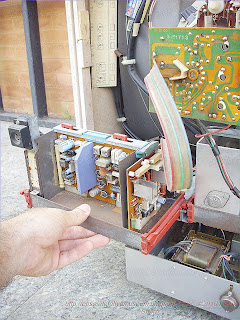

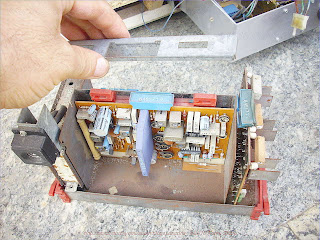

The SINUDYNE 2969 COLOR CHASSIS FR2 PROFESSIONAL 1000 is an excellent example of organization of a tv color chassis.

His full grouped multi modular concept is pretty unique and is rendering service and analisys of tv circuits easy and pleasant.

On the left side a group of signal units is present.

The power supply is located In the middle bottom side.

Right side the group of all deflections units and EHT parts.

The chassis shown is an example on how good was Italian engineering and industry and even if wasn't anyway capable to compete with the bigs it had anyway his limited but present role and fashion.

SINUDYNE 2969 COLOR CHASSIS FR2 PROFESSIONAL 1000 UNITS:

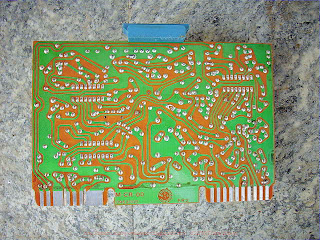

- SIGNAL GROUP BASE BOARD 8C-A-00 FR2

- RGB AMPLIFIER M-FV-00 0959000 FR2

- CHROMINANCE UNIT M-CR-00 0962000 FR2 TBA560C TBA550 TBA540

- IF AMPL DEM UNIT M-MF-00 0958000 FR2 TBA440

- IF SOUND + AMPL TBA120T M-MS-00 0963000 FR2

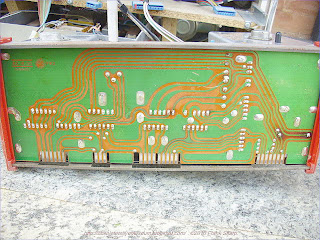

- DEFLECTION GROUP BASE BOARD PCB BC-B-00 FR2

- HOR OSC SYNCH M-00-00 0967000 FR2 TBA920

- FRAME VERTICAL OSCILLATOR UNIT M-OV-OO 0965000 FR2

- E/W + N/S CORRECTION UNIT M-RA-00 0969000

- SUPPLY UNIT M-AL-00 0970000 FR3.

THE

TBA920 SYNC/TIMEBASE IC It has been quite common for some time for sync

separation to be carried out in an i.c. but until 1971 this was as far

as i.c.s had gone in television receiver timebase circuitry. With the

recent introduction of the delta featured 110° colour series however

i.c.s have gone a step farther since this chassis uses a TBA920 as sync

separator and line generator. A block diagram of this PHILIPS /Mullard

i.c. is shown in Fig. 1.

THE

TBA920 SYNC/TIMEBASE IC It has been quite common for some time for sync

separation to be carried out in an i.c. but until 1971 this was as far

as i.c.s had gone in television receiver timebase circuitry. With the

recent introduction of the delta featured 110° colour series however

i.c.s have gone a step farther since this chassis uses a TBA920 as sync

separator and line generator. A block diagram of this PHILIPS /Mullard

i.c. is shown in Fig. 1.The video signal at about 2-7V peak -peak is fed to the sync separator section at pin 8, the composite sync waveform appearing at pin 7.

The noise gate switches off the sync separator when a positive -going input pulse is fed in at pin 9, an external noise limiter circuit being required .

The line sync pulses are shaped by R1 /C1 /C2/R2 and fed in to the oscillator phase detector section at pin 6.

The line oscillator waveform is fed internally to the oscillator phase detector circuit which produces at pin 12 a d.c. potential which is used to lock the line oscillator to the sync pulse frequency, the control potential being fed in at pin 15. The oscillator itself is a CR type whose waveform is produced by the charge and discharge of the external capacitor (C7) connected to pin 14. The oscillator frequency is set basically by C7 and R6 and can be varied by the control potential appearing at pin 15 from pin 12 and the external line hold control. Internally the line oscillator feeds a triangular waveform to the oscillator and flyback phase detector sections and the pulse width control section. The coincidence detector section is used to set the time constant of the oscillator phase detector circuit. It is fed internally with sync pulses from the sync separator section, and with line flyback pulses via pin 5. When the flyback pulses are out of phase with the sync pulses the impedance looking into pin 11 is high (21(Q). When the pulses are coincident the impedance falls to about 150Q and the oscillator phase detector circuit is then slow acting. The effect of this is to give fast pull -in when the pulses are out of sync and good noise immunity when they are in sync. The coincidence detector is controlled by the voltage on pin 10. When the sync and flyback pulses are in sync C3 is charged: when they are out of sync C3 discharges via R3. VTR use has been taken into consideration here. With a video recorder it is necessary to be able to follow the sync pulse phase variations that occur as a result of wow and flutter in the tape transport system, while noise is much less of a problem. For use with a VTR therefore the network on pin 10 can simply be left out so that the oscillator phase detector circuit is always fast acting. A second control loop is used to adjust the timing of the pulse output obtained from pin 2 to take into account the delay in the line output stage. The fly back phase detector compares the frequency of the flyback pulses fed in at pin 5 with the oscillator signal which has already been synchronised to the sync pulse frequency.

Any phase difference results in an output from pin 4 which is integrated and fed into the pulse width control section at pin 3. The potential at pin 3 sets the width of the output pulse obtained at pin 2: with a high positive voltage (via R11 and R12) at pin 3 a 1:1 mark -space ratio out- put pulse (32/us on, 32/us off) will be produced while a low potential at pin 3 (negative output at pin 4) will give a 16us output pulse at the same frequency. The action of this control loop continues until the fly- back pulses are in phase with a fixed point on the oscillator waveform: the flyback pulses are then in phase with the sync pulses and delays in the line output stage are compensated. The output obtained at pin 2 is of low impedance and is suitable for driving valves, transistors or thyristors: R9 is necessary to provide current limiting.

SINUDYNE 2969 COLOR CHASSIS FR2 PROFESSIONAL 1000 power supply CONSTANT-VOLTAGE CONVERTER EMPLOYING THYRISTOR:

A constant voltage converter having a rectifier for rectifying AC power and with a thyristor connected between the rectifier and a filter for selectively passing therethrough a rectified output to an output terminal. There is a wave generator connected to the output of the rectifier for producing a first signal and an intergrator circuit connected to the output of the wave generator for producing an integral output in response to this first signal. In addition there is a detector circuit for detecting a fluctuation of the rectified output power and for producing second signal. A comparison circuit is connected between the intergrator circuit and the detector circuit for producing third signal in accordance with the comparison. A trigger circuit is connected between the comparison circuit and the control gate of the thyristor for supplying a phase control signal to the thyristor to thereby obtain a constant voltage output regardless of the fluctuation of the rectified output.

1. A constant voltage converter comprising an input of a power supply means, an output terminal, filter means, rectifier means connected to said input for rectifying a.c. power and for supplying output thereof to said output terminal, thyristor means connected between said rectifier means and said filter means for selectively passing therethrough a rectified output to the output terminal by way of said filter means, saw-tooth wave generator means connected between the output of said rectifier means and at least one integrator circuit means for producing an integral output in response to a saw-tooth wave produced, a first transistor in said saw-tooth wave generator, the input of said integrator circuit means being connected to a collector of said first transistor, detector circuit means connected to said output terminal for detecting a fluctuation of the rectified output power and for producing an output signal, said detector circuit means having a second transistor, pulse generator circuit means connected between said saw-tooth wave generator means and said detector circuit means for producing a trigger pulse to said thyristor through a trigger means, a third transistor in said pulse circuit generator means, the base of said third transistor being connected to the output of said integrator circuit means, the emitter thereof being connected to the emitter of said second transistor in said detector circuit means, and the collector thereof being connected to the gate of the thyristor means so as to supply a phase control signal thereto, thereby obtaining a constant voltage output regardless of the fluctuation of the rectified output.

