the system of FIG. 1;

FIG. 3 depicts schematically illustrative apparatus for performing the ACC function in the system of FIG. 1; and

FIG. 4 depicts schematically illustrative apparatus for performing the color killer (and associated PAL switch resetting, and color subcarrier trap switching) functions in the system of FIG. 1.

I

n FIG. 1, a portion of a PAL color television receiver, incorporating an embodiment of the present invention, is illustrated. The video detector 11 recovers a PAL encoded signal from the output of the receiver's intermediate frequency amplifier (not illustrated). The detector output is applied to a video amplifier 15 via a manual contrast control 13, which is bypassed by a burst circuit 14.

n FIG. 1, a portion of a PAL color television receiver, incorporating an embodiment of the present invention, is illustrated. The video detector 11 recovers a PAL encoded signal from the output of the receiver's intermediate frequency amplifier (not illustrated). The detector output is applied to a video amplifier 15 via a manual contrast control 13, which is bypassed by a burst circuit 14.The manual contrast control 13 provides a facility for adjustment of the peak-to-peak magnitude of the video signals delivered to amplifier 15; however, the bypass circuit 14 permits the color synchronizing burst component to pass to amplifier 15 without being affected by contrast control adjustment. This arrangement ensures that contrast control adjustment does not introduce an undesired change in saturation of the image colors; i.e., the contrast control provides concomitant adjustments of the luminance and chrominance components, but does not disturb the burst component amplitude (to which subsequent ACC circuitry is responsive).

The output of video amplifier 15 is applied to a wideband luminance channel, including a luminance amplifier (not illustrated), and also, via chroma takeoff circuitry 17, to a chrominance channel, including a gain controlled bandpass amplifier 19. The chroma takeoff circuitry 17 provides a frequency selective input for the chrominance channel, passing the color subcarrier sideband components, to the substantial exclusion of low frequency luminance components; the chroma takeoff circuitry 17 also functions as a subcarrier trap for the luminance channel, significantly reducing the response of the luminance channel to signal frequencies in the vicinity of the color subcarrier. Desirably, the effectiveness of the trapping function is controlled as a function of whether the signal received is a monochrome or color transmission, with trapping eliminated in the former instance; the manner in which such trapping control is effected with be subsequently described.

The output of bandpass amplifier 19 is supplied to a 1H delay line assembly 21, which provides a pair of outputs representing additive and subtractive combinations of delayed and undelayed signals. At output terminal U of the delay line assembly 21, a combination is provided in which the B-Y components of succesive lines reinforce, whereas the shifting R-Y components tend to cancel; this output is supplied to an input terminal (35) of a B-Y demodulator 30. At a second output terminal (V) of the delay line assembly 21, a signal combination is provided in which the R-Y components of successive lines reinforce, whereas the B-Y components tend to cancel; this output is supplied to an input terminal (45) of an R-Y demodulator 40.

The source of reference oscillations for the demodulators is reference oscillator 65, operating at the subcarrier frequency (e.g., 4.43 MHz.) and subject to phase control in a manner to be described. An output of oscillator 65 is applied to a quadrature switch 67, controlled by a horizontal blanking pulse input, the switch serving to alternately deliver (a) reference oscillations in a B-Y phase (during each line interval to reference input terminal 31 of demodulator 30, and (b) reference oscillations in a R-Y phase (during each inter-line blanking interval) to reference input terminal 33 of demodulator 30.

The B-Y component output of delay line assembly 21 is thus subject to in-phase synchronous detection during each line interval to a provide a B-Y color-difference signal output at terminal 37, and a -(B-Y) color-difference signal output at terminal 39.

At this point, it is appropriate to note that the color synchronizing burst portion of the video signal amplified in video amplifier 15 has been retained with the line interval subcarrier sideband components throughout the chrominance channel (17, 19, 21). The constant phase -(B-Y) component of the swinging burst thus appears in the signal output at delay line assembly terminal U. This component, accordingly, is subject to quadrature synchronous detection in demodulator 30, in view of the delivery by quadrature switch 67 of reference oscillations in the R-Y phase to the (inverting) reference input terminal 33.

Reference oscillations in the R-Y phase are delivered in a linewise alternating fashion from the PAL switch apparatus 69, controlled by a horizontal blanking pulse input, to the respective reference input terminals (noninverting terminal 41 and inverting terminal 43) of R-Y demodulator 40. If the switching mode of the PAL switch 69 is the correct one, the alternating polarity line interval R-Y component at terminal V of delay line assembly 21 will be subject to in-phase detection by demodulator 40 in the desired fashion, developing a R-Y color-difference signal at output terminal 47, and a -(R-Y) color-difference signal at output terminal 49. The latter output signal is supplied, along with the -(B-Y) output of demodulator 30, to a matrix circuit 50, for development of a third (G-Y) color-difference signal.

An R-Y b

urst component also appears in the signal input to terminal 45 of the R-Y demodulator 40, and is subject to in-phase synchronous detection when the correct switching mode is in effect. An R-Y burst interval gate 71, coupled to output terminal 47 of demodulator 40, is gated by a suitably timed burst gate pulse to pass that portion of the R-Y demodulator output developed during the burst interval to a pair of circuits (ACC amplifier circuit 73 and keyed color killer circuit 77).

urst component also appears in the signal input to terminal 45 of the R-Y demodulator 40, and is subject to in-phase synchronous detection when the correct switching mode is in effect. An R-Y burst interval gate 71, coupled to output terminal 47 of demodulator 40, is gated by a suitably timed burst gate pulse to pass that portion of the R-Y demodulator output developed during the burst interval to a pair of circuits (ACC amplifier circuit 73 and keyed color killer circuit 77).The ACC (automatic chroma control) circuitry 73 functions to integrate and amplify the gated R-Y demodulator output in order to develop a control current for controlling the gain of bandpass amplifier 19. The gain control is effected in a direction to oppose spurious variations in the amplitude of the R-Y burst component (which is transmitted with fixed amplitude), thereby to minimize spurious variations in the chrominance signal amplitude that may result in incorrect saturation (chroma) of the displayed image colors. A facility for manual adjustment of the saturation of the image colors is provided in the form of a manual chroma control 75, which supplies an adjustable reference potential to ACC amplifier 73 for comparison with the gated R-Y demodulator output from gate 71 to determine the control current magnitude.