Conventional constant-voltage converters of the type employing a thyristor are arranged to phase shift and full-wave-rectify an input a.c. power applied thereto and to maintain the output voltages constant by regulating the firing angle of the thyristor in comparison of the output voltages with the phase-shifted and rectified input a.c. power. When, however, these converters are connected to a common a.c. source having a relatively high internal impedance, the waveform of the phase-shifted and rectified a.c. input power is distorted thereby causing undesired operations of the converters.

It is therefore an object of the present invention to provide a constant-voltage converter which correctly operates notwithstanding the distortion of the input a.c. voltage.

Another object of the invention is to provide a constant-voltage converter which effectively suppress an undesired rush current.

Another object of the invention is to provide a constant-voltage converter having an improved feed-back circuit of a substantially constant loop gain .

In the drawings:

FIG. 1 is a schematic view of a converter according to the present invention;

FIG. 2 is a diagram showing a circuit arrangement of the converter of FIG. 1;

FIG. 3 is a diagram showing various waveforms of signals appearing in the circuit of FIG. 2;

FIG. 4 is a diagram showing various waveforms appearing in the circuit of FIG. 2 when an a.c. power is supplied to the circuit;

FIG. 5 is a diagram showing another circuit arrangement of the converter of FIG. 1;

FIG. 6 is a diagram showing waveforms of signals appearing in the circuit of FIG. 5; and

FIG. 7 is a diagram showing further another circuit arrangement of generator the of FIG. 1.

Referring now to FIG. 1, a cons

tant-voltage converter 10 according to the present invention comprises a rectifier 11 having two input terminals 12 and 13 through which an a.c. power is supplied. The rectifier 11 is preferably a full-wave rectifier although a half-wave rectifier may be employed. An output 14 of the rectifier 11 is connected through a line 15 to an anode of a thyristor 16. The thyristor 16 passes therethrough the rectified a.c. power in only one direction from its anode to cathode when triggered by a trigger pulse through its gate. The cathode of the thyristor 16 is connected through a line 17 to an input of a smoothing filter 18. The smoothing filter 18 smoothes the power from the thyristor 16. An output of the smoothing filter 18 is connected through a line 19 to an output terminal 20. The output 14 of the rectifier 11 is also connected through a line 21 to a saw-tooth wave generator 22 which generates a saw-tooth wave signal having the same repetition period as the rectified input a.c. power. An output of the saw-tooth wave generator 22 is connected through a line 23 to one input of a trigger pulse generator 24. The other input of the trigger pulse generator 24 is connected through a line 25 to the line 19. An output of the trigger pulse generator 24 is connected through a line 26 to the gate of the thyristor 16. The trigger pulse generator 24 produces a trigger pulse on its output when the voltage of the saw-tooth wave signal reaches a level which is varied in response to the output voltage on the terminal 20. The trigger pulse generator 24 may be variously arranged and in this case arranged to comprise rectangular generator 27 having one input connected through the line 23 to the saw-tooth wave generator 22 and the other input connected through a line 28 to an output voltage detector 29. The detector 29 produces a reference signal representing the output voltage on the terminal 20. The pulse generator 27 is adapted to produces a rectangular pulse when the saw-tooth wave signal to the one input reaches a level which defined is in accordance with the reference signal. An output of the rectangular pulse generator 27 is connected through a line 30 to an input of a trigger circuit 31. The trigger circuit 31 is adapted to convert the rectangular pulse into a spike pulse. An output of the trigger circuit 31 is connected through the line 26 to the gate of the thyristor 16.

tant-voltage converter 10 according to the present invention comprises a rectifier 11 having two input terminals 12 and 13 through which an a.c. power is supplied. The rectifier 11 is preferably a full-wave rectifier although a half-wave rectifier may be employed. An output 14 of the rectifier 11 is connected through a line 15 to an anode of a thyristor 16. The thyristor 16 passes therethrough the rectified a.c. power in only one direction from its anode to cathode when triggered by a trigger pulse through its gate. The cathode of the thyristor 16 is connected through a line 17 to an input of a smoothing filter 18. The smoothing filter 18 smoothes the power from the thyristor 16. An output of the smoothing filter 18 is connected through a line 19 to an output terminal 20. The output 14 of the rectifier 11 is also connected through a line 21 to a saw-tooth wave generator 22 which generates a saw-tooth wave signal having the same repetition period as the rectified input a.c. power. An output of the saw-tooth wave generator 22 is connected through a line 23 to one input of a trigger pulse generator 24. The other input of the trigger pulse generator 24 is connected through a line 25 to the line 19. An output of the trigger pulse generator 24 is connected through a line 26 to the gate of the thyristor 16. The trigger pulse generator 24 produces a trigger pulse on its output when the voltage of the saw-tooth wave signal reaches a level which is varied in response to the output voltage on the terminal 20. The trigger pulse generator 24 may be variously arranged and in this case arranged to comprise rectangular generator 27 having one input connected through the line 23 to the saw-tooth wave generator 22 and the other input connected through a line 28 to an output voltage detector 29. The detector 29 produces a reference signal representing the output voltage on the terminal 20. The pulse generator 27 is adapted to produces a rectangular pulse when the saw-tooth wave signal to the one input reaches a level which defined is in accordance with the reference signal. An output of the rectangular pulse generator 27 is connected through a line 30 to an input of a trigger circuit 31. The trigger circuit 31 is adapted to convert the rectangular pulse into a spike pulse. An output of the trigger circuit 31 is connected through the line 26 to the gate of the thyristor 16.FIG. 2 illustrates a prefe

rred circuit arrangement of the converter shown in FIG. 1 which comprises a rectifier 11 of a full-wave rectifier consisting of rectifiers 40, 41, 42 and 43. Inputs of the rectifier are connected to terminals 12 and 13 through which an a.c. power is applied. The output 14 of the rectifier 11 is connected through a line 15 to an anode of a thyristor 16. A cathode of the thyristor 16 is connected through a line 17 to a smoothing filter 18 which includes a capacitor C4 having one terminal connected to the line 17 and the other terminal grounded. The output of the smoothing filter 18 is connected through a line 19 to an output terminal 20.

rred circuit arrangement of the converter shown in FIG. 1 which comprises a rectifier 11 of a full-wave rectifier consisting of rectifiers 40, 41, 42 and 43. Inputs of the rectifier are connected to terminals 12 and 13 through which an a.c. power is applied. The output 14 of the rectifier 11 is connected through a line 15 to an anode of a thyristor 16. A cathode of the thyristor 16 is connected through a line 17 to a smoothing filter 18 which includes a capacitor C4 having one terminal connected to the line 17 and the other terminal grounded. The output of the smoothing filter 18 is connected through a line 19 to an output terminal 20.The rectangular pulse generator 27 comprises a transistor T 2 of PNP type having a base connected through a resistor R 6 to the collector of the transistor T 1 . An emitter of the transistor T 2 is connected through a resistor R 7 to the emitter of the transistor T 1 . A collector of the transistor T 2 is grounded through a resistor R 8 and connected through the line 30 to one terminal of a capacitor C 4 of the trigger circuit 31. The other terminal of the capacitor C 4 is connected through a line 26 to the gate of the thyristor 16.

The output voltage detector 29 includes a transistor T 3 of NPN type having an emitter grounded through a zener diode ZD. A collector of the transistor T 3 is connected through a line 28 to the emitter of the transistor T 2 and, on the other hand, connected through a capacitor C 5 to the grounded. A base of the transistor T 3 is connected to a tap of an adjustable resistor R 9 connected through a resistor R 10 and a line 25 to the line 19 and connected, in turn, to the ground through a resistor R 11 .

When, in operation, an a.c. electric power is applied through the input terminals 12 and 13 of the rectif

ier 11, a full-wave rectified power as shown in FIG. 3 (a) appears on the output 14. The rectified power is applied through the line 15 to the anode of the thyristor 16. The thyristor 16 passes therethrough the rectified power while its firing angle is regulated by the trigger signal applied to the gate. The rectified power passed through the thyristor 16 is applied through the line 17 to the smoothing filter 18. The smoothing filter smoothes the power by removing the ripple component in the power. The smoothed power appears on the line 19 which is to be supplied to a load through the output terminal 20. The smoothed power on the line 19 is, on the other hand, delivered through the line 25 to the resistor R 10 of the output voltage detector 29. The resistor R 10 constitutes a voltage divider in cooperation with the resistors R 9 and R 11 . The output of the voltage divider is applied through the tap of the resistor R 9 to the base of the transistor T 3 . When the potential of the base of the transistor T 3 exceeds the zener voltage of the zener diode ZD, a base current flows through the transistor T 3 so as to render the transistor T 3 conductive. The potential of the collector of the transistor T 3 then varies in accordance with the voltage of the smoothed output power on the line 19. The potential variation at the collector of the transistor T 3 is then applied through the line 28 to the trigger pulse generator 27 and utilized to regulate the triggering timing of the thyristor 16.

ier 11, a full-wave rectified power as shown in FIG. 3 (a) appears on the output 14. The rectified power is applied through the line 15 to the anode of the thyristor 16. The thyristor 16 passes therethrough the rectified power while its firing angle is regulated by the trigger signal applied to the gate. The rectified power passed through the thyristor 16 is applied through the line 17 to the smoothing filter 18. The smoothing filter smoothes the power by removing the ripple component in the power. The smoothed power appears on the line 19 which is to be supplied to a load through the output terminal 20. The smoothed power on the line 19 is, on the other hand, delivered through the line 25 to the resistor R 10 of the output voltage detector 29. The resistor R 10 constitutes a voltage divider in cooperation with the resistors R 9 and R 11 . The output of the voltage divider is applied through the tap of the resistor R 9 to the base of the transistor T 3 . When the potential of the base of the transistor T 3 exceeds the zener voltage of the zener diode ZD, a base current flows through the transistor T 3 so as to render the transistor T 3 conductive. The potential of the collector of the transistor T 3 then varies in accordance with the voltage of the smoothed output power on the line 19. The potential variation at the collector of the transistor T 3 is then applied through the line 28 to the trigger pulse generator 27 and utilized to regulate the triggering timing of the thyristor 16.The full-wave rectified power is, on the other hand, applied through the line 21 to the saw-tooth wave generator 22. Since the resistors R 1 and R 2 consistute a voltage divider to reduce the voltage of the full-wave rectified power to a potential at the junction J 1 , a charging current to the capacitor C 1 flows from the emitter to the base of the transistor T 1 whereby the transistor T 1 repeats ON-OFF operation in accordance with the voltage of the rectified power. If the transistor T 1 is conductive when the voltage of the full-wave rectified power is lower than a threshold voltage v 1 as shown in FIG. 3(a), then the potential at the collector of the transistor T 1 is varied as shown in FIG. 3 (b) due to the charge and discharge of the capacitor C 2 . The variation of the potential at the collector of the transistor T 1 is supplied through the line 23 to the resistor R 6 of the trigger pulse generator 27.

As long as the voltage of the smoothed power on the line 19 equals to the rated output voltage, the transistor T 2 is adapted to become conductive when the voltage of the saw-tooth wave signal falls below a threshold value v 3 shown in FIG. 3(b). Therefore, a potential at the collector of the transistor T 2 varies as shown in FIG. 3(c). The potential variation, that is, a pulse signal at the collector of the transistor T 2 is supplied through the line 30 to the capacitor C 4 of the trigger circuit trigger 31. The trigger circuit 31 converts the pulse signal into a spike pulse or a trigger pulse shown in FIG. 3(d) which is then applied through the line 25 to the gate of the thyristor 16. Upon receiving the spike pulse, the thyristor 16 becomes conductive until the voltage of the rectified power on the line 15 falls below the cut-off voltage of the thyristor 16.

When the voltage of the smoothed power on the line 19 exceeds the rated output voltage, the collector current of the transistor T 3 increases with the result that the current flowing through the resistor R 7 increases. The threshold voltage of the transistor T 2 therefore reduces to a voltage v 2 as shown in FIG. 3(b). At this instant, leading edge of the pulse signal delays as shown by dot-and-dash lines in FIG. 3(c), so that each trigger pulse delays as shown by dot-and-dash line in FIG. 3(d). When on the contrary, the voltage of the smoothed signal on the line 19 lowers below the rated output voltage, the collector current of the transistor T 3 decreases whereby the threshold voltage rises to a voltage v 4 in FIG. 3(b). Each leading edge of the signal pulse now leads as shown by dotted line in FIG. 3(d). Being apparent from the above description, the appearance timing of each trigger pulse is regulated in accordance with the voltage of the smoothed power on the line 19 so that the voltage of the output voltage at the terminal 20 is held substantially constant.

Referring now to FIG. 4, start operation of the converte

r 10 is discussed hereinbelow in conjunction with FIG. 2. When an a.c. voltage is applied to the input terminals 12 and 13, the capacitor C 3 begins to be charged by the voltage on the line 15, and the capacitor C 5 also begins to be charged through the resistors R 3 and R 7 . It is important that the time constant of power supply circuit constituted by the resistor R 3 and the capacitor C 3 is selected to be much larger than that of the time constant of another power supply circuit constituted by the resistor R 7 and the capacitor C 5 . Thus, the emitter potential of the transistor T 1 is built up more quickly than that of the transistor T 2 . Upon completion of the charging of the capacitor C 3 , the saw-tooth wave generator 22 begins to generate saw-tooth wave signal as shown in FIG. 4(b). Since the capacitor C 5 is, on the other hand, slowly charged, the emitter voltage of the transistor T 2 slowly rises as shown in FIG. 4(c), so that, the threshold voltage of the transistor T 2 gradually rises as shown by a dotted line in FIG. 4 (b). Accordingly, the trigger pulses is produced on the gate of the thyristor 16 as shown in FIG. 4(d), whereby the firing angle of the thyristor 16 is gradually reduced as shown in FIG. 4(a) which illustrates the voltage at the output terminal 14 of the rectifier 11. The output voltage on the output terminal 20 therefore gradually rise up as shown in FIG. 4(e). It is to be understood that since the output voltage of the converter 10 starts to gradually rise up as shown in FIG. 4(e), an undesired rush current is effectively suppressed.

r 10 is discussed hereinbelow in conjunction with FIG. 2. When an a.c. voltage is applied to the input terminals 12 and 13, the capacitor C 3 begins to be charged by the voltage on the line 15, and the capacitor C 5 also begins to be charged through the resistors R 3 and R 7 . It is important that the time constant of power supply circuit constituted by the resistor R 3 and the capacitor C 3 is selected to be much larger than that of the time constant of another power supply circuit constituted by the resistor R 7 and the capacitor C 5 . Thus, the emitter potential of the transistor T 1 is built up more quickly than that of the transistor T 2 . Upon completion of the charging of the capacitor C 3 , the saw-tooth wave generator 22 begins to generate saw-tooth wave signal as shown in FIG. 4(b). Since the capacitor C 5 is, on the other hand, slowly charged, the emitter voltage of the transistor T 2 slowly rises as shown in FIG. 4(c), so that, the threshold voltage of the transistor T 2 gradually rises as shown by a dotted line in FIG. 4 (b). Accordingly, the trigger pulses is produced on the gate of the thyristor 16 as shown in FIG. 4(d), whereby the firing angle of the thyristor 16 is gradually reduced as shown in FIG. 4(a) which illustrates the voltage at the output terminal 14 of the rectifier 11. The output voltage on the output terminal 20 therefore gradually rise up as shown in FIG. 4(e). It is to be understood that since the output voltage of the converter 10 starts to gradually rise up as shown in FIG. 4(e), an undesired rush current is effectively suppressed.FIG. 5 illustrates another fo

rm of the converter 10 which is arranged identically to the circuit arrangement of FIG. 1 except that an integrator 50 is interposed between the output of the saw-tooth wave generator 22 and the input of the trigger pulse generator 27. The integrator 50 includes a resistor R 12 having one terminal connected to the output of the saw-tooth wave generator 22 and the other terminal connected to the input of the rectangular pulse generator 27, and a capacitor C 7 having one terminal connected to the other terminal of the resistor R 12 and the other terminal grounded.

rm of the converter 10 which is arranged identically to the circuit arrangement of FIG. 1 except that an integrator 50 is interposed between the output of the saw-tooth wave generator 22 and the input of the trigger pulse generator 27. The integrator 50 includes a resistor R 12 having one terminal connected to the output of the saw-tooth wave generator 22 and the other terminal connected to the input of the rectangular pulse generator 27, and a capacitor C 7 having one terminal connected to the other terminal of the resistor R 12 and the other terminal grounded.In operation, the saw-tooth wave generator 22 produces on its ouput a saw-tooth wave signal having decreasing exponential wave form portion as shown in FIG. 6 (a), although the saw-tooth wave signal ideally is illustrated in FIG. 3. This saw-tooth wave signal is converted by the integrator 50 into another form of saw-tooth wave having a increasing exponential wave form portion as shown in FIG. 6(b).

It should be noted that the saw-tooth wave signal of FIG. 6(a) has a smaller inclination near 180°. Hence, when the integrator 50 is omitted and the saw-tooth wave signal as shown in FIG. 6(a) is applied to the trigger pulse generator 27, the rate of change of the output voltage of the converter 10 become larger at a firing angle near to 1

80°. On the other hand, it is apparent from FIG. 6(c) that the rate of change the output voltage of the thyristor 16 with respect to the firing angle become large at a firing angle near to 180°. Therefore, the loop gain of the trigger pulse generator 24 increases when the firing angle of the thyristor 16 is near to 180°. It is apparent through a similar discussion that the loop gain of the trigger pulse generator 24 decreases when the firing angle is near to 90°. Such non-uniformity of the loop gain of the trigger pulse generator invites a difficulty of the regulation of the output voltage of the converter. It is to be noted that the saw-tooth wave signal shown in FIG. 6(b) has a large inclination at an angle near 180°. Therefore, when the saw-tooth wave signal of FIG. 6(b) is applied to the trigger pulse generator 24, the loop gain of the trigger pulse generator 24 is held substantially constant, whereby the output voltage of the converter is effectively held constant.

80°. On the other hand, it is apparent from FIG. 6(c) that the rate of change the output voltage of the thyristor 16 with respect to the firing angle become large at a firing angle near to 180°. Therefore, the loop gain of the trigger pulse generator 24 increases when the firing angle of the thyristor 16 is near to 180°. It is apparent through a similar discussion that the loop gain of the trigger pulse generator 24 decreases when the firing angle is near to 90°. Such non-uniformity of the loop gain of the trigger pulse generator invites a difficulty of the regulation of the output voltage of the converter. It is to be noted that the saw-tooth wave signal shown in FIG. 6(b) has a large inclination at an angle near 180°. Therefore, when the saw-tooth wave signal of FIG. 6(b) is applied to the trigger pulse generator 24, the loop gain of the trigger pulse generator 24 is held substantially constant, whereby the output voltage of the converter is effectively held constant.It is to be understood that the integrator 50 may be substituted for by a miller integrator and a bootstrap integrator. Furthermore, a plurality of integrator may be employed, if desired.

FIG. 7 illustrates another circuit arrangement of the converter according to the present invention, which is arranged identically to the circuit of FIG. 2 except for the trigger circuit 31 and the smoothing circuit 18.

The trigger circuit 31 of FIG. 7 comprises a transformer TR with primary and secondary coils. One terminal of the primary coil is connected to the resistor R 7 of the pulse generator 27. The other terminal of the primary coil is connected to a collector of a transistor T 4 of NPN type. The secondary coil has terminals respectively connected to the gate and cathode of the thyristor 16. An emitter of the transistor T 4 is grounded through a resistor R 13 . A base of the transistor T 4 is grounded through a resistor R 14 and connected through a capacitor C 8 to the collector of the transistor T 2 of the pulse generator 27.

The smoothing filter 18 of FIG. 7 comprises a choke coil CH connected to the lines 17 and 19, and to capacitors C 9 and C 10 which are in turn grounded. The circuit of FIG. 7 operates in the same manner as the circuit of FIG. 2.

Obviously many modifications and variations of the present invention are possible in the light of the above teachings. It is therefore to be understood that within the scope of the appended claims the invention may be practiced otherwise than as specifically described.

The CRT TUBE IS a TELEFUNKEN A66-410X.

SINUDYNE 2969 COLOR CHASSIS FR2 PROFESSIONAL 1000 NORD SOUTH (NORD/SUD) CORRECTION CIRCUIT ARRANGEMENT FOR CORRECTING THE DEFLECTION OF AT LEAST ONE ELECTRON BEAM IN A TELEVISION PICTURE TUBE BY MEANS OF A TRANSDUCTOR :

A circuit arrangement for raster correction in a television picture tube by means of a transductor whose power winding is connected in parallel with at least a portion of the line deflection coils, the line deflection genera

tor having a low internal impedance. In order to increase this impedance a mainly inductive impedance is connected in series with the generator. In a picture tube employing at least two electron beams the series impedance may include the convergence circuit. As a result the convergence in the corners of the picture screen is also improved. The linearity control circuit may likewise form part of the series impedance.

tor having a low internal impedance. In order to increase this impedance a mainly inductive impedance is connected in series with the generator. In a picture tube employing at least two electron beams the series impedance may include the convergence circuit. As a result the convergence in the corners of the picture screen is also improved. The linearity control circuit may likewise form part of the series impedance.1. A deflection circuit for a cathode ray tube comprising a transistor horizontal deflection generator; a horizontal deflection coil parallel coupled to said generator; means for pincushion correction of said tube comprising a saturable reactor having a control winding adapted to receive a vertical deflection signal and a power winding parallel coupled to at least a portion of said deflection coil; and means for increasing the effectiveness of said correction means comprising an impedance element external to said generator having a substantially inductive reactance series coupled between said generator and said coil. 2. A circuit as claimed in claim 1 wherein said generator comprises a transformer having a tap and said power winding has a first end coupled to said coil and a second end coupled to said tap. 3. A circuit as claimed in claim 1 wherein said impedance element comprises means for controlling the linearity of the beam deflection. 4. A deflection circuit for a cathode ray tube having at least two electron beams comprising a transistor horizontal deflection generator; a horizontal deflection coil parallel coupled to said generator; means for pincushion correction of said tube comprising a saturable reactor having a control winding adapted to receive a vertical deflection signal and a power winding parallel coupled to at least a portion of said deflection coil; means for increasing the effectiveness of said correction means comprising an Impedance element external to said generator having a substantially inductive reactance series coupled between said generator and said coil; and means for dynamically converging said beams comprising a convergence circuit coupled to said horizontal generator and to said transductor. 5. A circuit as claimed in claim 4 wherein said generator comprises a transformer having a tap and said power winding has a first end coupled to said coil and a second end coupled to said tap. 6. A circuit as claimed in claim 4 wherein said impedance element comprises means for controlling the linearity of the beam deflection.

A circuit arrangement for raster correction with the aid of a transductor is described, for example, in U.S. Pat. No. 3,444,422. In this patent the power winding of a transductor is connected in parallel with the horizontal deflection coils while the control winding receives a signal of field frequency so that the current of line frequency which flows through the deflection coils is modulated at the field

-frequency (East-West correction), whereas the vertical deflection current is modulated at the line frequency (North-South correction). However, in this known arrangement there is the difficulty that the transductor can exert little influence on the horizontal deflection current if the internal impedance of the deflection generator is low because the transductor then only constitutes an additional load on the generator. This is the case when the deflection generator includes a valve with feedback -- or a switch formed with one or more transistors. In order to be able to use a transductor arrangement also in such a case the circuit arrangement according to the invention is characterized in that a mainly inductive impedance is connected in series between the said parallel arrangement and the deflection generator.

Due to the step according to the invention the internal impedance of the deflection generator is increased and the different components of the circuit remain mainly inductive so that the deflection current is more or less linear when the voltage provided by the deflection generator during the line scan period is substantially constant. The series impedance may be, for example, a fixed coil. However, the invention is furthermore based on the recognition of the fact that the increase in the internal resistance of the horizontal deflection generator may not only be obtained by a constant impedance, but other arrangements envisaging other improvements of the deflection may be used for this purpose. In that case even special improvements may be obtained as will be apparent hereinafter and possible small non-linearities of the additionally used arrangements have no detrimental results.

It is true that in known convergence circuits in picture tubes employing a plurality of electron beams a satisfactory improvement is obtained for the central horizontal and vertical lines of a picture tube of the shadow mask type. However, it is found that convergence errors may subsist in the corners of the picture. Known circuit arrangements which correct these second-order errors are often complicated and expensive. In the circuit arrangement according to the invention a satisfactory compensation of such convergence errors is possible in a simple manner if the series impedance which is arranged between the horizontal deflection generator and the deflection coils includes the convergence circuit. In this manner the sum of the deflection current and of the current derived for the field correction and modulated by the transductor flows through the convergence circuit so that the desired additional convergence correction in the corners of the written raster is obtained.

In order that the invention may be readily carried into effect a few embodiments thereof will now be described in detail by way of example with reference to the accompanying diagrammatic drawings in which:

FIG. 1 shows a circuit arrangement in which the transductor is connected in parallel with the deflection coils, while in

FIG. 2 the transductor is only fed by part of the voltage applied to the deflection coils.

FIG. 1 shows two line-output transistors 1 and 2 which are arranged in series. The emitter of transistor 2 is connected to ground through a winding 3 while the collector of transistor 1 is connected through a winding 4 and a small series impedance 5, preferably a resistor, to the positive terminal of a supply source V b whose negative terminal is connected to ground.

Windings 3 and 4 are wound together with

an EHT-winding 6 on the same transformer core 7. The ends of windings 3 and 4 remote from each other are connected through the capacitor 10 for the S-correction to the deflection-unit consisting of two windings 8 and 9 arranged, for example, in parallel. The base of transistors 1 and 2 receive pulses of line frequency in a manner not shown in FIG. 1 so that these transistors are cut off during the flyback period. During the scan period, a substantially constant voltage is applied to the deflection unit. Consequently a more or less sawtooth-shaped current flows through windings 8 and 9. The bipartite power winding 11 of a transductor ensuring the raster correction is connected in parallel with this deflection unit 8, 9. The control winding 12 of said transductor, and a converting capacitor 13 in parallel therewith form part of the circuit for the vertical deflection through terminals 14 and 15. An adjustable coil 16 with which the raster correction can be adjusted exactly is connected in series with winding 12.

an EHT-winding 6 on the same transformer core 7. The ends of windings 3 and 4 remote from each other are connected through the capacitor 10 for the S-correction to the deflection-unit consisting of two windings 8 and 9 arranged, for example, in parallel. The base of transistors 1 and 2 receive pulses of line frequency in a manner not shown in FIG. 1 so that these transistors are cut off during the flyback period. During the scan period, a substantially constant voltage is applied to the deflection unit. Consequently a more or less sawtooth-shaped current flows through windings 8 and 9. The bipartite power winding 11 of a transductor ensuring the raster correction is connected in parallel with this deflection unit 8, 9. The control winding 12 of said transductor, and a converting capacitor 13 in parallel therewith form part of the circuit for the vertical deflection through terminals 14 and 15. An adjustable coil 16 with which the raster correction can be adjusted exactly is connected in series with winding 12.Windings 3 and 4 have the same number of turns so that pulses of the same amplitude and reversed polarity are produced at the emitter of transistor 2 and at the collector of transistor 1. As a result a disturbing radiation of these pulses is reduced. Furthermore, transistor types are chosen in this Example for transistors 1 and 2 whose collector-base diodes may function as efficiency diodes. All this has been described in U.S. Pat. No. 3,504,224.

According to the invention the convergence circuit 17 is arranged through a separation transformer 20 between the end of winding 3 remote from winding 4 and the horizontal deflection coils 8, 9. Furthermore, this current branch includes the linearity control circuit 21 which comprises the parallel arrangement of a resistor and a coil whose inductance is adjustable, for example, by means of premagnetization of the core of the coil. A current, which is the sum of the current for the deflection coils 8, 9 and of the current for the power winding 11 of the transductor, flows through the primary winding of transformer 20. This primary current is transformed to the secondary circuit of transformer 20 so that a current flows through convergence circuit 17.

In known arrangements the con

vergence current is only influenced by the deflection current itself. It has been found that in this case the convergence correction is not sufficient in the corners of the picture. At these areas, where the deflection in both directions is at a maximum, a greater intensity of the convergence current is required. This is especially the case in picture tubes having a great deflection angle and according to the invention this is achieved in that the current which is derived from the power winding 11 of the transductor for the raster correction is also applied to the convergence circuit. This current flows from the horizontal deflection generator constituted by windings 3 and 4 through the primary winding of transformer 20 to power winding 11 of the transductor. The transductor current is in fact at a minimum in the center of the picture and increases towards the edges and particularly towards the corners. Thus the convergence current varies in the desired manner. According to the invention the desired improvements of the convergence correction and simultaneously the likewise desired increase in the internal resistance of the horizontal deflection generator is consequently obtained without a considerable increase in the number of required circuit elements and without disturbing the normal operation of the circuit arrangement. Due to transformer 20 a terminal of convergence circuit 17 may be connected to ground so that the convergence can be adjusted safely. If necessary, a suitable impedance transformation may also be obtained with the aid of transformer 20.

The linearity control circuit 21 may alternatively be connected in series with the said branch which includes transformer 20. As a result the internal resistance of the horizontal deflection generator for the line frequency is further increased without the field correction and the convergence correction being disturbingly influenced.

FIG. 2 shows a modification of the circuit arrangement according to the invention in which the deflection current is not changed relative to that of FIG. 1. The end of power winding 11 of the transductor shown on the upper side of FIG. 1 is connected to ground in FIG. 2. In addition convergence circuit 17 is included between winding 3 and ground so that separation transformer 20 may be omitted. If as a first approximation the impedances 5 and 17 are assumed to be negligibly small relative to the other impedance of the circuit arrangement, power winding 11 may be considered to be connected to a tap on the deflection generator 3, 4. Consequently, only approximately half the voltage of the deflection generator is applied to transductor winding 11 which winding must

therefore be proportioned in such a manner that it can convey a current which is approximately twice as large as that of FIG. 1. This larger current also flows through convergence circuit 17 which, with the omission of separation transformer 20, is favorable for the convergence in the corners of the picture screen.

therefore be proportioned in such a manner that it can convey a current which is approximately twice as large as that of FIG. 1. This larger current also flows through convergence circuit 17 which, with the omission of separation transformer 20, is favorable for the convergence in the corners of the picture screen.In FIG. 2 the emitter of transistor 2 is connected to ground i.e., the said tap on the deflection generator. During the scan period the series arrangement of supply source V b and windings 3 and 4 FIG. 1 is substantially short-circuited by transistors 1 and 2. In order that these transistors in the circuit arrangement according to FIG. 2 operate under the same circumstances as those in FIG. 1, an additional winding 24 must be wound on core 7 between windings 4 and 6, winding 24 having the same number of turns as winding 3, and the collector of transistor 1 must be connected to the junction of windings 6 and 24.

The end of power winding 11 connected to ground in FIG. 2 may alternatively be connected for the desired adjustment of the corner convergence to a different tap on the transformer, that is to say, on winding 3 or 4.

Resistor 5 serves in known manner mainly as a safety resistor so that in case of an inadmissible load of the EHT, for example, as a result of flash-over in the picture tube, the supply voltage for transistors 1 and 2 is reduced so that overload of these transistors is avoided.

SINUDYNE 2969 COLOR CHASSIS FR2 PROFESSIONAL 1000 E/W CORRECTION Circuit arrangement in an image display apparatus for (horizontal) line deflection:

Line deflection circuit in which the deflection coil is east-west modulated. In order to cancel an east-west dependent horizontal linearity defect the inductance value of the linearity correction coil is made independent of the field frequency, for example by means of a compensating current. In an embodiment this current is supplied by the shunt coil of the east-west modulator.

1. Circuit arrang

ement for use with a line deflection coil, said circuit comprising a generator means adapted to be coupled to said coil for producing a sawtooth line-deflection current through said line deflection coil, said deflection current having a field-frequency component current, a horizontal linearity correction coil adapted to be coupled in series with said deflection coil and including an inductor having a bias-magnetized core, and means for making the inductance value of the linearity correction coil substantially independent of the field frequency component current. 2. Circuit arrangement as claimed in claim 1, wherein said making means includes a current supply source means for producing a compensating line-frequency sawtooth current through a winding of the linearity correction coil, the amplitude of the compensating current having a field-frequency variation. 3. Circuit arrangement as claimed in claim 2, wherein the direction of curvature of the field-frequency envelope of the compensating current is opposite to the direction of curvature of the field-frequency component current of the line deflection current, whereby the magnetic fields produced in the core of the correction coil by the two currents have the same direction. 4. Circuit arrangement as claimed in claim 2, wherein the direction of curvature of the field-frequency envelope of the compensating current is the same as the direction of curvature of the field-frequency component current of the line deflection current, whereby the magnetic fields produced in the core of the correction coil by the two currents have opposite directions. 5. Circuit arrangement as claimed in claim 2, wherein said correction coil further comprises an additional winding disposed on the core, said additional winding being coupled to said supply source means to receive the compensating current. 6. Circuit arrangement as claimed in claim 5, further comprising modulator means for modulating the line deflection current with said field frequency component, said modulator including a compensation coil coupled in series with said additional winding. 7. Horizontal linearity correction coil comprising a core made of a magnetic material and bias-magnetized by at least one permanent magnet, and an additional winding disposed on the core. 8. Image display apparatus including a circuit arrangement as claimed in claim 1.

y correction coil the linearity error due to the ohmic resistance of the deflection circuit is corrected. The sign of the bias magnetisation is chosen so that it is cancelled by the deflection current at the beginning of the deflection interval, so that the inductance of the correction coil is a maximum, whereas the voltage drop across the deflection coil then is a minimum. This voltage drop is adjustable by adjustment of the starting inductance of the correction coil. During the deflection interval the core gradually becomes saturated so that the inductance of, and the voltage drop across, the correction coil decrease. Thus the linearity error can be cancelled exactly at the beginning of the interval, that is to say on the left on the screen of the image display tube, and with a certain approximation at other locations.

was found in practice that the said two corrections are not independent of one another, that is to say the adjustment of the east-west modulation affects horizontal linearity. As long as the modulation depth is not excessive, a satisfactory compromise can be found. However, in display tubes having a deflection angle of 110° and particularly in colour display tubes in which the deflection coils have a converging effect also, it is difficult to find such a compromise. A tube of this type is described in "Philips Research Reports," volume Feb. 14, 1959, pages 65 to 97; the distribution of the deflection field is such that throughout the display screen the landing points of the electron beams coincide without the need for a converging device. Owing to this field distribution, however, the pin-cushion-shaped distortion in the image displayed in the east-west direction is greater than in comparable display tubes of another type. Hence there must be east-west modulation of the line deflection current to a greater depth. It is true that under these conditions horizontal linearity can correctly be adjusted over a given horizontal strip after the east-west modulation has been adjusted correctly, i.e., for a rectangular image, but it is found that in other parts of the display screen a serious linearity error remains. When vertical straight lines are displayed as straight lines in the right-hand part of the screen, they are displayed as curved lines in the left-hand part.

simplified circuit diagram of a line deflection circuit of an image display apparatus, not shown further. The circuit includes the series combination of a line deflection coil L y , a linearity correction coil L and a trace capacitor C t , which series combination is traversed by the line deflection current i y . The collector of an npn switching transistor T r and one end of a choke coil L 1 are connected to a junction point A of a diode D, a capacitor C r and the said series combination. The other end of the choke coil is connected to the positive terminal of a supply voltage source which supplies a substantially constant direct voltage V b and to the negative terminal of which the emitter of transistor Tr is connected. This negative terminal may be connected to earth. The other junction point B of elements D and C r and of the series combination of elements C t , L y and L is connected to one terminal of a modulation source M for east-west correction which has its other terminal connected to earth. Diode D has the pass direction shown in the FIG.

simplified circuit diagram of a line deflection circuit of an image display apparatus, not shown further. The circuit includes the series combination of a line deflection coil L y , a linearity correction coil L and a trace capacitor C t , which series combination is traversed by the line deflection current i y . The collector of an npn switching transistor T r and one end of a choke coil L 1 are connected to a junction point A of a diode D, a capacitor C r and the said series combination. The other end of the choke coil is connected to the positive terminal of a supply voltage source which supplies a substantially constant direct voltage V b and to the negative terminal of which the emitter of transistor Tr is connected. This negative terminal may be connected to earth. The other junction point B of elements D and C r and of the series combination of elements C t , L y and L is connected to one terminal of a modulation source M for east-west correction which has its other terminal connected to earth. Diode D has the pass direction shown in the FIG.  ottom left-hand part of FIG. 3 flows through the coil, the field strength H varies proportionally about the value H 0 , for the mean value of the current is zero. Because the curve of L is not linear, the variation L(t) of L, which is shown in the top right-hand part, is not a linear function of time. The resulting curve may be regarded as composed of a linear component and a substantially parabolic component which is to be taken into account when choosing the capacitance of capacitor C t .

ottom left-hand part of FIG. 3 flows through the coil, the field strength H varies proportionally about the value H 0 , for the mean value of the current is zero. Because the curve of L is not linear, the variation L(t) of L, which is shown in the top right-hand part, is not a linear function of time. The resulting curve may be regarded as composed of a linear component and a substantially parabolic component which is to be taken into account when choosing the capacitance of capacitor C t . . The amplitude of current i 2 and the turns number of winding L 2 can be chosen so that current i y flows through inductances the total value of which is not dependent upon the field frequency. The curve L(t) of FIG. 3 remains substantially unchanged. Consequently the undesirable field-frequency modulation is removed without variation of the bias magnetization, which would have been varied if current i 2 were a field-frequency current. Obviously the same result can be achieved by a choice such of the direction of current i 2 and of the winding sense of winding L 2 that the two field strengths are subtracted one from the other, whilst the curvature of the envelope of current i 2 has the same direction as that of the envelope of current i y .

C' t . One end of winding L 2 is connected to the junction point of capacitor C' t and the coil L, whilst the other end is connected to earth via coil L'. The capacitances of capacitors C 1 and C 2 and the location of the tapping on coil L 1 are chosen so that the sawtooth currents flowing through L y , and L' and L 1 have the same retrace time, whilst the field-frequency linearity defect of FIg. 2 is cancelled by correctly proportioning winding L 2 .

C' t . One end of winding L 2 is connected to the junction point of capacitor C' t and the coil L, whilst the other end is connected to earth via coil L'. The capacitances of capacitors C 1 and C 2 and the location of the tapping on coil L 1 are chosen so that the sawtooth currents flowing through L y , and L' and L 1 have the same retrace time, whilst the field-frequency linearity defect of FIg. 2 is cancelled by correctly proportioning winding L 2 . TBA920 line oscillator combination

DESCRIPTION

DESCRIPTIONThe line oscillator combination TBA920 is a monolithic

integrated circuit intended for the horizontal deflection of the black and white

and colour TV sets

picture tube.

FEATURES:

SYNC-PULSE SEPARATION

OPTIONAL NOISE INVERSION

GENERATION OF A LINE FREQUENCY VOL-

TAGE BY MEANS OF AN OSCILLATOR

PHASE COMPARISON BETWEEN SYNC-

PULSE AND THE OSCILLATOR WAVEFORM

PHASE COMPARISON BETWEEN THE OS-

CILLATOR WAVEFORM AND THE MIDDLE OF

THE LINE FLY-BACK PULSE

AUTOMATIC SWITCHING OF THE VARIABLE

TRANSCONDUCTANCE AND THE VARIABLE

TIME CONSTANT TO ACHIEVE NOISE SUP-

PRESSION AND, BY SWITCHING OFF, POS-

SIBILITY OF TAPE-VIDEO-REGISTERED RE-

PRODUCTION

SHAPING AND AMPLIFICATION OF THE OS-

CILLATOR WAVEFORM TO OBTAIN PULSES

FOR THE CONTROL OF DRIVING STAGES IN

HORIZONTAL, DEFLECTION CIRCUITS

USING EITHER TRANSISTORS OR THYRISTORS.

SINUDYNE 2969 COLOR CHASSIS FR2 PROFESSIONAL 1000 CONTACTLESS TOUCH SENSOR PROGRAM CHANGE KEYBOARD CIRCUIT ARRANGEMENT FOR ESTABLISHING A CONSTANT POTENTIAL OF THE CHASSIS OF AN ELECTRICAL DEVICE WITH RELATION TO GROUND :

Circuit arrangement for establishing a reference potential of a chassis of an electrical device such as a radio and/or TV receiver, such device being provided with at least one contactless touching switch operating under the AC voltage principle. The device is switched by touching a unipole touching field in a contactless manner so as to establish connection to a grounded network pole. The circuit arrangement includes in combination an electronic blocking switch and a unidirectional rectifier which separates such switch from the network during the blocking phase.

1. A circuit arrangement for establishing, at the chassis of an electrical device powered by a grounded AC supply network, a reference potential with relation to ground, said device having at least one contactless touching switch operating on the AC voltage principle, the switch being operated by touching a unipole touching field in a contactless manner, said arrangement comprising an electronic switch for selectively blocking the circuit of the device from the supply network, a half-wave rectifier including a pair of diodes individually connected in series-aiding relation between the terminals of the supply network and the terminals of the device for separating the electronic blocking switch from the supply network during a blocking phase defined by a prescribed half period of the AC cycle, and a pair of condensers individually connected in parallel with the respective diodes. 2. A circuit arrangement according to claim 1, wherein the capacitances of the two condensers are of equal magnitude.

1. A circuit arrangement for establishing, at the chassis of an electrical device powered by a grounded AC supply network, a reference potential with relation to ground, said device having at least one contactless touching switch operating on the AC voltage principle, the switch being operated by touching a unipole touching field in a contactless manner, said arrangement comprising an electronic switch for selectively blocking the circuit of the device from the supply network, a half-wave rectifier including a pair of diodes individually connected in series-aiding relation between the terminals of the supply network and the terminals of the device for separating the electronic blocking switch from the supply network during a blocking phase defined by a prescribed half period of the AC cycle, and a pair of condensers individually connected in parallel with the respective diodes. 2. A circuit arrangement according to claim 1, wherein the capacitances of the two condensers are of equal magnitude. In electronic devices, for example TV and radio receivers, there are used in ever increasing numbers electronic touching switches for switching and adjusting the functions of the device. In one known embod

iment of this type of touching switch, which operates on a DC voltage principle, the function of the electronic device, is contactlessly switched by touching a unipole touching field, the switching being carried out by means of an alternating current voltage. When using such a unipole touching electrode, one takes advantage of the fact that the AC current circuit is generally unipolarly grounded. In order to close the circuit by touching the touching surface via the body of the operator to ground, it is necessary to provide an AC voltage on the touching field. In one special known embodiment there is employed a known bridge current rectifier for the current supply. This type of arrangement has the drawback that the chassis of the device changes its polarity relative to the grounded network pole with the network frequency. With such construction considerable difficulties appear when connecting measuring instruments to the device, such difficulties possibly eventually leading to the destruction of individual parts of the electronic device.

iment of this type of touching switch, which operates on a DC voltage principle, the function of the electronic device, is contactlessly switched by touching a unipole touching field, the switching being carried out by means of an alternating current voltage. When using such a unipole touching electrode, one takes advantage of the fact that the AC current circuit is generally unipolarly grounded. In order to close the circuit by touching the touching surface via the body of the operator to ground, it is necessary to provide an AC voltage on the touching field. In one special known embodiment there is employed a known bridge current rectifier for the current supply. This type of arrangement has the drawback that the chassis of the device changes its polarity relative to the grounded network pole with the network frequency. With such construction considerable difficulties appear when connecting measuring instruments to the device, such difficulties possibly eventually leading to the destruction of individual parts of the electronic device.In order to avoid these drawbacks, the present invention provides a normal combination of a unidirectional rectifier with an electronic blocking switch that separates the chassis of the electronic device from the network during the blocking phase. In accordance with the present invention, the polarity of the chassis of the electronic device does not periodically change, because the electronic device is practically separated from the network during the blocking phase of the unidirectional rectifier by means of the electronic blocking switch.

In a further embodiment of the invention a further rectifier is connected in series with the unidirectional rectifier in the connection between the circuit and the negative pole of the chassis. Such further rectifier is preferably a diode which is switched in the transfer direction of the unidirectional rectifier. According to another feature of the invention there are provided condensers, a respective condenser being connected parallel with each of the rectifiers. Preferably the two condensers have equal capacitances. Because of the use of such condensers, which are required because of high frequency reasons, during the blocking phase there is conducted to the chassis of the electronic device an AC voltage proportional to the order of capacitances of the condensers. Thus there is placed upon the touching field in a desired manner an AC voltage, and there is thereby assured a secure functioning of the adjustment of the device when such touching occurs.

I

n the embodiment of the invention employing two rectifiers there is the further advantage that over a bridging over of the minus conduit of the rectifier that is connected between the network and the negative pole of the chassis connection, no injuries can be caused by a measuring instrument in the electronic device itself and in the circuit arrangement connected thereto.

n the embodiment of the invention employing two rectifiers there is the further advantage that over a bridging over of the minus conduit of the rectifier that is connected between the network and the negative pole of the chassis connection, no injuries can be caused by a measuring instrument in the electronic device itself and in the circuit arrangement connected thereto.In the accompanying drawing:

The sole FIGURE of the drawing is a circuit diagram of a preferred embodiment of the invention.

In the illustrated embodiment the current supply part of the device, shown at the left, is connected via connecting terminals A and B to an AC voltage source, the terminal B being grounded at 8. The current supply part consists of a unidirectional rectifier in the form of a diode 1 with its anode connected to the terminal I, the cathode of diode 1 being connected to one input terminal 9 of an electronic device 2. In the device 2 there is also arranged a sensor circuit 3, shown here mainly as a block, circuit 3 being shown as including a pnp input transistor the emitter of which is connected to an output terminal 11 of the device 2. The collector of such transistor is connected to the other output terminal 12 of the device 2. The base of the transistor is connected by a wire 13 to a unipolar touching field 4 which may be in the form of a simple metal plate instead of the pnp transistor shown, the sensor circuit itself may consist of a standard integrating circuit which controls, among other things, the periodic sequential switching during the touching time of the touching field 4. All of the circuits of the electronic device 2 are isolated in a known manner from the chassis potential. Between the network terminal B and the negative pole 10 of the chassis there is arranged in the direction opposite that of diode 1 a further diode 5, the anode of diode 5 being connected to the terminal 10, and the cathode of diode 5 being connected to the terminal B of the current supply. To provide for HF type bridging of the diodes 1 and 5 there are arranged condensers 6 and 7 respectively, which are connected in parallel with such diodes.

The invention functions by reason of the fact that in an AC network separate devices radiate electromagnetic waves which produce freely traveling fields in the body of the person who is operating and/or adjusting the device, thereby producing an alternating current through his body to ground, as indicated by the - line at the right of the circuit diagram. If now the person operating the device touches the switching field 4, then the pnp type input transistor of the sensor circuit 3, which is placed on a definite reference potential (for example 12 Volts) and is connected with the negative halfwave of the AC voltage potential, is made conductive. There is thereby released a control command in the sequential switching, for example, for switching the electronic device to the next receiving channel. It is understood that the most suitable connection is formed between ground and the touching field 4 by means of a wire. By the use of such wires it would be assured that in all cases the base of the transistor in circuit 3 is connected to ground. This would, however, not permit anyone to operate the switch without the use of an auxiliary means such as a wire. It will be assumed that the touching almost always results directly via the almost isolated human body. For this reason the AC current fields are necessary, because otherwise there cannot always be provided a ground contact. Thus this connection is established via the body resistance of the person carrying out the touching of the switch.

The positive half wave of the alternating current travels to the terminal 9 of the electronic device 2 after such current has been rectified and smoothed by the devices 1, 6. Such positive halfwave is also conducted to the sensor circuit 3. The thus formed current circuit is closed by way of the chassis of the electronic device 3, the diode 5, and the terminal B. When there is a negative halfwave of the alternating current delivered by the current supply, both diodes 1 and 5 remain closed so that the chassis of the device 2 remains separated from the network during the blocking phase. Nevertheless, by means of condensers 6 and 7 the chassis is placed in a definite network potential, which depends on the relationship of the order of magnitude of the two condensers 6 and 7. When the capacitances of such condensers are equal, there is placed upon the chassis of the device 2 the constant reference potential, and simultaneously there is present via the sensor circuit 3 the required AC voltage at the touching field 4 for adjusting the function or functions of the device 2 upon the touching of the touching field 4.

The positive half wave of the alternating current travels to the terminal 9 of the electronic device 2 after such current has been rectified and smoothed by the devices 1, 6. Such positive halfwave is also conducted to the sensor circuit 3. The thus formed current circuit is closed by way of the chassis of the electronic device 3, the diode 5, and the terminal B. When there is a negative halfwave of the alternating current delivered by the current supply, both diodes 1 and 5 remain closed so that the chassis of the device 2 remains separated from the network during the blocking phase. Nevertheless, by means of condensers 6 and 7 the chassis is placed in a definite network potential, which depends on the relationship of the order of magnitude of the two condensers 6 and 7. When the capacitances of such condensers are equal, there is placed upon the chassis of the device 2 the constant reference potential, and simultaneously there is present via the sensor circuit 3 the required AC voltage at the touching field 4 for adjusting the function or functions of the device 2 upon the touching of the touching field 4.The reference character 15 indicates a terminal or point at which the potential of the chassis of the device 2 may be measured. As above explained, the diode 5 causes the potential of the chassis at 15 to be separated from the network ground when a negative AC halfwave arrives. It will be noted that the return conduit of the circuit is held at a fixed chassis potential. The input transistor of the sensor circuit 3 remains, however, locked because it is subjected to a DC current of about 12 volts. If now, by means of touching the touching field 4, the chassis potential is connected to ground, then the transistor switches through and releases a switching function.

A suitable sensor which may be employed for the circuit 3 herein may be a sensor known as the "SAS 560 Tastatur IS," manufactured and sold by Siemens AG.

It is to be understood that the present invention is not limited to the illustrated environment. They can also be used in electronic blocking switch including a Thyristor circuit, which in the same manner separates the electronic device during the blocking phase from the network rectifier. With such Thyristor circuit the drawbacks described in the introductory portion of the specification of known circuit arrangements are also avoided.

Although the invention is illustrated and described with reference to a plurality of preferred embodiments thereof, it is to be expressly understood that it is in no way limited to the disclosure of such a plurality of preferred embodiments, but is capable of numerous modifications within the scope of the appended claims.

SINUDYNE 2969 COLOR CHASSIS FR2 PROFESSIONAL 1000 PHILIPS PAL CHROMA DELAY LINE:An improved ultrasonic delay line comprising a solid glass body having one or more slits in the side walls extending inwardly from the outer edge faces of the body. The slits are arranged in the path of the propagating ultrasonic energy so as to effectively increase the number of energy transmission paths in the body by acting as additional energy reflecting surfaces. The slits extend the effective length of the delay line. The slits also operate to reduce undesired cross-coupling between the input and output transducers.

aim 9 wherein said wall slit extends 11. A delay line as claimed in claim 9 wherein said fourth and fifth edge walls intersect one another and said wall slit extends inwardly from the 12. A delay line is claimed in claim 1 wherein said body has a generally rectangular shape and a second wall slit extending inwards from an outer edge wall of the body so as to reflect the ultrasonic energy, the first and second wall slits extending inwards from opposite parallel edge walls 13. A delay line as claimed in claim 9 further comprising first and second electromechanical transducers coupled to said body at one or more edge 14. A delay line as claimed in claim 11 further comprising first and second electromechanical transducers coupled to said body at said fourth and fifth edge walls, respectively, thereby to reduce direct coupling of 15. An ultrasonic delay line comprising a solid body having a plurality of energy reflecting edge walls and composed of ultrasonic wave energy transmitting material, said edge walls being arranged to provide a first point for introducing ultrasonic energy and a second point for extracting said energy from the body and further providing a plurality of multiply reflected internal transmission paths for delaying said ultrasonic energy, an energy reflecting surface positioned in the desired energy transmission path and formed by a wall slit arranged to block the passage therethrough of impinging ultrasonic energy and extending inwards from an outer edge wall of the solid body thereby to redirect said energy through the body, and a second wall slit extending inwards from an outer edge wall of the body so as to reflect the ultrasonic energy, the first and second wall slits extending inwards from opposite parallel edge walls of the body, and wherein said body has a parallelogram cross-section and said first and second wall slits extend orthogonally inwards from the longer pair of 16. A delay line as claimed in claim 12 further comprising first and second electromechanical transducers coupled to said body at said first and second points which are located on edge walls other than the edge walls 17. An ultrasonic delay line comprising a solid body having at least five energy reflecting edge walls and composed of ultrasonic wave energy transmitting material, two of said edge walls being parallel to each other and two other edge walls being at right angles thereto, a fifth edge wall being at an angle of approximately 135° to each of two adjacent edge walls, said edge walls being arranged to provide a first point for introducing ultrasonic energy and a second point for extracting said energy from the body and further providing a plurality of multiply reflected internal transmission paths for delaying said ultrasonic energy, and an energy reflecting surface positioned in the desired energy transmission path and formed by a wall slit extending into the body centrally of and orthogonal to one of the edge walls located opposite to the fifth edge wall and arranged to block the passage therethrough of impinging ultrasonic energy thereby to redirect said energy through the 18. A delay line as claimed in claim 17 further comprising first and second electromechanical transducers coupled to said body at said first and 19. A delay line as claimed in claim 18 wherein said first and second energy points are located on the fifth edge wall.

It is also known to increase the length of the transmission path of an ultrasonic wave by including specially shaped openings in the solid medium to provide additional reflective surfaces. In this case such openings have to be very accurately positioned and dimensioned to ensure proper operation.

In connection with such delay lines there arises a number of problems. Some of these concern the solid medium itself and its thermal properties. Delay lines using wavelengths equivalent to several Megahertz require very accurate dimensioning to reduce internal energy scatter and give an accurate source of extraction. This requires a solid medium having a very low temperature coefficient. A special glass having such properties is available but it is relatively costly for use in mass production so that any design steps that will allow an overall reduction in the mass of the delay medium will not only in itself reduce thermal problems but will also reduce overall costs.

In certain color television receiver systems a prescribed signal delay is required so that the delay line has to provide stable operation and yet lend itself to mass production at a very low cost.

Another problem which confronts the designer of such delay lines is the prevention of direct signal coupling between the application and extraction points of the signal which can result in the desired delayed signal being masked by a strong undelayed signal arriving at the extraction point. A further problem is the suppression of alternative signal paths which contribute a train of secondary spurious signals each having a different delay and which make extraction of the wanted delayed signal difficult.

The purpose of this invention is to provide a simple delay line construction in which the overall mass of the delay line medium is reduced in a manner which will also allow greater freedom from expensive manufacturing processes as well as providing enhanced electro-acoustical performance.

According to this invention there is provided an ultrasonic delay line using a solid medium through which an ultrasonic signal wave is made to travel and which is reflected over a plurality of paths to increase the time delay between the application point of the ultrasonic signal and its point of extraction, wherein the path followed by the ultrasonic waves includes at least one reflecting surface constituted by the side wall or face of a slit extending inwards from an edge face of the solid medium.